A bell type sintering box protection device

A protective device and sintering box technology, which is applied to bell-type furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as elongated, weld cracked boxes, and achieve the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical scheme of the present invention is described in detail below in conjunction with specific embodiment:

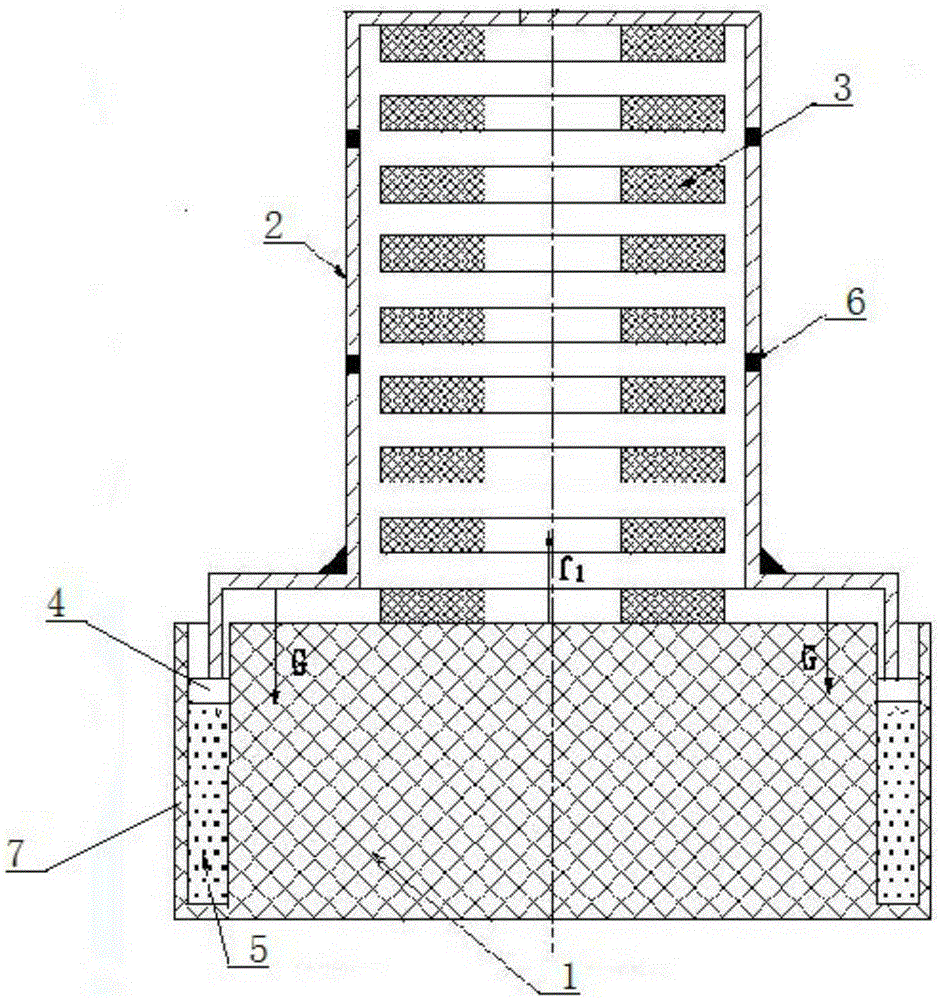

[0011] Such as figure 1 A bell-jar sintering box protection device shown includes a base 1, a sintering box 2, and a graphite disc 3 inside the sintering box 2, and the sintering box 2 is welded by a shell head, a shell and a shell bottom welding point 6, There is a backing plate 4 with an inverted U-shaped cross-section at the bottom of the sintering box, and a water tank 7 is arranged at the corresponding position between the base 1 and the backing plate. The backing plate 4 is placed in the water tank 7, and there is sealing water 5 as a buffer between them.

[0012] When working, first apply a certain pressure to the sintering box 2, and keep it constant. When the sintering box 2 is subjected to external force, the force is transmitted to the backing plate 4, and then the sealing water is compressed, and the energy is converted into internal energy s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com