A fixed spring protection device for a bell-type sintering box

A protection device, sintering box technology, applied in bell-type furnaces, lighting and heating equipment, etc., can solve problems such as elongation, weld cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

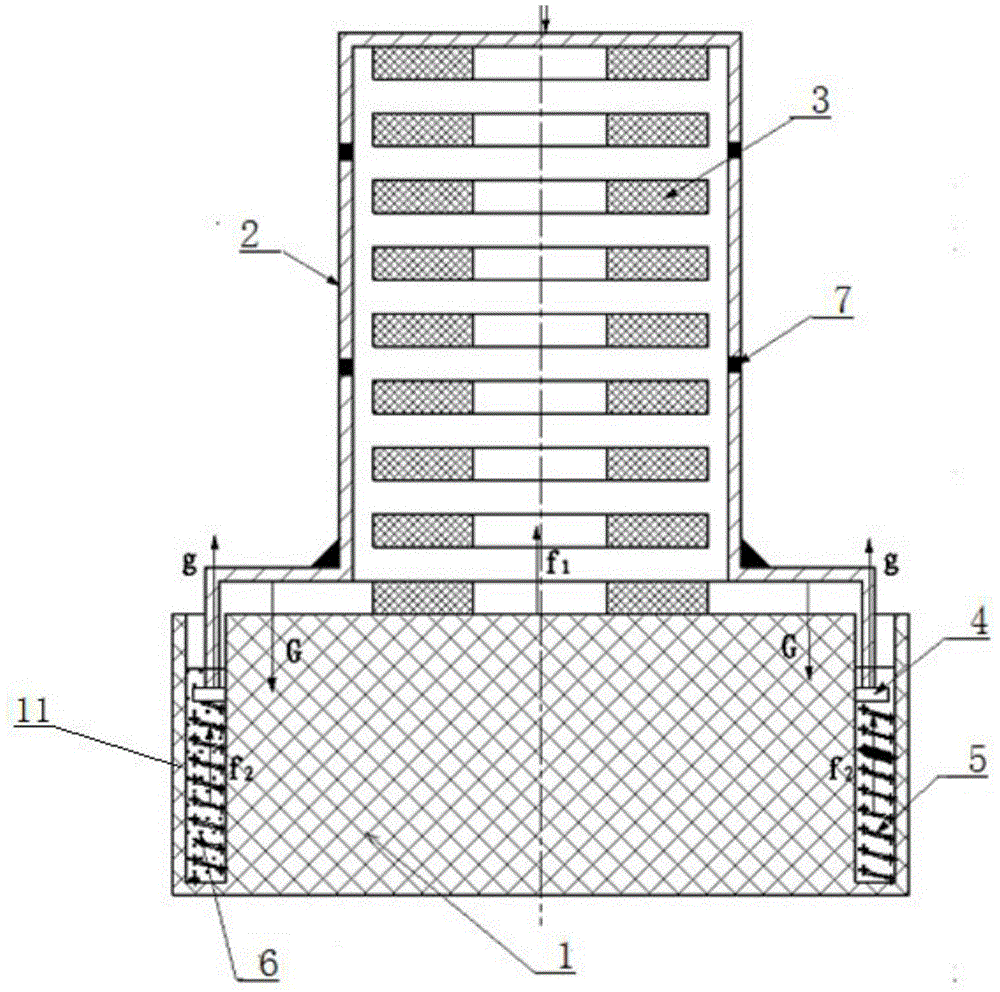

[0017] Such as figure 1 and figure 2 A fixed spring protection device for a bell-type sintering box is shown, including a base 1, a sintering box 2 and a graphite disc 3 inside the sintering box 2, wherein the bottom of the sintering box 2 has a backing plate with an inverted U-shaped cross section 4. There is a water tank 11 at the corresponding position of the base 1, and the backing plate 4 is placed in the water tank 11, and there is a fixed spring 5 between them.

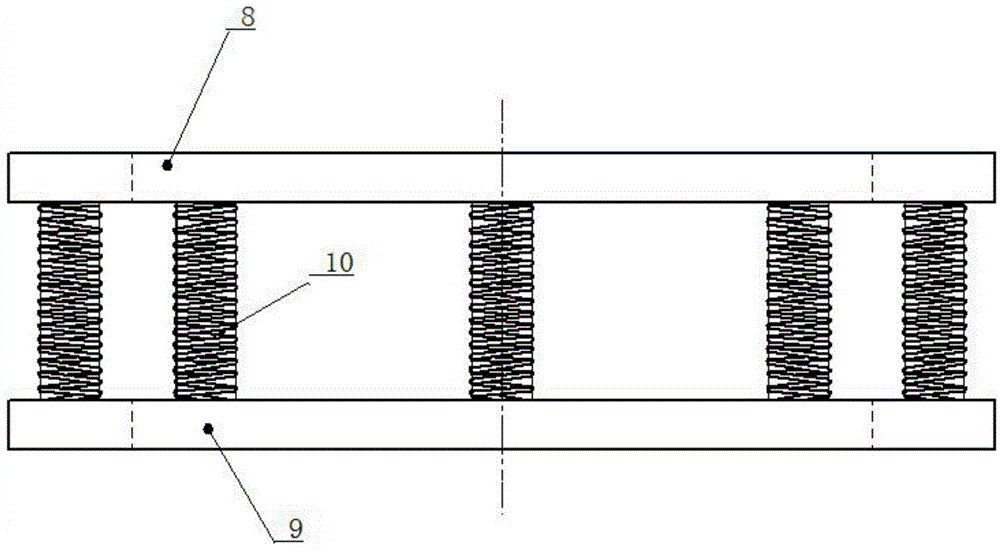

[0018] In order to prevent the fixed spring 5 from turning sideways under the action of force, the fixed spring 5 is designed to be composed of a ring support plate 8, a spring 10 and a ring chassis 9, wherein the two ends of the spring 10 are welded on the ring support On the plate 8 and the ring chassis 9.

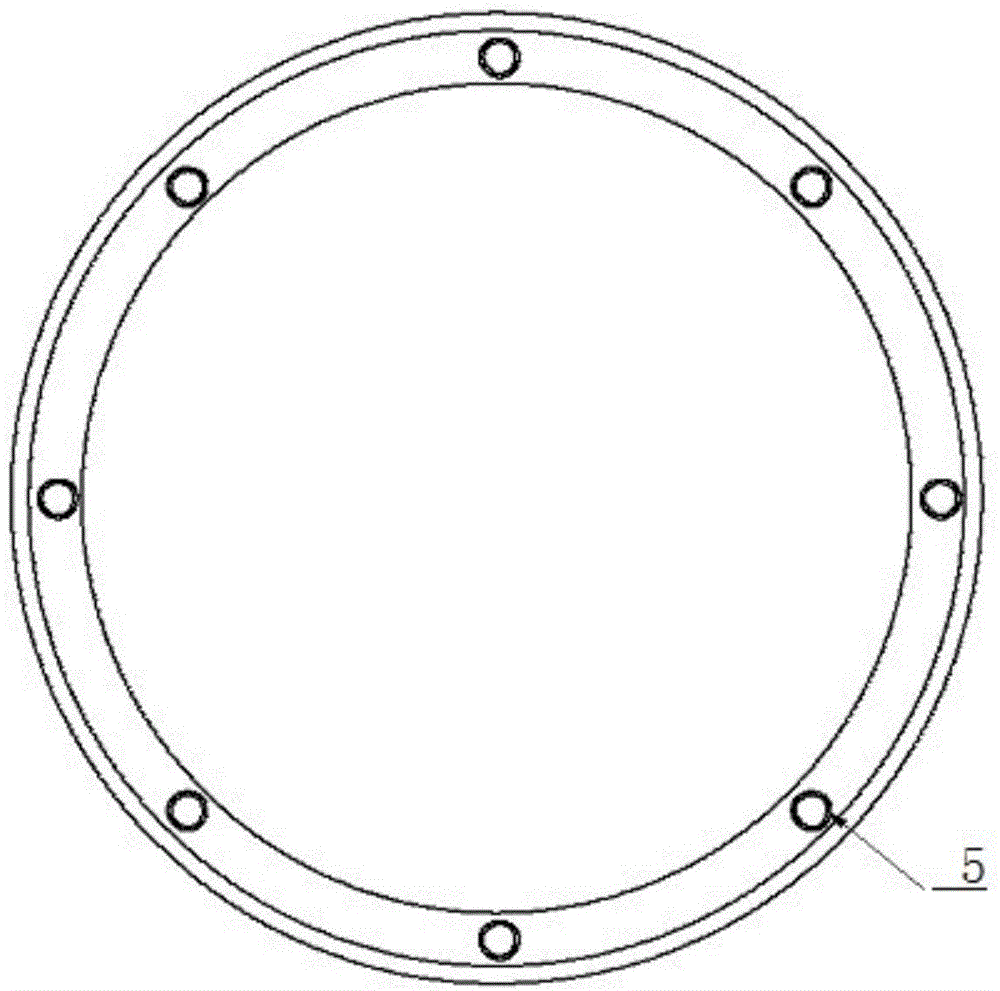

[0019] In order to ensure that the springs are balanced when they are under the pressure of the sintering box 2, there are three fixed springs 5, which are evenly distributed among the fixed springs 5....

Embodiment 2

[0021] In order to enhance the effect of the fixed spring and play a double protection role, the water tank 11 shown has sealing water 6, and other structures are the same as the first embodiment.

Embodiment 3

[0023] There are four springs 5, which are evenly distributed among the fixed springs 5, and other structures are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com