Hydraulic infinitely-variable speed transmission device

A technology of hydraulic stepless transmission and transmission, which is applied in transmission control, components with teeth, belts/chains/gears, etc. It can solve the problems of high manufacturing precision of hydraulic components, narrow high-efficiency range, and low transmission efficiency. , to achieve the effect of improving work reliability, improving transmission efficiency and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

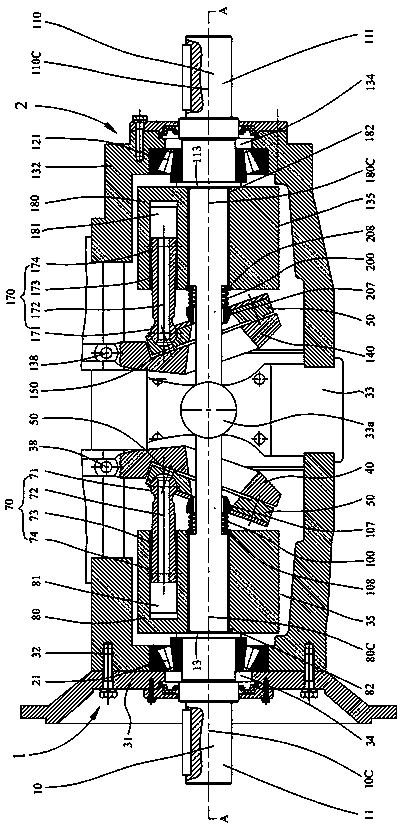

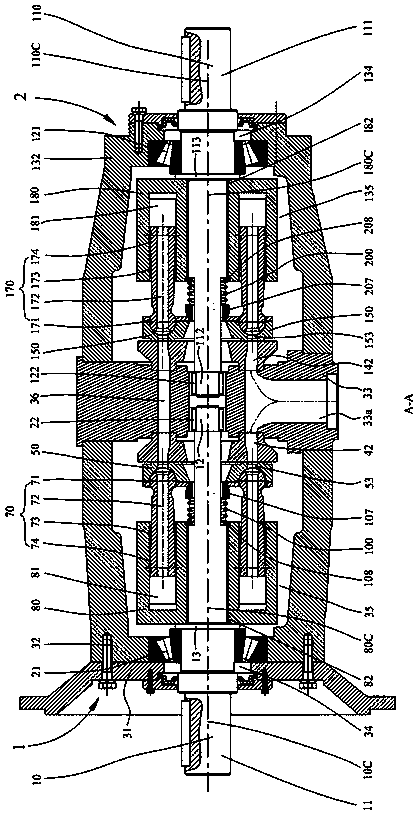

[0045] like Figure 1-9 Shown is one of the embodiments of the hydraulic continuously variable transmission device of the present invention. In the preferred embodiment shown, the hydraulic continuously variable transmission device includes a sliding plate axial piston pump 1, a The disc axial piston pump 1 is coaxially arranged with the sliding disc axial piston motor 2 and the end seat 33 sandwiched between the sliding disc axial piston pump 1 and the sliding disc axial piston motor 2 , the sliding plate axial piston pump 1 and the sliding plate axial piston motor 2 are through-shaft structures, and the sliding plate axial piston pump 1 and the sliding plate axial piston motor 2 are connected by bolts The end seat 33 is fixed to form a three-body structure.

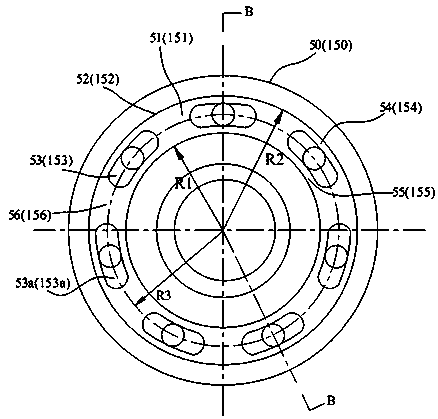

[0046] For the sliding plate type axial piston pump 1, it includes a distribution sliding plate subassembly, which includes a pump swash plate 40 and a pump sliding plate 50 supported on the pump swash plate 40. The s...

Embodiment 2

[0069] like Figure 10-16 As shown, the main difference from Embodiment 1 is that the outer peripheral portion of the sliding plate 50 / 150 is provided with a third bearing 23 / 123 for support, and the outer peripheral portion of the swash plate is provided with a support stop portion 41a / 141a. A third bearing 23 / 123 is interposed between the inner sides of the support stop portions 41a / 141a, and the sliding plate 50 / 150 is supported on the third bearing 23 / 123 in a radially constrained state. The third bearing 23 / 123 may be set to include but not limited to one of a radial thrust ball bearing, a needle roller bearing, a cylindrical roller bearing, a tapered roller bearing, and a radial ball bearing.

[0070] During the operation of the hydraulic continuously variable transmission device, the plunger 70 / 170 in the high-pressure area is subjected to the high-pressure oil pressure of the plunger hole 81 / 181 of the cylinder body, and exerts a close pressure on the sliding plate 50 / ...

Embodiment 3

[0078] like Figure 13 As shown, the main difference from other embodiments is that a flow distribution plate 90 / 190 is sandwiched between the sliding plate 50 / 150 and the swash plate 40 / 140 in the sliding plate pair, and the static pressure bearing surface 51 / 151 is supported on the flow distribution On the plate 90 / 190 and maintain a sliding fit with the distribution plate 90 / 190, the flow plate is fixed on the swash plate by means of pins or the like. The advantage of interposing the flow distribution plate 90 / 190 between the sliding plate 50 / 150 and the swash plate 40 / 140 is that it is easier and less expensive to replace the flow distribution plate later than to replace the swash plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com