Method for cutting foaming cement board by means of wet process

A technology of foamed cement board and cutting method, which is applied in the field of foamed cement board, can solve the problems of large size deviation, short curing time, cracks, etc., and achieve the effects of improving product quality, increasing cutting efficiency, and reducing dust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

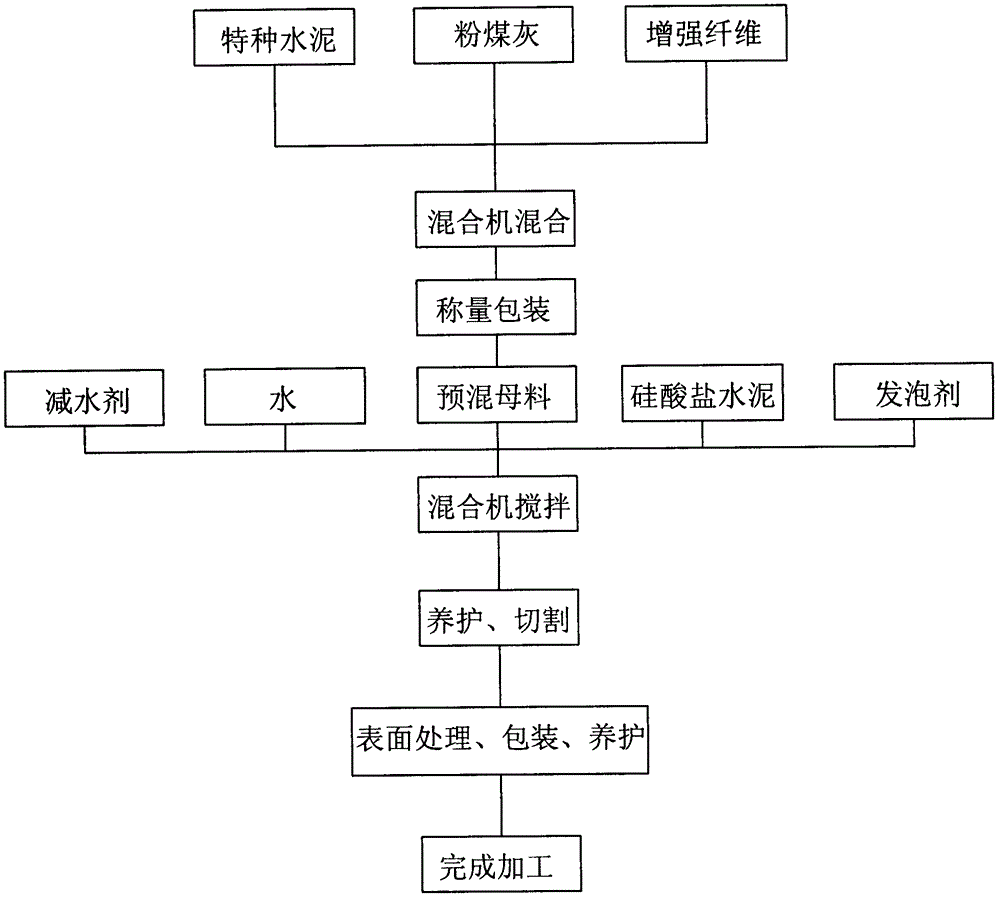

Image

Examples

specific Embodiment 1

[0029] (1) Weighing 90 parts of special cement, 5 parts of fly ash and 0.3 part of reinforcing fiber, put into a mixer and mix;

[0030] (2) Put the above mixed masterbatch into water at a temperature of 35°C, add 15 parts of Portland cement, 0.2 parts of early strength naphthalene-based water reducer and 5 parts of hydride, and stir in a mixer. The speed is 160 rpm;

[0031] (3) Pour the above-mentioned uniformly stirred slurry into a foaming mould, and stop for maintenance to obtain a foamed cement board;

[0032] (4) Removing the formwork after curing the above-mentioned foamed cement board for 20 minutes, and then cutting it into foamed cement boards of required specifications through a cutting device;

[0033] (5) Surface treatment, packaging, film covering and curing of the cut foamed cement board will be completed after 14 days.

specific Embodiment 2

[0034] (1) Weigh 95 parts of special cement, 6 parts of fly ash and 0.5 parts of reinforcing fiber, and put them into the mixer for mixing;

[0035] (2) Put the above mixed masterbatch into water, the water temperature is 36°C, add 20 parts of Portland cement, 0.15 parts of early-strength naphthalene-based superplasticizer and 6 parts of aluminum powder, and stir in the mixer. The speed is 180 rpm;

[0036] (3) Pour the above-mentioned uniformly stirred slurry into a foaming mould, and stop for maintenance to obtain a foamed cement board;

[0037] (4) Removing the formwork after curing the foamed cement board for 25 minutes, and then cutting it into foamed cement boards of required specifications by a cutting device;

[0038] (5) Surface treatment, packaging, film covering and curing of the cut foamed cement board will be completed after 14 days.

specific Embodiment 3

[0039] (1) Weigh 100 parts by weight of special cement, 10 parts of fly ash and 1 part of reinforcing fiber, and put them into a mixer to mix;

[0040] (2) Put the above mixed masterbatch into water, the water temperature is 40°C, add 30 parts of Portland cement, 0.5 parts of early-strength melamine superplasticizer and 8 parts of aluminum powder, and stir in the mixer. The speed is 250 rpm;

[0041] (3) Pour the above-mentioned uniformly stirred slurry into a foaming mould, and stop for maintenance to obtain a foamed cement board;

[0042] (4) Removing the formwork after curing the above-mentioned foamed cement board for 30 minutes, and then cutting it into foamed cement boards of required specifications through a cutting device;

[0043] (5) Surface treatment, packaging, film covering and curing of the cut foamed cement board will be completed after 14 days.

[0044] Among them, during the preparation process of the foamed cement board, the stirring speed has a great influ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com