Aerated concrete and preparation method thereof

A technology of air-entrained concrete and additives, applied in the field of concrete, can solve the problems of low physical strength of air-entrained concrete, achieve the effects of preventing rapid shrinkage, increasing water retention performance, and increasing bonding degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

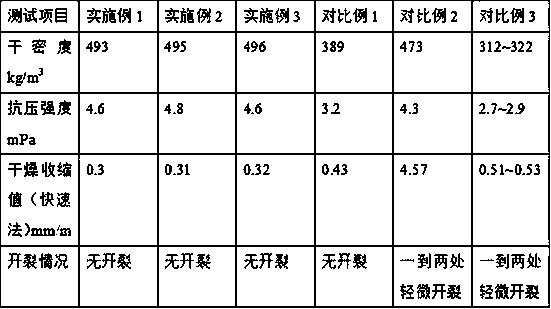

Examples

preparation example Construction

[0026] The preparation method of increasing agent comprises the steps:

[0027] A. Mix kyanite, diatomaceous earth, and zinc oxide in a mass ratio of 6:3~6:2, put them into a calciner, and calcinate at 2300~2600°C for 50 minutes, and then use 4~6°C carbon dioxide to The calcined product is cooled to room temperature, the calcined product is collected, ball milled, and the ball milled product is collected;

[0028] B. Put the ball mill and 1.1mol / L ammonia water into the reactor according to the mass ratio of 4:10~16 and mix evenly, then add P123 with 10~15% of ball mill mass and 13~17% of ball mill mass with acetic acid and stir and mix , and preheat at 40~45°C for 50 minutes;

[0029] C. After preheating, add tetraethyl silicate with 40-45% of ball-milled mass and 1-2 times of ball-milled absolute ethanol, mix well, heat at 50-55°C for 1 hour, and cool to room temperature Stand still for 8 hours, discharge, filter, dry, and crush at 800r / min for 40 minutes, collect the crus...

Embodiment 1

[0036] The additives are configured by mixing water reducer, early strength agent and surfactant in a mass ratio of 3:2:0.8.

[0037] The choice of water reducer is polycarboxylate superplasticizer.

[0038] The choice of early strength agent is triethanolamine.

[0039] The surfactant is configured by mixing alginic acid and sorbitan fatty acid ester at a mass ratio of 1:7.

[0040] The preparation method of increasing agent comprises the steps:

[0041] A. Mix kyanite, diatomaceous earth, and zinc oxide evenly in a mass ratio of 6:6:2, put them into a calciner, and calcinate at 2600°C for 50 minutes, and then use 6°C carbon dioxide to cool the calcined product to room temperature , collect calcined matter, ball mill, collect ball milled matter;

[0042] B. Put the ball mill and 1.1mol / L ammonia water into the reactor according to the mass ratio of 4:16 and mix them evenly, then add P123 with 15% of the mass of the ball mill and 17% of the acetic acid with the mass of the ...

Embodiment 2

[0050] The additives are configured by mixing water reducer, early strength agent and surfactant in a mass ratio of 2:2:0.7.

[0051] The choice of water reducer is lignosulfonate water reducer.

[0052] The choice of early strength agent is triethanolamine.

[0053] The surfactant is configured by mixing alginic acid and sorbitan fatty acid ester at a mass ratio of 1:5.

[0054] The preparation method of increasing agent comprises the steps:

[0055] A. Mix kyanite, diatomaceous earth, and zinc oxide uniformly in a mass ratio of 6:4:2, put them into a calciner, and calcinate at 2500°C for 50 minutes, and then use 5°C carbon dioxide to cool the calcined product to room temperature , collect calcined matter, ball mill, collect ball milled matter;

[0056] B. Put the ball mill and 1.1mol / L ammonia water into the reactor according to the mass ratio of 4:15 and mix them evenly, then add P123 with 13% of the mass of the ball mill and 15% of the acetic acid with the mass of the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com