Hoisting structure of UHPC short rib precast slab

A prefabricated plate and hoisting technology, applied in the erection/assembly of bridges, bridge parts, bridge materials, etc., can solve the problems of difficult demoulding, damage to prefabricated plates and molds, and plate rib extrusion inner membrane, etc., to avoid difficulty in demoulding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

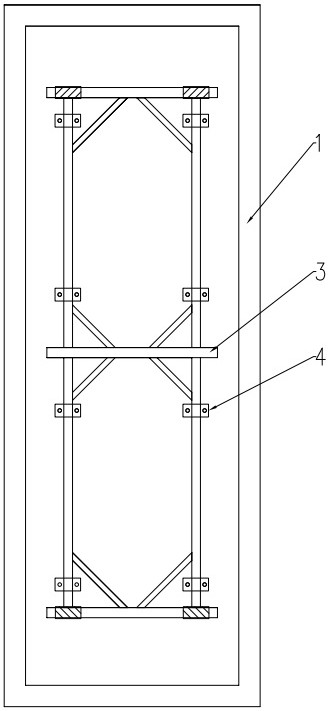

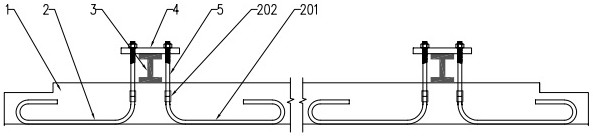

[0016] Such as figure 1 , figure 2 As shown, this is a UHPC low-rib precast panel hoisting structure of the embodiment, including a UHPC low-rib precast panel 1, and the upper plane of the UHPC low-rib precast panel 1 is pre-embedded with more than two internal thread hoisting connections symmetrically with the central axis. Device 2, the internal thread hoisting connection devices 2 are arranged in pairs, and the two internal thread hoisting connection devices 2 are arranged symmetrically in the width direction of the UHPC low-rib prefabricated slab 1 . The internal thread lifting connection device 2 includes an annular steel bar 201 and an internal thread sleeve 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com