Hanging ring integrated infusion bottle forming process

A molding process and infusion bottle technology, applied in coating and other directions, can solve the problems of high positioning accuracy, difficult demolding, high injection pressure and clamping force, etc., to ensure quality, avoid workshop environmental pollution, and eliminate contaminated bottles effect on physical risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

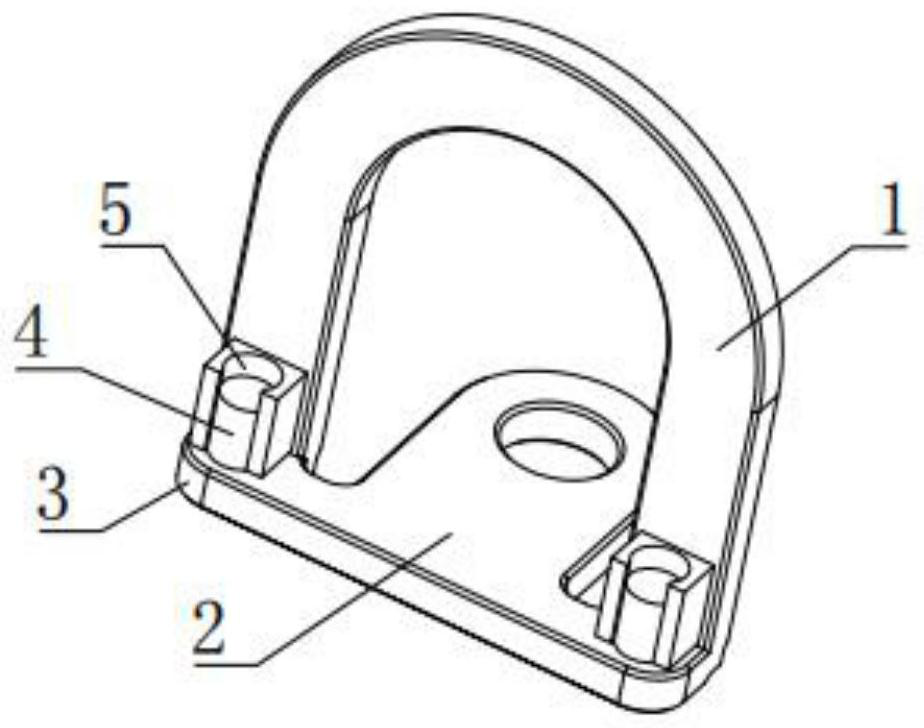

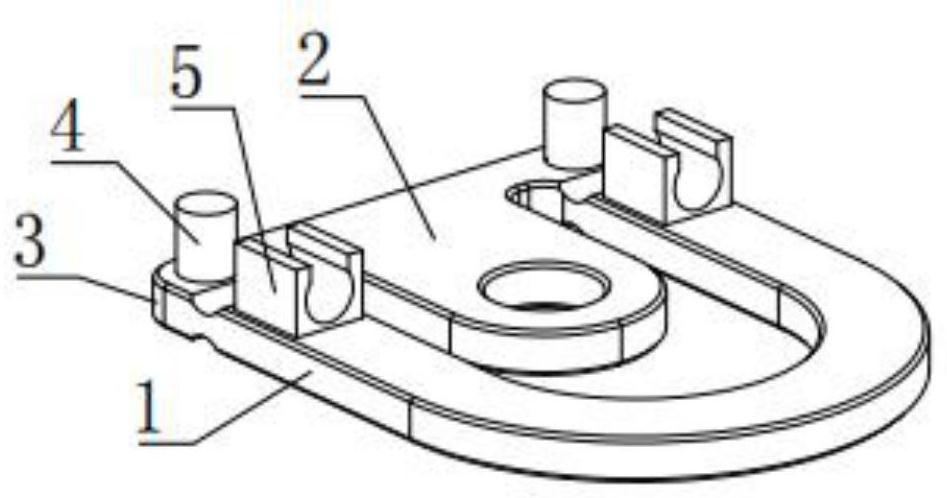

[0030] A suspension ring, comprising a suspension ring body 1, a connecting part 2, a hinge part 3, and at least one fixing column 4 for maintaining the suspension ring body 1 in a working state, and a fixing ferrule 5 adapted to the fixing column 4, the The fixing column 4 is arranged on the hinge part 3, and the fixing ferrule 5 is arranged on the suspension ring body 1;

[0031] The suspension ring body 1 is a U-shaped, circular or elliptical structure;

[0032] The connecting part 2 is used to connect the lifting ring body 1 and the preform, and the hinge parts 3 are arranged on both sides of the connecting part 2 , and the connecting part 2 is connected with the lifting ring body 1 through the hinge part 3 .

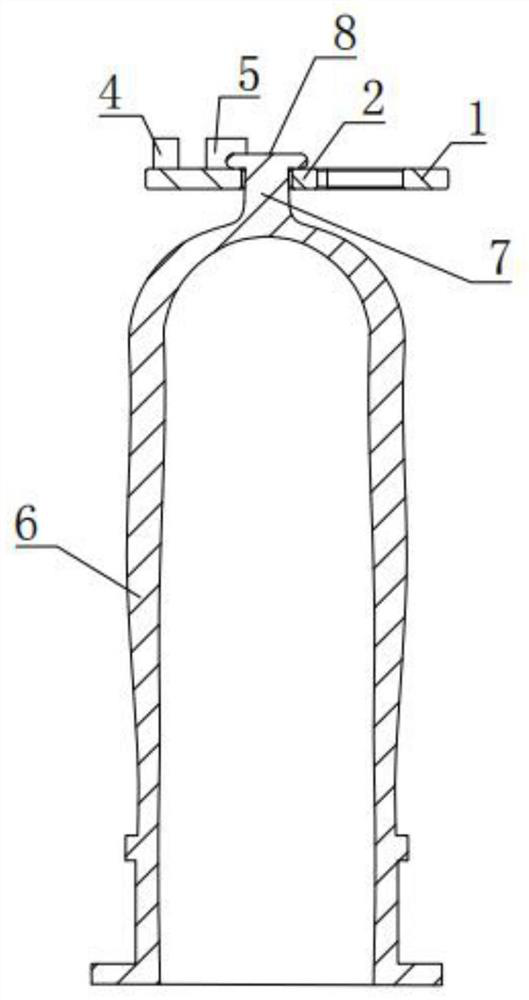

[0033] An infusion bottle 9 with integrated suspension rings is obtained by blowing a preform with suspension rings.

[0034] A kind of ring-integrated transfusion bottle 9 molding process, comprises the following steps:

[0035] S1. Preform molding injection mold...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the connection part 2 in the step S2 is fixed outside the sprue column 7 . The connection of the suspension ring is set more firmly in this way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com