Purifying, adsorbing and sterilizing material and application thereof

An adsorption material and air purification technology, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, antibacterial drugs, etc. Density drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

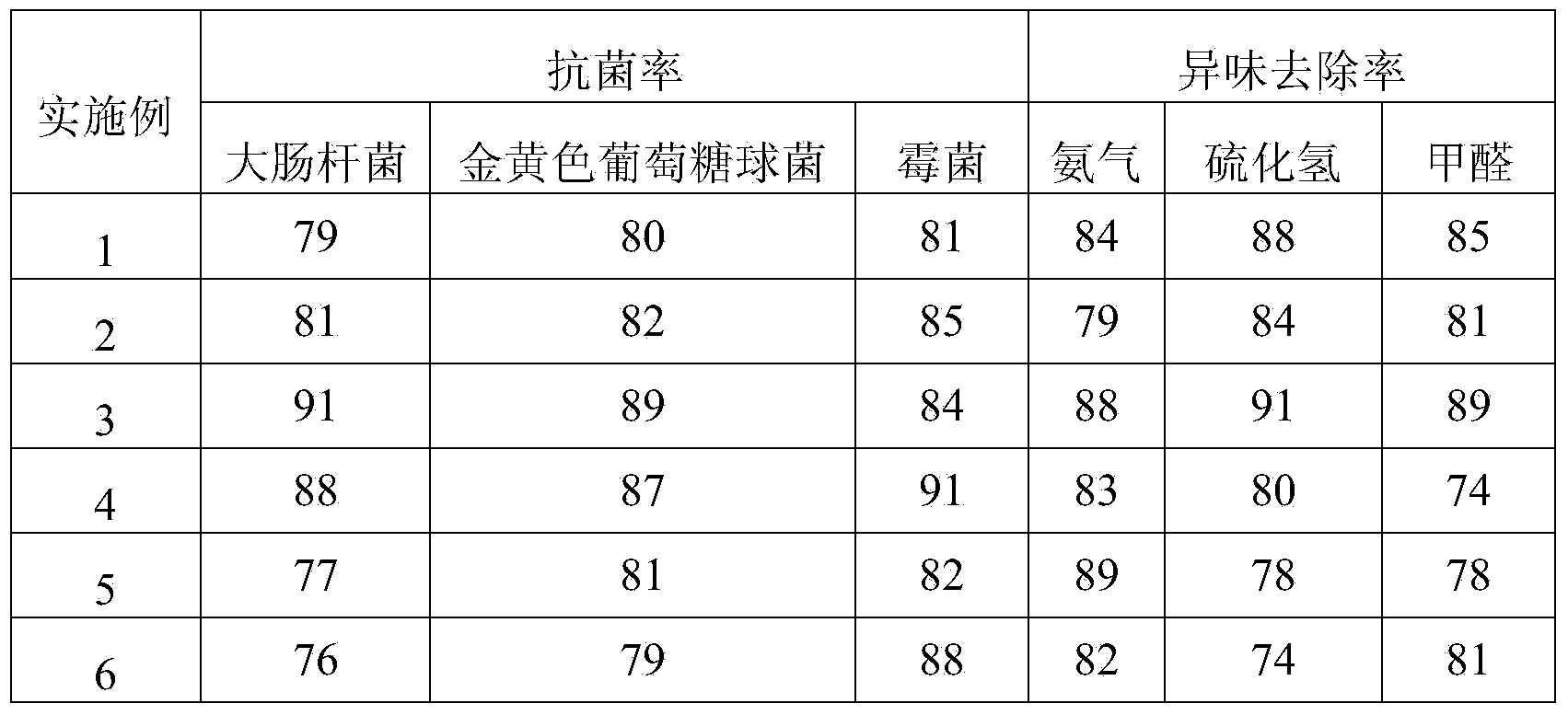

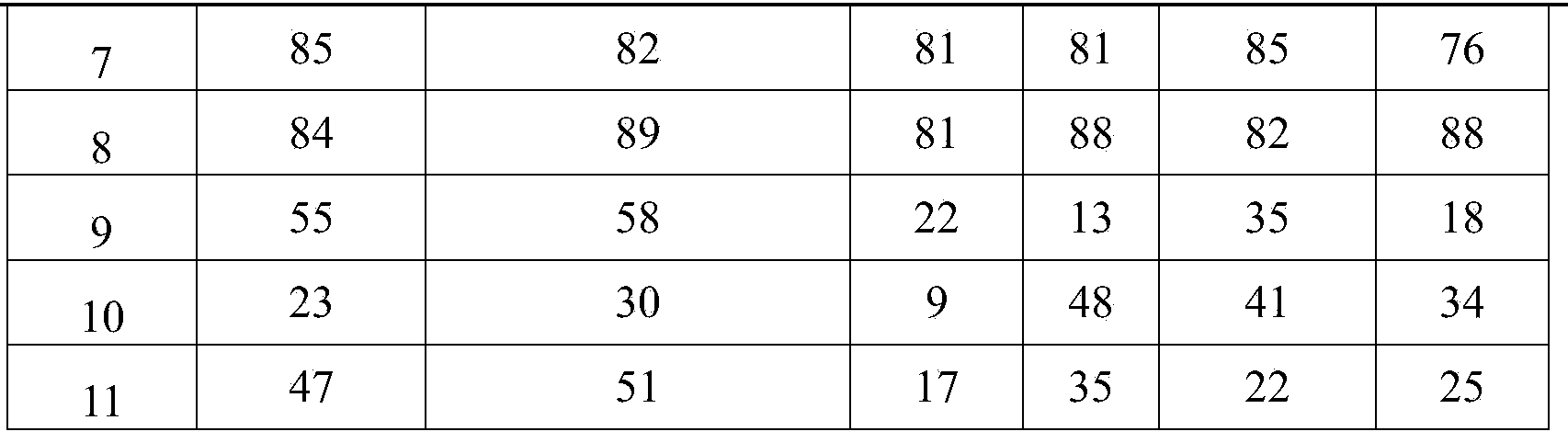

Examples

Embodiment 1

[0031] 10kg of high-purity nano-montmorillonite, 10kg of nano-zinc oxide, and 20kg of activated carbon. The proportion of activated carbon accounts for the main component in places with heavy harmful gases.

[0032]Prepare compressed filter element air purification material: mix activated carbon, zinc oxide, and montmorillonite evenly, add food-grade adhesive, sinter and compress to form. The inside and outside of the compressed filter element are respectively wrapped with a layer of non-woven fabric with filtering effect to ensure that the filter element will not drop the mixture powder. The two ends of the filter element are equipped with soft nitrile rubber gaskets, so that the filter element can be installed in the filter cartridge with good sealing performance. . Preferably, alumina, especially activated alumina, can also be properly added.

Embodiment 2

[0034] Nano-montmorillonite 20kg, nano-zinc oxide 10kg, activated carbon 20kg. Environments with heavy bacteria, fungi, molds, toxins, ammonia, and nitrogen.

[0035] Prepare bulk filter element air purification material: directly mix the required activated carbon, zinc oxide, and montmorillonite mixed particles evenly. When in use, put the mixture granules into a plastic shell and close both ends. It is preferable to put a non-woven filter piece before closing the end cap to ensure that the filter element will not drop the mixture powder during use. According to the requirements, the end caps can be made into different types of connection ports.

Embodiment 3

[0037] 10kg of high-purity nano-montmorillonite, 40kg of nano-zinc oxide, and 10kg of activated carbon. Environments with high requirements for killing bacteria, fungi, molds, toxins, etc.

[0038] The preparation method is as follows: take the raw material, add it to 1 times the weight of 0.01mol / L sodium hydroxide aqueous solution, heat to 45-50°C, stir for 1 hour, filter and collect the solid phase, and vacuum dry at 110°C. Get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com