Mould removal processing method for alcoholizing expired mouldy tobacco leaves

A treatment method and technology of tobacco leaves, which is applied in the field of tobacco processing, can solve the problems of increasing the utilization rate of mildewed tobacco leaves, wind and mildew on the surface of tobacco leaves, etc., and achieve the effect of reducing tobacco loss and economic loss and increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

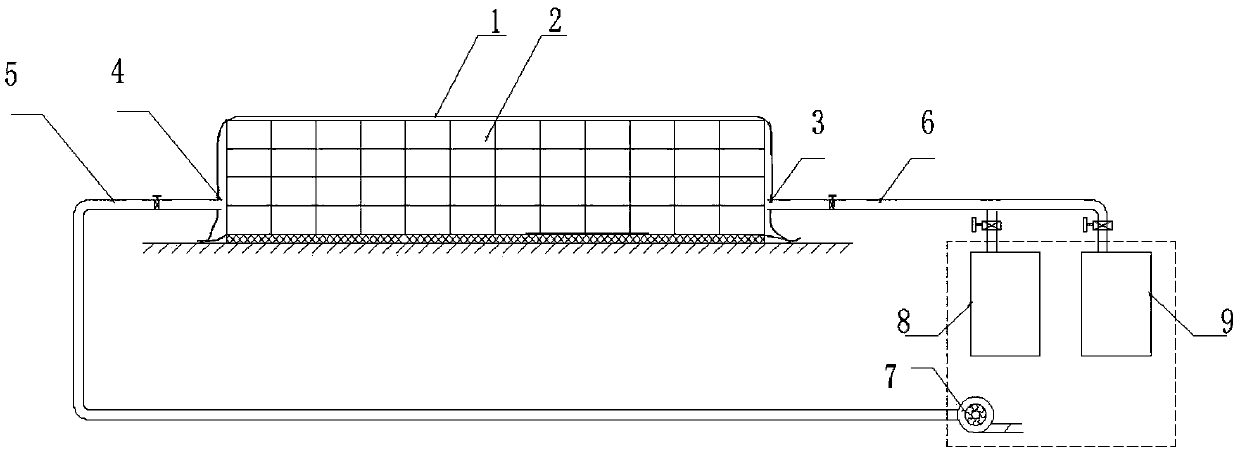

Method used

Image

Examples

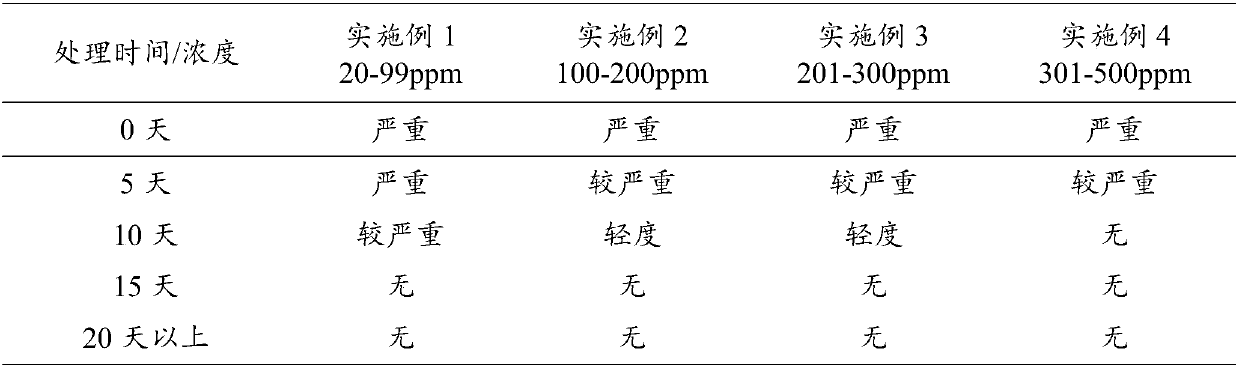

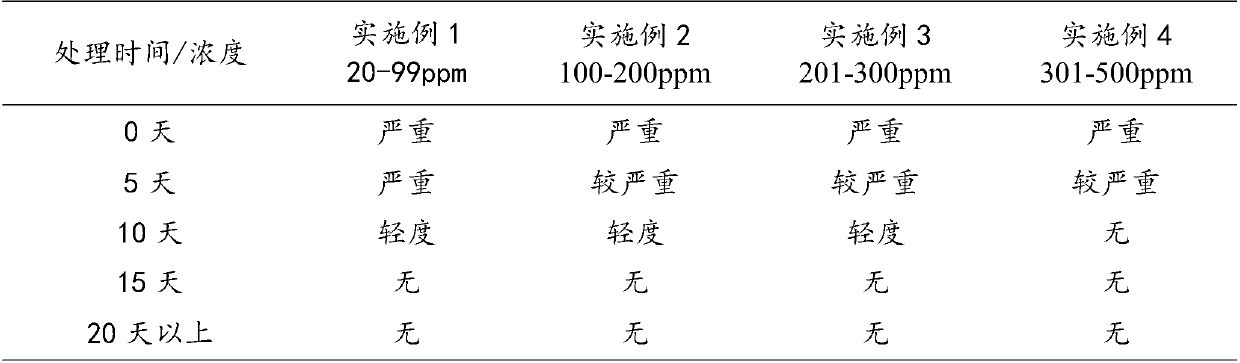

Embodiment 1

[0027] 1. Fill high-purity nitrogen into the sealed stack to reduce the oxygen concentration in the sealed stack to below 2% and maintain it, and ensure that the ambient oxygen concentration in the sealed stack is always in low oxygen through daily nitrogen supplementation and other control operations state;

[0028] 2. Fill the space with ozone with a concentration of 20-99ppm. The frequency of the introduction of ozone gradually decreases from the first stage to the third stage, wherein the first stage is treated for 7-10 days, the second stage is treated for 11-20 days, and the third stage is the second stage after. In the first stage, treat 4-5 times a day, in the second stage, 2-3 times a day, and in the third stage, 1-2 times a day. It should be noted that at this stage, nitrogen will be filled to reduce the oxygen concentration in the sealed stack to below 2% and maintain it, the same below.

Embodiment 2

[0030] 1. Fill high-purity nitrogen into the sealed stack to reduce the oxygen concentration in the sealed stack to below 2% and maintain it, and ensure that the ambient oxygen concentration in the sealed stack is always in low oxygen through daily nitrogen supplementation and other control operations state;

[0031] 2. Fill the space with ozone with a concentration of 100-200ppm. The frequency of the introduction of ozone gradually decreases from the first stage to the third stage, wherein the first stage is treated for 7-10 days, the second stage is treated for 11-20 days, and the third stage is the second stage after. In the first stage, treat 4-5 times a day, in the second stage, 2-3 times a day, and in the third stage, 1-2 times a day.

Embodiment 3

[0033] 1. Fill high-purity nitrogen into the sealed stack to reduce the oxygen concentration in the sealed stack to below 2% and maintain it, and ensure that the ambient oxygen concentration in the sealed stack is always in low oxygen through daily nitrogen supplementation and other control operations state;

[0034] 2. Fill the space with ozone at a concentration of 201-300ppm. The frequency of the introduction of ozone gradually decreases from the first stage to the third stage, wherein the first stage is treated for 7-10 days, the second stage is treated for 11-20 days, and the third stage is the second stage after. In the first stage, treat 4-5 times a day, in the second stage, 2-3 times a day, and in the third stage, 1-2 times a day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com