Limited self-restricting reinforced concrete slab member in bending and manufacturing method thereof

A technology of reinforced concrete slabs and flexural members, which is applied in the directions of building members, floor slabs, building structures, etc., can solve the problems of slab cracks such as floor slabs or roof slabs, which are not well solved, and the bonding strength and structural rigidity are not enough. , There are no problems such as the formation of self-restraining concrete, and the effect of simple production method, low production cost and good crack width is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

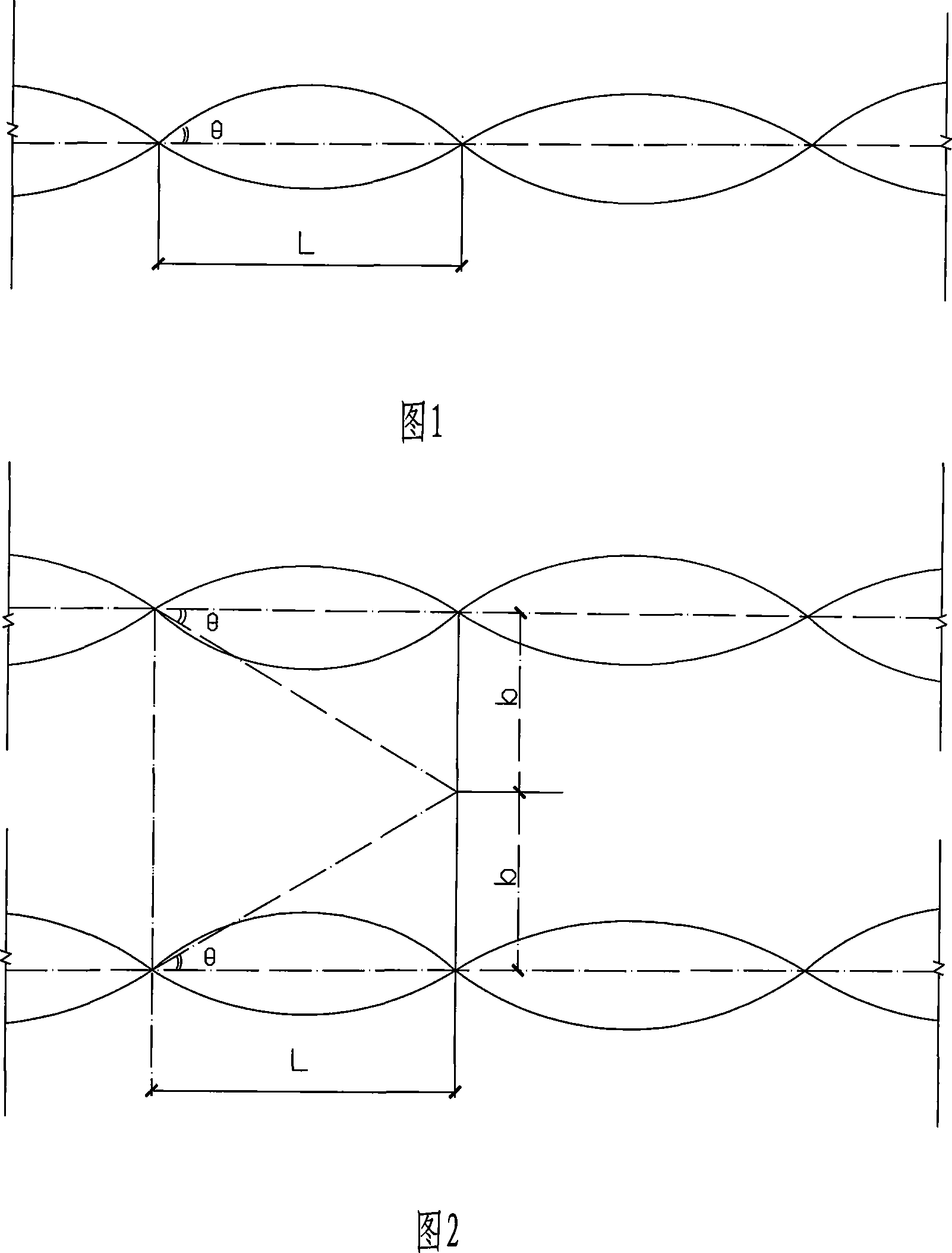

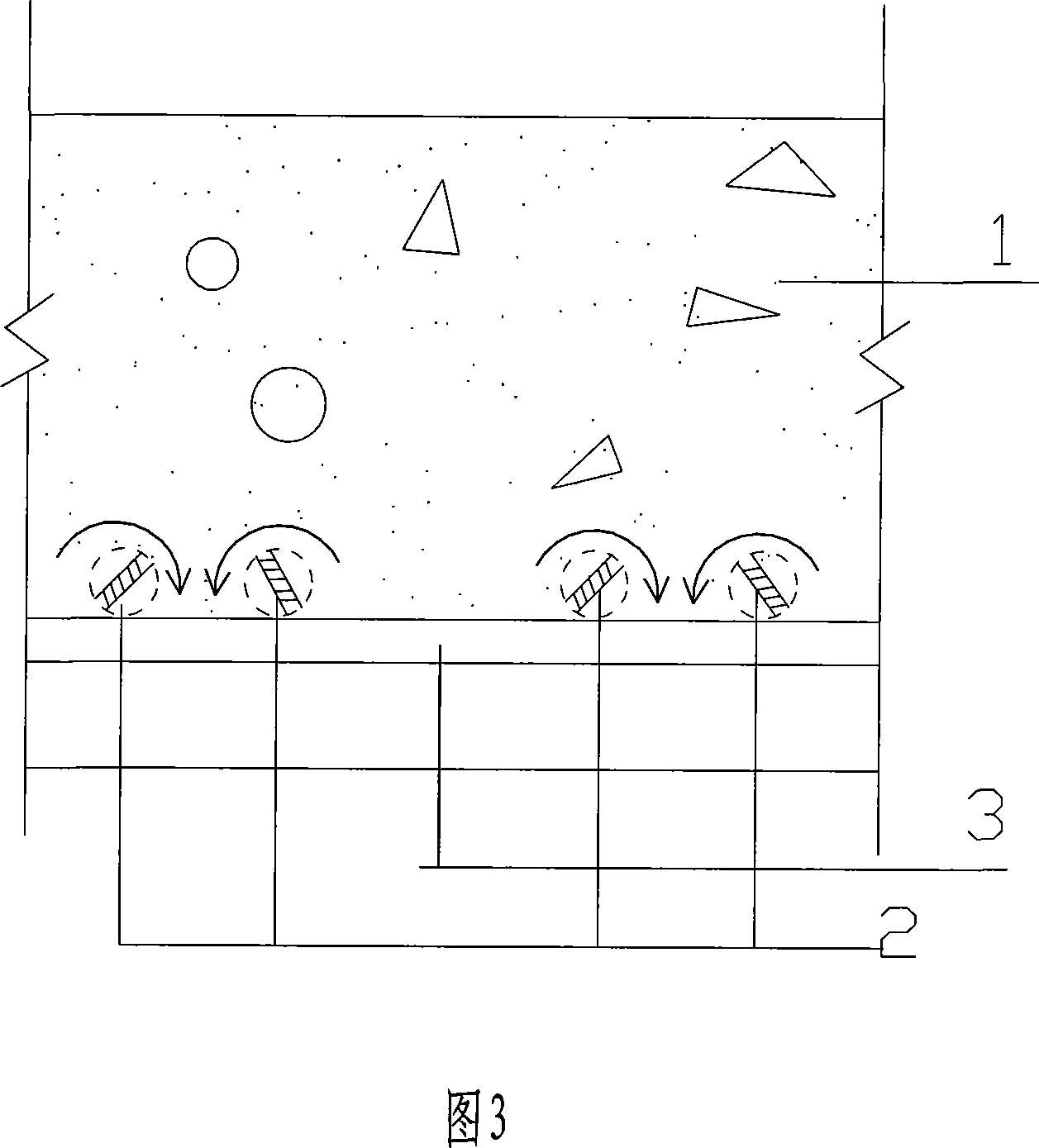

[0032] As shown in Figure 1, the spiral cold-rolled twisted steel bar used in the present invention is a cross-section such as approximately rectangular, square, circular, etc. formed by continuous cold rolling and cold twisting of smooth round steel bar raw materials. For special-shaped steel bars that undergo periodic helical changes along the axis of the steel bar, the distance of a periodic change in the section is called pitch L, and the helical angle is generally between 35° and 40°.

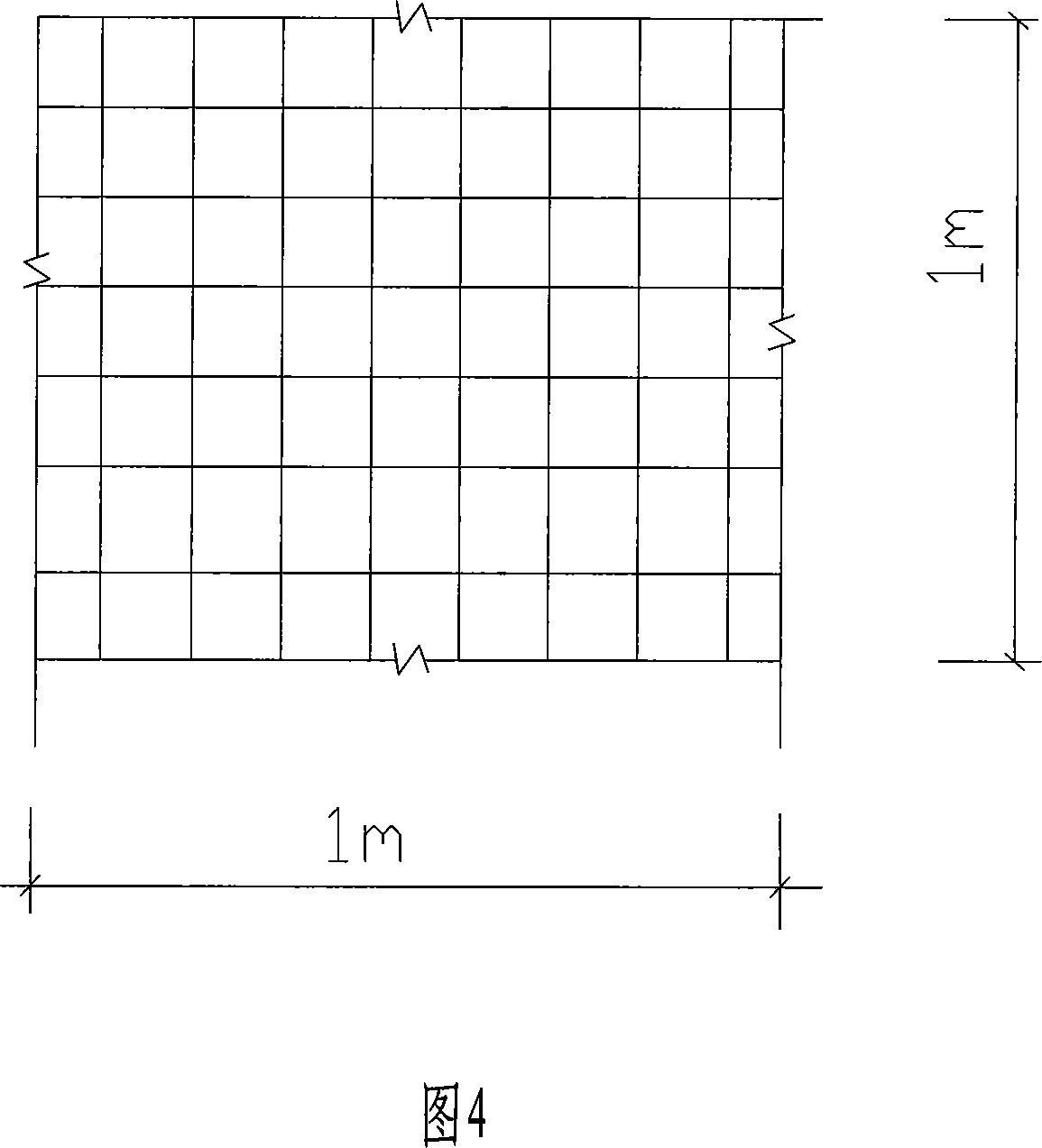

[0033] As shown in Figure 3, Figure 5, Figure 6, and Figure 7.

[0034] The present invention's limited self-constrained reinforced concrete slab-type flexural member includes concrete 1 and several stressed cold-rolled twisted steel bars 2 (that is, cold-rolled twisted steel bars are used as stressed steel bars) whose cross-section is spiral, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com