Prefabricated part mould convenient to remove and hoist and construction method thereof

A technology of prefabricated components and construction methods, applied in the directions of molds, manufacturing tools, unloading devices, etc., can solve the problems of many operating procedures and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

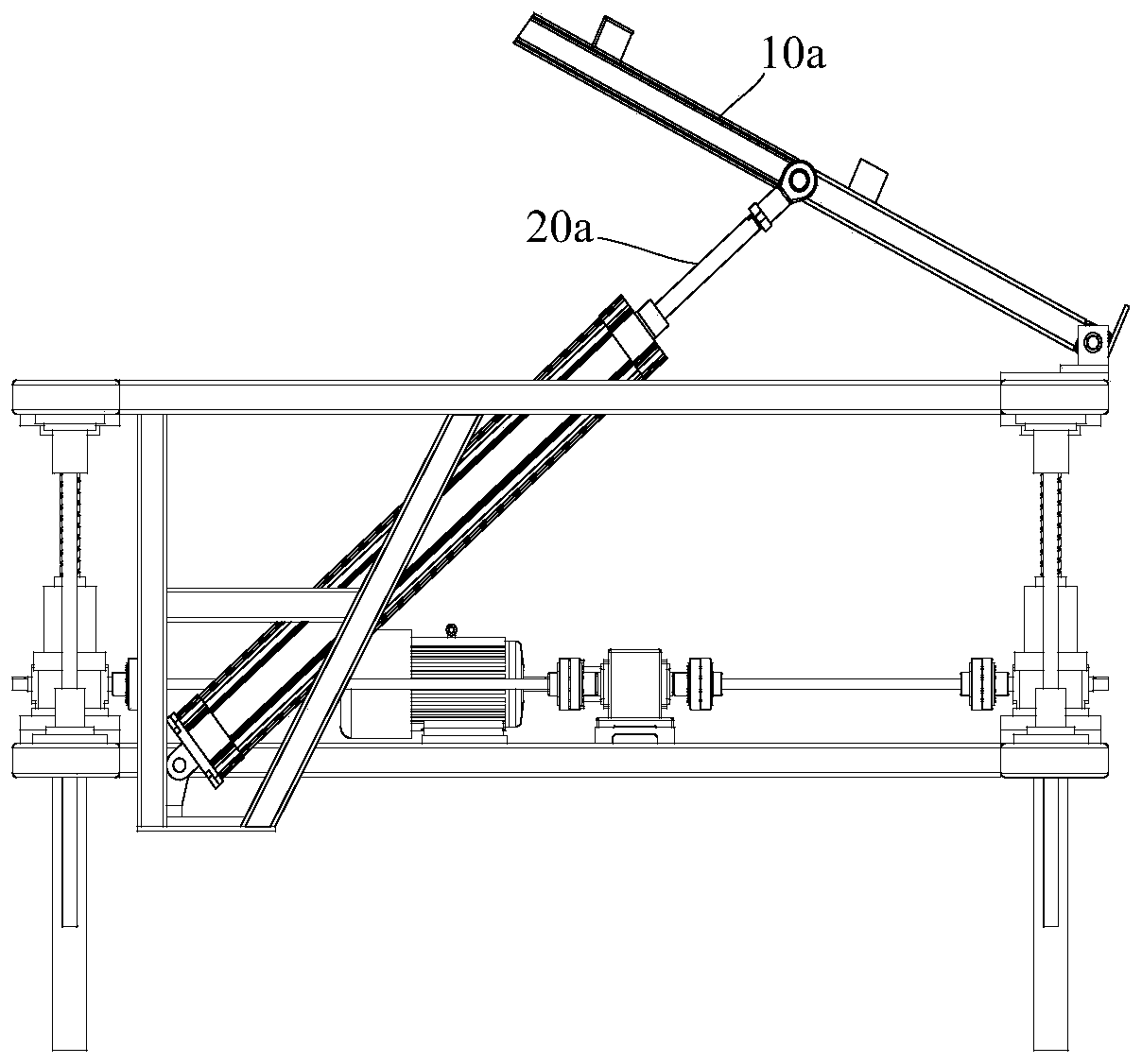

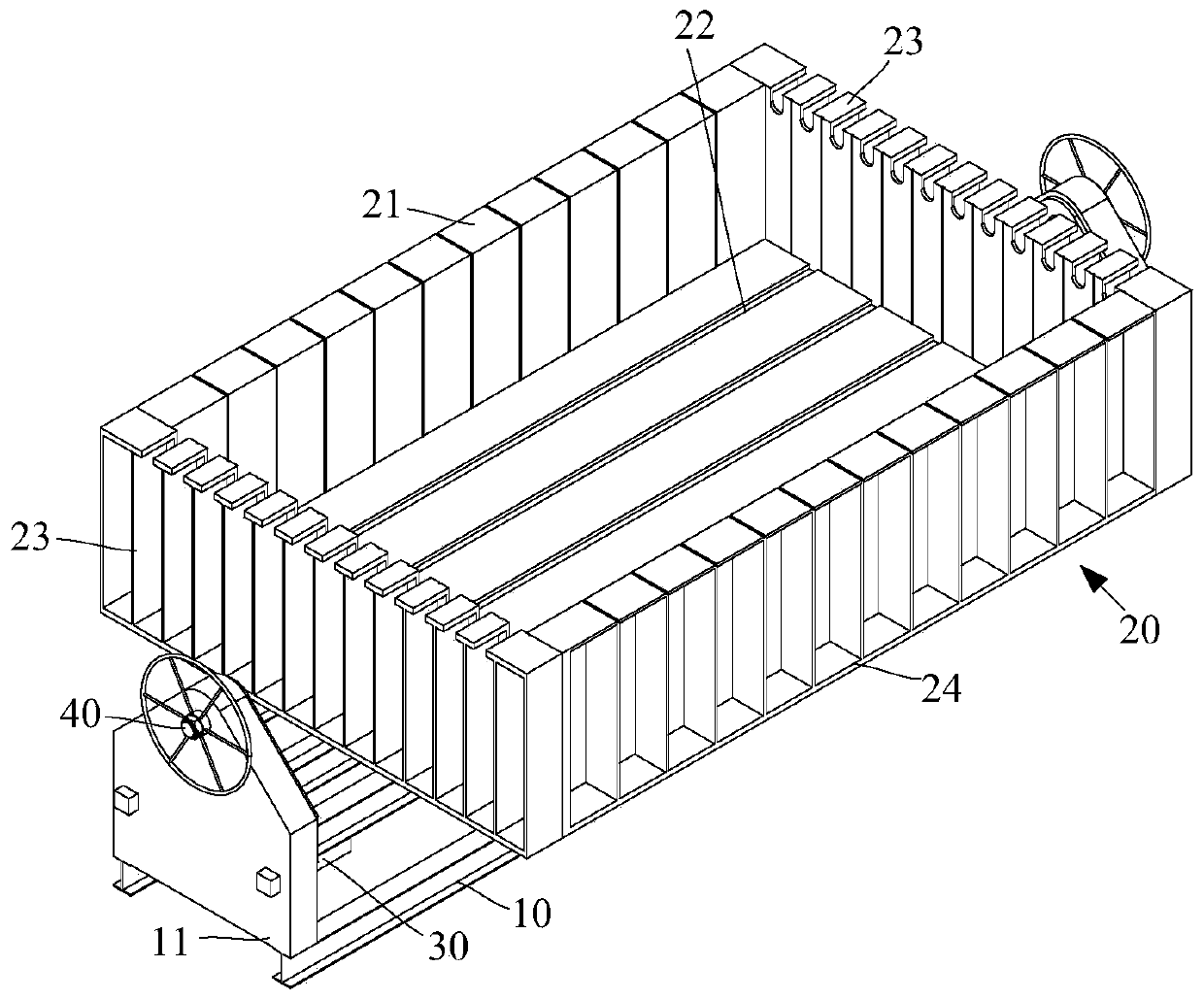

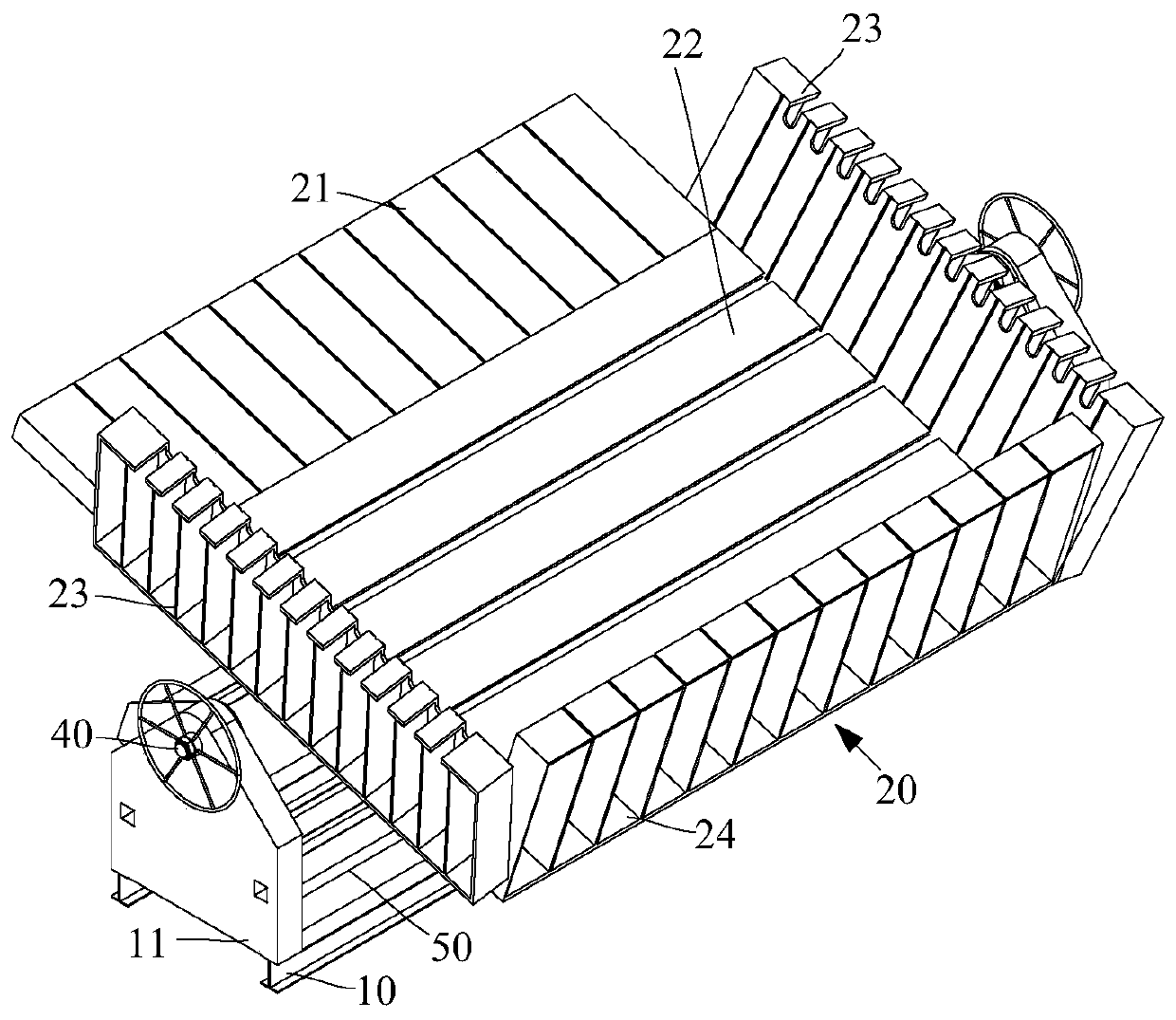

[0052] refer to figure 2 , which shows a schematic structural view of the lateral arrangement of the prefabricated component molds that facilitate demolition and lifting in the present invention. image 3 It is a structural schematic diagram after the rotation of the mold of the prefabricated component that is convenient for demolition and lifting in the present invention. combine figure 1 and figure 2 As shown, the prefabricated component mold that is convenient for demolition and lifting of the present invention includes: a base 10; a mold box 20 that is hinged on the base 10 at opposite ends through an adjustment piece 40, and a pouring space is formed inside the mold box 20 and includes a side part that can Open and close side mold 21; and a plurality of balance pins 30 inserted in the base 10 in a detachable manner, before pouring the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com