Spraying device for casting demold cleaning

A spraying device and casting demoulding technology, which is applied to casting equipment, manufacturing tools, cleaning hollow objects, etc., can solve the problems of prolonging the cleaning cycle, low spraying and curing efficiency, and shortening the cleaning cycle, so as to promote cooling and improve uniformity of spraying The effect of degree and curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

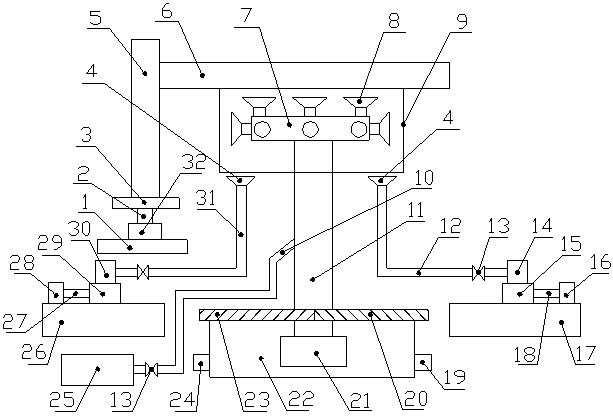

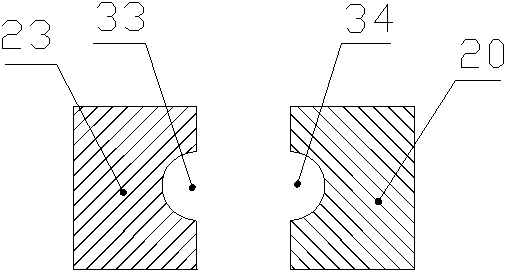

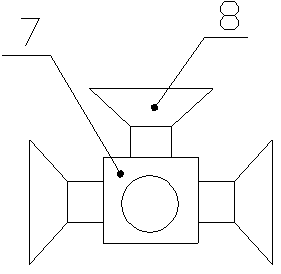

[0021] Such as Figure 1-5As shown, a casting demoulding cleaning and spraying device includes a support base 1, a release agent storage box 22, a base A26 and a base B17 located on the left and right sides of the release agent storage box 22, and the upper end of the support base 1 passes through The hydraulic cylinder base is connected with a hydraulic cylinder C32, the upper end of the piston rod C2 of the hydraulic cylinder C32 is connected with a support plate 3, the upper end of the support plate 3 is fixedly connected with a column 5, and the upper right side of the column 5 is fixedly connected with a The connecting rod 6, the lower end of the connecting rod 6 is connected with the casting mold 9, the left side of the upper end of the base A26 and the right side of the upper end of the base B17 are respectively connected with the hydraulic cylinder A28 and the hydraulic cylinder B16 through the hydraulic cylinder seat, and the hydraulic cylinder A28 and the hydraulic cy...

Embodiment 2

[0024] like Figure 1-5 As shown, a casting demoulding cleaning and spraying device includes a support base 1, a release agent storage box 22, a base A26 and a base B17 located on the left and right sides of the release agent storage box 22, and the upper end of the support base 1 passes through The hydraulic cylinder base is connected with a hydraulic cylinder C32, the upper end of the piston rod C2 of the hydraulic cylinder C32 is connected with a support plate 3, the upper end of the support plate 3 is fixedly connected with a column 5, and the upper right side of the column 5 is fixedly connected with a The connecting rod 6, the lower end of the connecting rod 6 is connected with the casting mold 9, the left side of the upper end of the base A26 and the right side of the upper end of the base B17 are respectively connected with the hydraulic cylinder A28 and the hydraulic cylinder B16 through the hydraulic cylinder seat, and the hydraulic cylinder A28 and the hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com