Casting demolding cleaning and spraying device

A spraying device and casting demoulding technology, which is applied to casting equipment, manufacturing tools, and equipment for transporting molds, etc., can solve the problems of increased casting cost, unevenness, waste of mold release liquid, etc., and achieve reduced production costs and thin film layers. Uniform and reduce the effect of defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

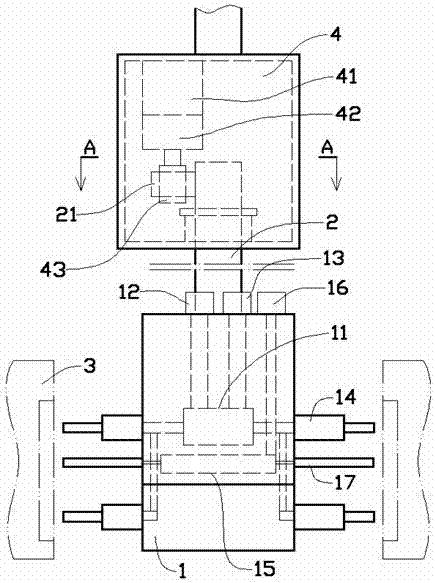

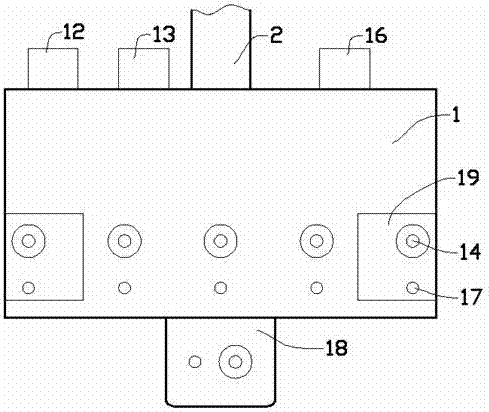

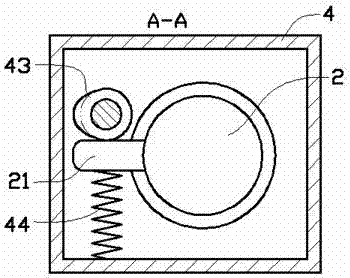

[0014] Such as figure 1 and figure 2 As shown in the embodiment, the casting demoulding cleaning and spraying device includes an installation block 1, and the installation block 1 is assembled on the mechanical arm through the connecting column 2, and the mechanical arm is fixedly assembled on the frame of the casting machine. The casting mold 3 of the above-mentioned casting machine includes two pieces that can be opened and closed horizontally on the left and right. The installation block 1 can be driven by the mechanical arm to the middle of the two separate casting molds of the casting machine; the inside of the installation block 1 is designed with a liquid buffer Cavity 11, the upper part of the installation block 1 is respectively designed with a clean water interface 12 and a release liquid interface 13 connected with the liquid buffer chamber 11; the clean water interface 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com