Patents

Literature

35results about How to "Reach replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

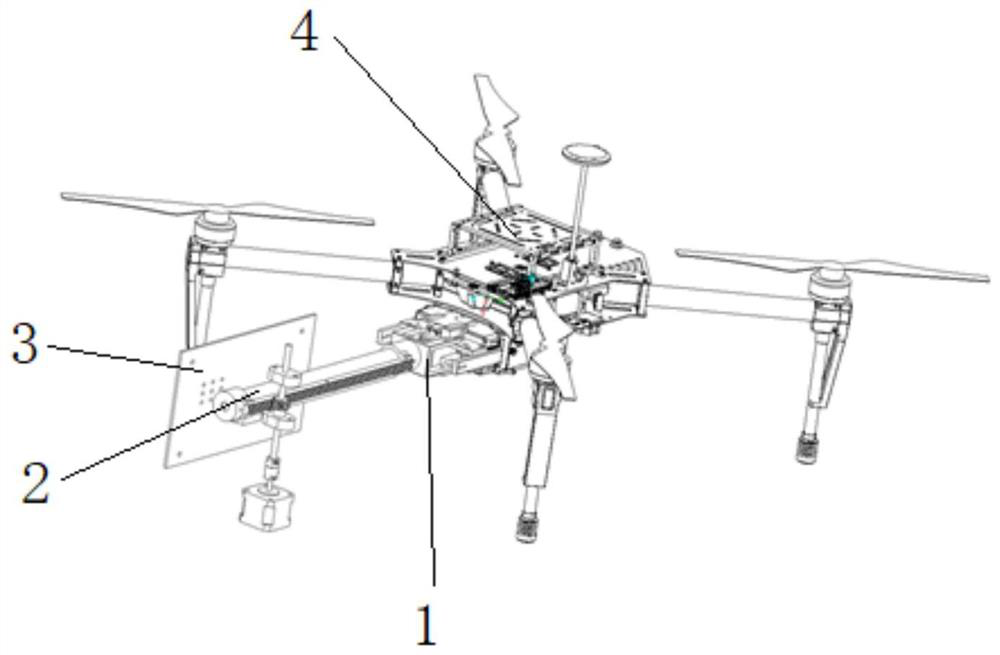

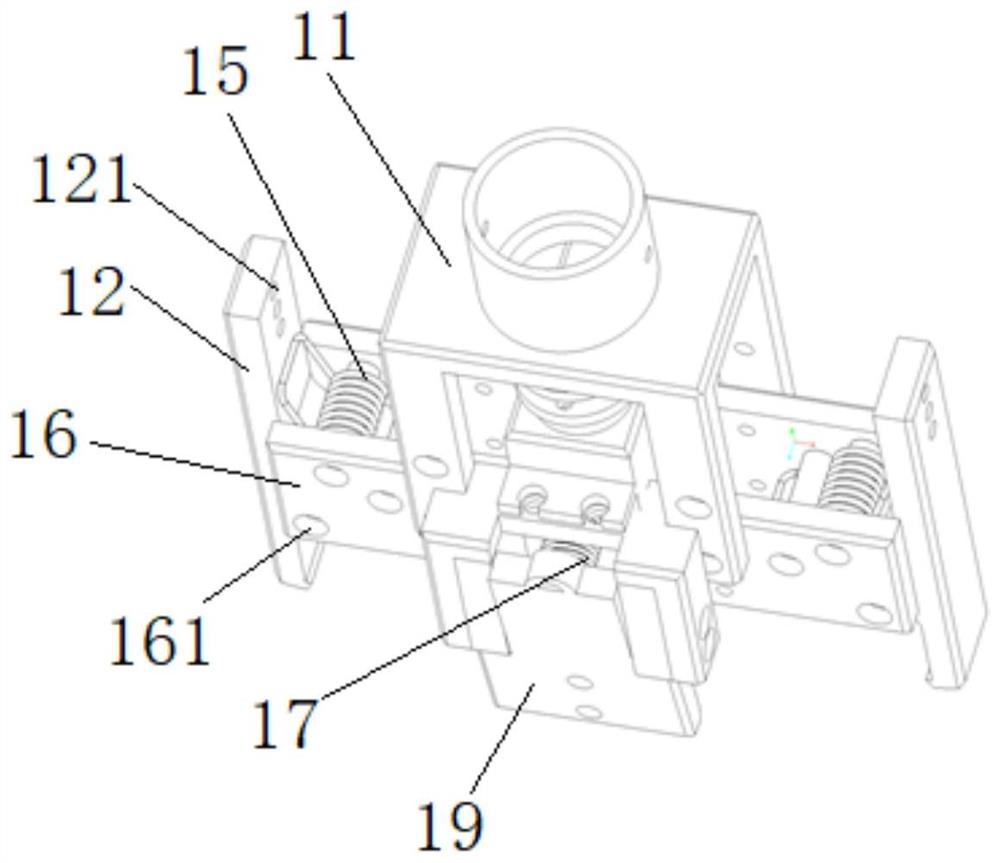

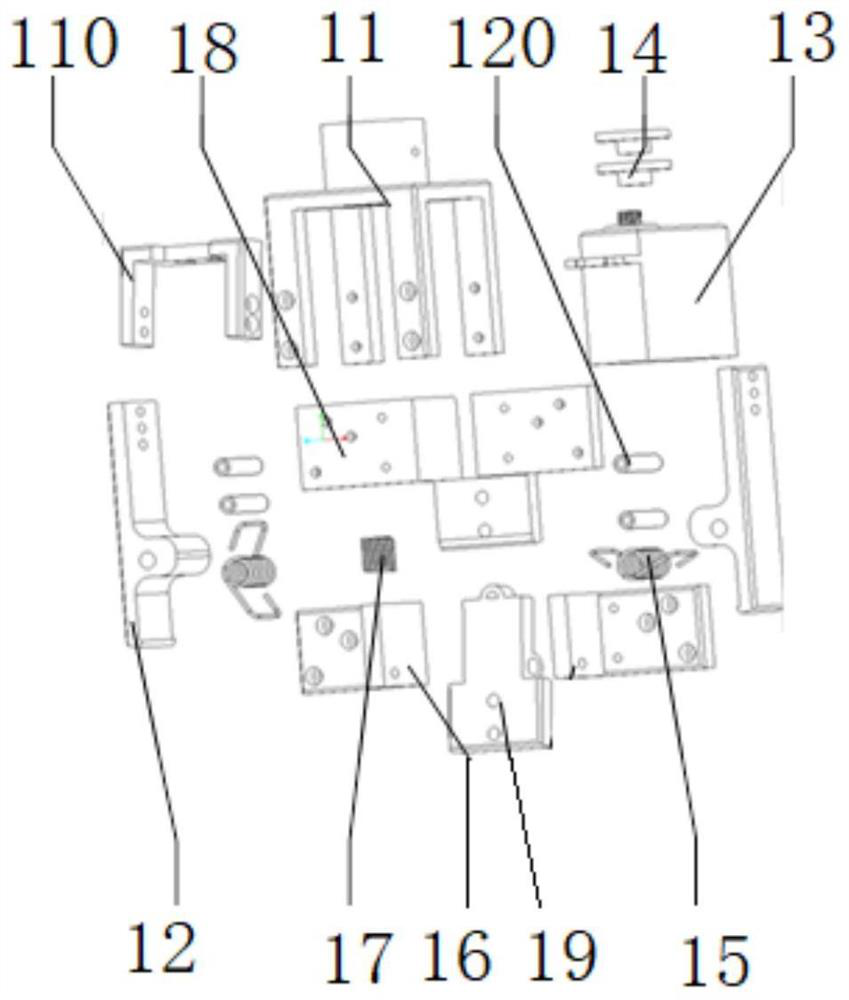

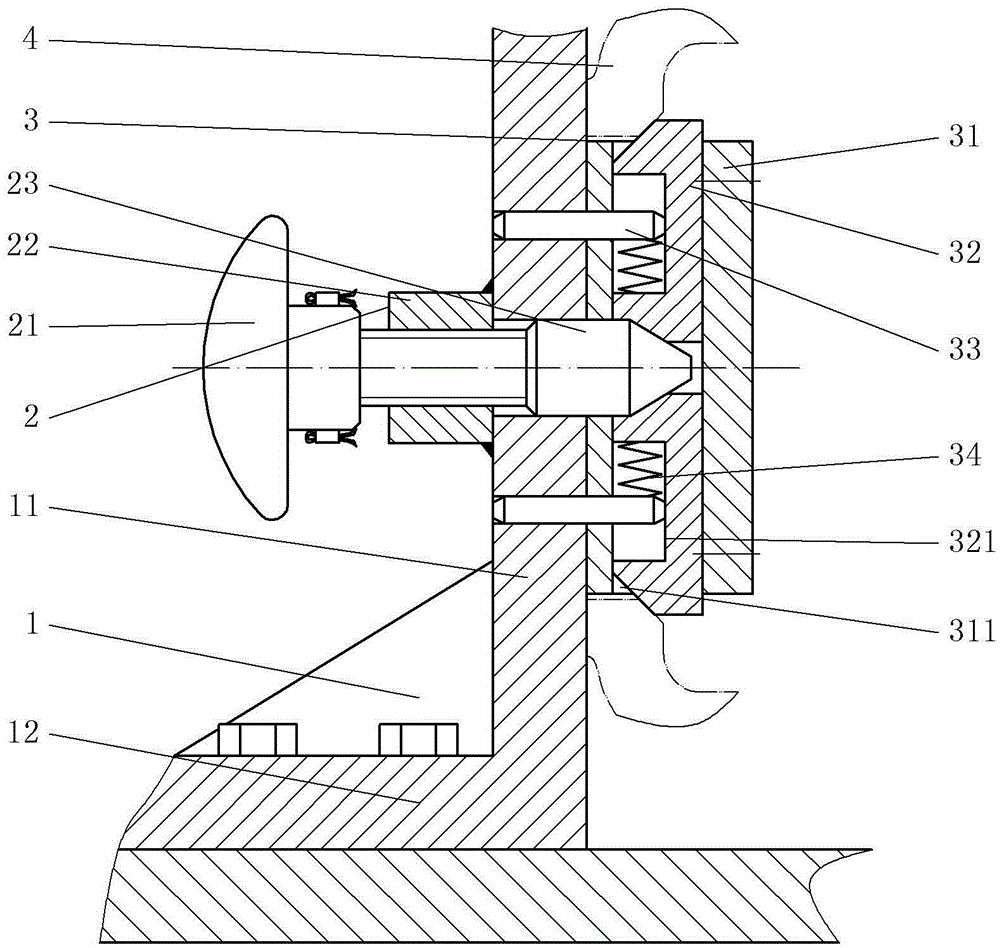

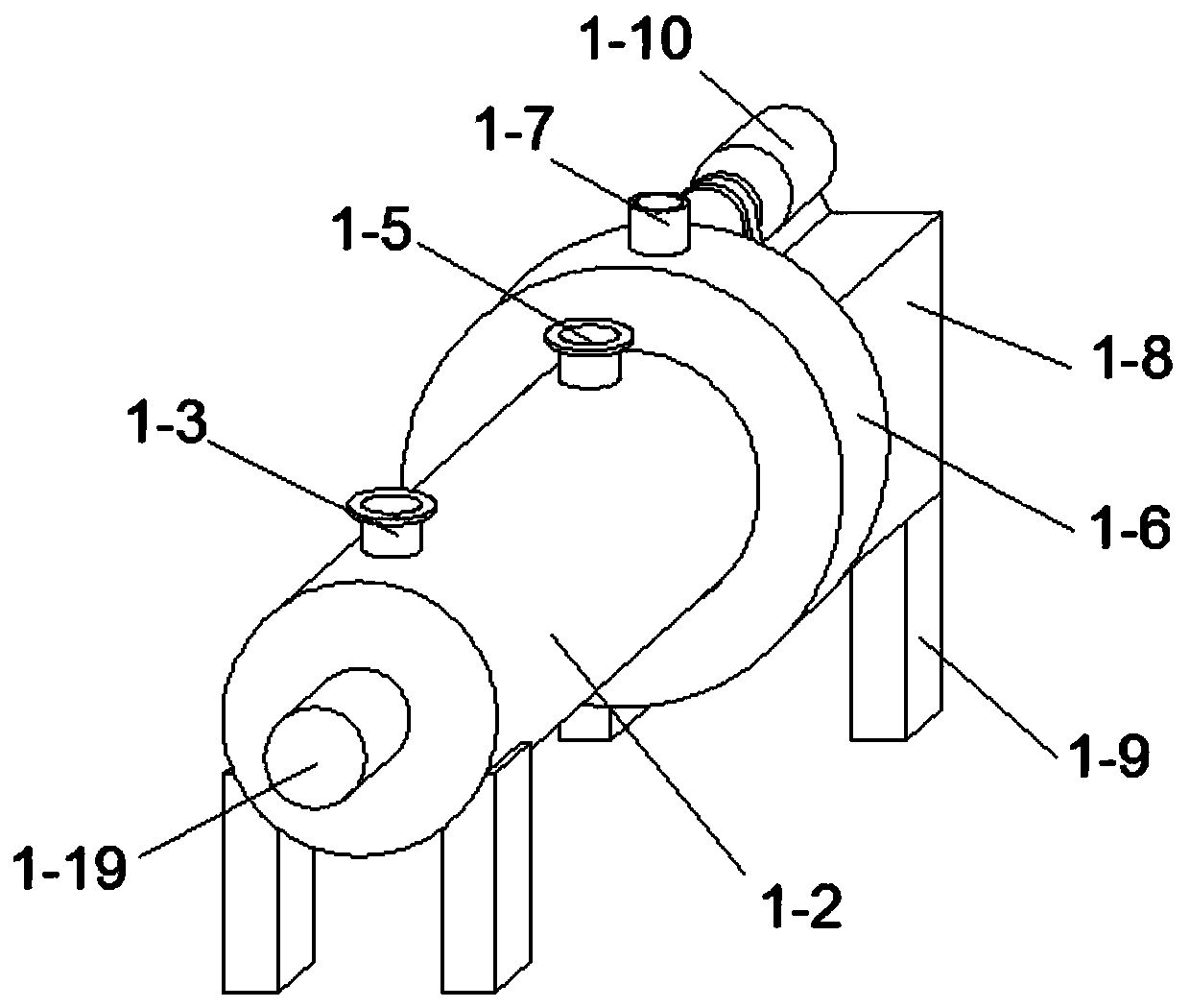

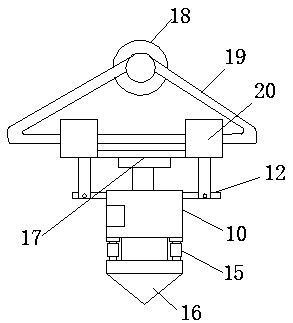

Grabbing device for replacing battery of unmanned aerial vehicle

InactiveCN112046331AReach replacementWith waterproof functionCharging stationsGripping headsSteering wheelElectrical battery

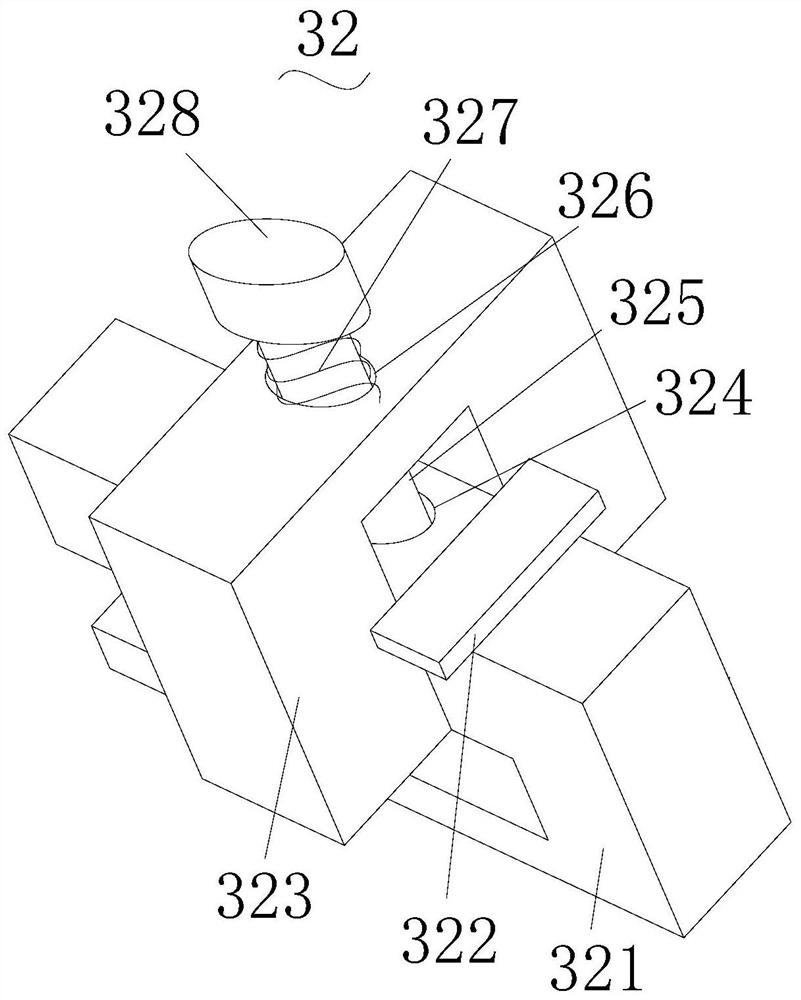

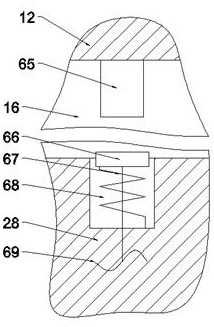

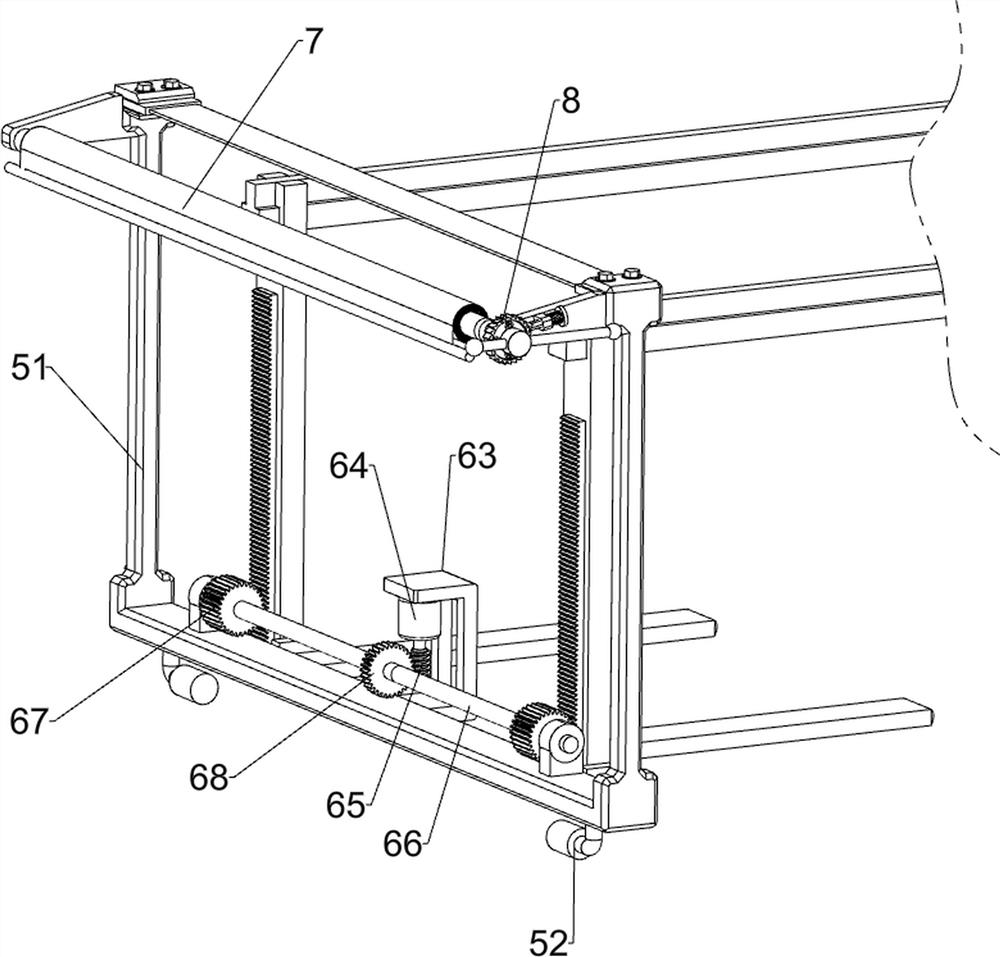

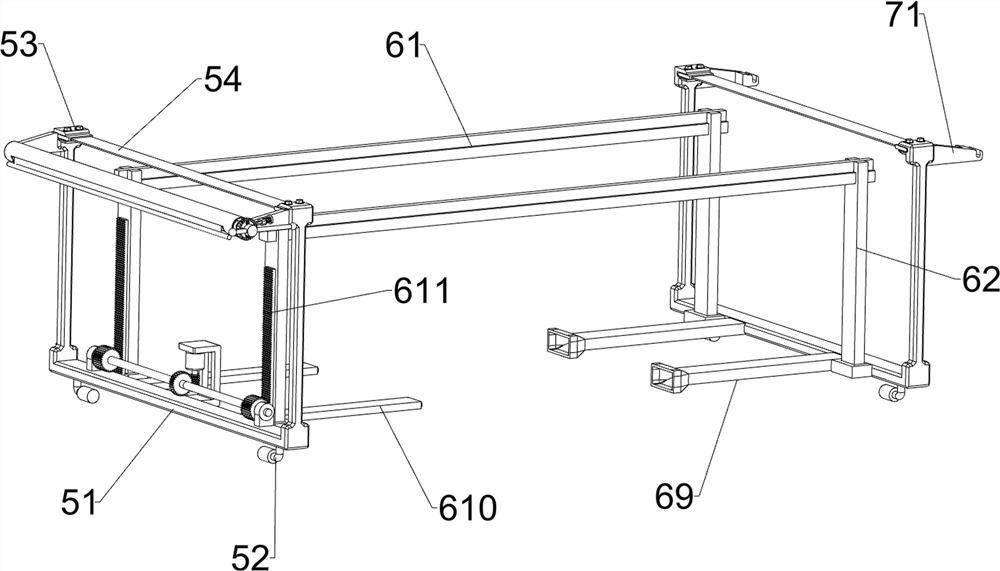

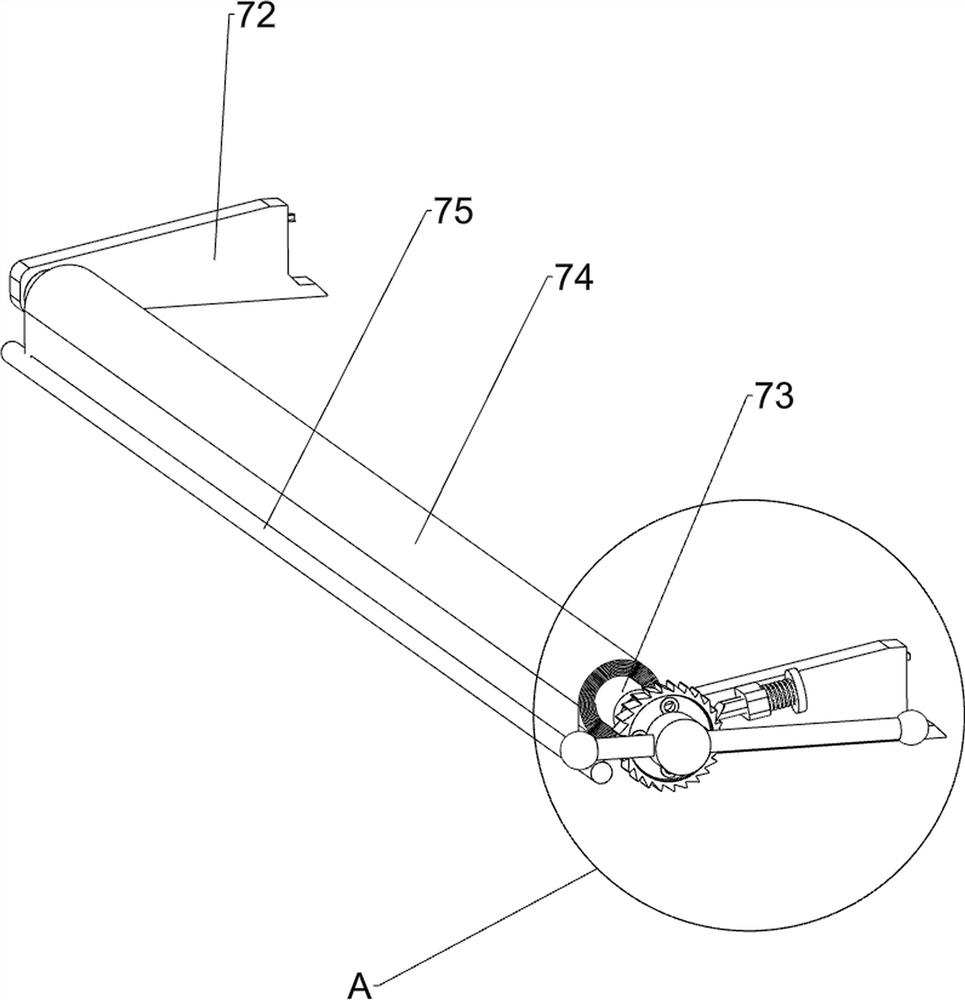

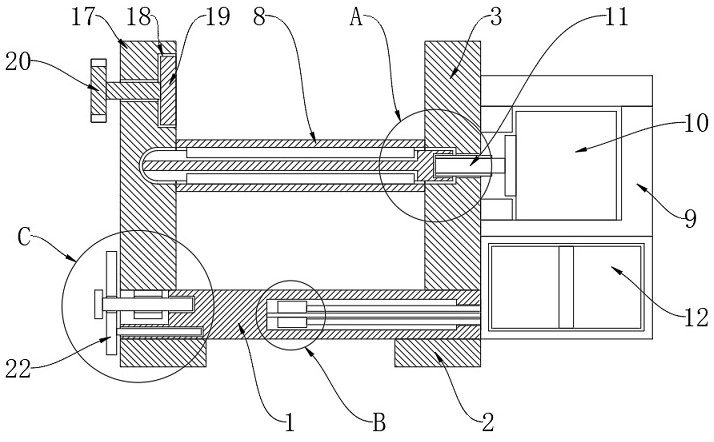

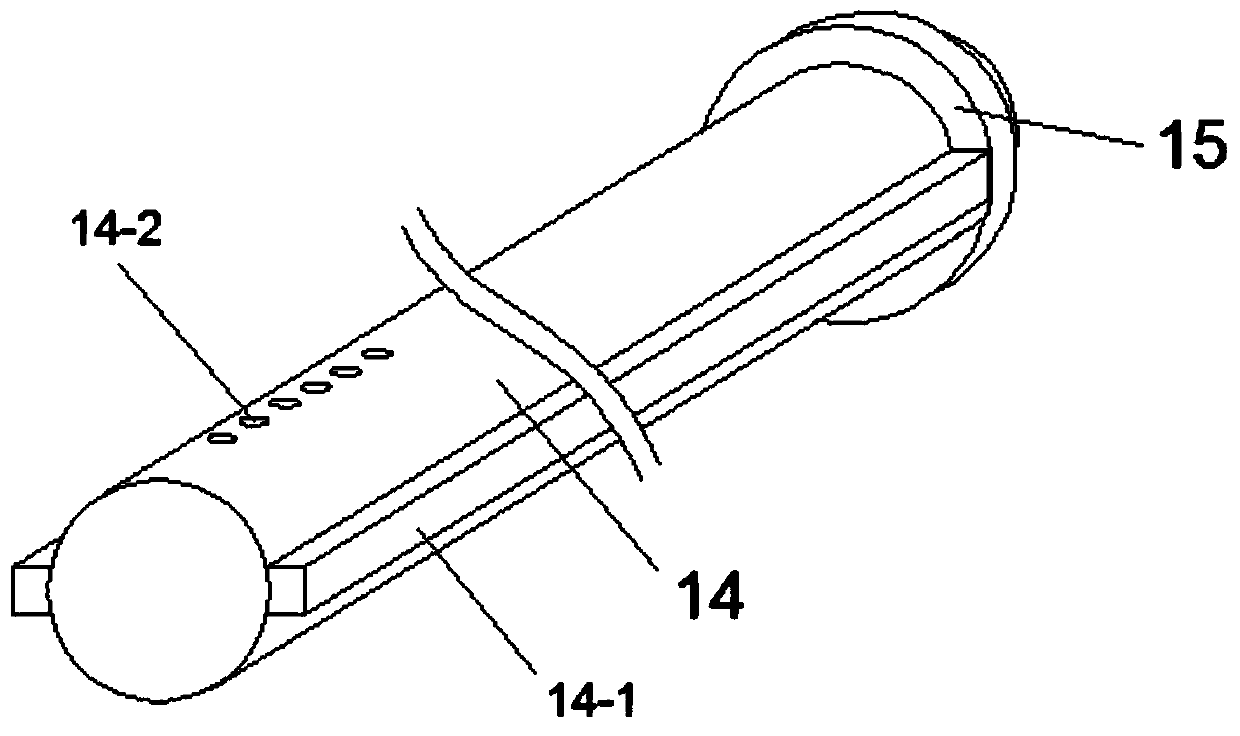

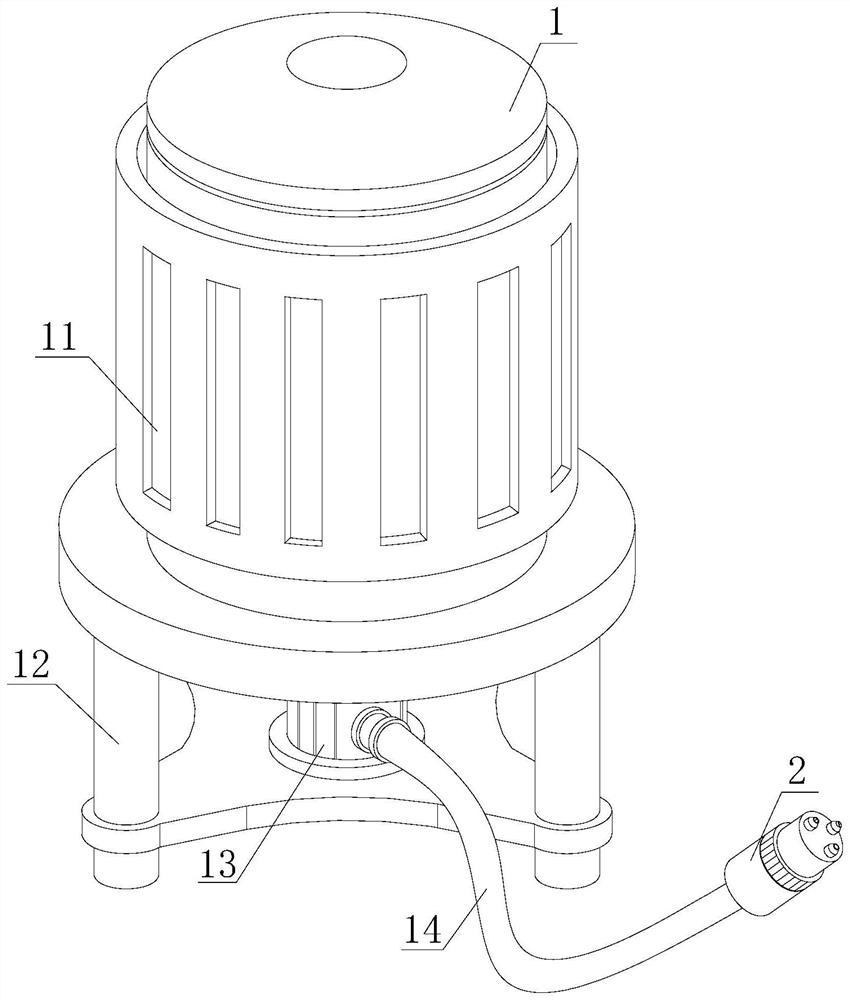

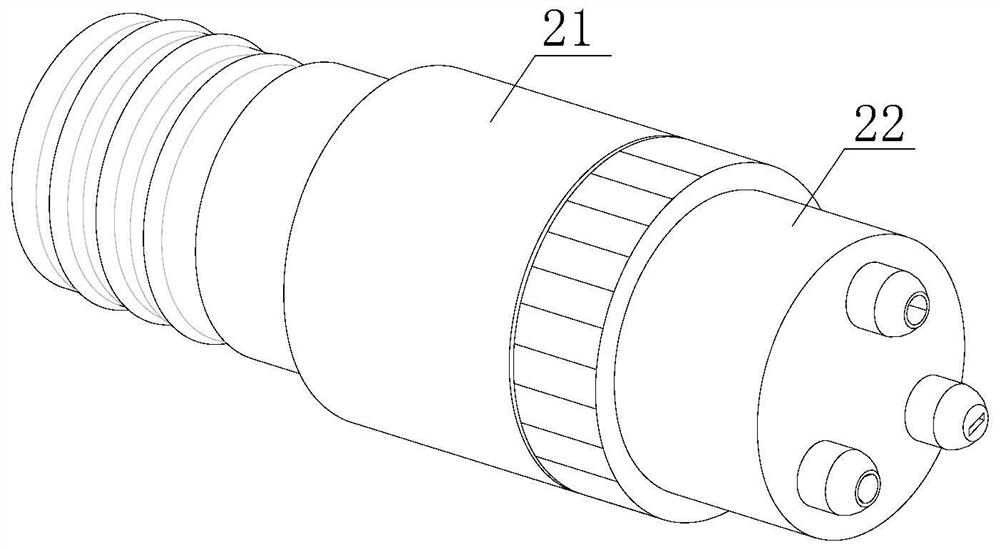

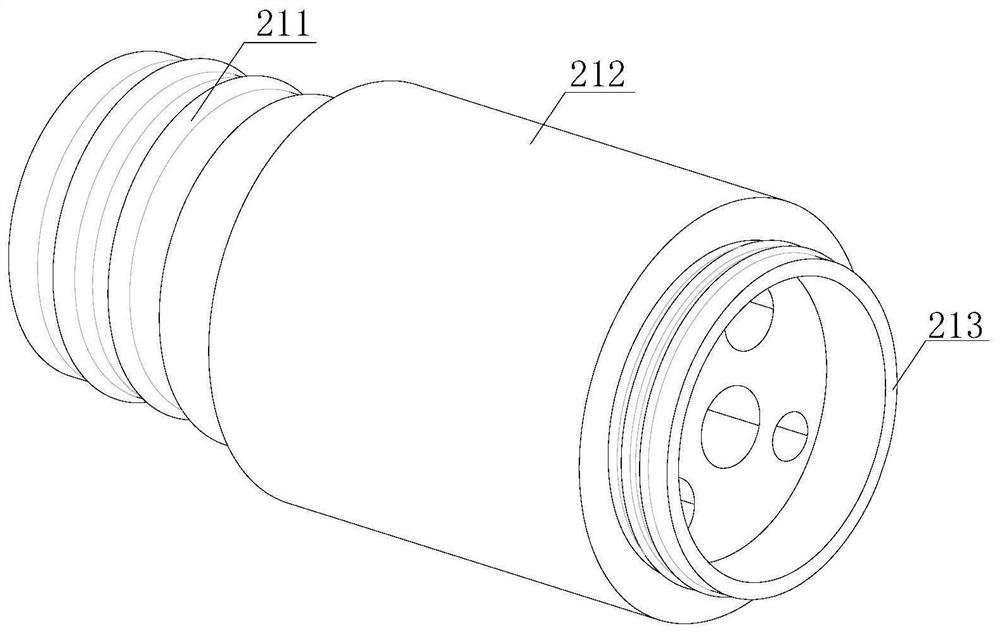

The invention belongs to the technical field of unmanned aerial vehicle battery replacement, and particularly relates to a grabbing device for replacing a battery of an unmanned aerial vehicle. The grabbing device comprises a mechanical claw and a mechanical arm matched with the mechanical claw, and the mechanical claw comprises a base, torsional springs, a steering engine, a steering wheel and clamping claws arranged on the two sides of the base; the steering engine is fixedly connected with the steering wheel, a steel wire rope is installed between the steering wheel and the clamping claws,the base is fixedly connected with installation plates, the installation plates are movably connected with the clamping claws, and the torsional springs are installed on the installation plates and movably matched with the clamping claws; when the steering engine drives the steering wheel to rotate, the steering wheel drives the steel wire rope to move and is linked with the grabbing parts of theclamping claws to open; when the steering wheel stops rotating, under the action of the torsional springs, the grabbing parts of the clamping claws are tightened towards the middle, so that the clamping claws grab the battery and push the battery to the unmanned aerial vehicle in cooperation with the mechanical arm; and a hand and elbow mechanism is achieved through the linear motion mechanical arm and the mechanical claw, the purpose of replacing the lithium battery of the unmanned aerial vehicle is achieved, and the automation degree is high.

Owner:浙江浙能天然气运行有限公司 +1

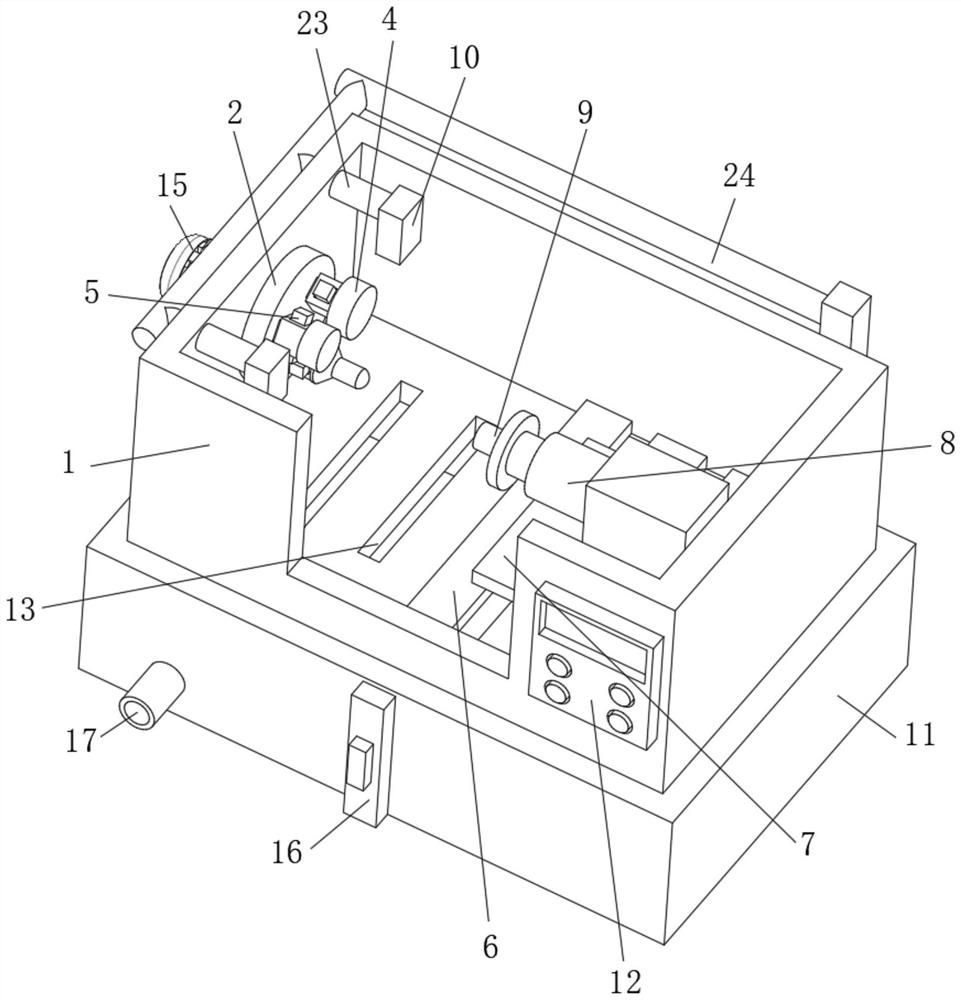

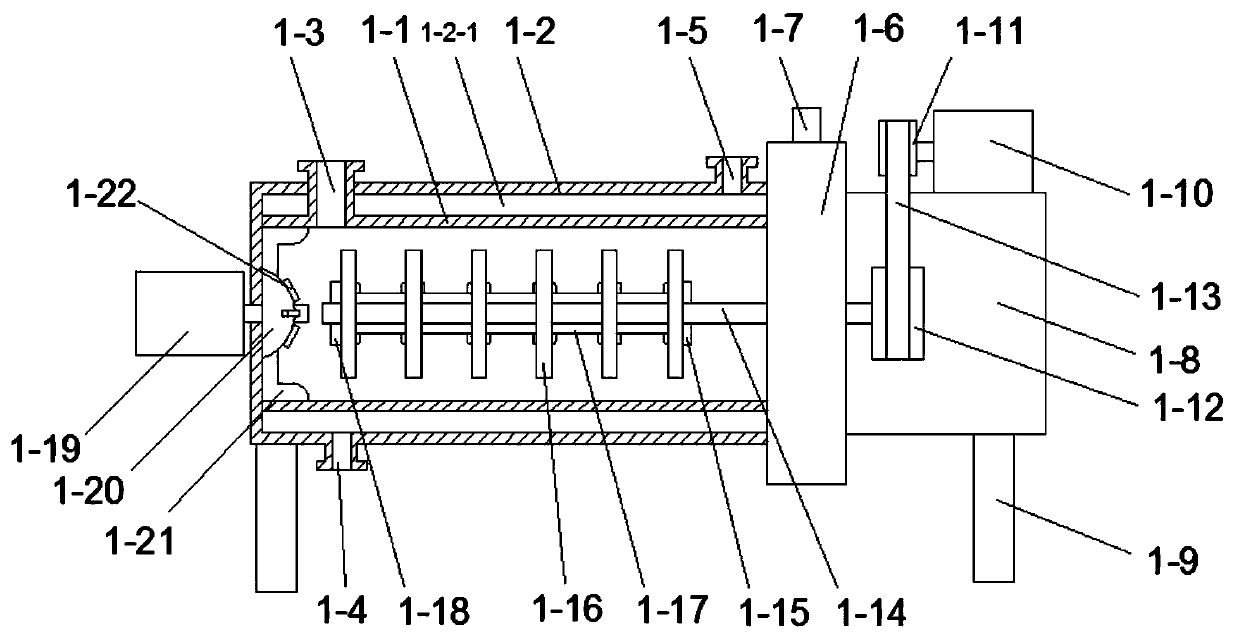

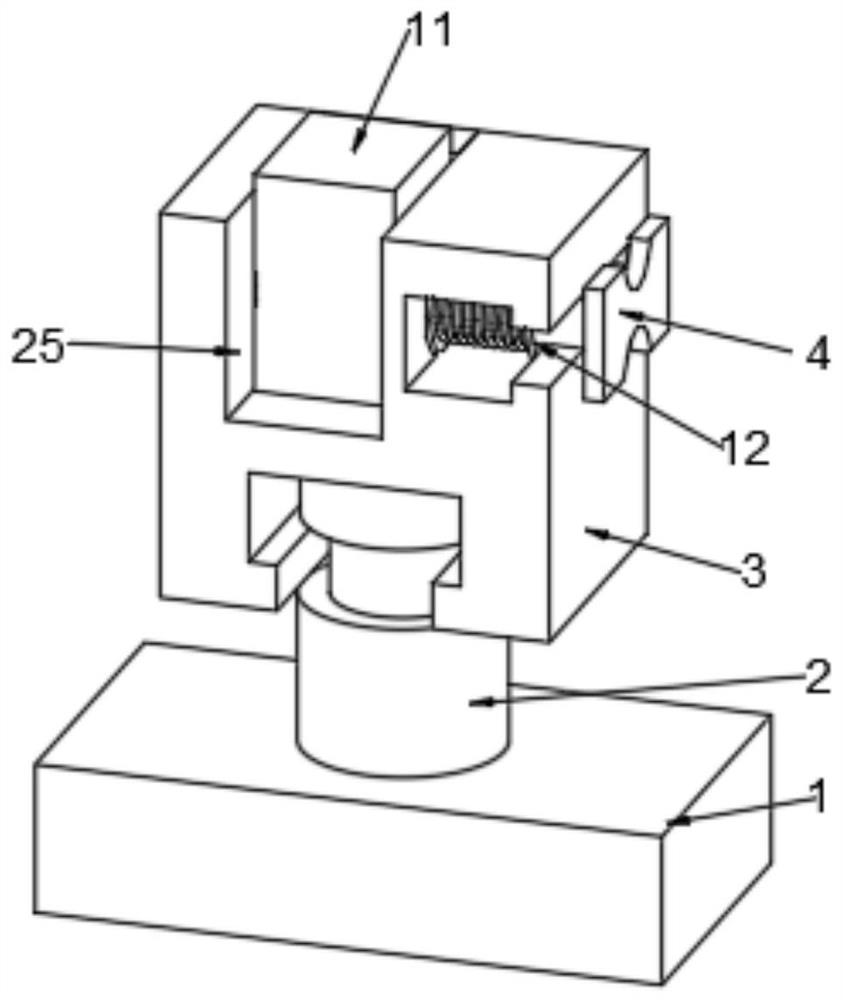

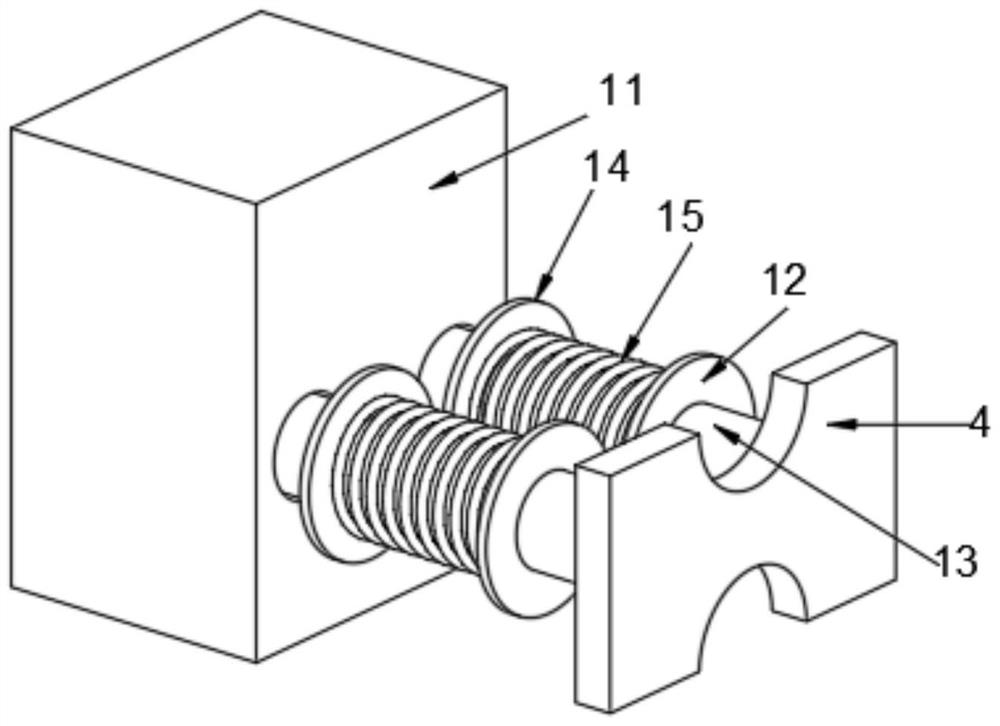

Quick center clamp for cutter and using method of quick center clamp

InactiveCN109202105ANovel structureDimensionally stable processingTailstocks/centresEngineeringBiomedical engineering

The invention provides a quick center clamp for a cutter and a using method of the quick center clamp. The quick center clamp comprises a device main body, a movable installation mechanism and a localreplacement mechanism. The device main body comprises a front cover and a clamping chuck. The rear end surface of the front cover is jointed with the front end surface of the clamping chuck. The movable installation mechanism is installed at the front end of the clamping chuck. The movable installation mechanism comprises a center, a first screw, a rear cover, a spring, a first circular groove and a second limiting ring. The local replacement mechanism is installed on the outer surface of the front end of the clamping chuck. The local replacement mechanism comprises dovetail joint grooves, dovetail joint strips, an external thread ring, second countersunk holes and second screws. The quick center clamp and the using method have the following beneficial effects that the purpose of movableinstallation is achieved, no alignment is needed, the efficiency is improved, mass production is facilitated, and the purpose of replacing the external thread ring is achieved.

Owner:广州市镭迪机电制造技术有限公司

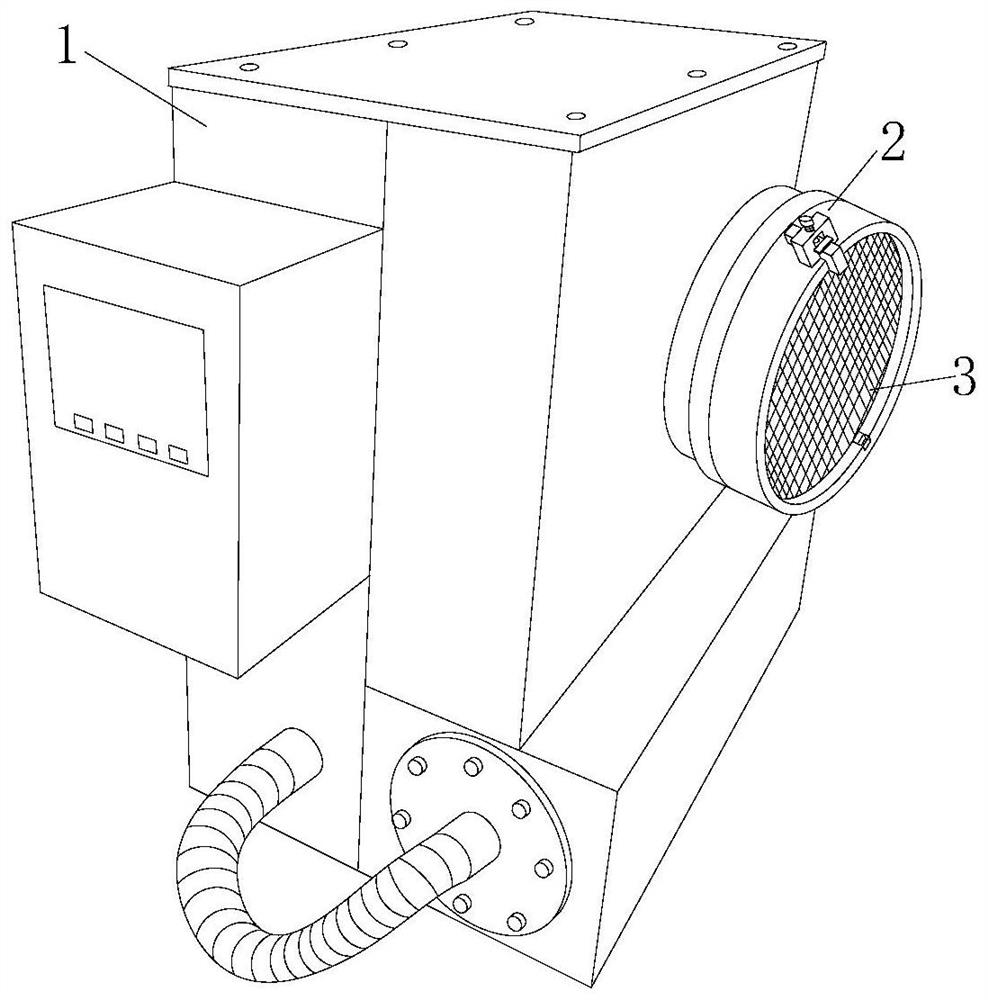

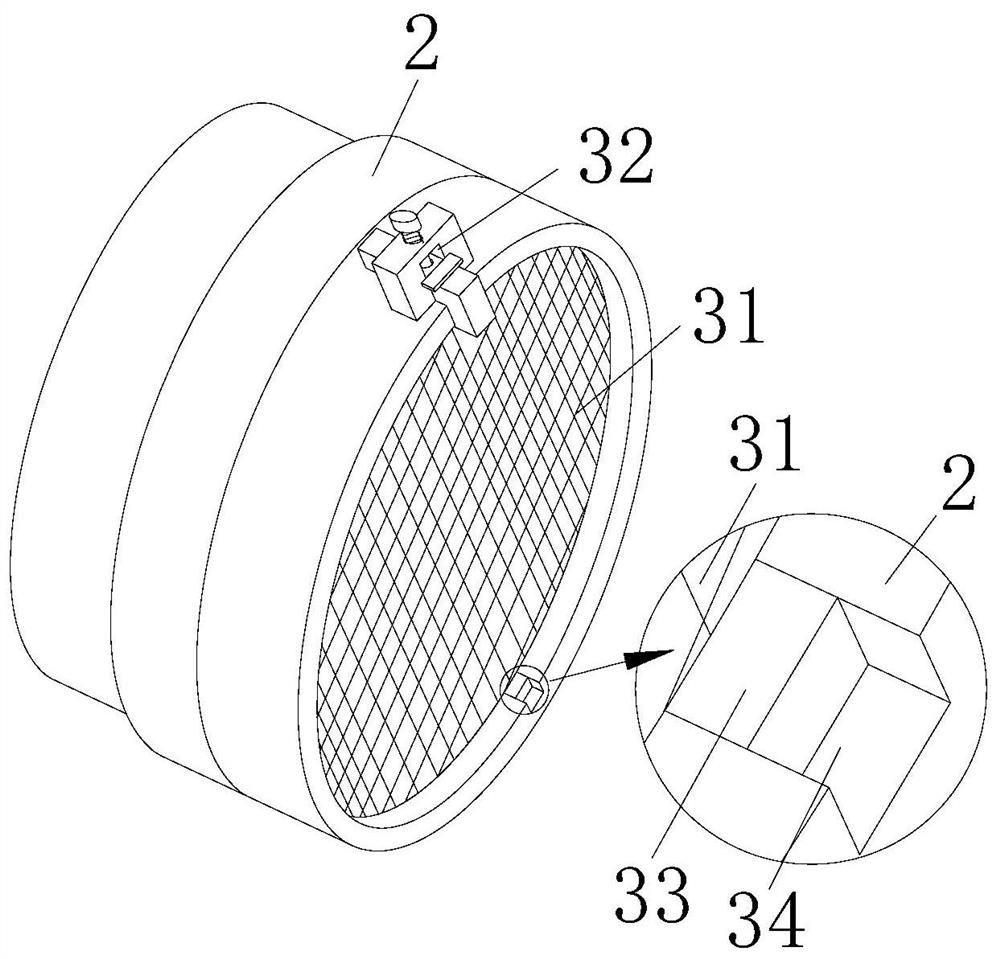

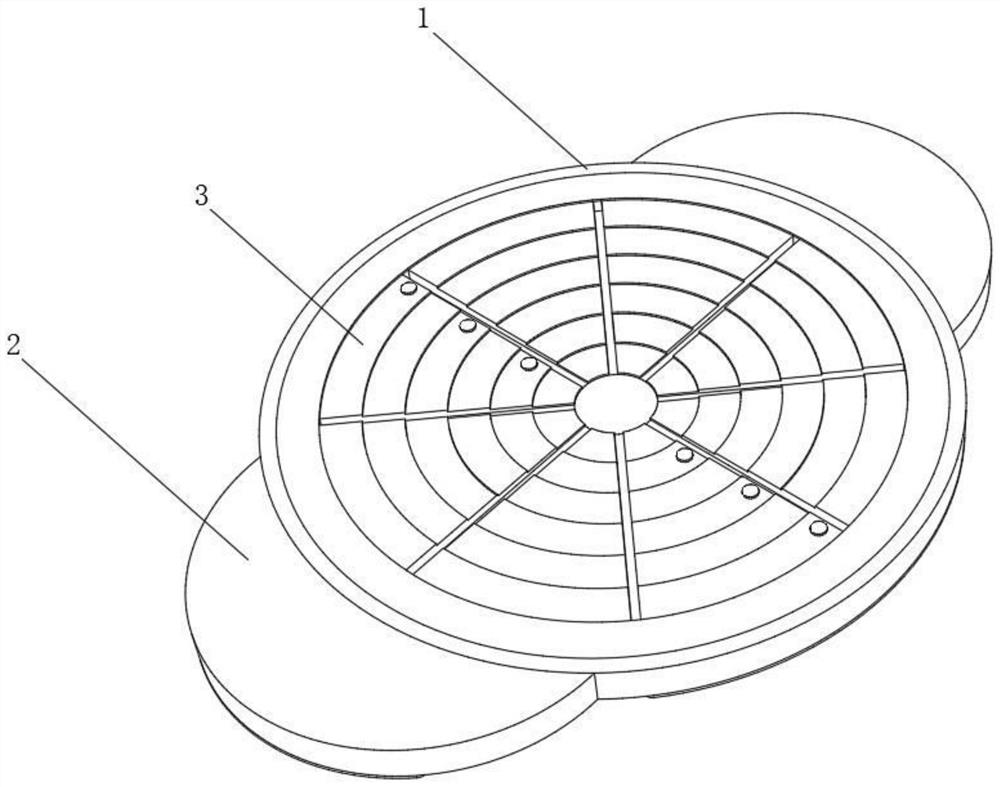

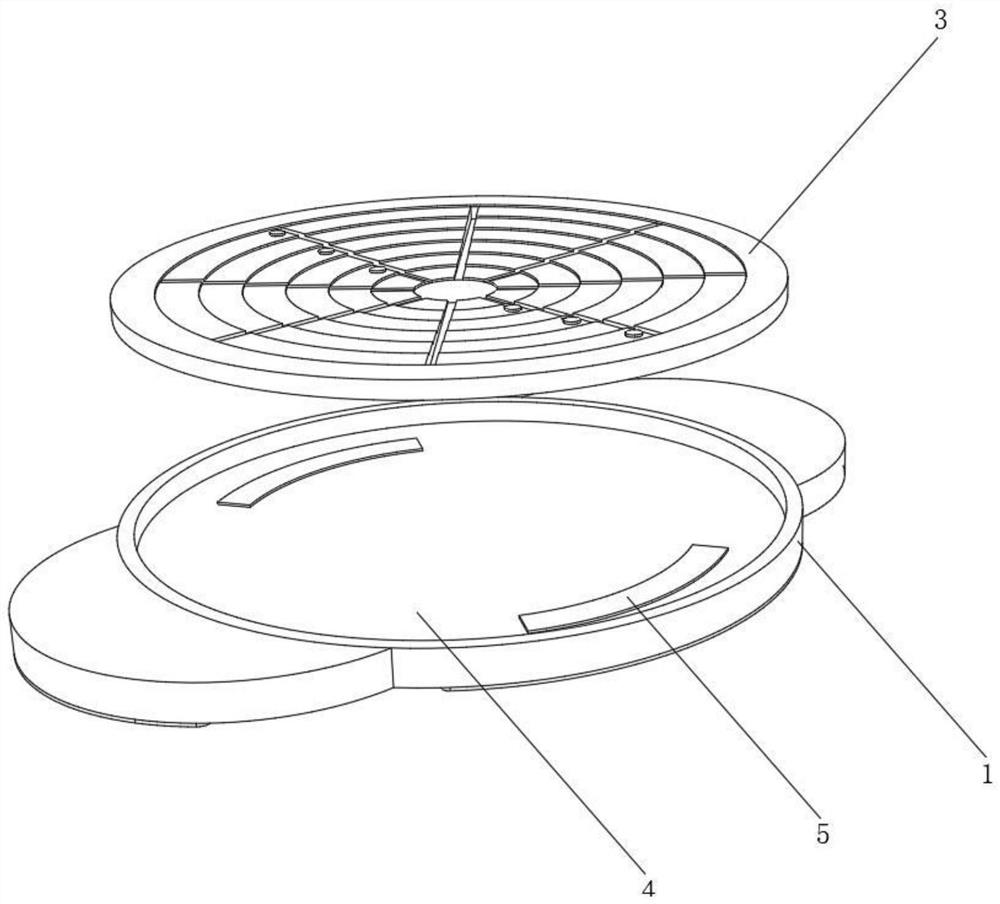

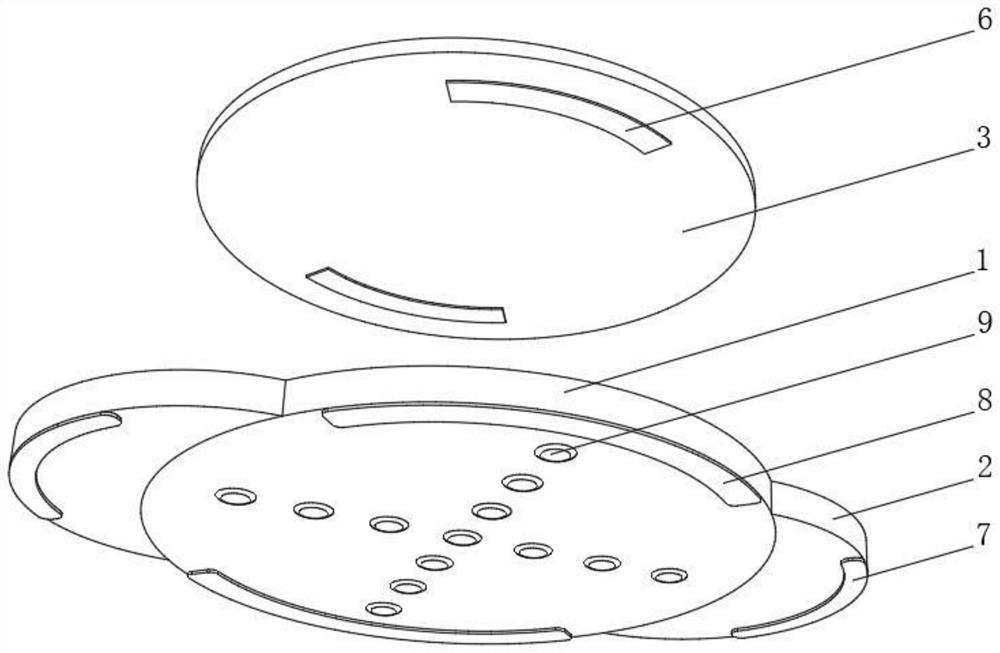

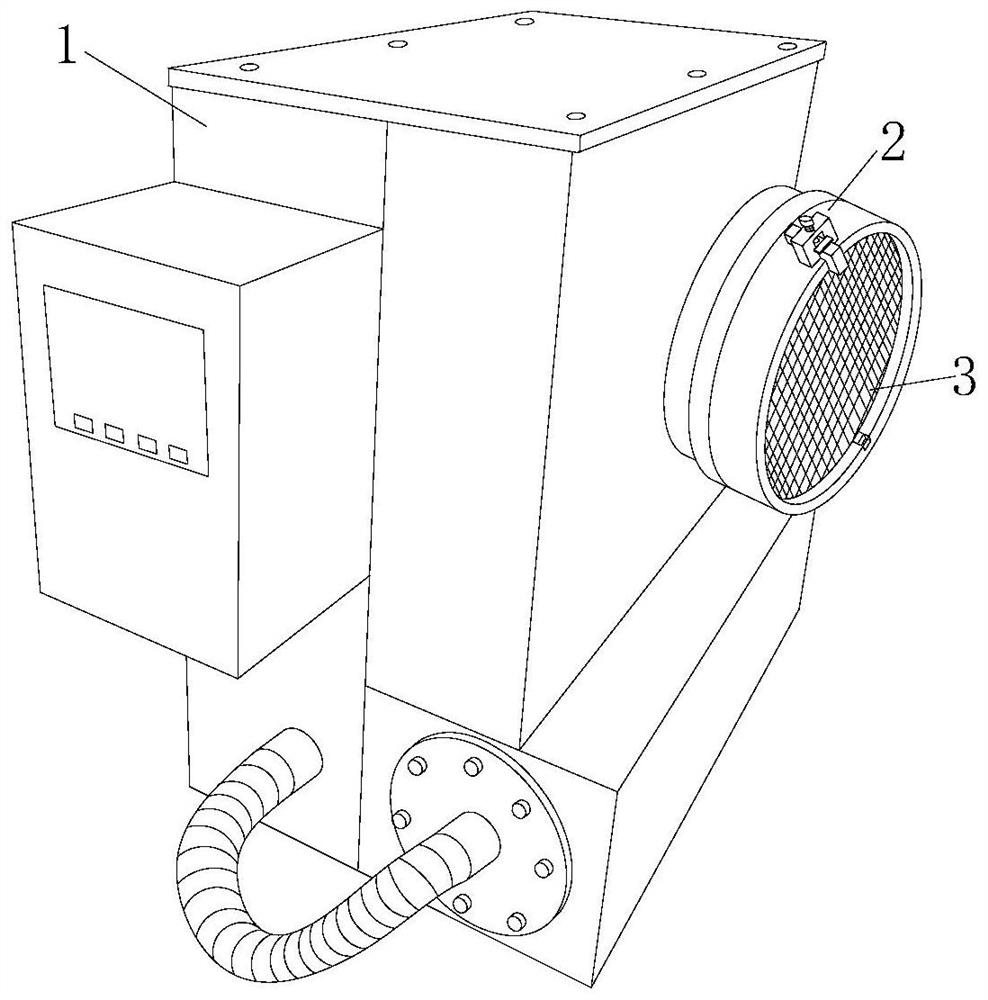

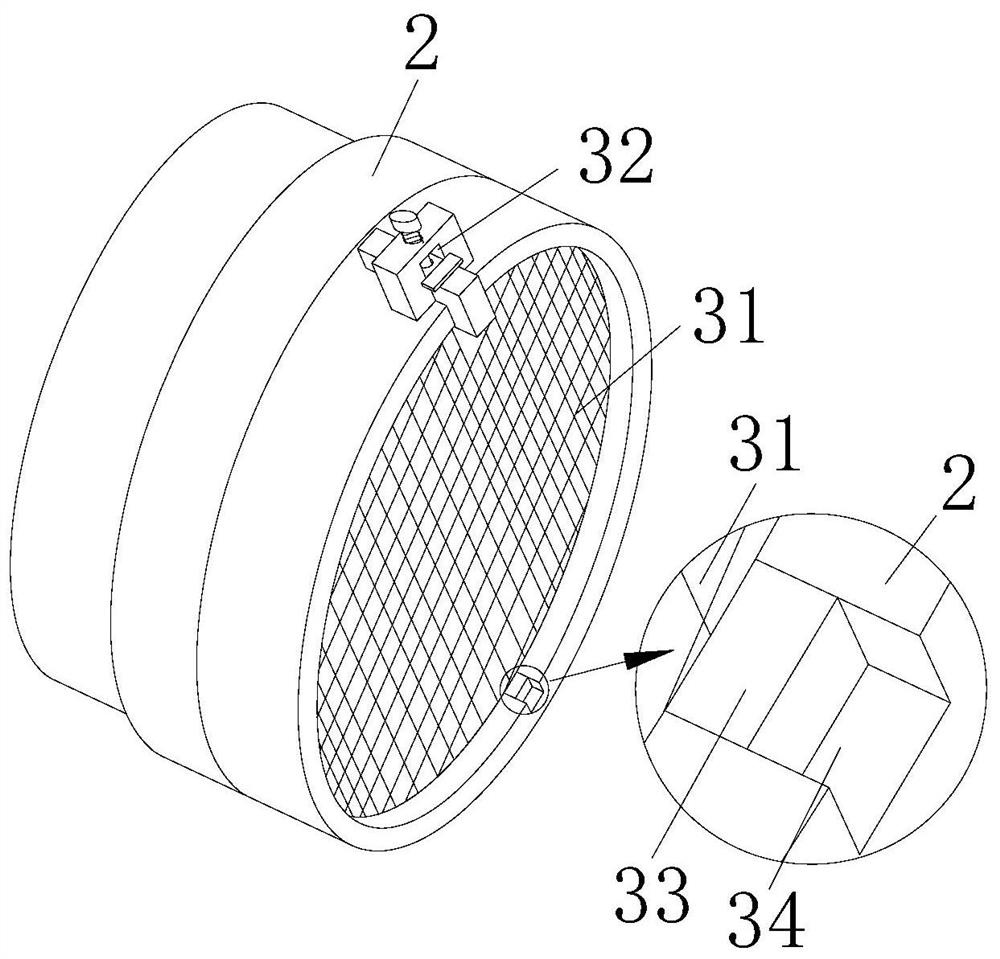

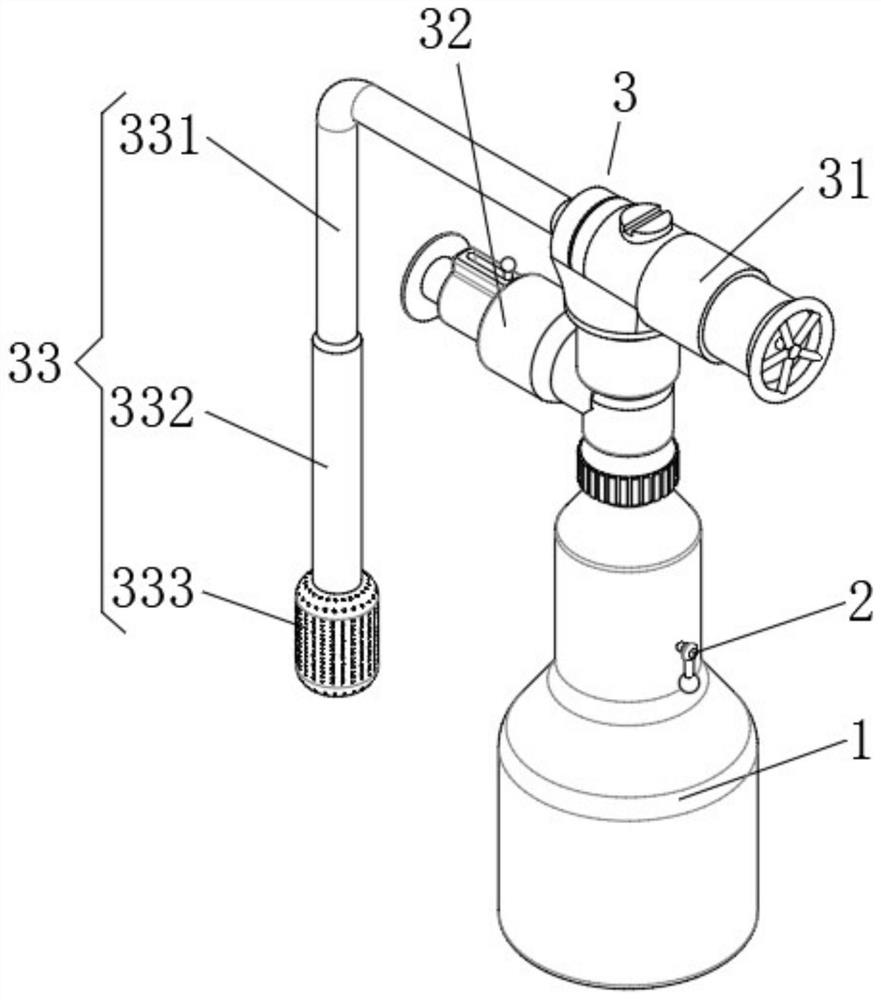

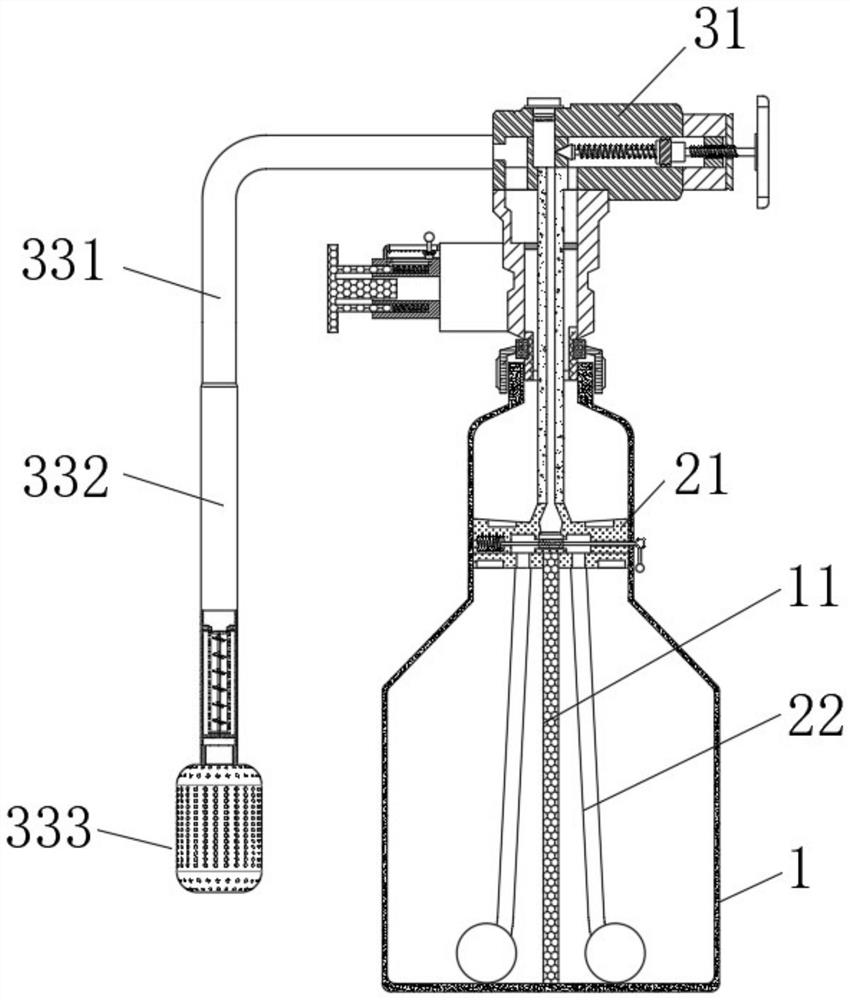

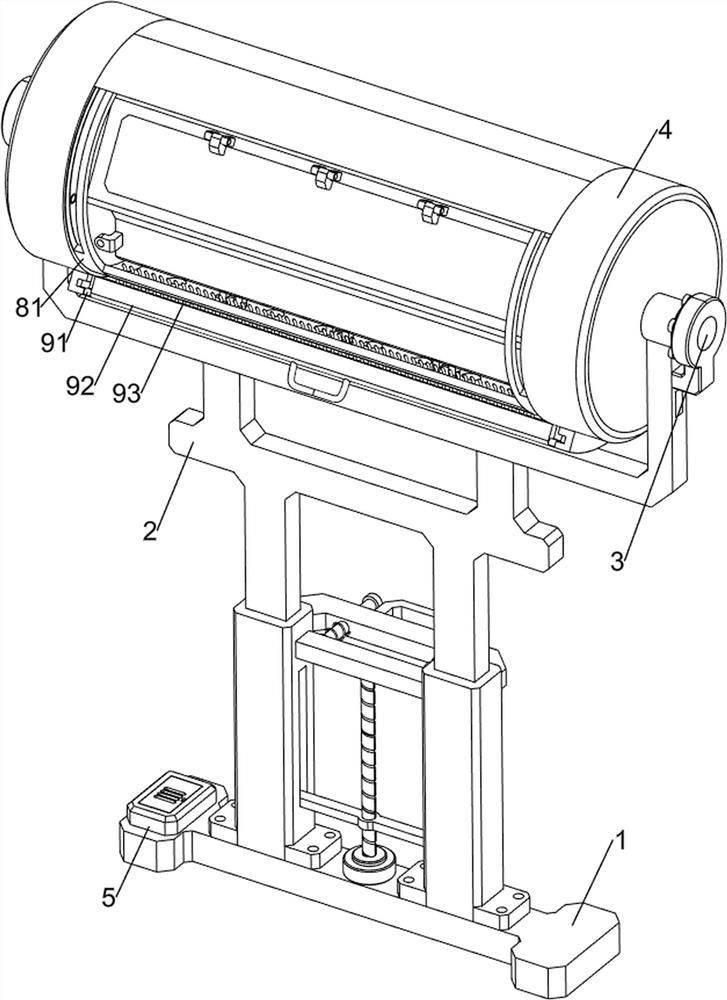

Environment-friendly plant ventilation mechanism

ActiveCN112303782AImprove cleanlinessAvoid pollutionDispersed particle filtrationLighting and heating apparatusVentilation tubeFresh air

The invention relates to an environment-friendly plant ventilation mechanism. The environment-friendly plant ventilation mechanism comprises a filter screen body and a locking and fixing mechanism, wherein the filter screen body is detachably arranged in a ventilation pipe, the locking and fixing mechanism is used for locking the ventilation pipe and the filter screen body, and a main knocking mechanism is arranged on one side, facing the interior of the ventilation pipe, of the filter screen body. According to the environment-friendly plant ventilation mechanism, a filtering mechanism is arranged on a ventilation pipe mechanism in an existing fresh air system, the design of the filtering mechanism is used for achieving the effect of filtering air, so that in the actual working process, solid particles in the discharged air can be filtered, and as a result, the discharged air is prevented from polluting the environment; and meanwhile, the solid particles in the ambient air can enter abuilding, so that the cleanliness of the air in the building is guaranteed, and as a result, the filtering mechanism is additionally arranged in the ventilation mechanism, the market requirement is better met, and the application value is higher.

Owner:中节能(湖州)科技城投资建设发展有限公司

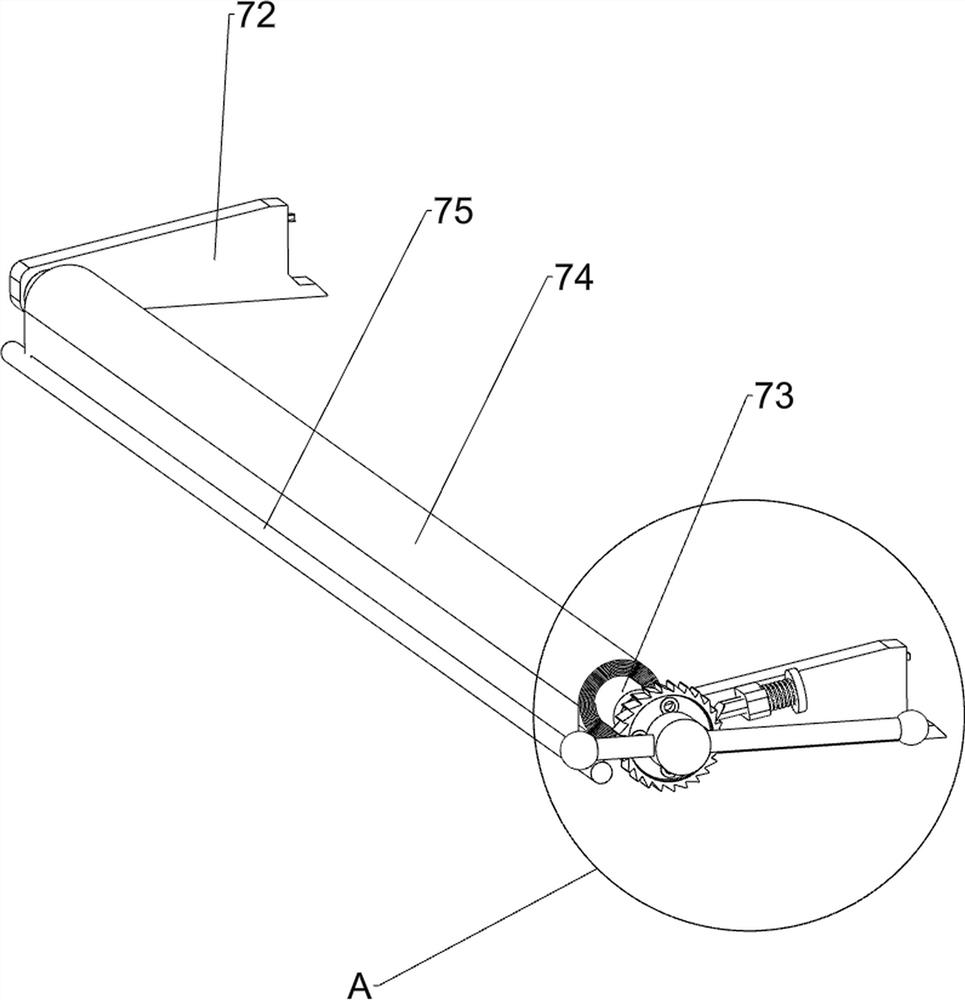

Overhead ground wire lifting device

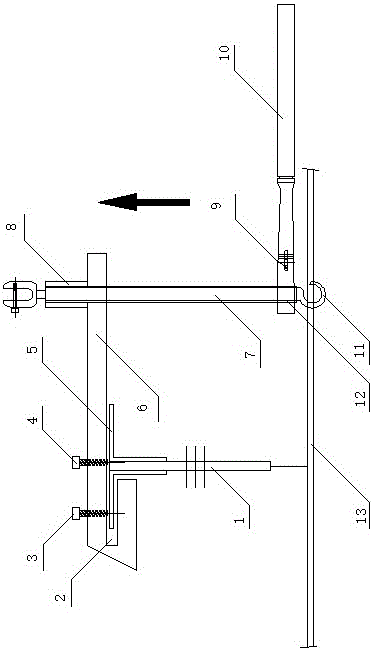

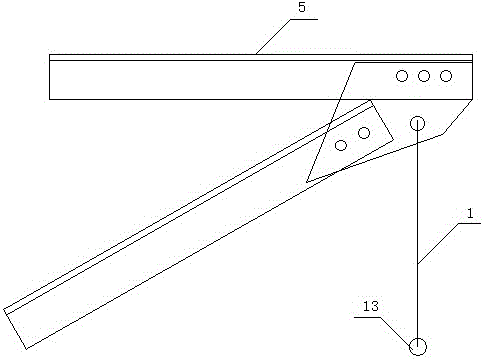

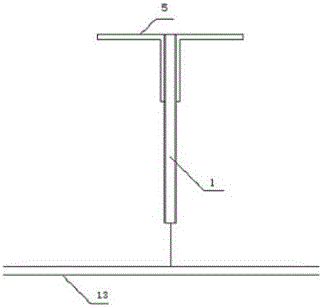

InactiveCN106129902AReduce weightReach checkLifting devicesApparatus for overhead lines/cablesTowerScrew thread

The invention belongs to the field of electric power device maintenance and specifically relates to an overhead ground wire lifting device. A ground wire cross-arm clamping tool groove is clamped on one side of a ground wire cross-arm, a ground wire cross-arm fixed clamping tool is fixed on the ground wire cross-arm via a first clamping tool fixing screw bolt and a second clamping tool fixing screw bolt, and a ground wire hook is welded and fixed on a lower end head of a lifting lead screw; a part, positioned above the ground wire hook, of a lower end of the lifting lead screw is connected with one end of a handle via a ratchet mechanism arranged on a left end part of handle; an upper end of the lifting lead screw is connected with a lifting lead screw nut in a threaded manner after running through a lead screw fixing hole positioned on a side, opposite to the ground wire cross-arm clamping tool groove, of the ground wire cross-arm fixed clamping tool; the lifting lead screw nut is welded and fixed above the lead screw fixing hole. The fixed clamping tool made of novel material is employed in the overhead ground wire lifting device, the fixed clamping tool is fixed on iron tower ground wire cross-arm tower material, the lead screw fixed on the clamping tool is used for lifting or dropping an overhead ground wire, and an aim of checking, repairing or changing the ground wire can be attained. Operation time is shortened, and overhaul efficiency is improved.

Owner:HAIDONG POWER SUPPLY COMPANY STATE GRID QINGHAI ELECTRIC POWER +1

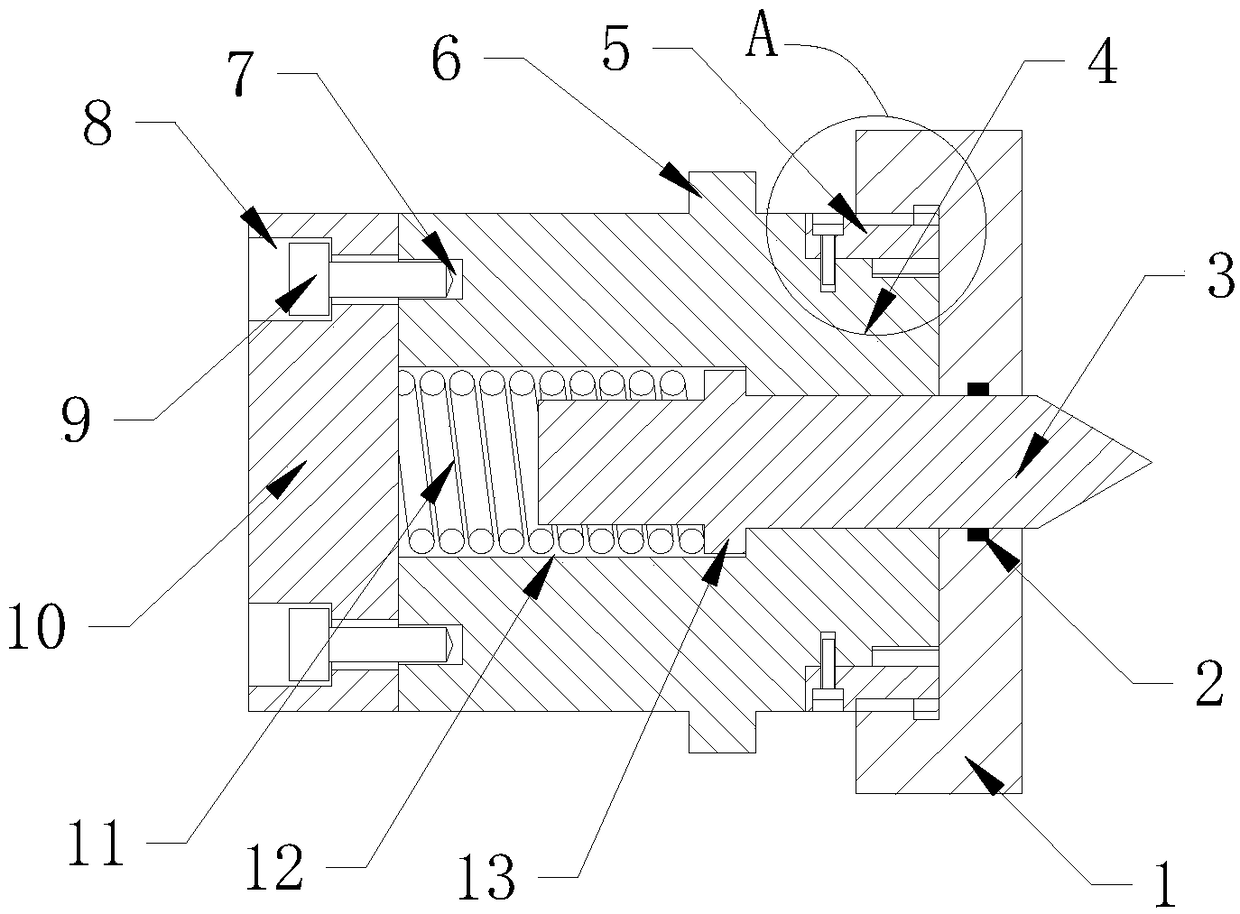

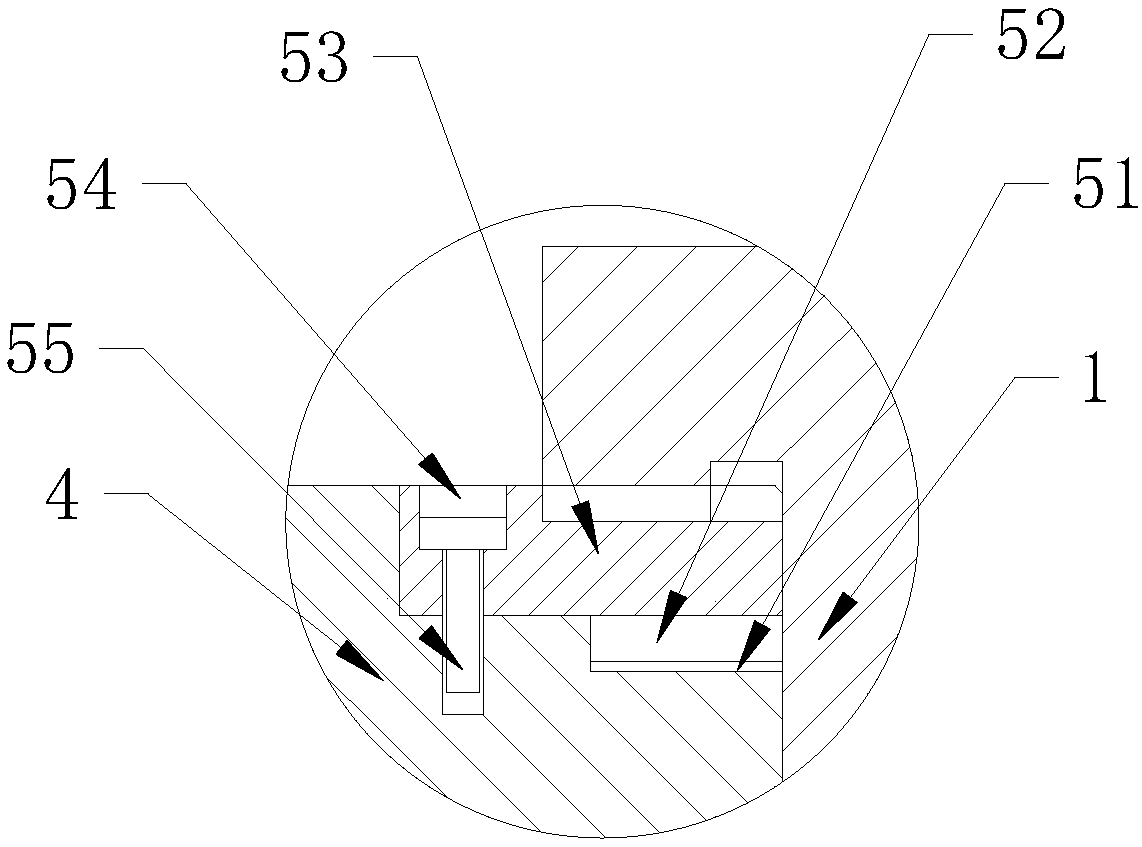

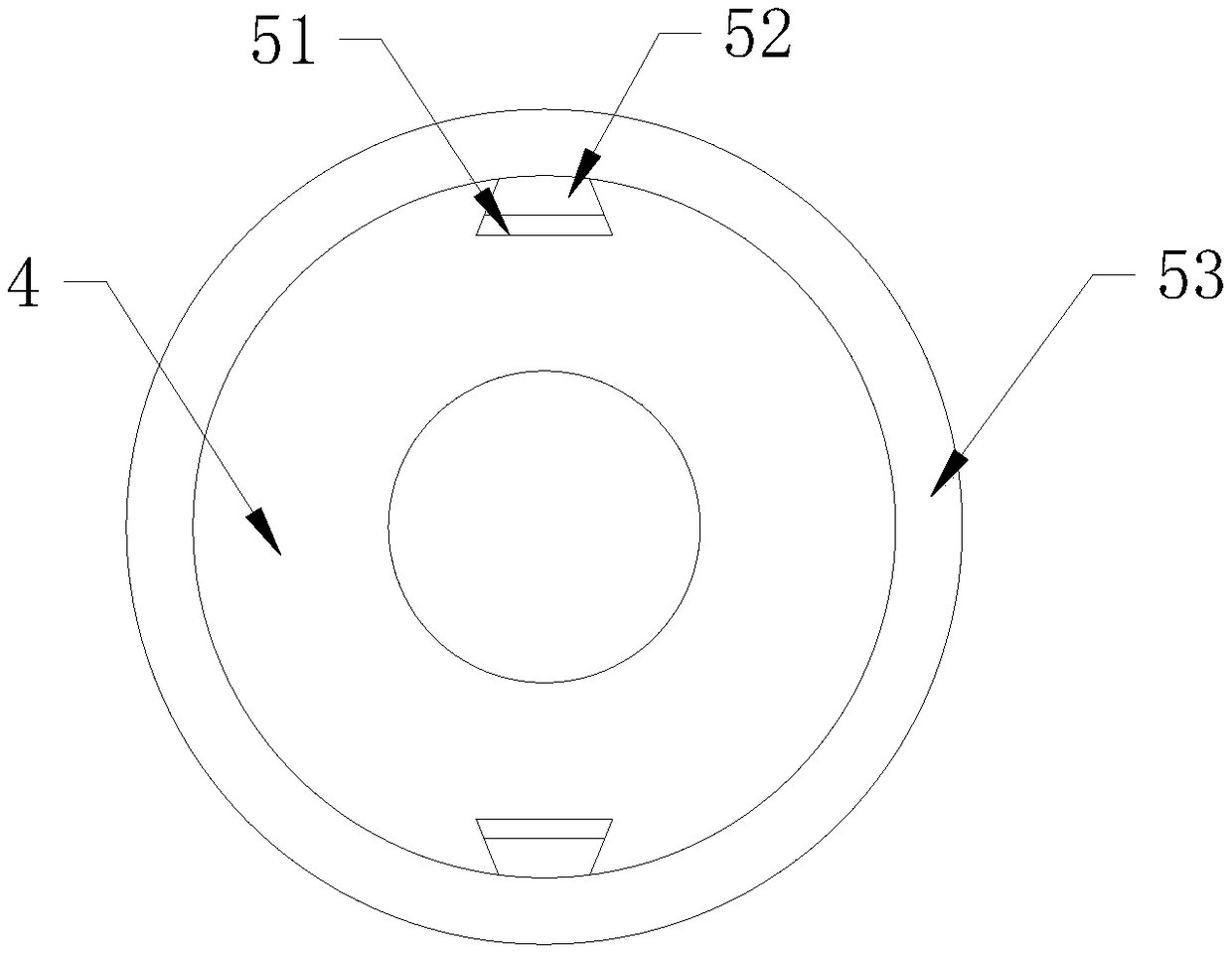

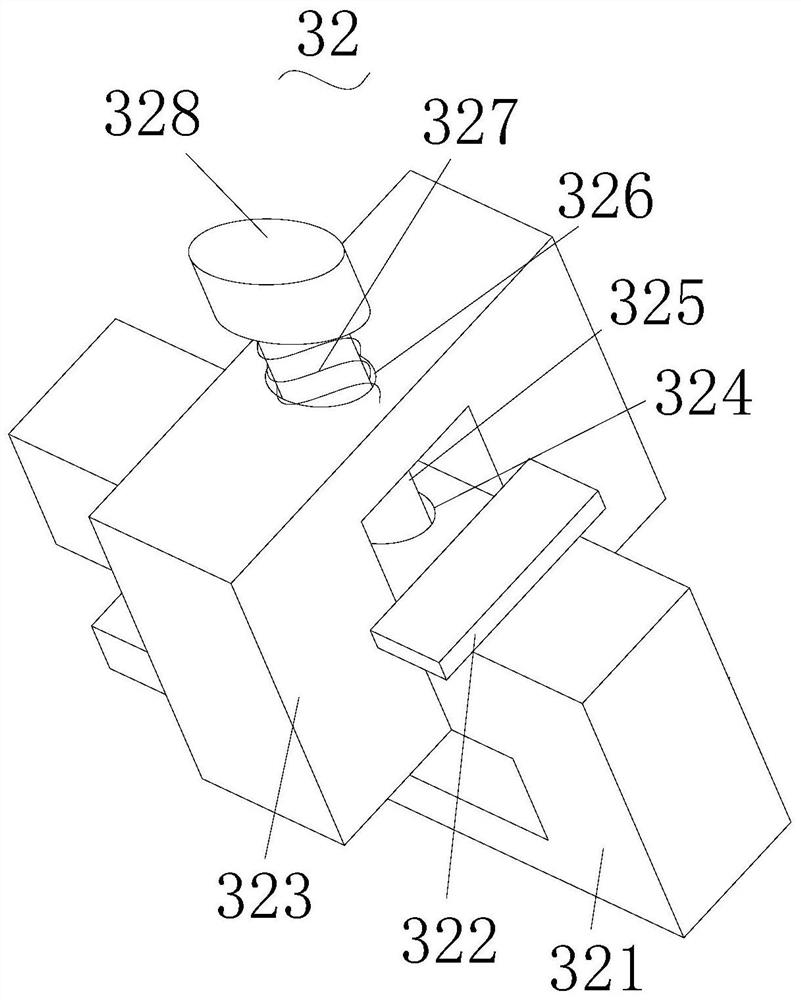

Positioning clamp for outer cover of taper clutch

InactiveCN105382691AMeet positioning clampingReach replacementGrinding work supportsPlane surface grinding machinesClutch

The invention discloses a positioning clamp for an outer cover of a taper clutch and relates to a clamp. The positioning clamp for the outer cover of the taper clutch comprises a fixing part, a clamping part and a driving part. The fixing part is in an L shape. The clamping part and the driving part are arranged on the two sides of the fixing part respectively. The driving part comprises a fixing sleeve, a driving rod and a handle. The fixing sleeve is fixed to the left side of a clamping installation block and is provided with an inner thread. An outer thread is arranged at one end of the driving rod, and a frustum with the taper of 45 degrees is arranged at the other end of the driving rod. The outer thread of the driving rod is matched with the inner thread of the fixing part. The clamping part comprises clamping blocks and a clamping block positioning seat. The three clamping blocks are in a long bar square block shape. The two ends of each clamping block are semicircular, and wedge faces with the inclination of 45 degrees are arranged at the two ends of each clamping block. The clamping blocks are installed on the clamping block positioning seat in a sliding manner so that the clamp can conduct positioning and clamping from the inner circumference of the outer cover of the clutch, and the outer circumference of the outer cover of the taper clutch is ground at a time.

Owner:CHONGQING SHUAICHANG MACHINE MFG

Gynecological sickbed convenient for replacing bed sheet

ActiveCN112006856AReach replacementComfortable replacementNursing bedsMedical transportSurgeryBiomedical engineering

The invention relates to a sickbed, in particular to a gynecological sickbed convenient for replacing a bed sheet. The technical problem to be solved by the invention is how to design the gynecological sickbed convenient for replacing a bed sheet, wherein a patient does not need to get out of the bed when replacing the bed sheet. In order to solve the technical problem, the invention provides thegynecological sickbed convenient for replacing the bed sheet. The sickbed comprises: a bed frame, wherein a bed board is arranged at the top of the bed frame; two special-shaped guide rails, wherein the special-shaped guide rails are connected to the two sides of the bottom of the bed frame respectively; and a moving mechanism which is arranged on the bed board. Through cooperation of the moving mechanism, a supporting assembly and a lifting mechanism, the effect of replacing the bed sheet is achieved.

Owner:JILIN UNIV

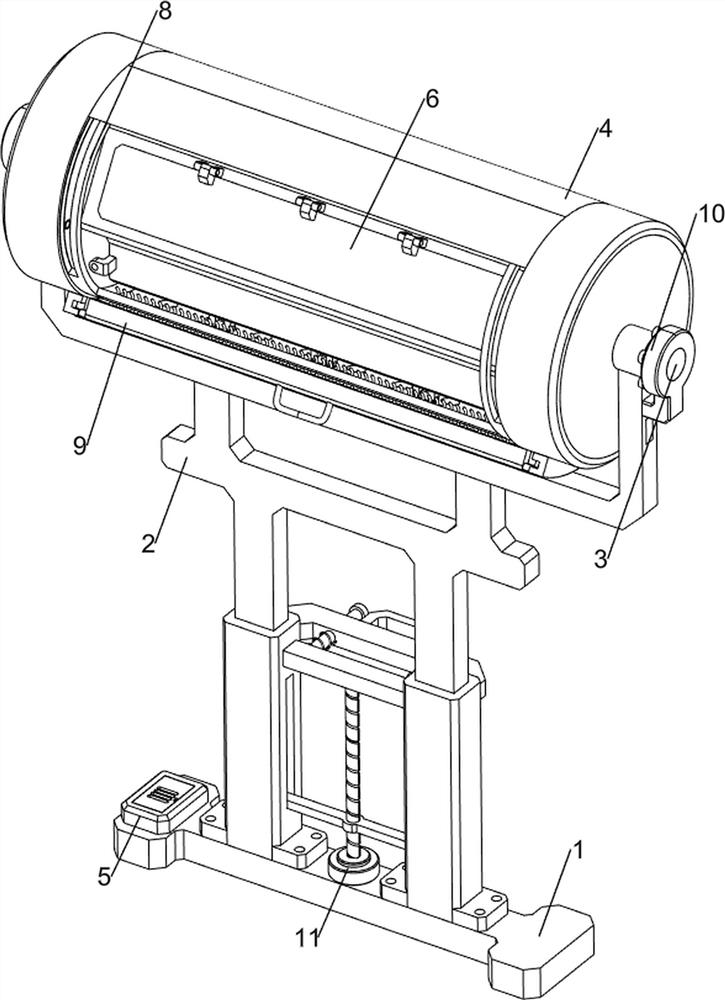

Powder sieve capable of working continuously

InactiveCN107081262ATo achieve the effect of continuous feedingReach replacementSievingScreeningEngineeringMechanical engineering

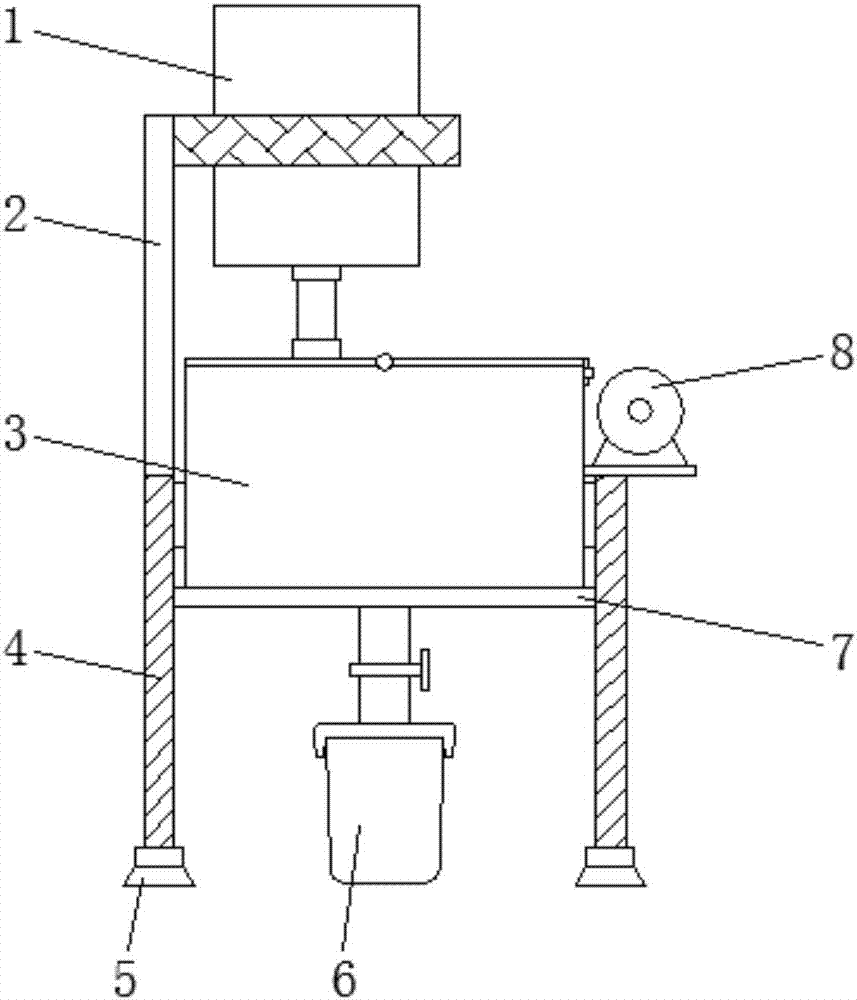

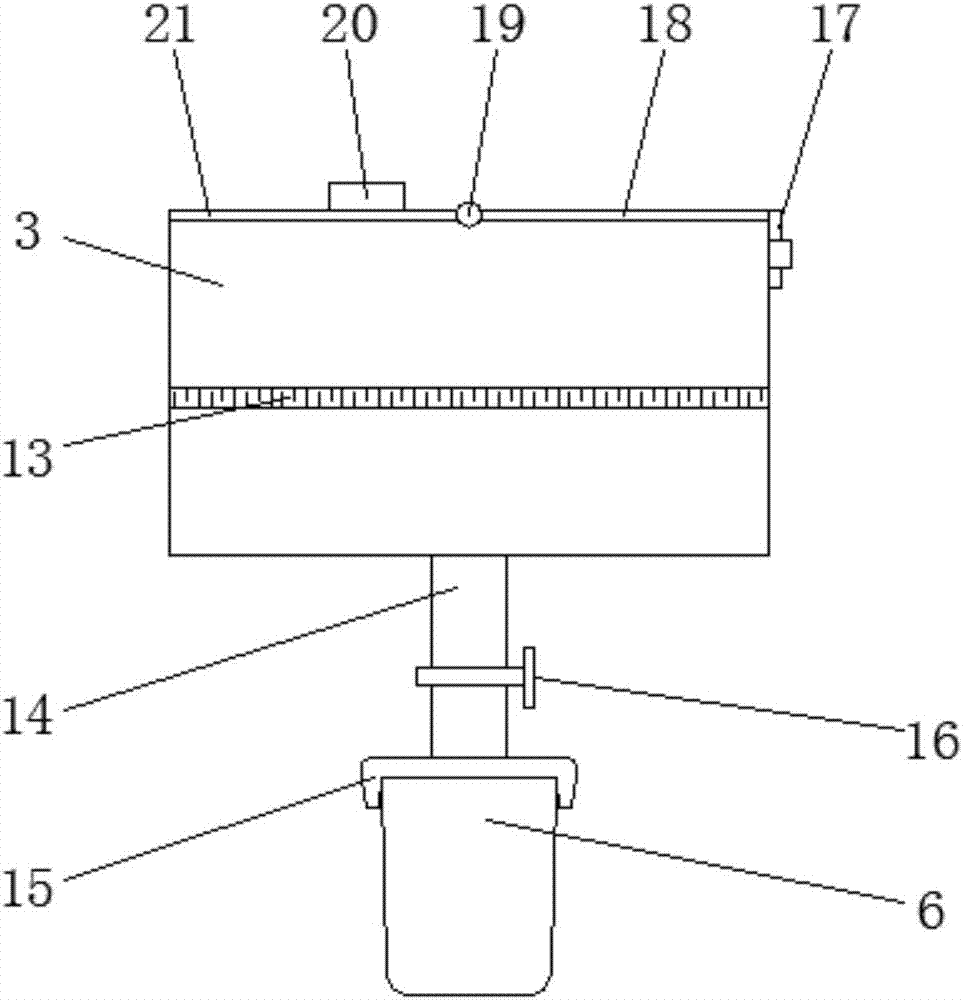

The invention discloses a powder sieve capable of working continuously. The powder sieve comprises a raw material box, a first supporting frame, a powder sieving machine, two second supporting frames, a finished product barrel, a sealing barrel cover and a movable sealing door, wherein the top of one side of one second supporting frame is connected with the raw material box through the first supporting frame; the raw material box consists of a fixed sleeve ring, a material discharging valve, a material conveying pipe and a box door; the raw material box is connected with one end of the top of the first supporting frame through the fixed sleeve ring at the middle part; the box door is fixedly mounted at the top of the raw material box; the bottom of the raw material box is connected with the top of the material conveying pipe through the material discharging valve; the two second supporting frames are connected with each other through an annular fixing frame; the powder sieving machine is fixedly mounted at the top of the annular fixing frame; and the powder sieving machine consists of a sieving net, the movable sealing door, a rotating shaft, a material inlet and a fixed sealing door. By the arrangement of the raw material box at the top of the powder sieving machine, the powder sieve achieves an effect of continuously supplying materials to the powder sieving machine.

Owner:YANCHENG DONGFANG TIANCHENG MACHINERY

Grinding device for removing burrs of hardware parts

PendingCN114227431AAchieve separationSolve the blockageEdge grinding machinesGrinding wheel securing apparatusWater storage tankProcess engineering

The invention discloses a grinding device for removing burrs of hardware parts, and relates to the technical field of hardware part machining, in particular to the grinding device for removing the burrs of the hardware parts, the grinding device comprises a grinding device body, and a rotating disc is arranged on the left side of the interior of the grinding device body. According to the grinding device for removing the burrs of the hardware parts, through cooperation of the grinding device body, the water storage tank, the filter plate and the water spraying pipe, the filter plate is used for filtering water, the separation effect of water and impurities is achieved, the water purification effect is achieved, the problem that all connecting water pipes are blocked is effectively solved, the mode that the filter plate is used for removing the impurities of the water is adopted, and the practicability is high. And the situation that impurities fall into all the connecting water pipes along with flowing of water, and consequently all the connecting water pipes are blocked is avoided, the dredging effect of workers on all the connecting water pipes is saved, the workload of the workers is reduced, and it is guaranteed that the continuous water outlet dust falling procedure of deburring machining of hardware parts is conducted stably.

Owner:安徽尧工数控科技有限公司

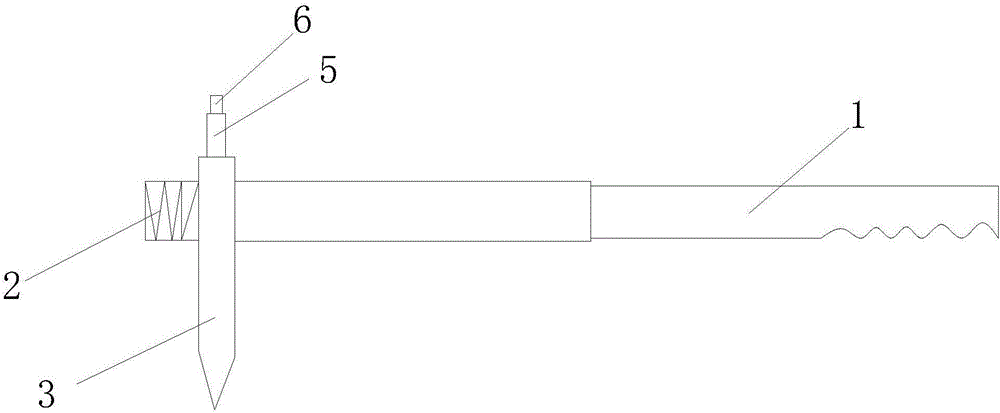

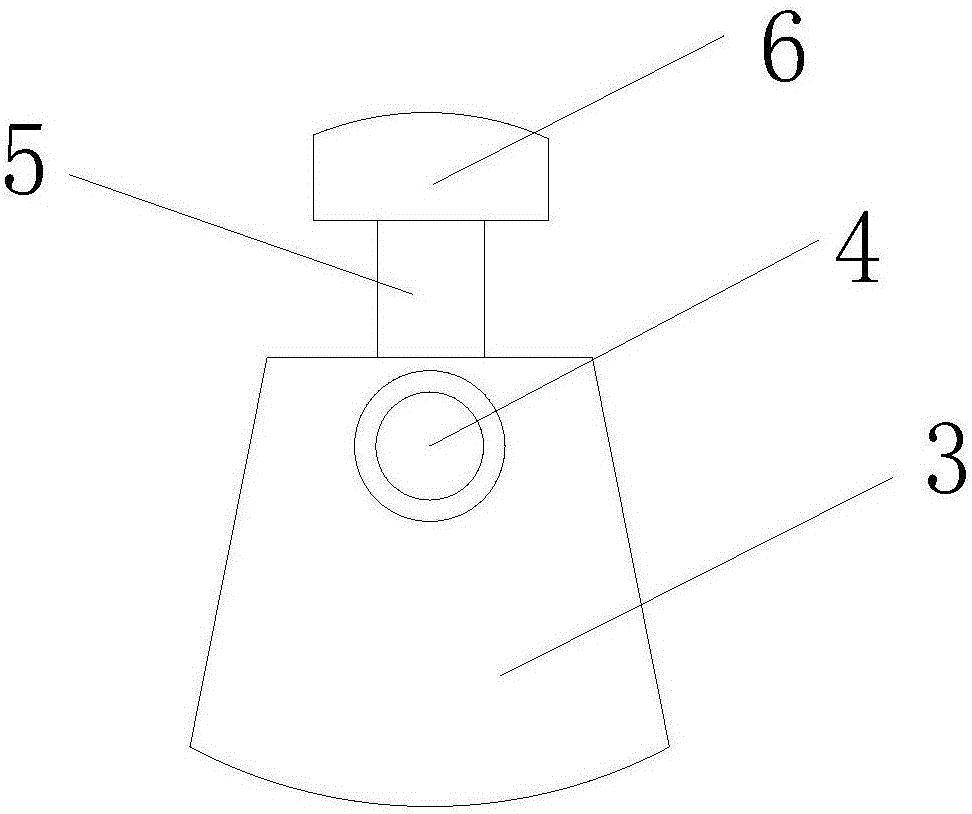

Detachable hoe

The invention discloses a detachable hoe which comprises a hoe handle, wherein a thread groove is formed in the surface of one end of the hoe handle, the hoe handle is in threaded connection with a hoe blade through the thread groove, the hoe blade is provided with a through hole which is internally provided with a thread adaptive to the thread groove, a bracket is welded at the top of the hoe blade, and a small hoe blade is welded at the top end of the bracket. According to the detachable hoe, through the arrangement of the thread groove and the through hole, the detachable effect of the hoe handle and the hoe blade can be achieved, so that the hoe is relatively easy to carry, the hoe blade and the hoe handle can be changed easily, and the use is relatively convenient; due to the arrangement of an anti-sliding grove, the anti-sliding effect is achieved, so that a user feels comfortable when the hoe is used, and the use effect of the hoe is good; and due to the arrangement of the small hoe blade, the more convenient use effect of the hoe can be achieved, so that the hoeing range of the hoe is relatively accurate and the hoe can be used more conveniently.

Owner:钟贵洪

Medical nursing pad facilitating calculation of bleeding amount

PendingCN114681209AReach replacementAchieve fixityCatheterDiagnostic recording/measuringMedical staffBlood flow

The invention belongs to the field of medical nursing pads, and particularly relates to a medical nursing pad convenient for calculating bleeding amount, which comprises a protection pad main body, protection wings adhered to two sides of the protection pad main body, a replacement pad arranged at the top of the protection pad main body, a built-in cavity formed in the top of the protection pad main body, and secondary magic tapes connected to two sides of the top of the protection pad main body, the secondary hook-and-loop fasteners are located in the built-in cavity, the two sides of the bottom of the replacement pad are fixedly connected with the primary hook-and-loop fasteners, through the arrangement of the device, the replacement pad can be replaced and fixed, large-amplitude actions made by a puerpera are reduced, the risk that the wound of the puerpera is cracked is reduced, and the puerpera is prevented from being damaged. Therefore, the bleeding amount can be judged according to the positions of the arc-shaped marking line and the scale line through which blood flows, the bleeding amount of a patient is accurately and intuitively displayed, and medical staff can conveniently and quickly judge the condition of the patient.

Owner:HANGZHOU RED CROSS HOSPITAL

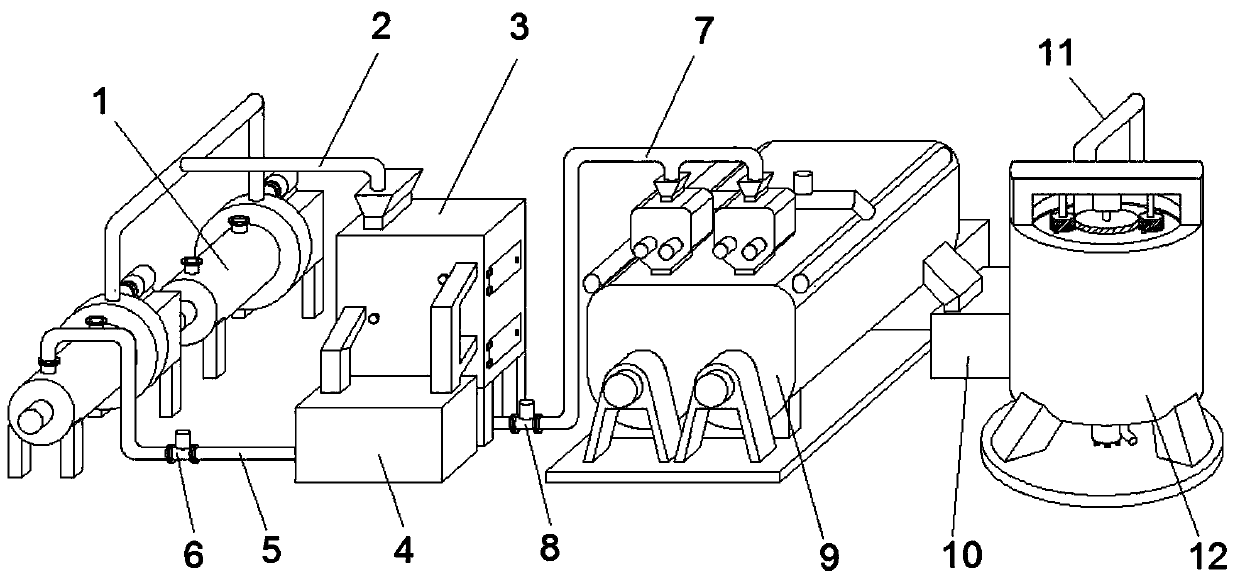

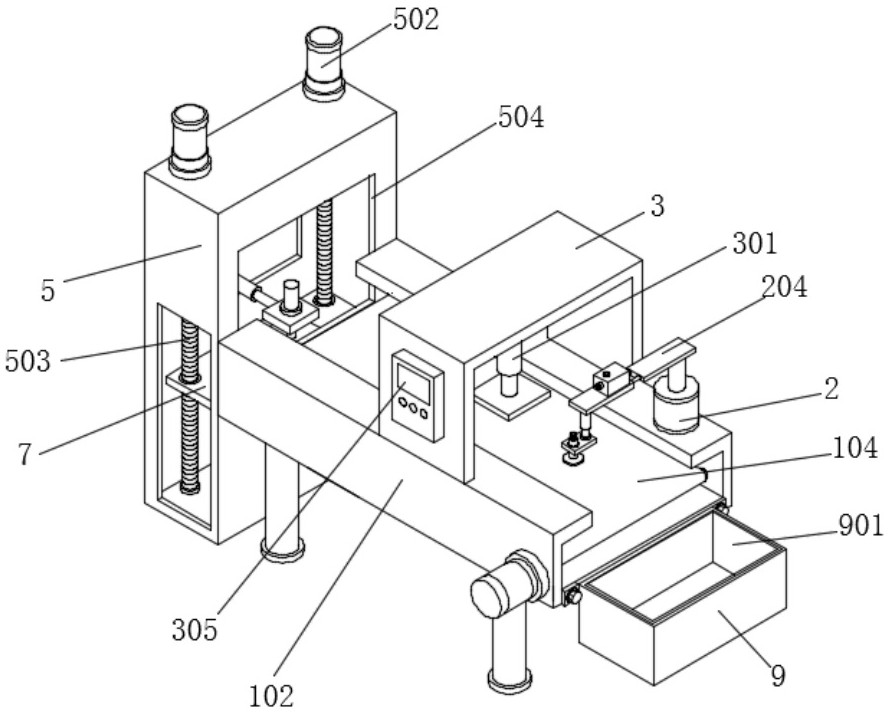

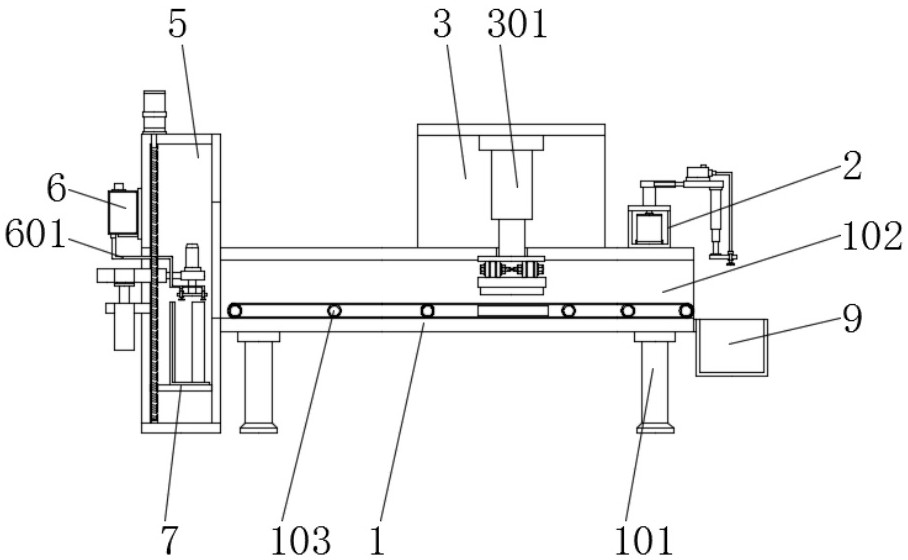

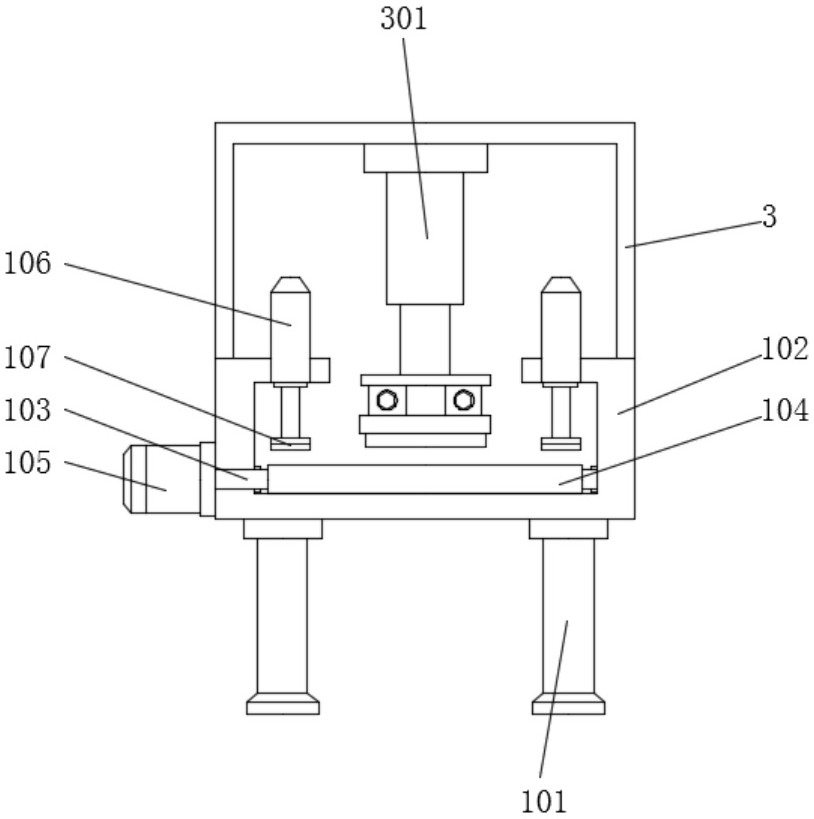

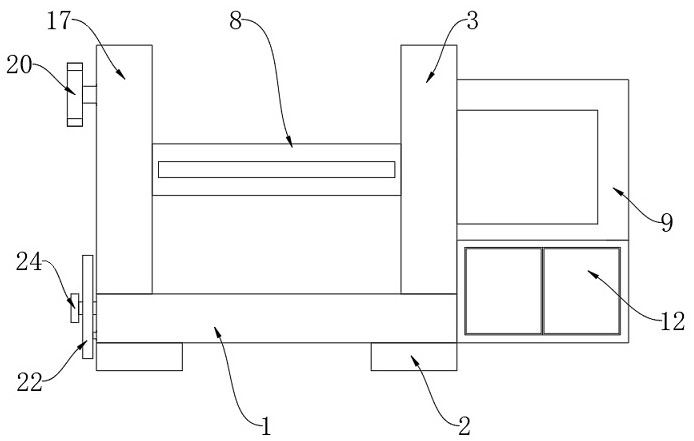

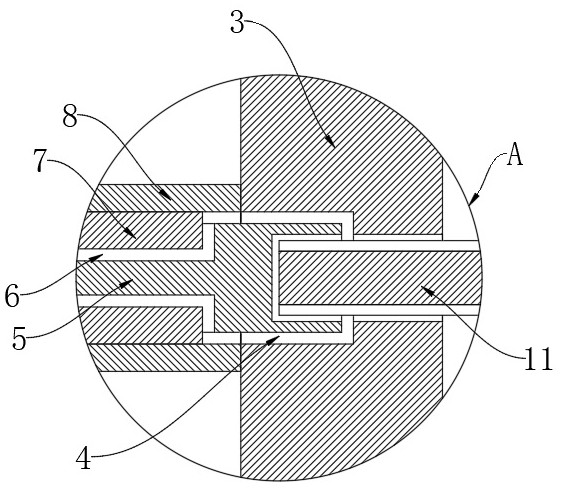

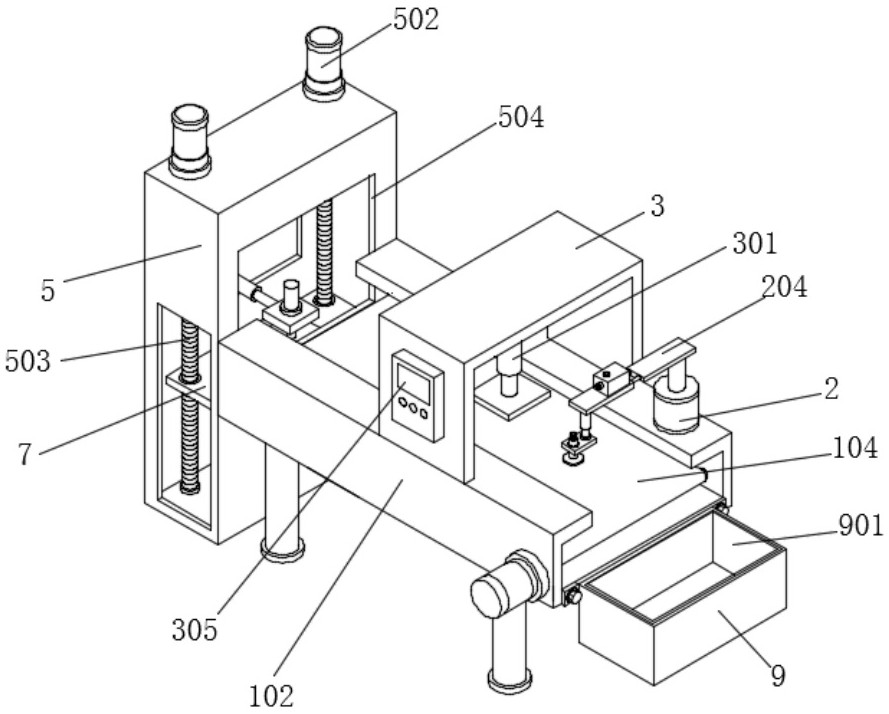

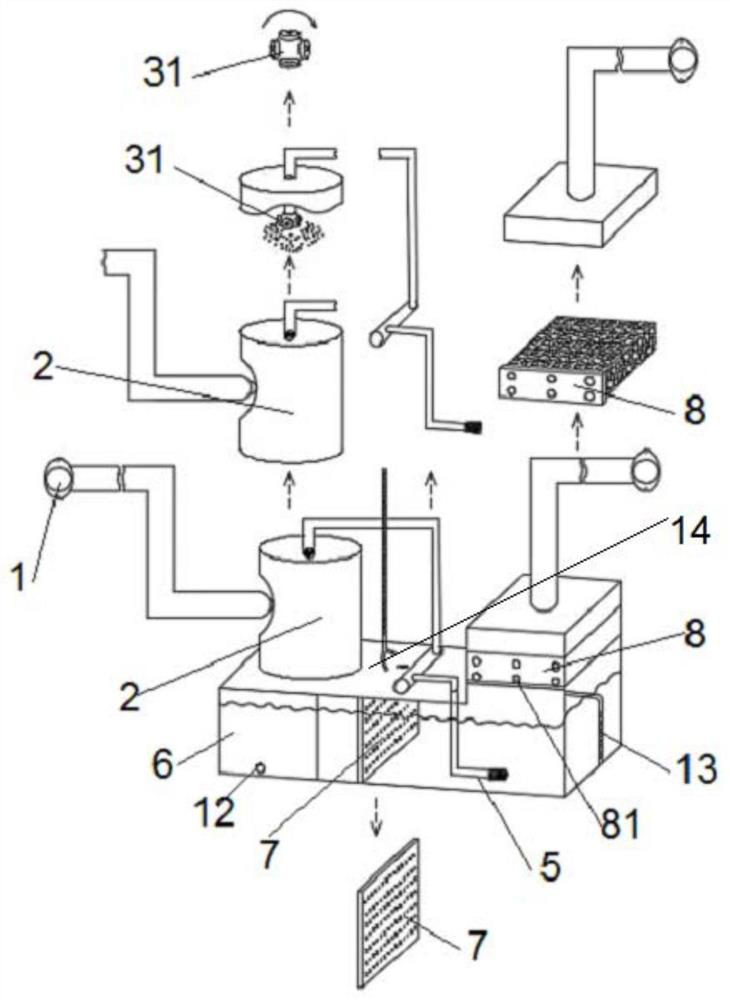

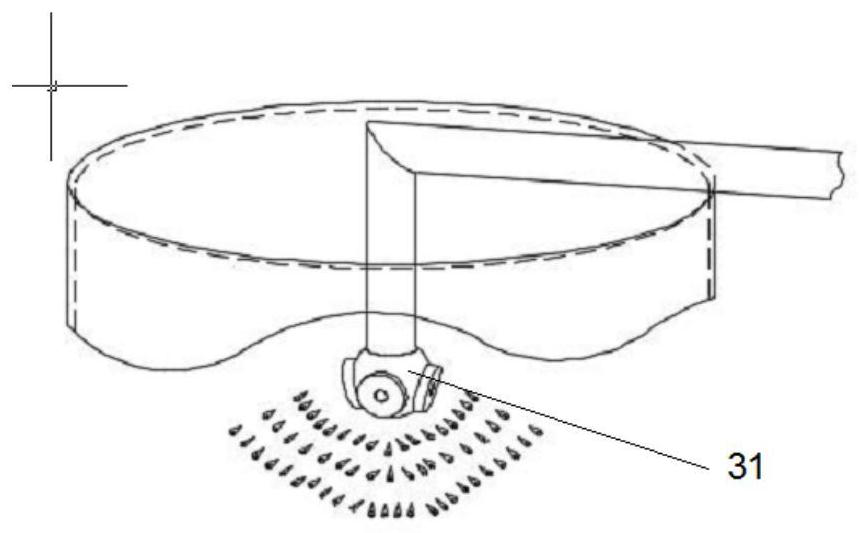

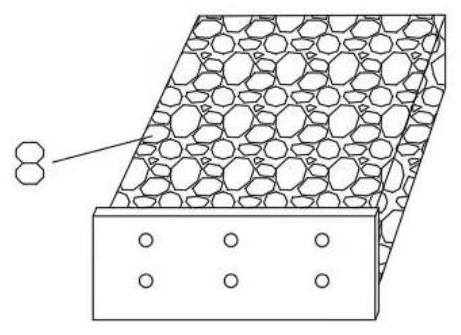

Preparation production line of environment-friendly fireproof waterborne coating

PendingCN110193407AReach replacementRegulation stabilityShaking/oscillating/vibrating mixersTransportation and packagingProduction lineSander

The invention relates to a preparation production line of an environment-friendly fireproof waterborne coating. The preparation production line comprises two sand mills, a sanding feeding pipe, a sieving machine, a sieved material collecting box, a sanded material returning pipe, a sanded material returning pump, a sieving feeding pipe, a sieving feeding pump, a kneading machine, a kneaded material collecting box, a kneaded material feeding pipe and a mixing device. The sieving machine is arranged on one side of the sand mills and is connected to the two sand mills through the sanding feedingpipe; the sieved material collecting box is connected to one sand mill through the sanded material returning pipe; the sanded material returning pump is arranged on the sanded material returning pipe;the kneading machine is connected to the kneading machine through the sieving feeding pump; the sieving feeding pump is arranged on the sieving feeding pipe; the top of the kneaded material collecting box is connected to a kneading discharge port; and the mixing device is connected to the kneading machine through the kneaded material feeding box. By structurally designing equipment, part of assemblies of the equipment can be detached and cleaned, so that the production efficiency of the whole production line is high. The produced waterborne coating is good in performance.

Owner:丹阳市现代实业有限公司

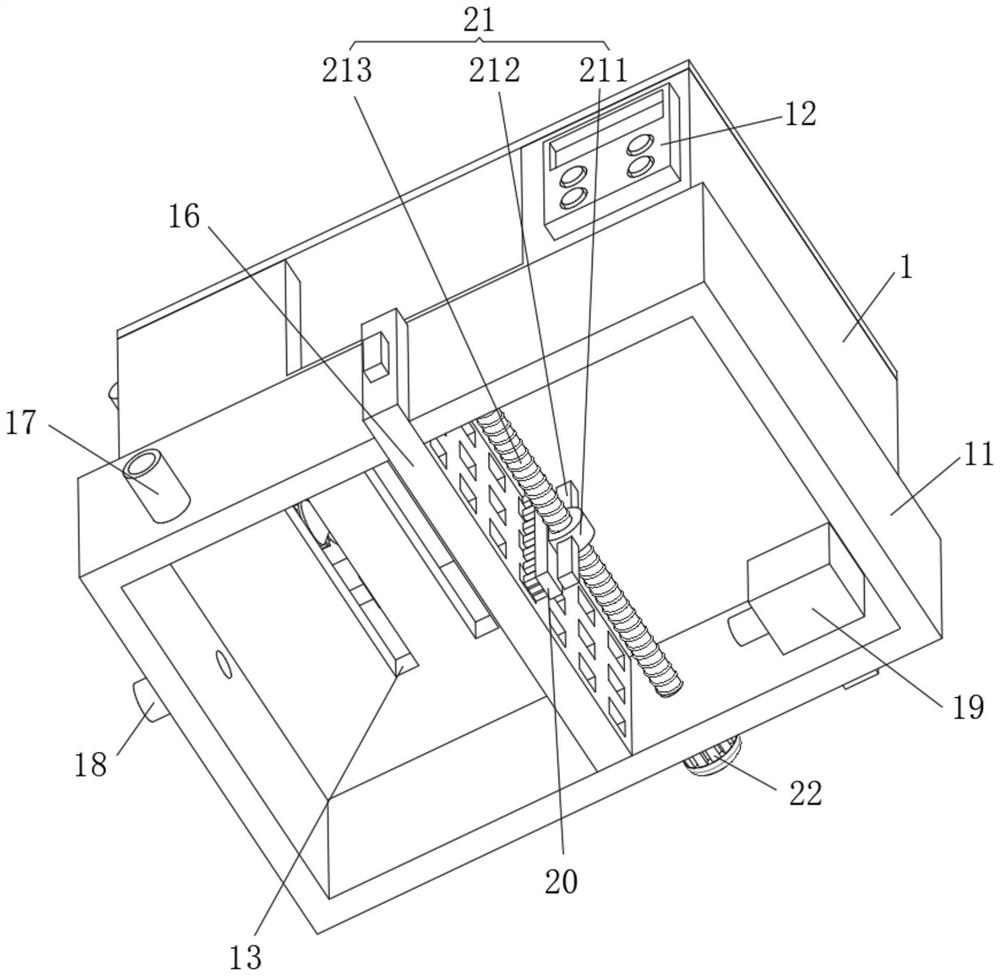

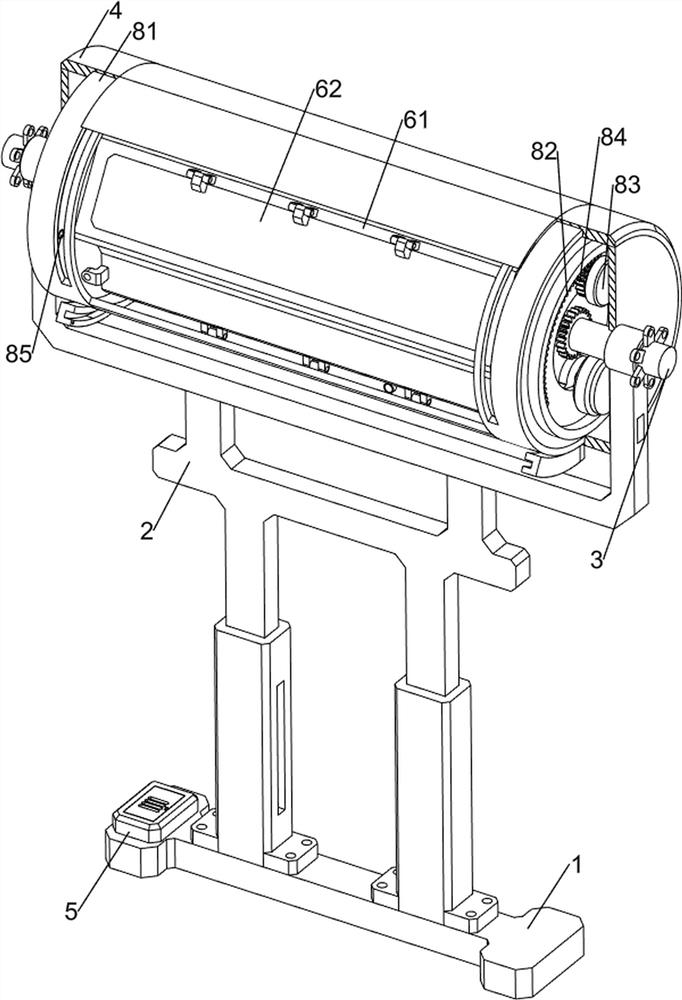

Automatic winding copper wire fixing device for mass production hollow part electroplating

InactiveCN112609229AAchieve the purpose of windingReach replacementElectrolysis componentsCopper wireGear wheel

The invention relates to the related field of industrial electroplating, and discloses an automatic winding copper wire fixing device for mass production hollow part electroplating. The automatic winding copper wire fixing device comprises a main box body, an upper fixing cavity penetrating front and back is formed in the main box body, the upper side of the upper fixing cavity communicates with two or more reciprocating fixing block cavities which are symmetrically arranged left and right with the fixing cavity as the center. Reciprocating rack cavities are formed in the upper sides of the reciprocating fixing block cavities in a communicating mode, reciprocating gear cavities located in the upper sides of the reciprocating fixing block cavities are formed in the inner sides of the reciprocating rack cavities in a communicating mode, and the purpose of winding the two ends of a fixing rod is achieved by controlling a copper wire to pass through an upper spiral guide groove and a fixed extending cavity. Under the driving of an extending guide cavity and a contact guide belt, the copper wire penetrates through a workpiece belt wheel cavity and a workpiece through hole in the workpiece belt wheel cavity to connect the workpiece with the fixed rod, and finally, a grooved wheel shaft is driven to rotate through the meshing of a grooved wheel shifting block and a four-grooved wheel, so that the wound workpiece and the fixed rod are replaced, and the purpose of reciprocating winding is achieved.

Owner:郑州强贵电子科技有限公司

Electronic chip punching tool with clamping structure

ActiveCN114012918AEasy loadingEasy to moveSemiconductor/solid-state device manufacturingWorking accessoriesRotary stageElectric machinery

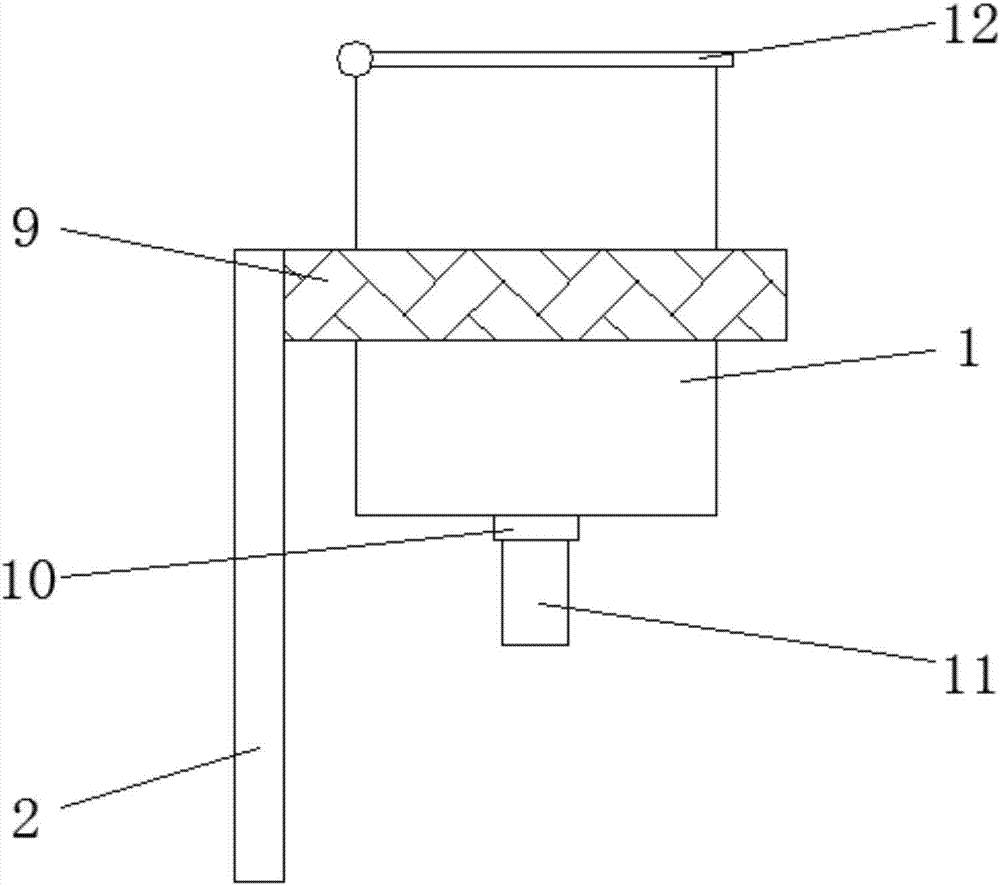

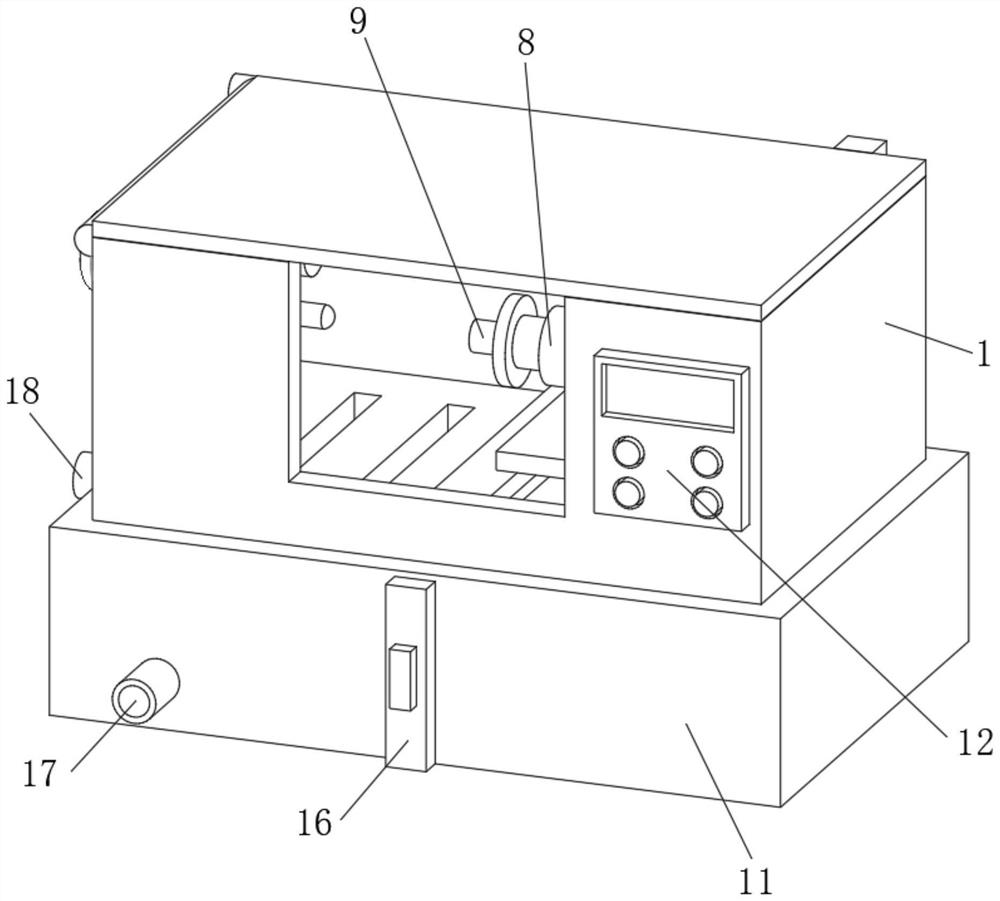

An electronic chip punching tool with a clamping structure is disclosed in the invention, and comprises a supporting plate, two supporting frames are symmetrically installed at the top of the supporting plate, a fixing box is installed at the tops of the supporting frames, a driving motor is installed in the fixing box, a rotating table is installed at the output end of the driving motor through a connecting rod, a fixing frame is installed on the top of the supporting frame, a waste collecting box is installed on one side of the supporting frame through bolts, and a damping pad is installed on the inner side of the waste collecting box. A feeding frame is installed on the other side of the supporting plate. A threaded rod is installed, in the feeding process, a servo motor operates to drive the threaded rod to rotate, the threaded rod rotates to drive an internal thread lantern ring on the outer side to ascend through threads, and the internal thread lantern ring ascends to drive a lifting table to ascend, so that the height of the tool is adjusted, it is guaranteed that chips on the uppermost layer of the tool are kept at the proper height all the time, and feeding of the tool is facilitated.

Owner:NANTONG MINICHIP MICRO ELECTRONICS

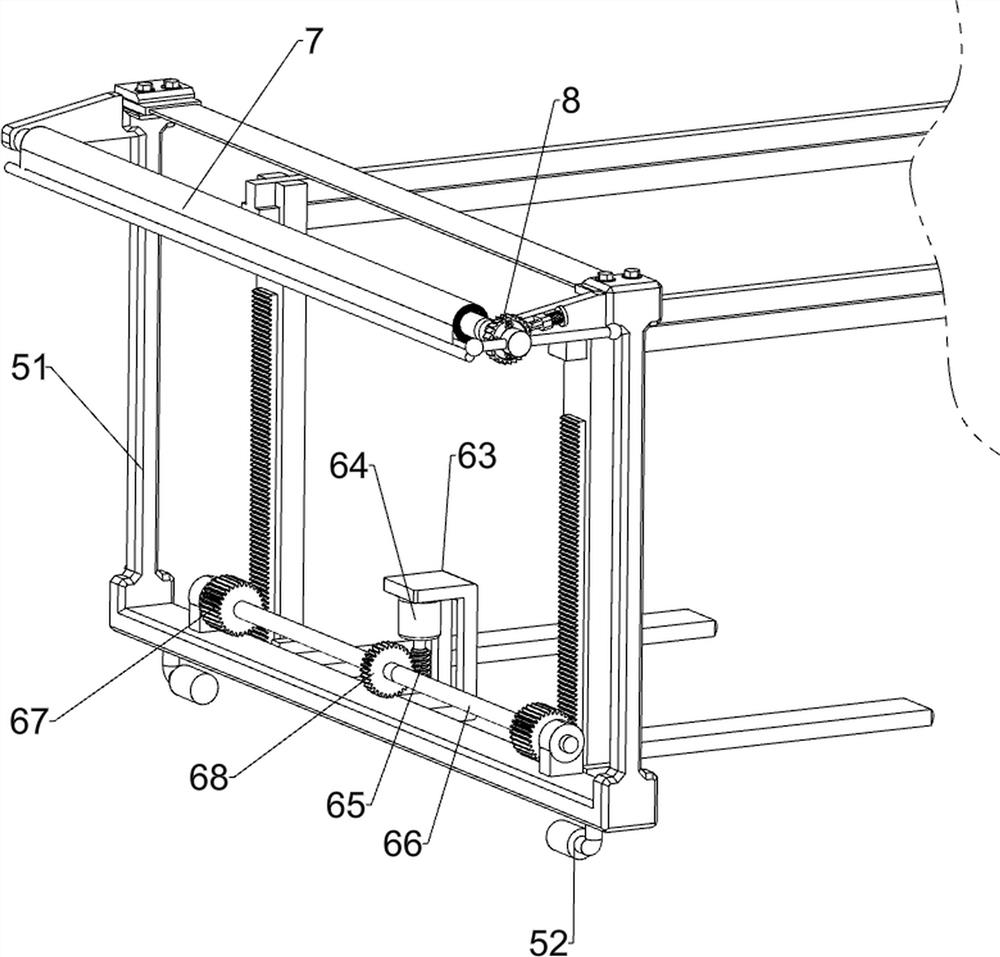

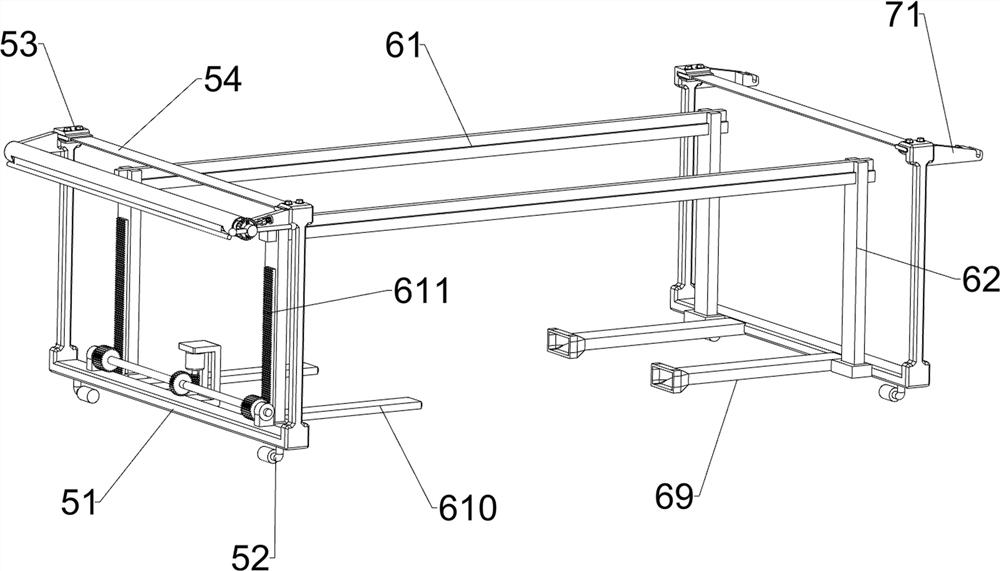

A gynecological hospital bed that is convenient for changing sheets

ActiveCN112006856BReach replacementComfortable replacementNursing bedsMedical transportEngineeringChanging bed linen

The invention relates to a sick bed, in particular to a gynecological sick bed which is convenient for changing sheets. The technical problem to be solved by the present invention is how to design a gynecological bed that does not require the patient to get out of bed when changing the bed sheet. In order to solve the above-mentioned technical problems, the present invention provides such a gynecological bed that is convenient for changing sheets, including: a bed frame, the top of which is connected with a bed board; Both sides of the bottom; the moving mechanism is arranged on the bed board. The present invention achieves the effect of changing the bed sheets through the cooperation of the moving mechanism, the support assembly and the lifting mechanism.

Owner:JILIN UNIV

Winding mechanism for stainless steel strip machining equipment

The invention discloses a winding mechanism for stainless steel strip machining equipment. The winding mechanism comprises a supporting bottom plate, wherein a supporting block is fixedly connected tothe bottom of the supporting bottom plate, a fixing plate is fixedly connected to one side of the upper surface of the supporting bottom plate, a circular groove is formed in one side of the fixing plate, a positioning circular rod is rotationally connected to the inner wall of the circular groove, a sliding groove is formed in the surface of the positioning circular rod, and a positioning clamping plate is slidably connected to the inner wall of the sliding groove. According to the winding mechanism for the stainless steel strip machining equipment, through the arrangement of the positioningcircular rod, the positioning clamping plate and a limiting sleeve, the limiting sleeve conveniently sleeves the positioning circular rod through the positioning clamping plate; through the arrangement of a driving motor and a transmission rod, the driving motor is conveniently inserted and fixed to one end of the positioning circular rod through the transmission rod; through the arrangement of astorage box, temporary objects can be conveniently stored; and through the arrangement of a limiting plate and a positioning block, the limiting plate can conveniently support the storage box and a motor box, and therefore the effect that the stainless steel strip machining equipment is convenient to wind is achieved.

Owner:齐晓红

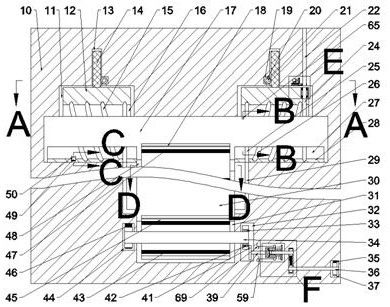

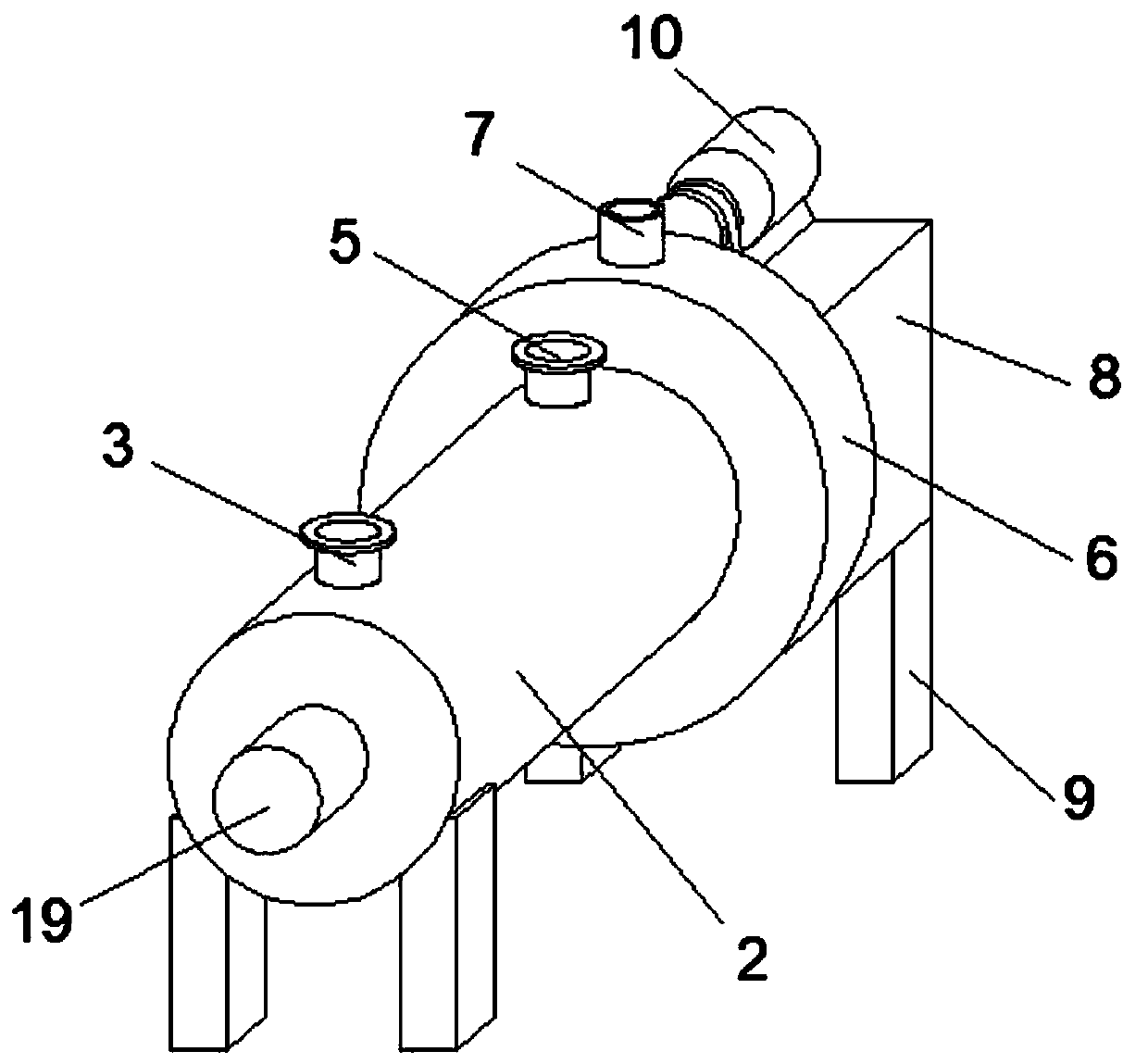

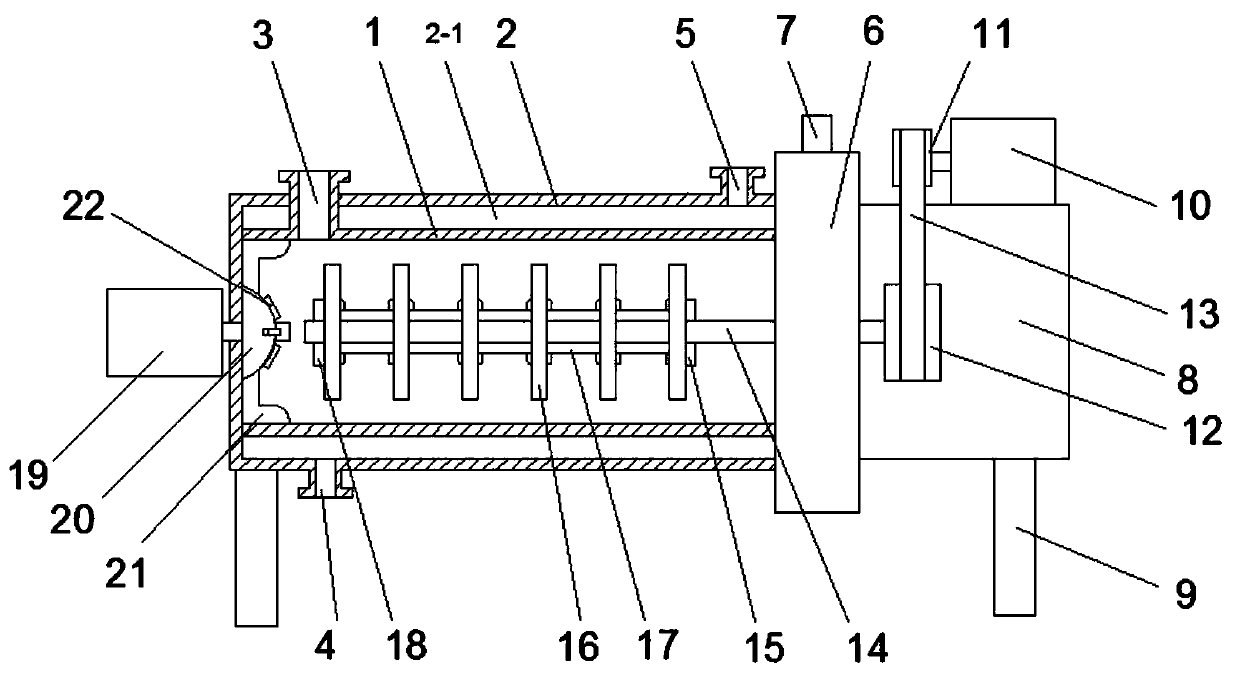

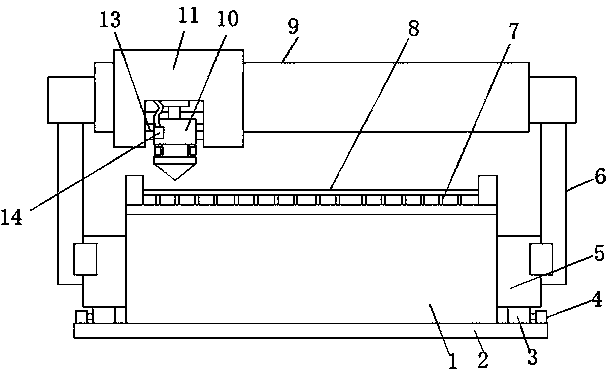

Sand grinding tool of ultrathin fireproofing water-based paint

The invention discloses a sand grinding tool of ultrathin fireproofing water-based paint. The sand grinding tool of the ultrathin fireproofing water-based paint comprises a sand grinding inner cylinder, a sand grinding outer cylinder, a sand grinding feeding port, a cooling water inlet pipe, a cooling water outlet pipe, an outlet cylinder, a sand grinding discharge port, a sand grinding shell, sand grinding machine bottom feet, a sand grinding motor, a sand grinding motor belt pulley, a sand grinding shaft belt pulley, a sand grinding belt, a sand grinding shaft, a fixed abutting disc, sand grinding discs, a connecting block, a movable abutting disc, a turbulent motor, a turbulent base, turbulent claws and turbulent convex blocks, wherein the sand grinding motor is arranged on one side ofthe top surface of the sand grinding shell, the sand grinding shaft is transversely arranged in the sand grinding inner cylinder, the sand grinding discs are fixedly connected with the sand grinding shaft, the connecting block is arranged between the two sand grinding discs, the movable abutting disc is fixedly connected with a movable shaft, and one end of the turbulent motor extends into the sand grinding inner cylinder and is fixedly connected with the turbulent base. According to the sand grinding tool, the number of the sand grinding discs can be increased and decreased, the distance between the sand grinding discs can be adjusted, meanwhile, a plurality of kinds of turbulent structures are adopted, so that raw materials are kept in a high-efficiency sand grinding state in a sand grinding cylinder, and the sand grinding efficiency, speed, and precision is high.

Owner:丹阳市现代实业有限公司

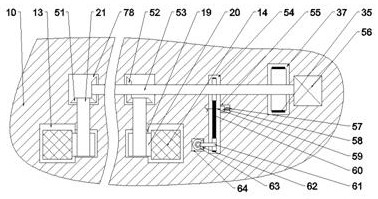

A sandblasting machine with adjustable sandblasting frequency for metal surface treatment and its operation method

The invention discloses a sandblasting machine with adjustable sandblasting frequency for metal surface treatment and an operation method thereof, which comprises a sandblasting mechanism and an adjustable nozzle mechanism. The adjustable nozzle mechanism is installed on the sandblasting mechanism and pulled out Move the three straight-through water channel connecting column blocks, rotate the three straight-through water channel connecting column blocks, align the nozzle head to be used with the connecting pipe socket through the connecting pipe, and insert the connecting pipe into the connecting pipe socket to achieve the effect of replacing the nozzle head. Three groups of different structures The nozzle head of the nozzle makes the flow of the sand liquid in the nozzle head changed, so as to achieve different ejection frequencies and ejection shapes. At the same time, it also discloses an operation method of a sandblasting machine with adjustable sandblasting frequency for metal surface treatment. Reversely screw the internal thread locking ring, unscrew it from the external thread frame ring, and screw it to the On the external threaded connector, the connection between the three straight water channel connecting columns and the inner cavity channel connecting column is disconnected, so as to achieve the effect of convenient disassembly and connection.

Owner:芜湖天锐捷精密电子设备有限公司

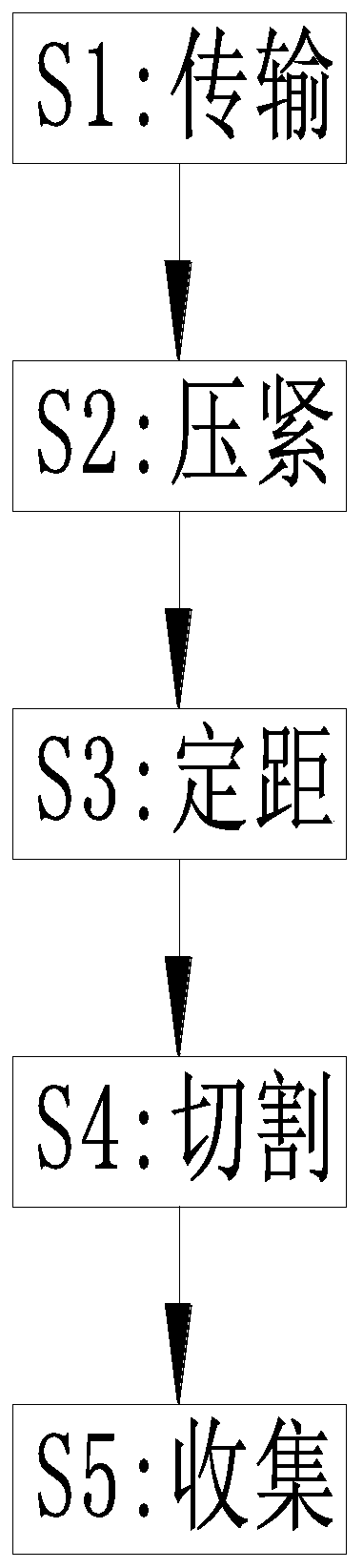

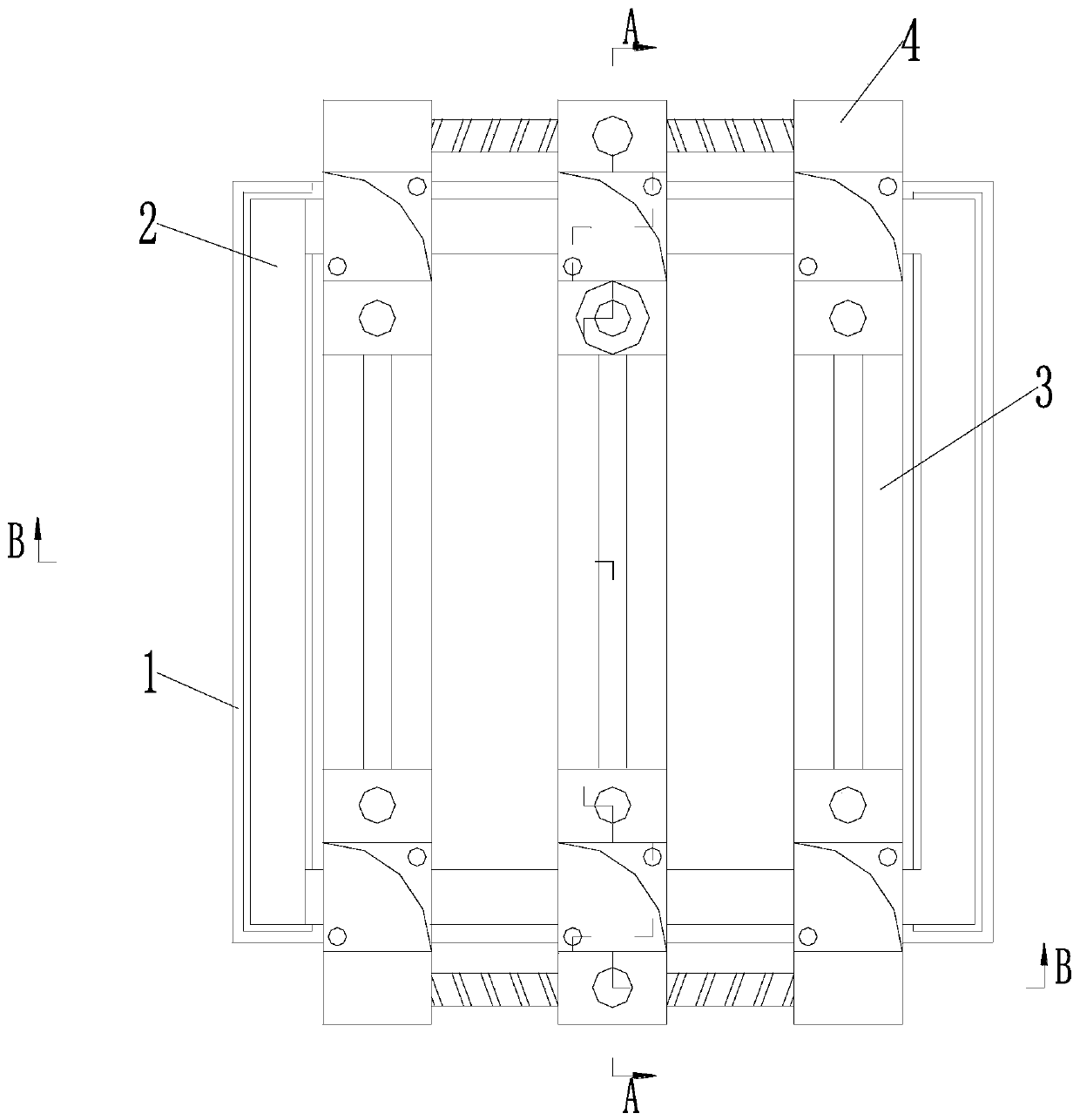

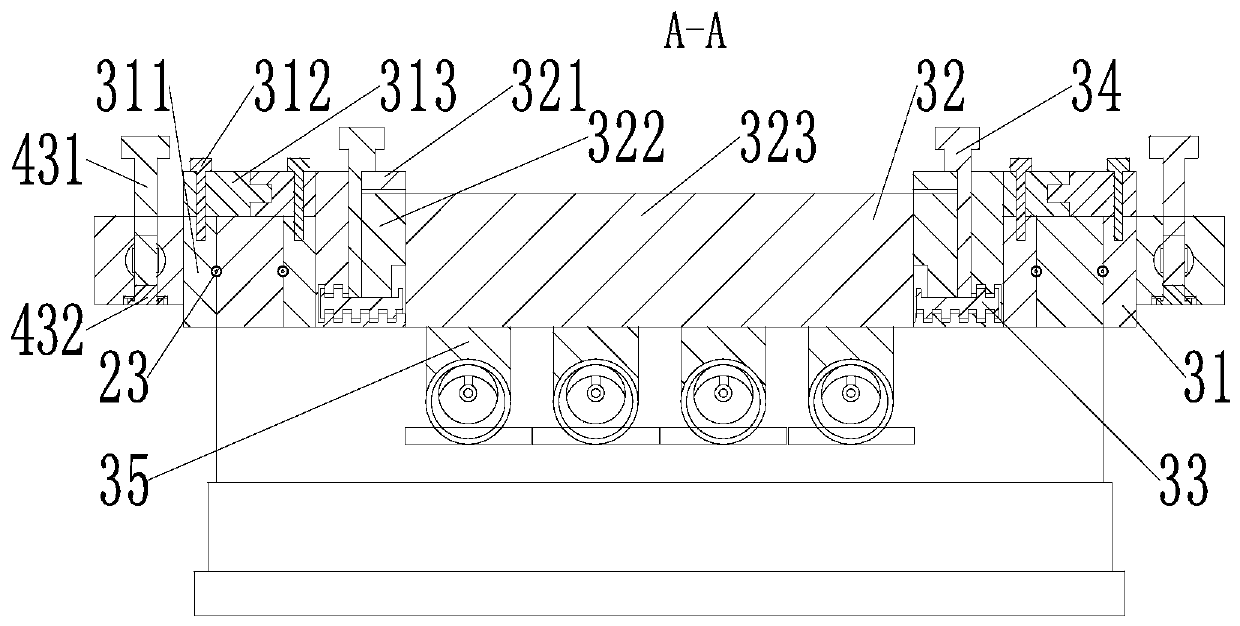

Method for manufacturing and processing light weight carbon fiber plates

ActiveCN110480736AThe error value is smallQuick and easy disassemblyMetal working apparatusFiberEngineering

The invention provides a method for manufacturing and processing light weight carbon fiber plates. The method is completed through the cooperation of an operation table, a telescopic bracket, a cutting plate mechanism and a positioning device. Through the adoption of the method disclosed by the invention, the problems that in the conventional manufacturing and processing process of the carbon fiber plates, when the cutting width of a cutting machine is adjusted, the cutting distance needs to be adjusted one by one, so that the error value is large, and the widths of the cut carbon fiber platesare large in differences can be solved; the problems that the processing dimension requirements of the carbon fiber plates are different, cutting tools need to be replaced, the thickness and the dimension of the cutting tools are not the same, and the working grooves of the cutting tools need to be replaced or adjusted, so that production time is wasted, and in the disassembling process, important parts are liable to damage can be solved; and the problems that after the carbon fiber plates are cut, according to purposes and requirements, deburring treatment is also performed on the cut carbonfiber plates, so that the production working procedures are increased, and in the process that the carbon fiber plates are transferred to deburring treatment equipment, positioning also needs to be performed one again can be solved.

Owner:上海丽派节能科技有限公司

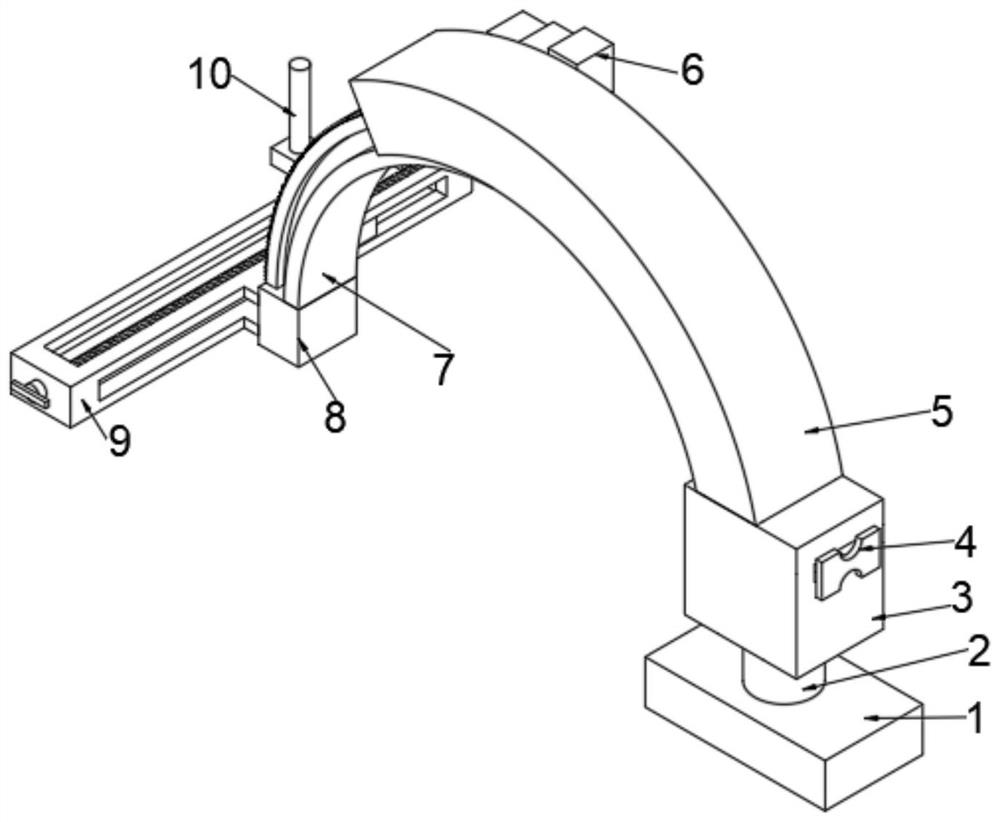

Driving arm suitable for medical surgical robot

PendingCN113952039AEasy to operateTo achieve the purpose of stretchingSurgical manipulatorsSurgical robotsPhysical medicine and rehabilitationRobot hand

The invention relates to the technical field of medical robots, and discloses a driving arm suitable for a medical surgical robot. The driving arm comprises a mounting seat, wherein a first connecting column is fixedly mounted at the top end of the mounting seat; a limiting ring block is arranged at the top end of the first connecting column; a first connecting seat is movably mounted on the outer side of the limiting ring block at the top end of the first connecting column; a first mounting cavity and a second connecting hole are formed in the first connecting seat; and a first limiting plate is fixedly mounted on the inner wall of the first mounting cavity. By use of the driving arm, a first rotating shaft can be driven to rotate when a motor on one side of the first mechanical arm rotates, a gear can be driven to rotate when the first rotating shaft rotates, the gear and a tooth block are connected in a meshed mode, so that when the gear rotates, a second mechanical arm can be driven to move in the first mechanical arm through the tooth block, and extend, therefore, the purpose that the driving arm of the medical robot can be extended is achieved, and a user can operate the manipulator more conveniently.

Owner:苏州艾克特斯医疗科技有限公司

An environment-friendly plant ventilation mechanism

ActiveCN112303782BImprove cleanlinessAvoid pollutionDispersed particle filtrationLighting and heating apparatusVentilation tubeParticulates

The invention relates to an environment-friendly factory building ventilation mechanism, which includes a filter screen body and a locking and fixing mechanism. The main knocking mechanism is provided on the side of the filter body facing the inside of the ventilation pipe; the present invention is provided with a filter mechanism on the ventilation pipe mechanism in the existing fresh air system, and the design of the filter mechanism is used to filter air. In this way, in the actual working process, the solid particles in the exhausted air can be filtered, so as to ensure that the discharged air avoids polluting the environment, and at the same time, the fixed particles in the ambient air can enter the building, thereby ensuring the building The cleanliness of the air in the object, so in the present invention, a filter mechanism is added in the ventilation mechanism, which is more in line with market demand and has higher application value.

Owner:中节能(湖州)科技城投资建设发展有限公司

Multifunctional capacitor maintaining and disassembling device

InactiveCN111940860AAchieve the effect of integration of maintenance and disassemblyReach replacementSoldering apparatusMetal working apparatusEngineeringElectronic component

The invention relates to the technical field of electronic component maintaining and disassembling tools, and discloses a multifunctional capacitor maintaining and disassembling device which comprisesa shell. A triangular block is fixedly installed on the right side of the top of the inner wall of the shell. A disassembling pipe is movably installed on the left side of the triangular block. A triangular block is movably installed on the left side of the disassembling pipe. A fixing block is fixedly installed at the bottom of each triangular block. A rack is arranged at the bottom of each fixing block. Bearings are fixedly installed between the inner walls of the shell. A first thread rod is movably installed between the two bearings. An electricity storing device transmits electricity through a transmission line to electrify an electric soldering iron, a heating part in the electric soldering iron heats an electric soldering head, then a capacitor can be disassembled through the disassembling pipe, thus the effect of capacitor maintaining and disassembling integration is achieved, the first thread rod is rotated to drive the racks, the racks drive the triangular blocks, then a second thread rod drives a rotating mechanism, the rotating mechanism drives the disassembling pipe, and thus the effect of replacing and storing disassembling tools is achieved.

Owner:李红伟

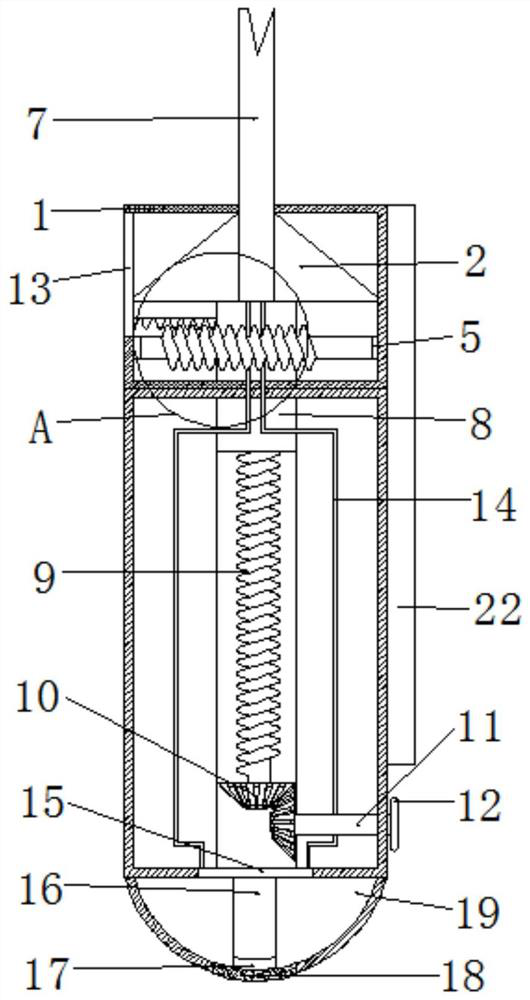

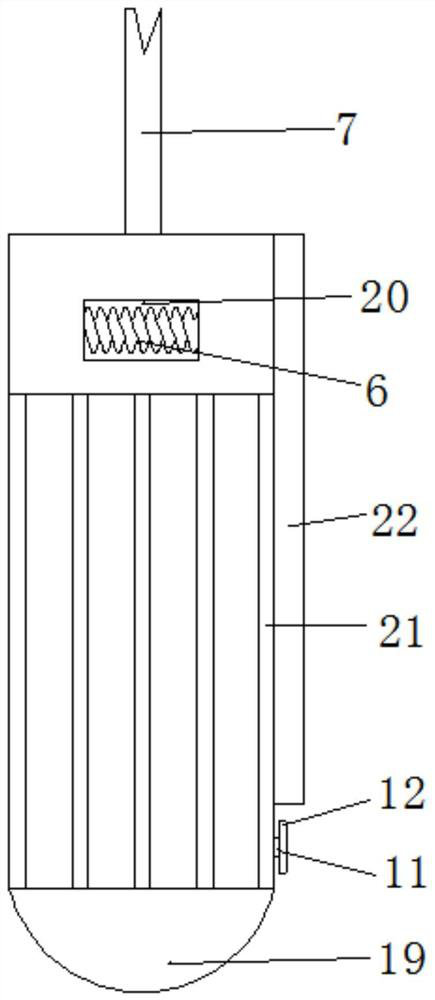

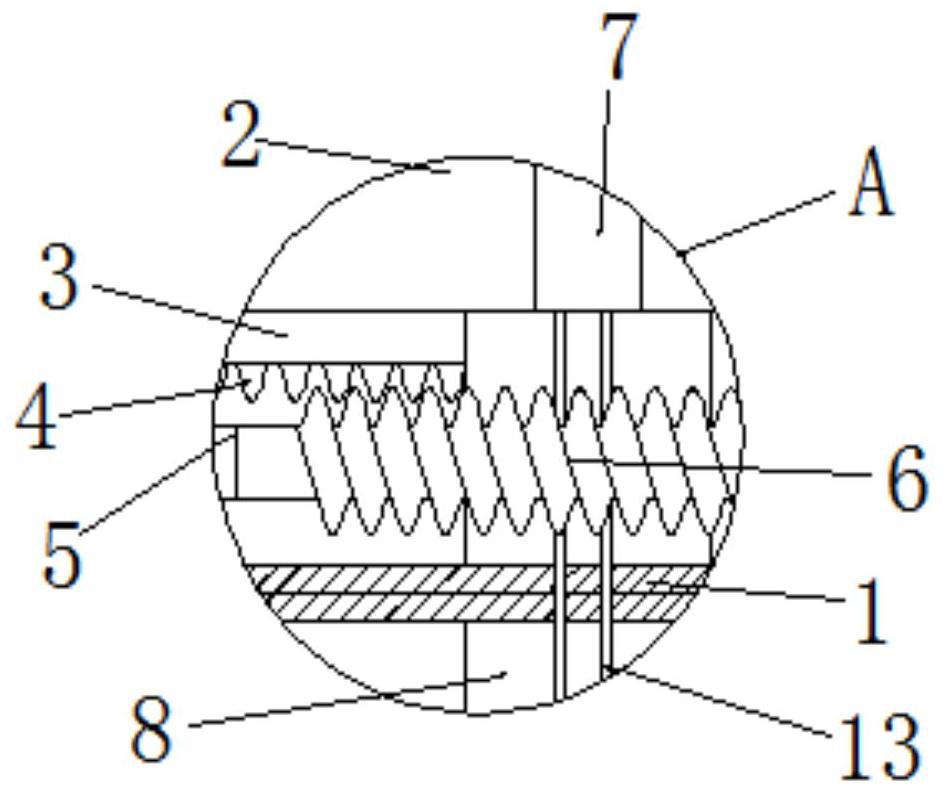

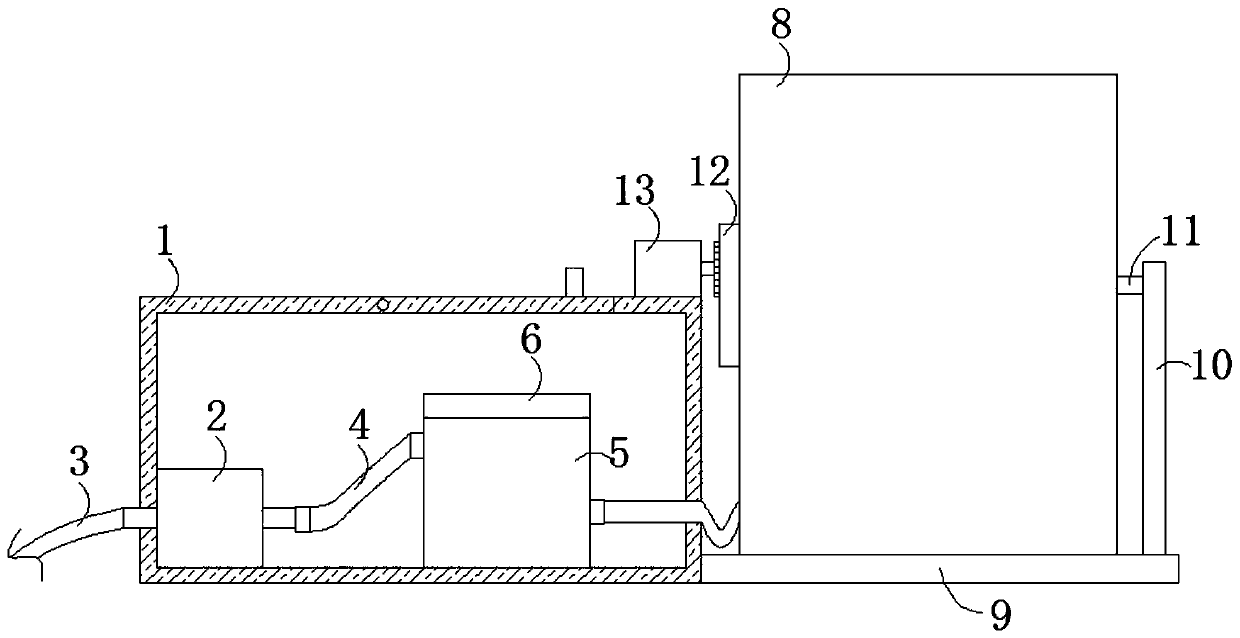

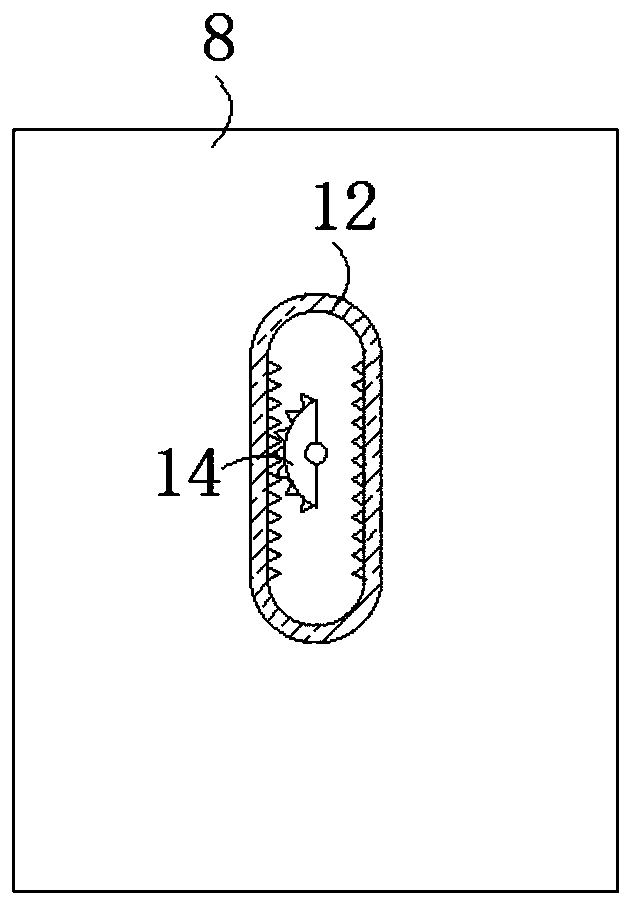

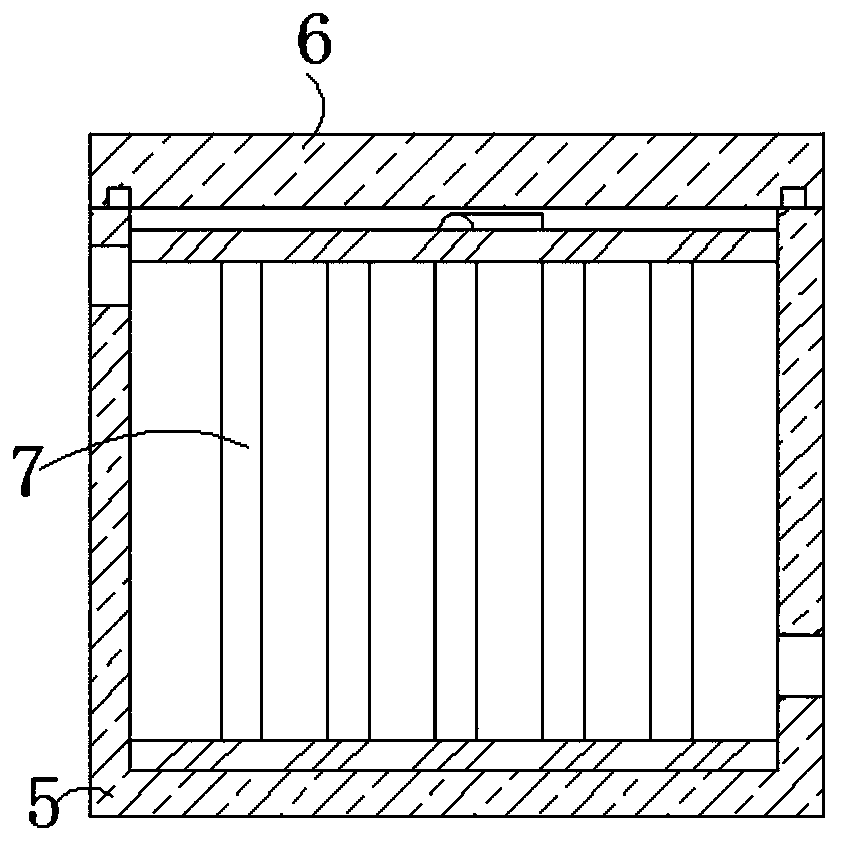

Same-floor drainage system for building toilet

InactiveCN110761370AAchieve the purpose of storageReach replacementDomestic plumbingArchitectural engineeringWater resources

The invention relates to the field of building drainage, and discloses a same-floor drainage system for a building toilet, to solve the problem that a large amount of accumulated water easily caused in a toilet cannot be reused. According to the scheme, the same-floor drainage system comprises a drainage tank main body; a pump is fixedly connected with the inner wall on the left side of the bottomof the drainage tank main body; a filter box is fixedly connected with the inner wall of the bottom of the drainage tank main body; a sealing cover is fixedly connected with the top of the filter box; a filter core is arranged in the filter box; a placing plate is fixedly connected with the outer wall of a right side box body of the drainage tank main body; a water bucket is arranged at the top of the placing plate; and a fixing rod welded with the top of the placing plate is arranged on the right side of the water bucket. The same-floor drainage system is ingenious in conception and novel indesign, and impurities such as hair and the like in the accumulated water in the toilet can be filter conveniently, so that the accumulated water is relatively pure, the accumulated water in the toilet can thus be reused, a water resource is further saved, and the same-floor drainage system is suitable for market promotion.

Owner:湖州扬清环境科技有限公司

A punching tool for an electronic chip with a clamping structure

ActiveCN114012918BEasy loadingEasy to moveSemiconductor/solid-state device manufacturingWorking accessoriesRotary stageWaste collection

The invention discloses a punching tool for an electronic chip with a clamping structure, which includes a support plate, two sets of support frames are symmetrically installed on the top of the support plate, and a fixing box is installed on the top of the support frame. The inside of the fixed box is equipped with a drive motor, the output end of the drive motor is equipped with a rotary table through a connecting rod, the top of the support frame is equipped with a fixed frame, and one side of the support plate is equipped with a waste collection box through bolts, A shock pad is installed on the inner side of the waste collection box; a loading rack is installed on the other side of the support plate. In the present invention, a threaded rod is installed. During the feeding process, the threaded rod is driven to rotate through the operation of the servo motor. The threaded rod rotates through the thread to drive the outer inner threaded collar to rise, and the inner threaded collar rises to drive the lifting platform to rise. Adjust the height of the device to ensure that the chip on the top layer of the device is always kept at an appropriate height, which is convenient for loading the device.

Owner:NANTONG MINICHIP MICRO ELECTRONICS

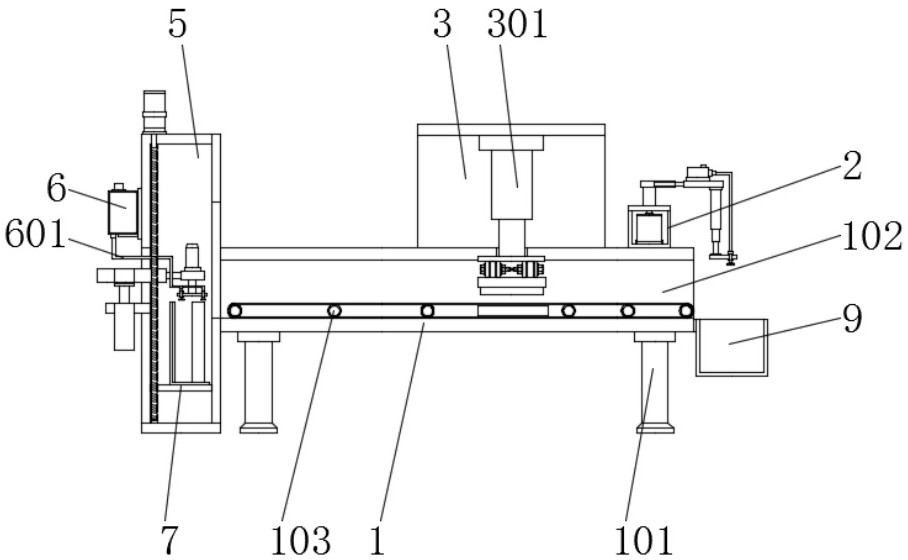

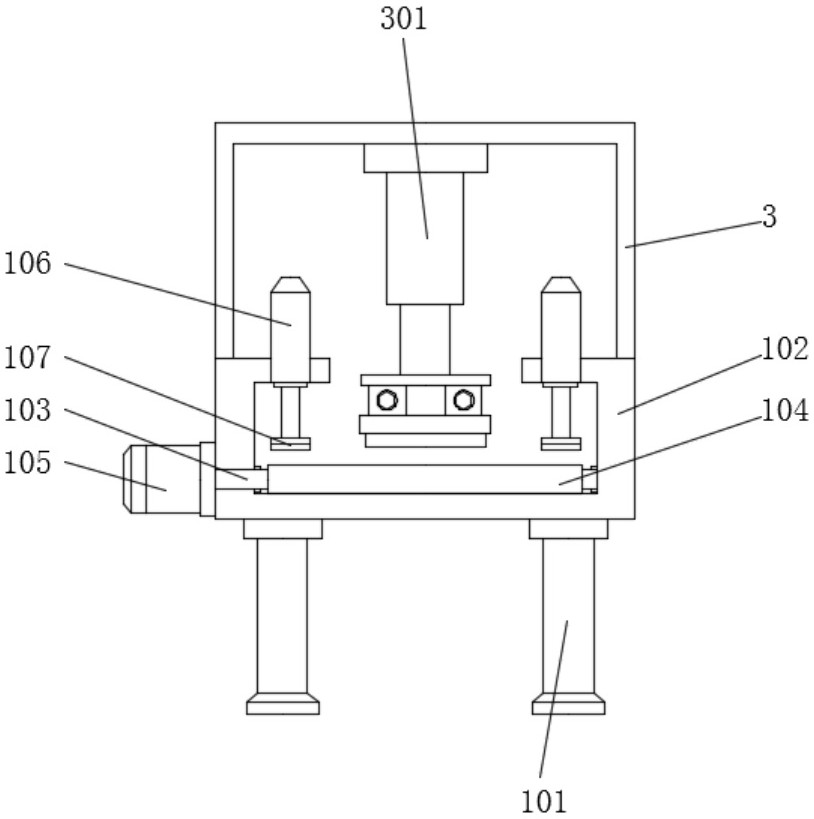

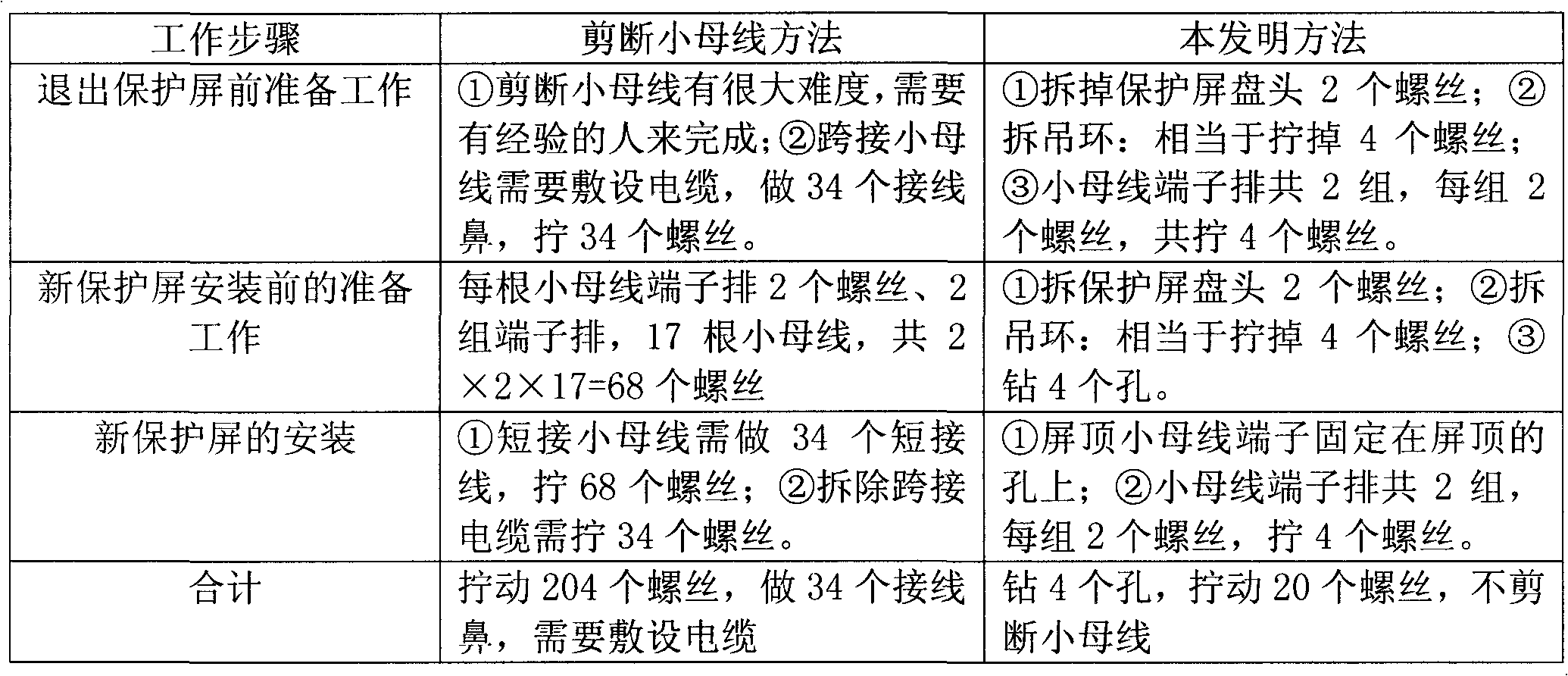

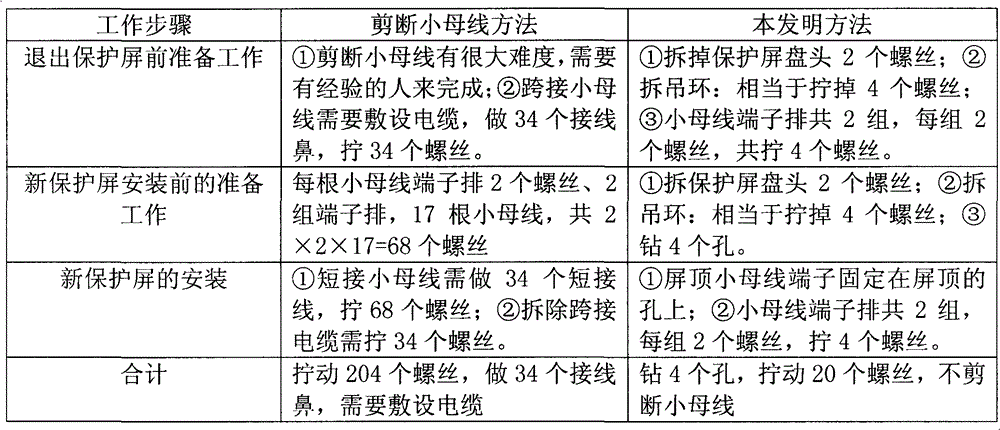

Method for changing protective screen without cutting small bus for transformer substation

ActiveCN102510016AShorten the construction periodReach replacementSwitchgearPower substationMechanical engineering

The invention discloses a method for changing a protective screen without cutting a small bus for a transformer substation. By means of condition that a new protective screen is as high as the old one, the small bus at the top of the screen cannot be lifted up after the new protective screen is installed. The method comprises the steps of: pushing the protective screen out of the original place after detaching a connecting wire in the old protective screen and separating a small bus terminal row from the top of the screen; detaching an accessory installed at the top of the new protective screen; pushing the new protective screen into the installing place and fixing the small bus terminal row at the top of the screen on the new protective screen so as to achieve the purpose of changing the protective screen. According to the method disclosed by the invention, a work loop in which the dangerous point of cutting the small bus is not easy to control is avoided, the protective screen is changed without cutting the small bus so that the dangerous point in the working process is easy to control; meanwhile the time for changing the protective screen is shortened to 2.5 days, and thereby the construction period is shortened by 1.5 days.

Owner:STATE GRID CORP OF CHINA +2

Method for changing protective screen without cutting small bus for transformer substation

The invention discloses a method for changing a protective screen without cutting a small bus for a transformer substation. By means of condition that a new protective screen is as high as the old one, the small bus at the top of the screen cannot be lifted up after the new protective screen is installed. The method comprises the steps of: pushing the protective screen out of the original place after detaching a connecting wire in the old protective screen and separating a small bus terminal row from the top of the screen; detaching an accessory installed at the top of the new protective screen; pushing the new protective screen into the installing place and fixing the small bus terminal row at the top of the screen on the new protective screen so as to achieve the purpose of changing the protective screen. According to the method disclosed by the invention, a work loop in which the dangerous point of cutting the small bus is not easy to control is avoided, the protective screen is changed without cutting the small bus so that the dangerous point in the working process is easy to control; meanwhile the time for changing the protective screen is shortened to 2.5 days, and thereby the construction period is shortened by 1.5 days.

Owner:STATE GRID CORP OF CHINA +2

Ship tail gas decomposing device

PendingCN112459868AReach replacementExhaust apparatusSilencing apparatusCombustion chamberMarine engineering

The invention discloses a ship tail gas decomposing device. Tail gas exhausted by a ship can enter a shell from a machine connecting body, meanwhile, a high-pressure water pump can pump a vehicle ureasolution in the shell through a second pipeline, the vehicle urea solution is discharged into the shell through a first pipeline, the vehicle urea solution discharged into the shell can absorb the tail gas exhausted by the ship, and the vehicle urea solution absorbing the tail gas falls on the lower end of the shell; and due to the fact that the lower end of the shell communicates with one side of the shell, a refrigerating machine condensation plate is installed in the middle of a liquid storage tank, the ship tail gas, cooled vehicle urea and an anti-freezing solution are fully mixed, and anitrogen acid beverage is produced according to the requirement. Therefore, the vehicle urea solution can enter a cavity of the shell, the vehicle urea solution is recycled, and the vehicle urea solution can reduce harmful substances in the ship tail gas; and in addition, the tail gas absorbing the harmful substances can enter the shell and is finally discharged to a filter connector through a sponge filter screen. Through the sponge filter screen, the sponge filter screen can filter air impurities and water, the harmful substances in the ship tail gas can be further reduced, and the discharge amount of the ship tail gas is reduced. The ship tail gas enters a ship engine filter to be mixed with air, the ship tail gas enters a combustion chamber to do work circularly, the tail gas is not discharged, and environmental protection is achieved.

Owner:饶开亮

Steel plate machining device with laser cutting machine head capable of being conveniently replaced

InactiveCN108453376AEasy to replaceReach replacementLaser beam welding apparatusSheet steelArchitectural engineering

The invention discloses a steel plate machining device with a laser cutting machine head capable of being conveniently replaced. The steel plate machining device comprises a laser cutting machine body, wherein a bottom plate is fixedly connected to the bottom of the laser cutting machine body, sliding blocks are movably connected to the left side and the right side of the top of the bottom plate,a motor is fixedly connected to the right side of each sliding block, a supporting block is fixedly connected to the top of each sliding block, and a supporting stand column is fixedly connected to the right wall of each supporting block. According to the steel plate machining device with the laser cutting machine head capable of being conveniently replaced, a laser head body is matched with a rotating circular cylinder, and the rotating circular cylinder is adopted for braking the laser head body to enable the laser head body to move left and right; distinguished from an existing technical scheme, a belt is fixedly connected to the outer wall of the rotating circular cylinder, the belt is used for dragging the supporting blocks, and the rotating circular cylinder rotates in degrees, so that when the laser head body is cut, self direction regulating can be achieved, and a preset program is completed for cutting out an ideal model.

Owner:江苏华梁制造集团有限公司

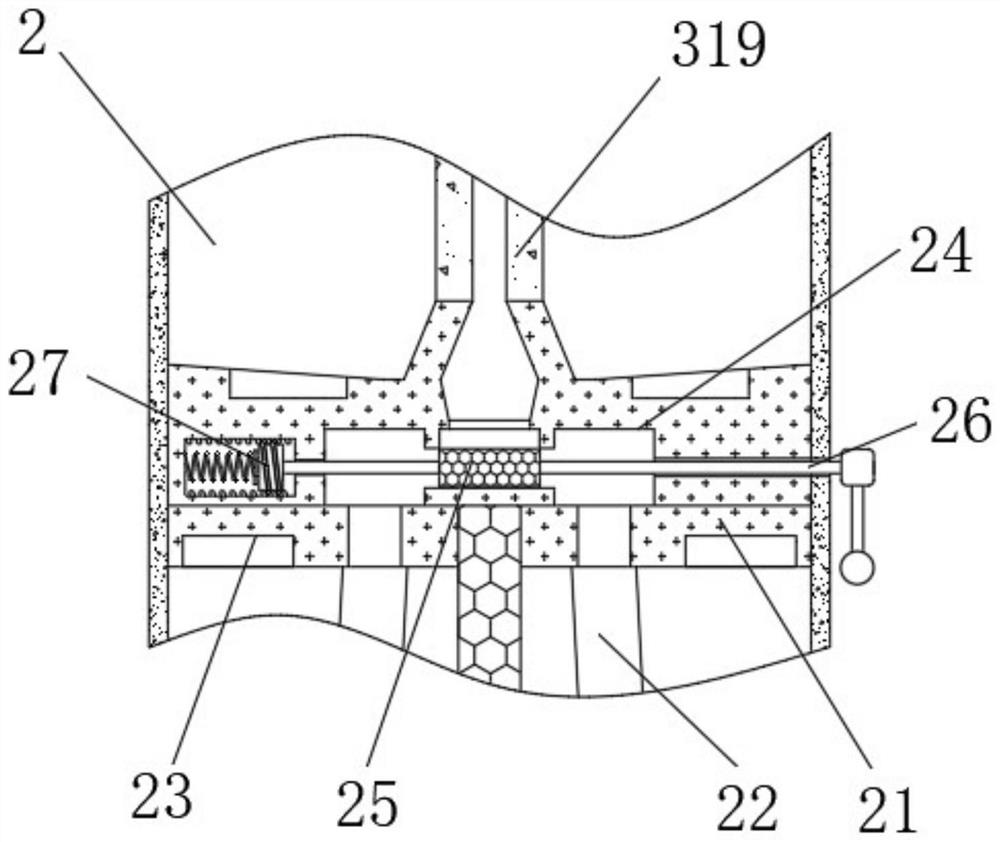

Noninvasive gynecological nursing medication device

ActiveCN113633878AReach replacementEasy to clean and disinfectMedical devicesAgainst vector-borne diseasesNursing careGynecology department

The invention relates to the technical field of gynecological nursing, and discloses a noninvasive gynecological nursing medication device which comprises a liquid storage bottle, a liquid changing mechanism is fixedly connected to the interior of the liquid storage bottle, a partition plate is arranged between the liquid changing mechanism and the liquid storage bottle, the liquid changing mechanism comprises an inner valve body, and two pipettes are fixedly connected to the bottom of the inner valve body; a through air inlet is formed in the inner valve body, the top of the liquid storage bottle is fixedly connected with an infusion mechanism, and the infusion mechanism comprises a pressure regulating mechanism, a pressurizing mechanism and a medicine application mechanism. A control rod is rotated to drive a threaded head to rotate, and under the driving action of the threaded head, the threaded head drives an inner valve block to slide in a three-way cavity, so that the effect of replacing output liquid is achieved, disinfectant cleaning and medicine replacement at any time are facilitated, cleaning and disinfection work before medicine application is facilitated, the medicine application effect is improved, and the use effect of the device is improved.

Owner:重庆两江新区人民医院

Diode illuminating lamp holder convenient to adjust and replace

PendingCN114135828AReach replacementAchieve the effect of replacing LED lightsFouling preventionLighting support devicesEngineeringLED lamp

The invention relates to an illuminating lamp holder, in particular to a diode illuminating lamp holder convenient to adjust and replace. The invention provides a dustproof diode illuminating lamp holder convenient to adjust and replace. A diode lighting lamp holder convenient to adjust and replace comprises a first supporting frame, a second supporting frame, a first baffle, a rotating mechanism and a fixing mechanism, the second supporting frame is arranged on the first supporting frame in a sliding mode, the first baffle is arranged on the second supporting frame, and the rotating mechanism is connected among the second supporting frame, a first rotating shaft and the first baffle. And a fixing mechanism is arranged in the rotating mechanism. According to the LED lamp convenient to replace, people manually move the two first movable rods to the outer side, then people take out an old LED lamp, a new LED lamp is supported between the two first movable rods by hands, then people move the first movable rods to the inner side, the LED lamp is clamped by the first movable rods, and therefore the effect of replacing the LED lamp is achieved.

Owner:赣州祖聆电子商务有限公司

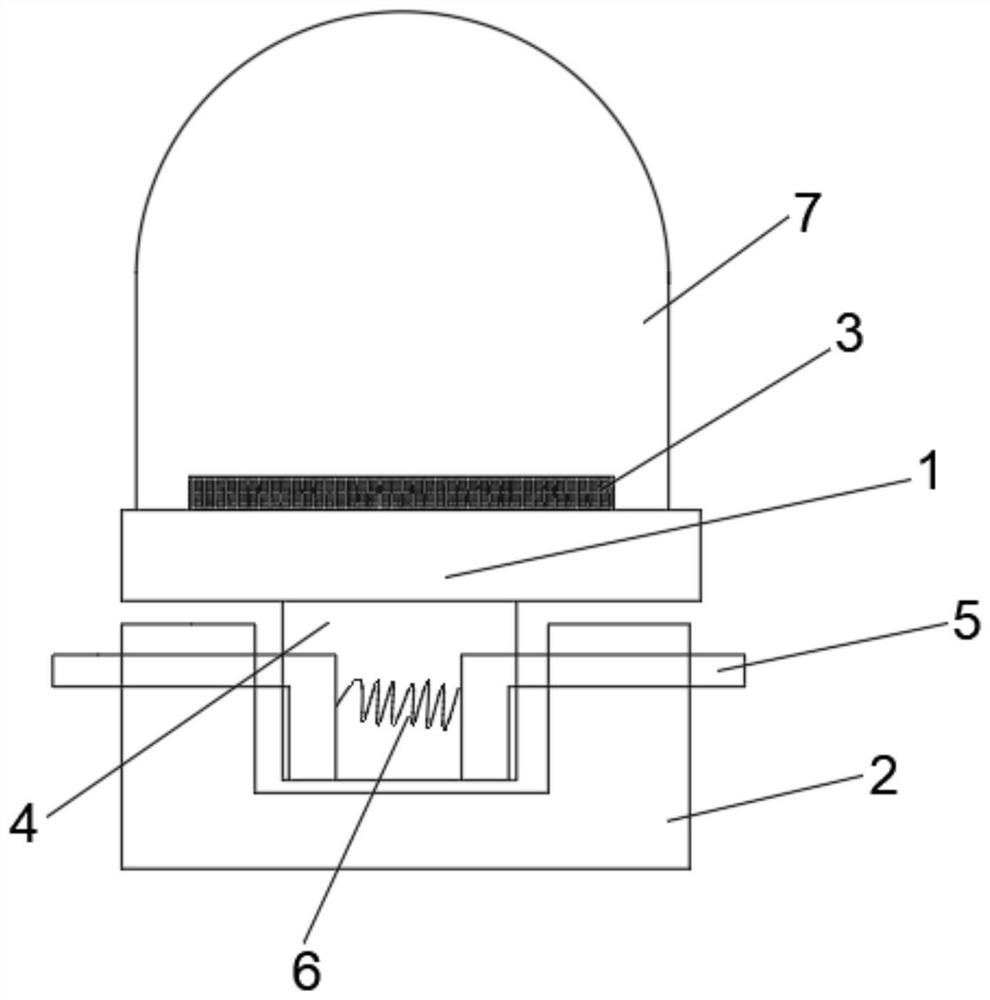

LED lamp bead and dispensing method thereof

InactiveCN112259662AReach replacementTo achieve the purpose of maintenanceSemiconductor devicesLED lampMechanical engineering

The invention discloses an LED lamp bead and a dispensing method thereof. TheLED lamp bead comprises a lamp bead fixing seat and a base, an LED chip is arranged in the lamp bead fixing seat, the lampbead fixing seat is connected to the base in an inserted mode, limiting grooves are formed in the two opposite inner side walls of a square groove, a cavity is formed in the lamp bead fixing seat, anda limiting mechanism corresponding to the limiting grooves is arranged in the cavity; the limiting mechanism comprises two symmetrically-arranged L-shaped limiting blocks, the side walls, close to each other, of the vertical ends of the two limiting blocks are jointly and fixedly connected with a spring, and the two opposite outer side walls of the base are each provided with an operation groovecommunicated with the cavity. When the LED chip or the lamp bead fixing seat needs to be replaced or maintained, by arranging the limiting mechanism, an operator manually enables fingers to penetratethrough the two operation grooves and enables the two limiting blocks to move close to each other, and when the horizontal ends of the limiting blocks are separated from the limiting grooves, the lampbead fixing seat can be easily separated from the base; therefore, the purpose of replacing or maintaining the LED chip or the lamp bead fixing seat is achieved.

Owner:江西瑞晟光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com