Grabbing device for replacing battery of unmanned aerial vehicle

A technology of grabbing device and machine battery, which is applied in the field of UAV battery replacement, can solve the problems of low degree of automation, complex structure of replacement mechanism, and complex structure, and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

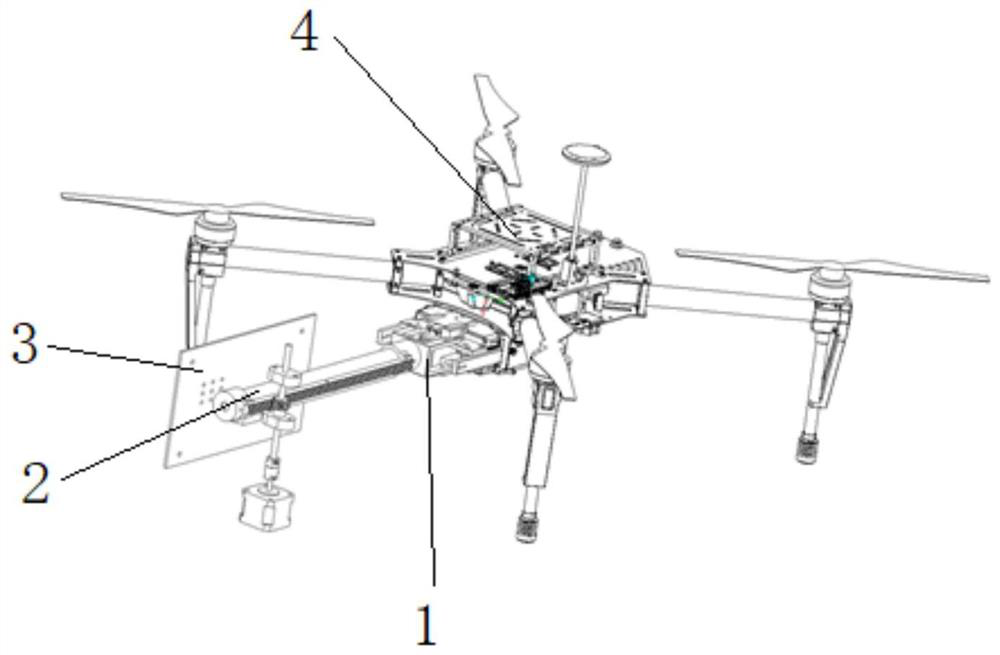

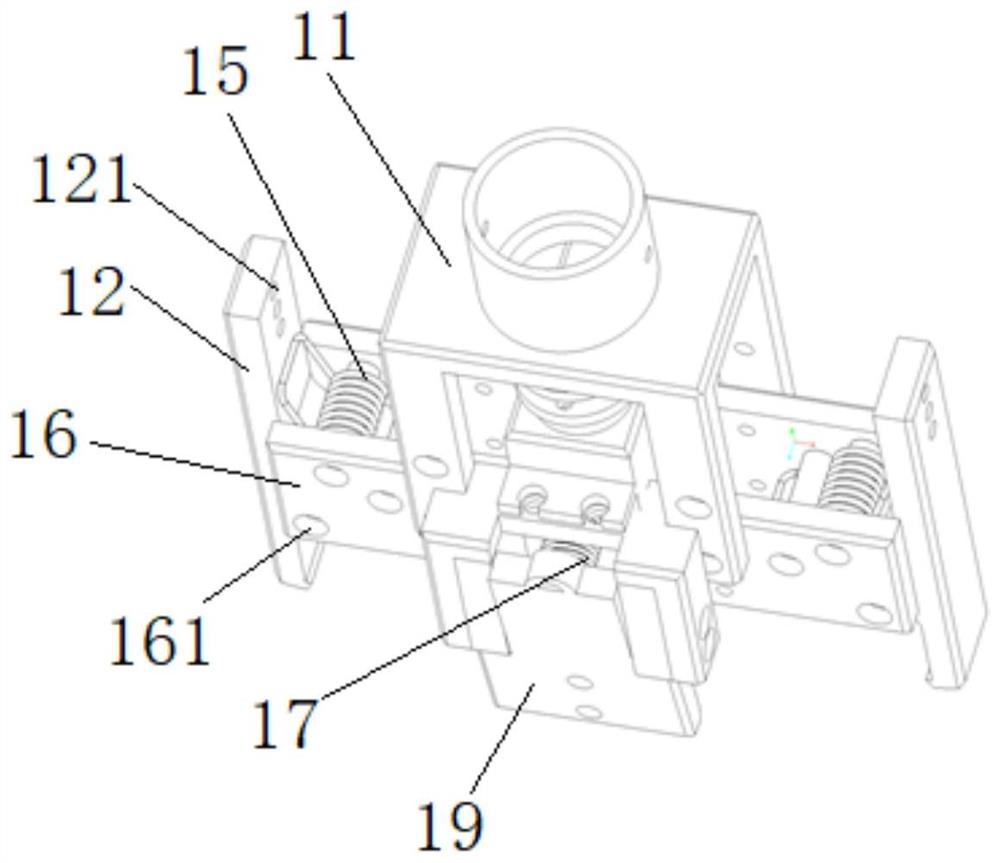

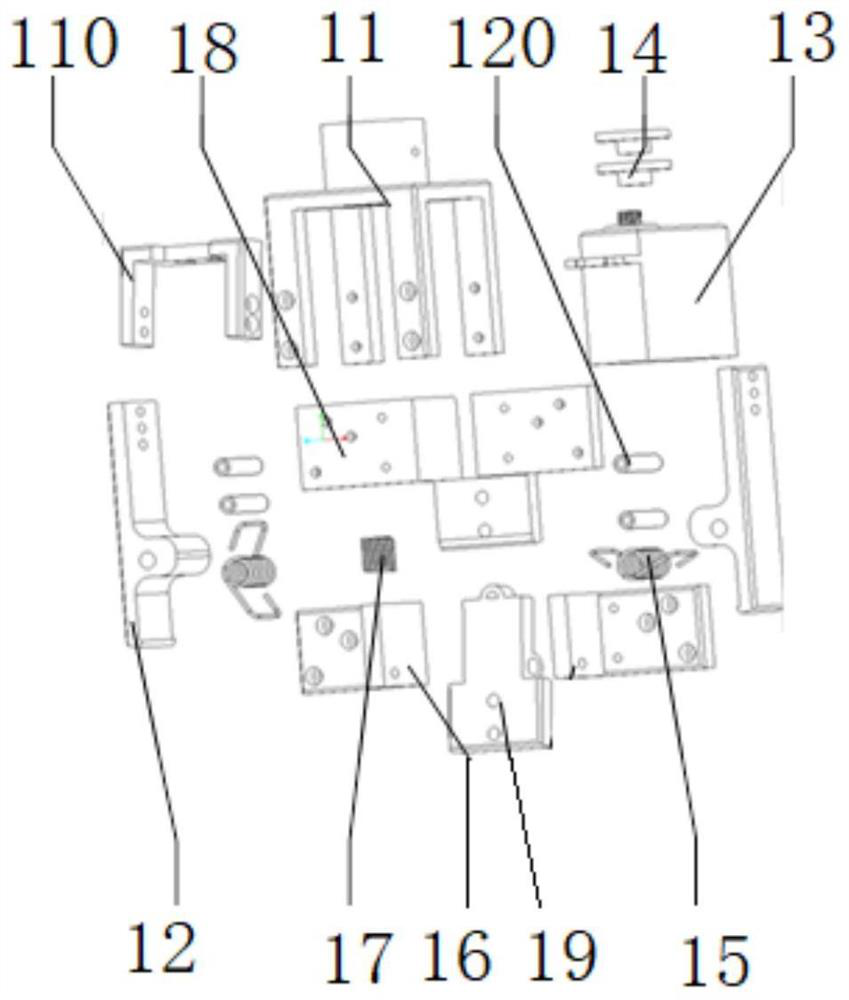

[0036] like Figure 1 to Figure 10 As shown, this embodiment provides a grasping device that can be used for battery replacement of a drone, including a mechanical claw 1 and a mechanical arm 2 matched with the mechanical claw 1. The mechanical claw 1 includes a base 11, a torsion spring 15, a rudder 13, the steering wheel 14 and the clamping jaws 12 arranged on both sides of the base 11; the steering gear 13 is fixedly connected with the steering wheel 14, a wire rope is installed between the steering wheel 14 and the clamping jaw 12, and the base 11 is fixedly connected to the mounting plate 16, The mounting plate 16 is movably connected with the clamping jaw 12, the torsion spring 15 is installed on the mounting plate 16, and the torsion spring 15 is movably matched with the clamping jaw 12; when the steering gear 13 drives the steering wheel 14 to rotate, the steering wheel 14 drives the wire rope to move, and The grasping part 122 of the linkage jaw 12 is opened; when the...

Embodiment 2

[0048] This embodiment provides a grabbing device that can be used for UAV battery replacement. The difference from Embodiment 1 is:

[0049] like Figure 11 As shown, in this embodiment, the manipulator and the manipulator are respectively controlled by the lower computer, the lower computer sends a pulse signal to the motor through the driver, and the lower computer sends a PWM signal to the steering gear through the controller, and controls the manipulator through the motor and the steering gear respectively. Movement with mechanical claw. The motor and servo are powered by the power supply and controlled by the switch. It is beneficial to the cooperative movement of the mechanical claw and the mechanical arm when grabbing the battery, improving the accuracy and facilitating the control.

[0050] The linear motion manipulator and the manipulator are installed and fastened together, and the lower computer executes the control commands to the motor and the steering gear, so...

Embodiment 3

[0053] This embodiment provides a grabbing device that can be used for UAV battery replacement. The difference from Embodiment 1 is:

[0054] In this embodiment, the grasping device has a waterproof function, and the linear motion manipulator is fixed in the casing. When the lithium polymer battery of the drone is replaced, it can be grasped by the manipulator and stored in the middle of the casing. The mechanical parts of the grabbing device are all aluminum alloy, stainless steel or nylon parts, and the motor and steering gear also have waterproof function, and the circuit connection has no exposed interface, so it can play a waterproof safety function. The grabbing device for battery replacement on the drone power exchange ground station is rainproof and can be placed outdoors, but due to the lithium polymer battery, the grabbing device is not suitable for immersion in water or heavy rain.

[0055] For other specific structures, refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com