LED lamp bead and dispensing method thereof

A technology of LED lamp beads and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of large man-hours, complicated installation methods, and low production efficiency, so as to improve luminous efficiency and solve multiple excitation problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

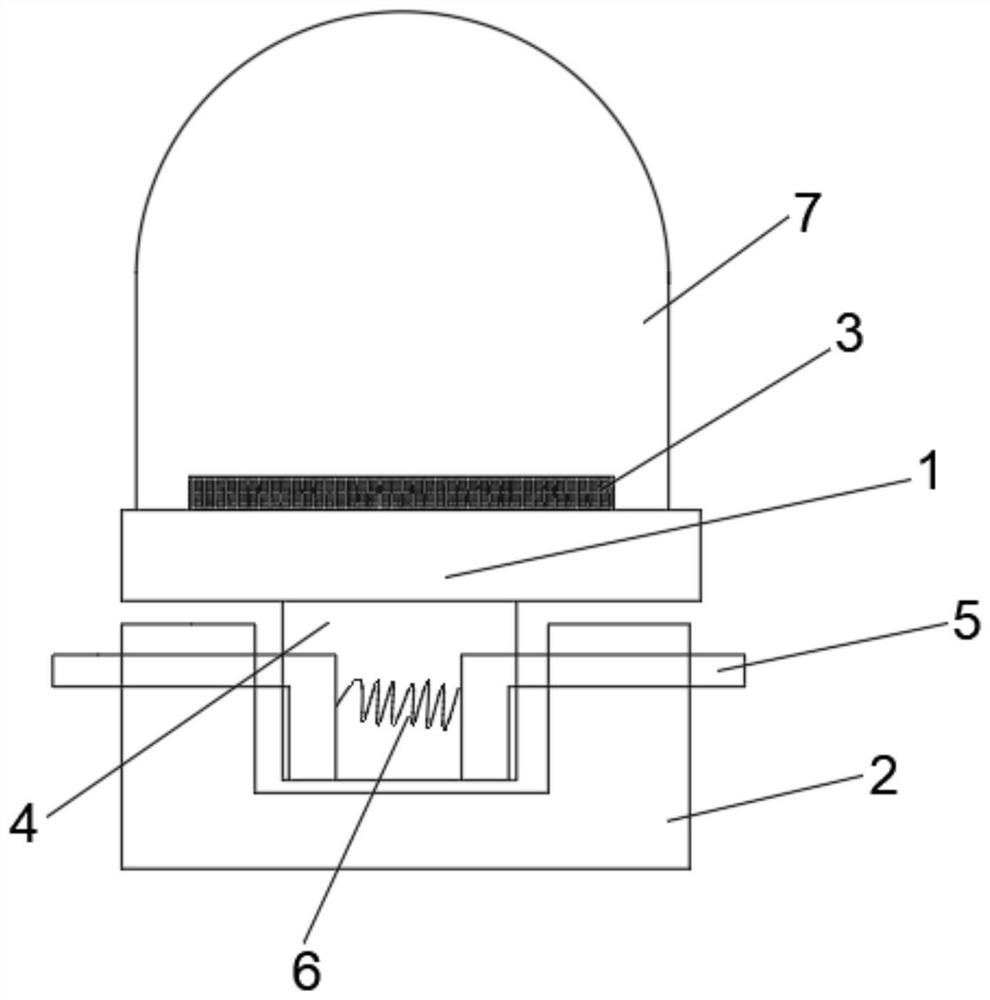

[0024] Such as figure 1 As shown, the present invention provides an LED lamp bead and a dispensing method thereof,

[0025] It includes a lamp bead holder 1 and a base 2, the lamp bead holder 1 is provided with an LED chip 3, the base 2 is provided with a square groove, and the lamp bead holder 1 is plugged into the square groove Inside, the two opposite inner walls of the square groove are provided with limiting grooves, and the lamp bead holder 1 is provided with a cavity 4 inside, and the interior of the cavity 4 is provided with a spacer corresponding to the limiting groove. The limit mechanism includes two symmetrically arranged L-shaped limit blocks 5, and the horizontal ends of the two limit blocks 5 respectively pass through the cavity 4 and extend to the inside of the two limit grooves A spring 6 is fixedly connected to the side walls adjacent to the vertical ends of the two limiting blocks 5, and the two opposite outer walls of the base 2 are provided with operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com