Method for changing protective screen without cutting small bus for transformer substation

A technology of protective screen and small busbar, applied in electrical components, switchgear and other directions, can solve the problem of uneven top of the protective screen, and achieve the effect of saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

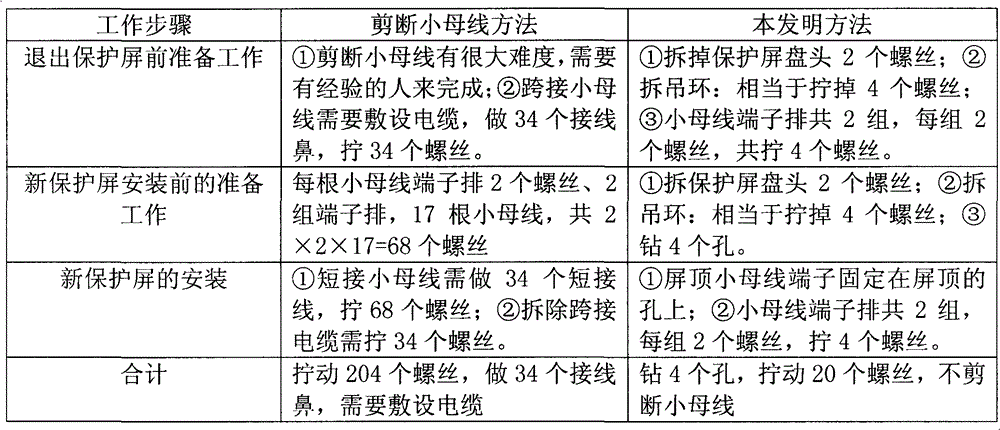

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Embodiment: A method for replacing the protective screen without cutting the small busbar in a substation. The height of the new protective screen is the same as that of the old protective screen. The specific steps are as follows:

[0032] A. Operation steps before exiting the old protective screen:

[0033] (1), remove the old protective screen head, remove the protective screen top ring;

[0034] (2) Set a large piece of waste plastic cloth as insulating material between the hand and the small bus bar, and remove the down lead of the small bus bar; since the original down lead of the small bus bar is connected to the side screw of the small bus bar terminal block, you can cut off the small For busbar down-leads, wrap the exposed wire ends with insulating tape;

[0035] (3) Remove the terminal base screw used to fix the small bus bar on the top of the screen, so that the small bus bar and its base are separated from the protective screen;

[0036] (4) When all the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com