Quick center clamp for cutter and using method of quick center clamp

A top-notch and fast technology, which is applied to the accessories of the tool holder, tailstock/top, manufacturing tools, etc., can solve the problems of low machining accuracy, no partial replacement, small outer diameter, etc., and achieve stable processing dimensions and novel structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

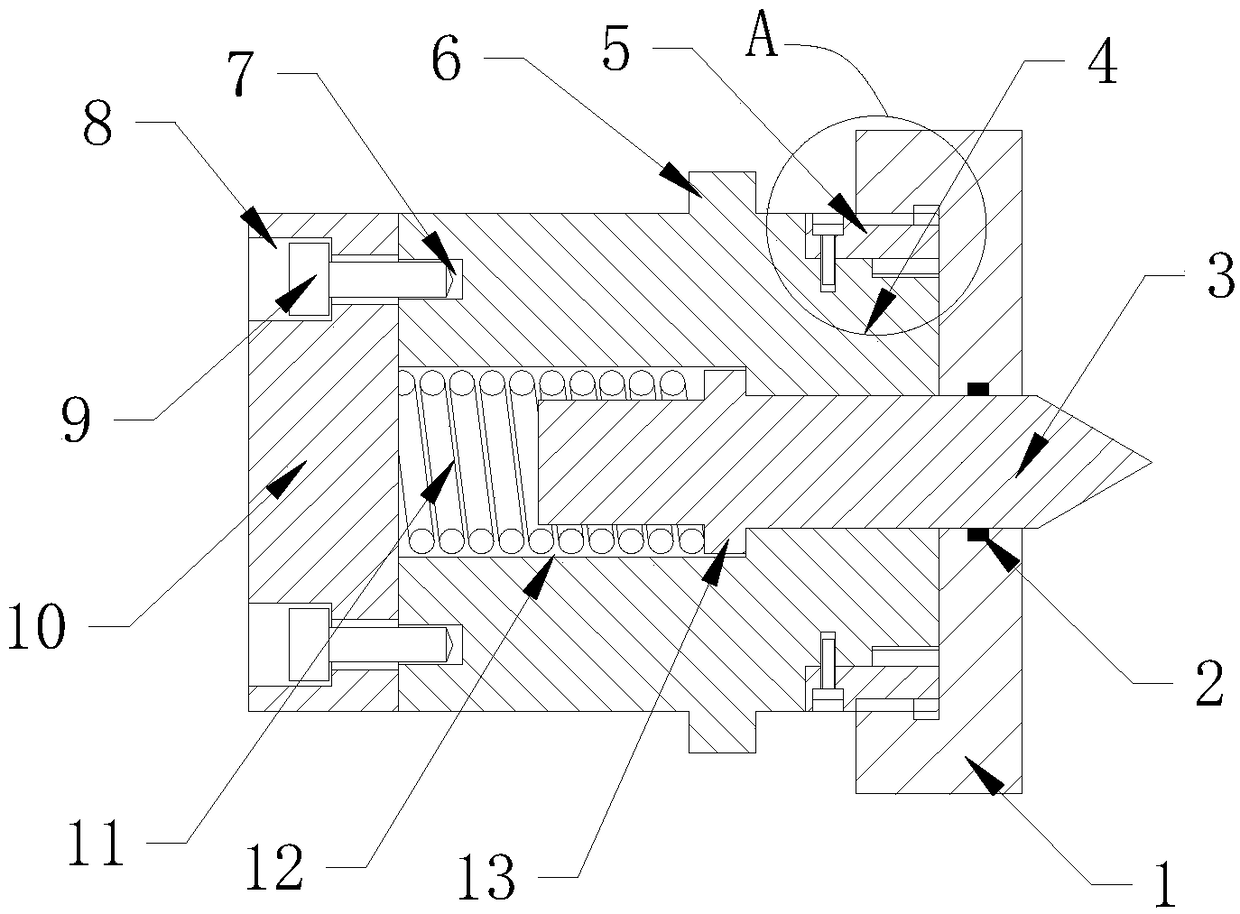

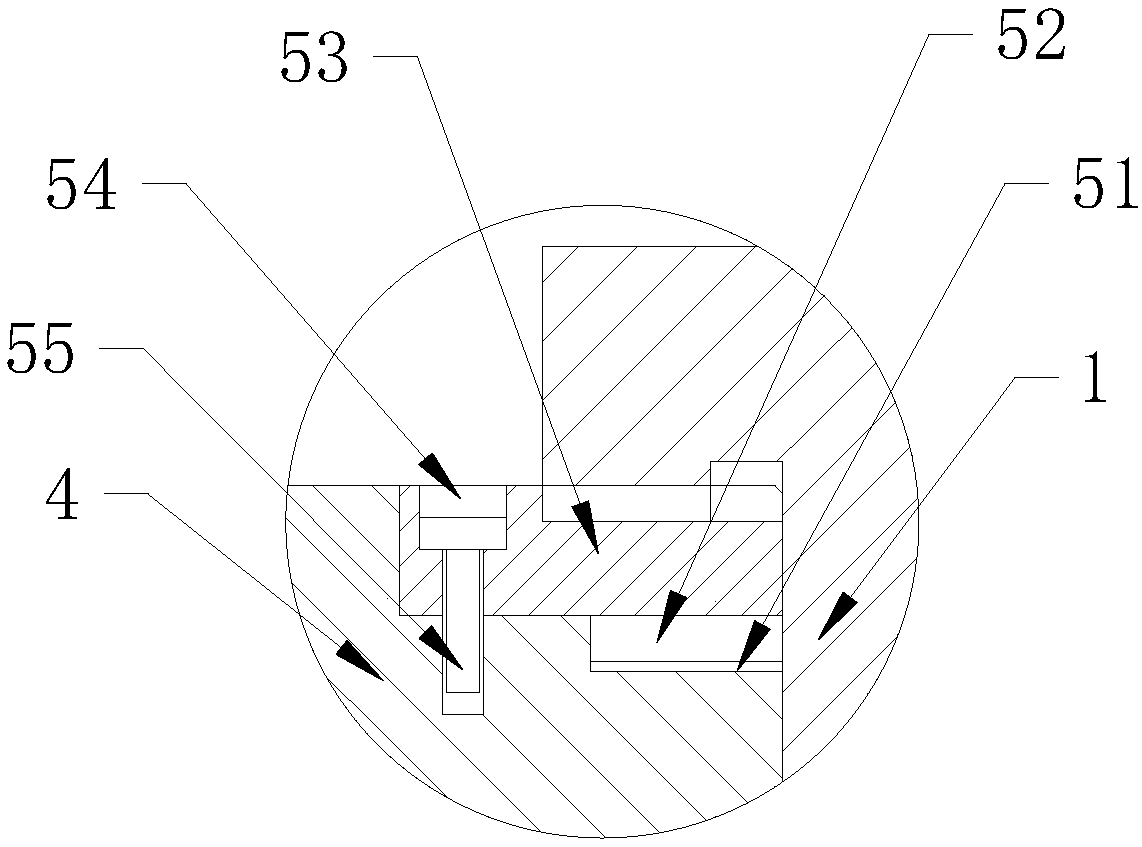

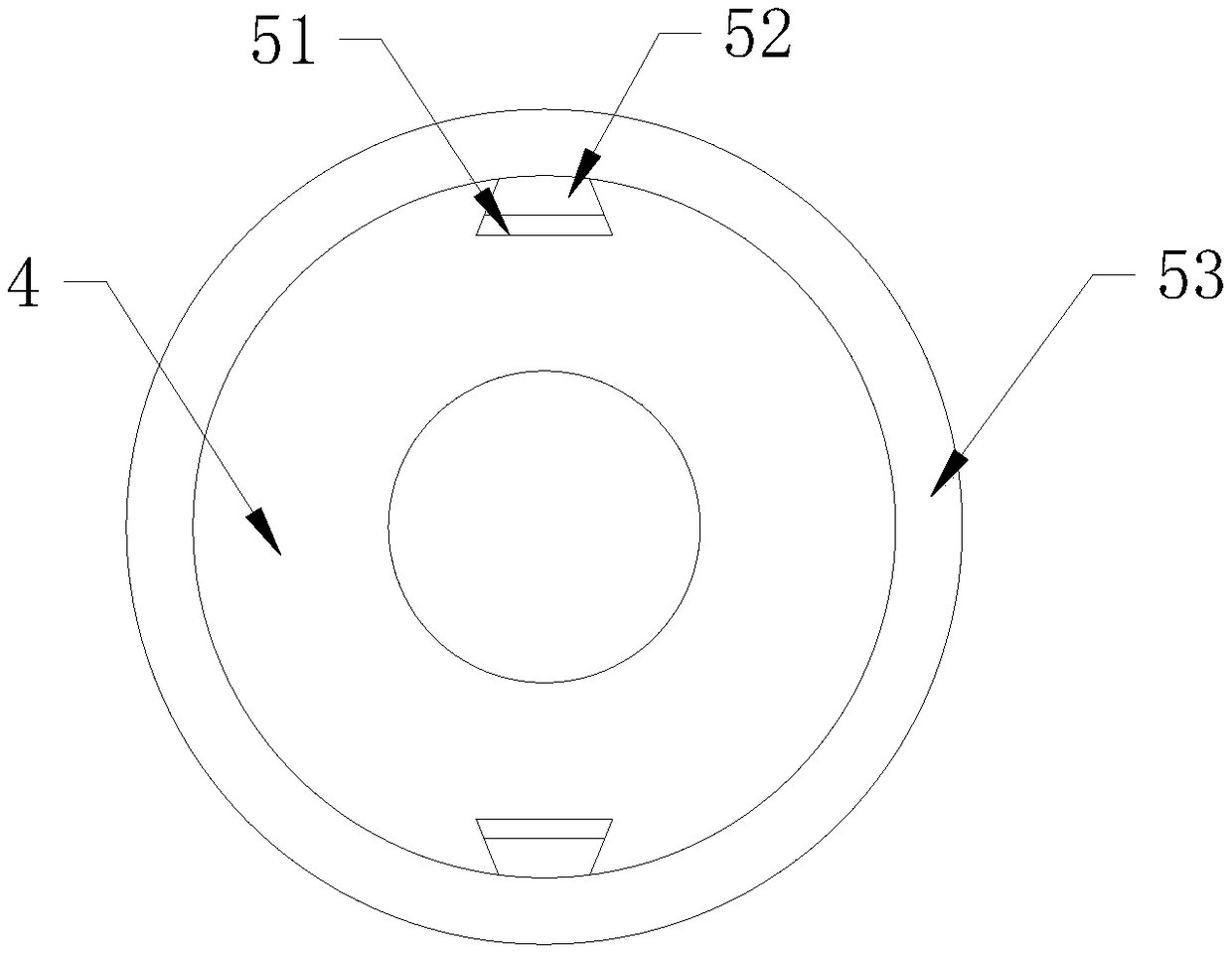

[0023] see Figure 1-Figure 3 , the present invention provides a technical solution: a fast tip clamp for cutting knives, including a device main body, a movable installation mechanism and a partial replacement mechanism, the device main body includes a front cover 1 and a clamping disc 4, the rear end surface of the front cover 1 The front faces of the clamping discs 4 fit together, and the movable installation mechanism is installed on the front end of the chucking disc 4. The movable installation mechanism includes a top 3, a screw 9, a rear cover 10, a spring 11, a circular groove 12 and a limit ring 2 13, The partial replacement mechanism is installed on the outer surface of the front end of the clamping disc 4, and the partial replacement me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com