Electronic chip punching tool with clamping structure

A technology for electronic chips and punching tools, applied in manufacturing tools, fine working devices, circuits, etc., can solve the problems of lack of blanking structure, lack of loading structure, and inability to adjust the size of punching and cutting, so as to reduce the working pressure. , Avoid offset or instability, and facilitate the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

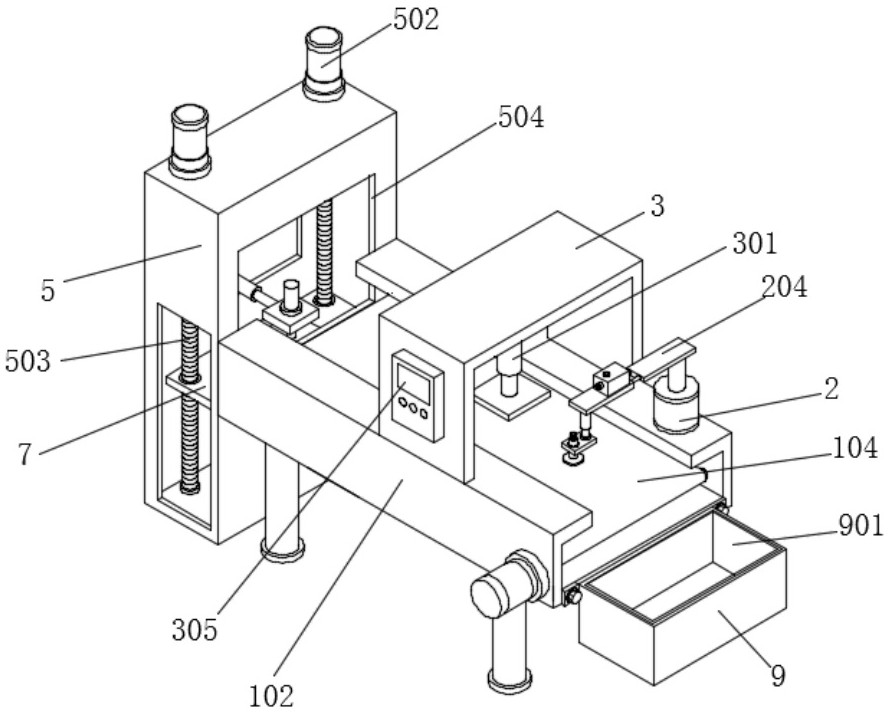

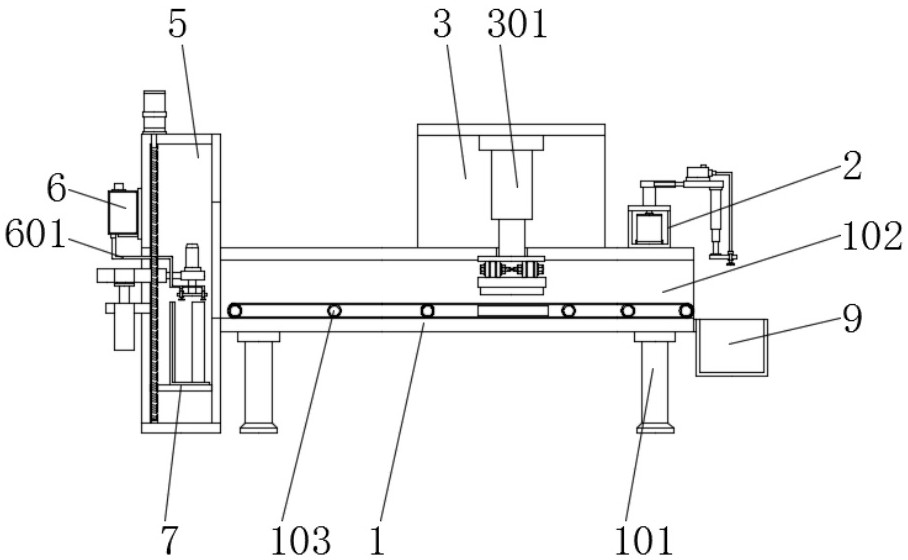

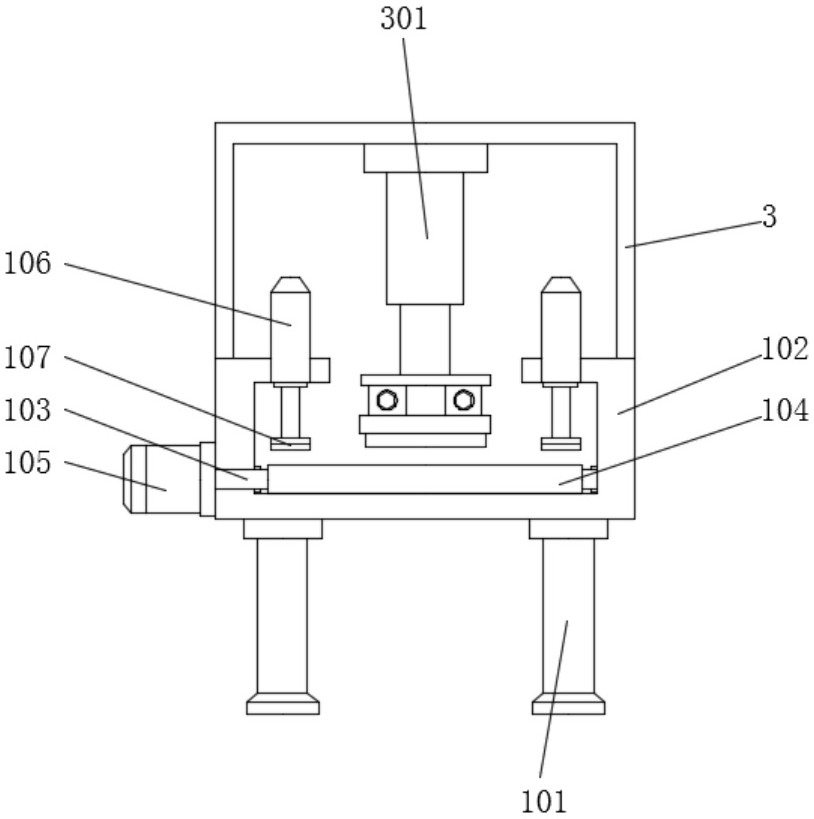

[0040] Embodiment 1, including a support plate 1, the bottom of the support plate 1 is equipped with a fixed column 101 through bolts, and the fixed column 101 supports the support plate 1 on the top to ensure that the support plate 1 remains stable, and it is convenient for the support plate 1 to support the support frame 102 on the top. Support, the inner side of the support frame 102 is installed with a rotating rod 103, the outer side of the rotating rod 103 is equipped with a transmission belt 104, the outer wall of the supporting frame 102 is equipped with a motor 105, the output end of the motor 105 is connected with one end of the rotating rod 103, and the supporting frame The top of 102 is installed with extruding rod 106 through, and extruding pad 107 is installed on the bottom of extruding rod 106, and the top of supporting plate 1 is symmetrically installed with two groups of supporting frames 102, and the top of supporting frame 102 is equipped with fixed frame 3, ...

Embodiment 2

[0042] Embodiment 2 includes a support plate 1, a fixed box 2 is installed on the top of the support frame 102, a driving motor 201 is installed inside the fixed box 2, and the fixed box 2 supports the driving motor 201 to ensure that the driving motor 201 can run smoothly. The output end of 201 is equipped with rotary platform 202 through connecting rod, and the top of rotary platform 202 is equipped with support column 203, and the top of support column 203 is equipped with support bar 204, and the inside of support bar 204 is equipped with adjustment arm 205, and the adjustment arm One end of 205 is equipped with movable arm 206, and the bottom of movable arm 206 is equipped with telescopic arm 207, and the bottom end of telescopic arm 207 is equipped with mounting table 208, and the top of movable arm 206 is equipped with the first suction pump 4, the first suction pump 4 An air outlet 401 is installed on the top of the first air suction pump 4, a first air suction pipe 402...

Embodiment 3

[0044]Embodiment 3 includes a support plate 1, a loading rack 5 is installed on the other side of the support plate 1, and the side of the loading rack 5 away from the support plate 1 is connected with a door body 501 through a hinge. When materials need to be placed, Open the door body 501 to facilitate workers to place the chips. The door body 501 is located on the side outside the loading rack 5 and is equipped with a second air pump 6 through bolts. The bottom of the second air pump 6 is equipped with a second air suction pipe 601. The air extraction pipe 601 runs through the inner side of the movable groove 505, the bottom end of the second air extraction pipe 601 is equipped with a splicing joint 602, the side of the loading frame 5 close to the support plate 1 is provided with a feeding window 504, and the inner side of the door body 501 is provided with a movable window 504. Groove 505, and movable groove 505 is positioned at the below of second suction pump 6, and door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com