Positioning clamp for outer cover of taper clutch

A technology for positioning fixtures and clutches, applied in the direction of manufacturing tools, grinding workpiece supports, grinding machines, etc., can solve the problems of time-consuming, butt-joint ridges, and lengthy processing process, and achieve the effect of improving processing efficiency and eliminating butt-joint ridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

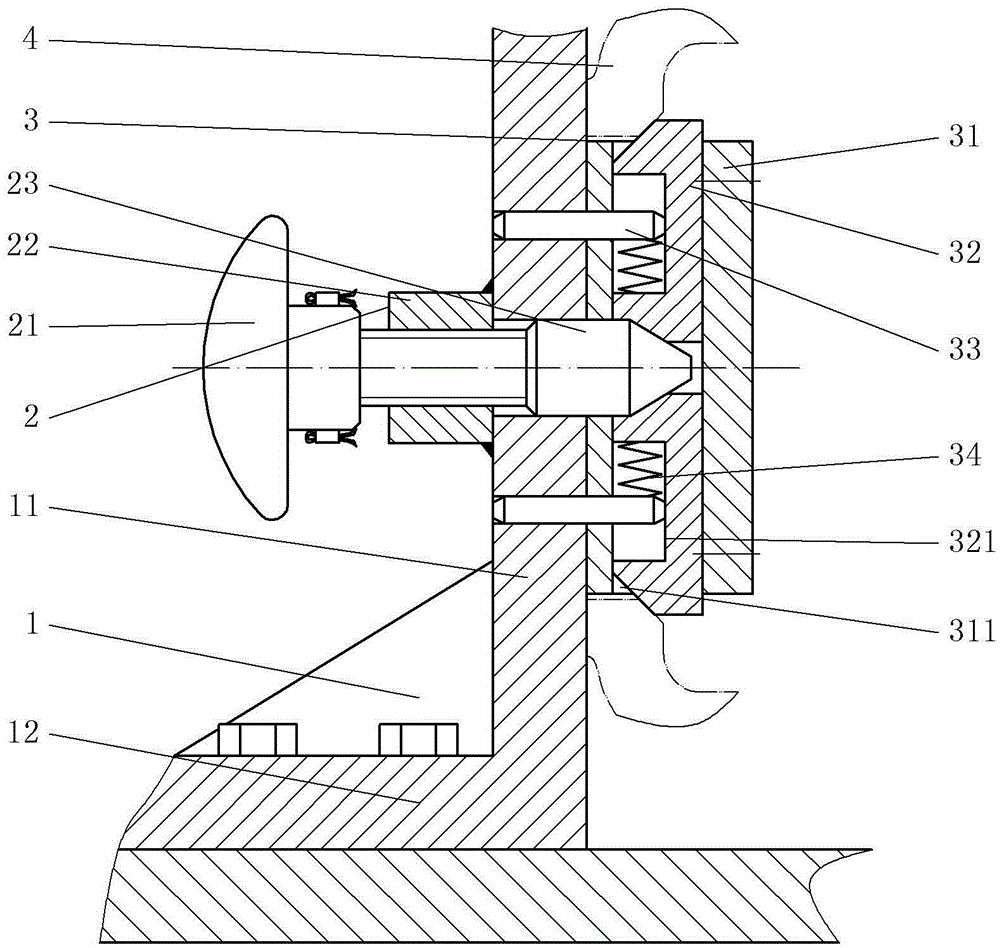

[0012] The reference signs in the drawings of the description include: fixed part 1, driving part 2, clamping part 3, taper clutch cover 4, clamping installation block 11, base 12, handle 21, fixed sleeve 22, driving rod 23, clamping Block positioning seat 31, clamping block 32, pin 33, return spring 34, strip hole 321, clamping block positioning groove 311.

[0013] The embodiment is basically as attached figure 1 As shown: the positioning fixture for the tapered clutch cover includes a fixed part 1, a clamping part 3 and a driving part 2; the fixed part 1 is L-shaped, integrally formed, and has a vertical clamping installation block 11 and a horizontal base 12, The clamping part 3 and the driving part 2 are respectively installed on both sides of the clamping installation block 11, wherein the clamping part 3 includes a fixed sleeve 22, a drive rod 23 and a handle 21; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com