A Combined Fixture for Laser Shock Strengthening Steam Turbine Blades

A technology of laser shock strengthening and steam turbine blades, which is applied in the field of mechanical engineering, can solve the problems of blade positioning and clamping difficulties, and achieve the effects of easy clamping operation, low production cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

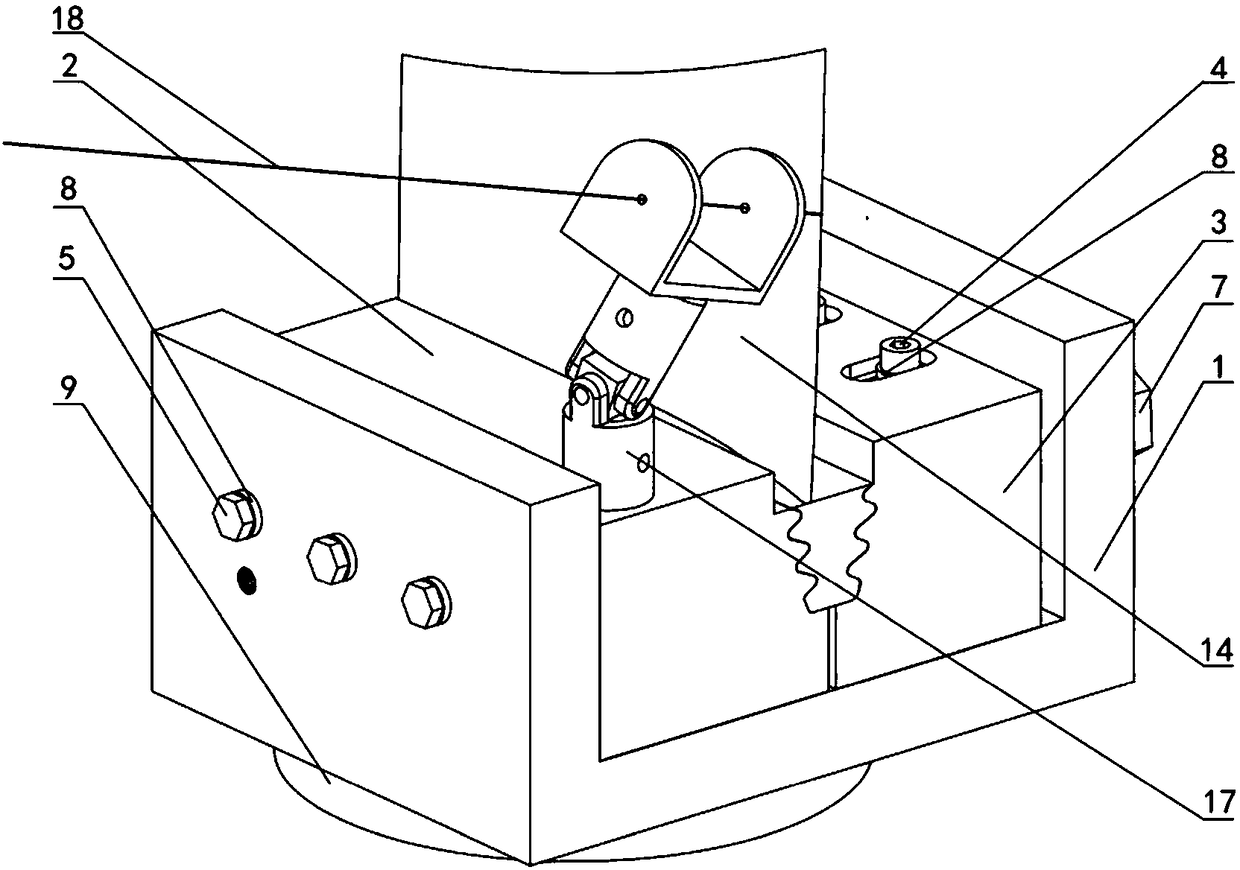

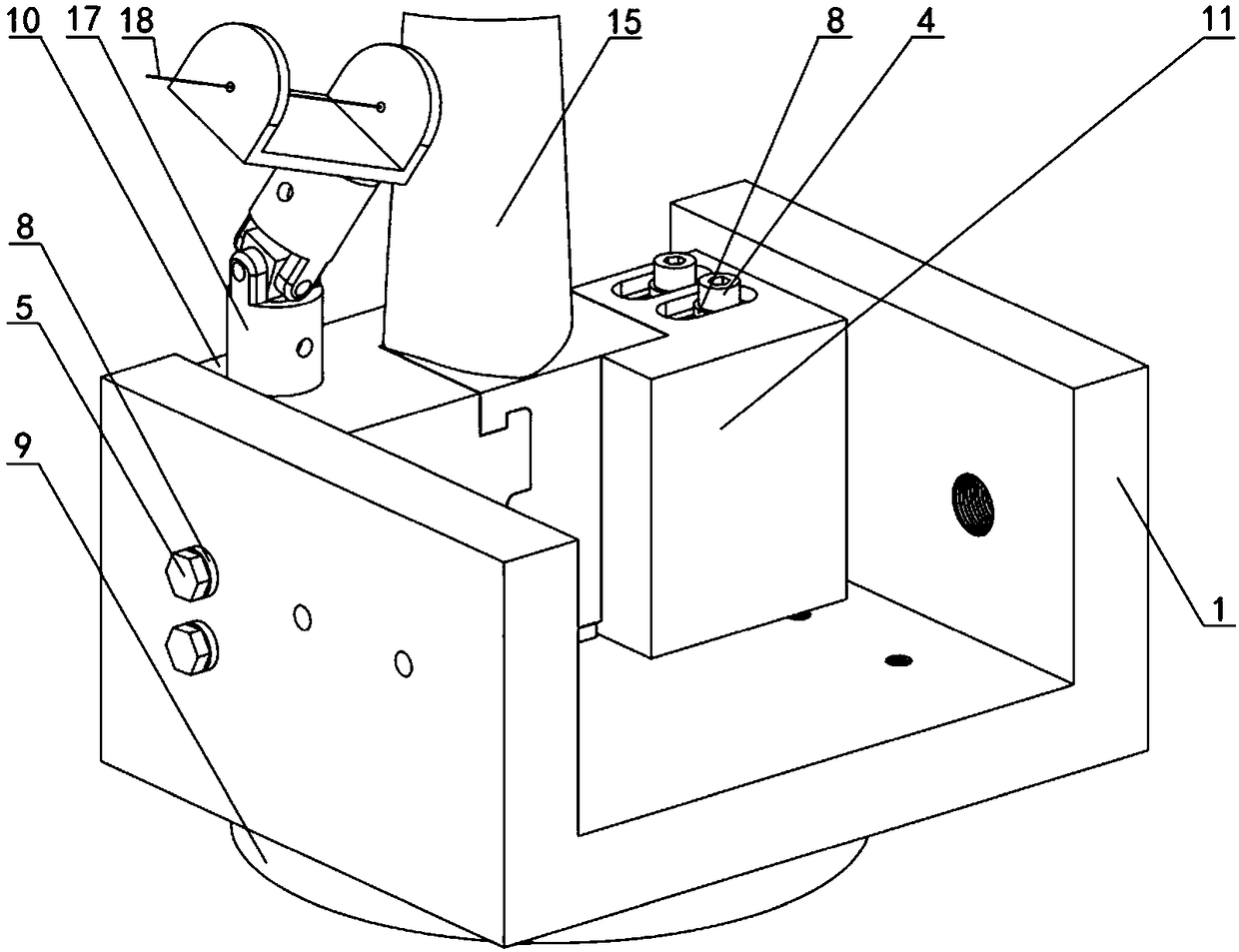

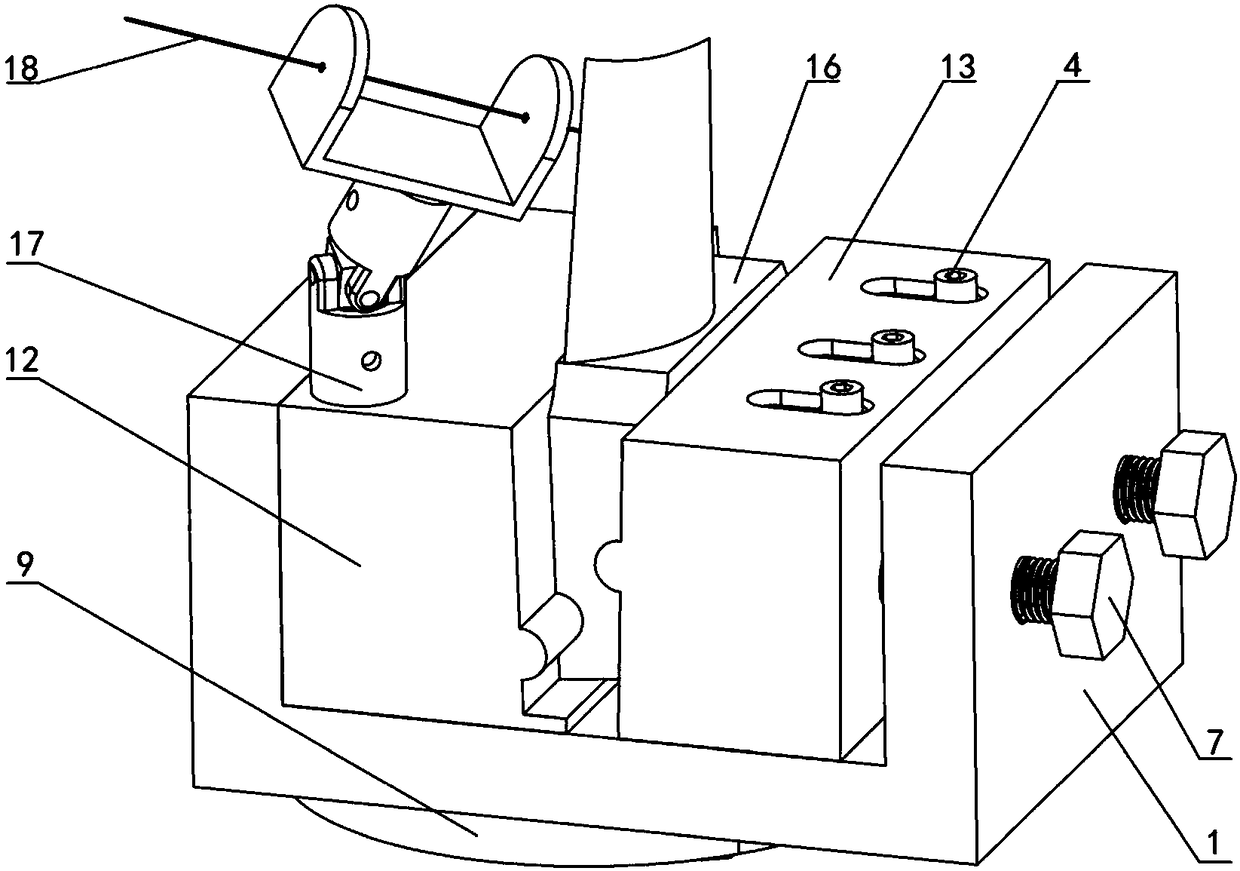

[0040] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

[0041] As shown in the figure, the present invention includes clamping body 1, left clamping body 2 for fir tree-shaped blade root, right clamping body 3 for fir tree-shaped blade root, hexagon socket bolt 4, screw clamping mechanism 7, connection Flange 9, left clamping body 10 for outsourcing shoulder double T-shaped blade root, right clamping body 11 for outsourcing shoulder double T-shaped blade root, left clamping body 12 for fork-shaped blade root, for The right folder 13 and the collimator 17 of the fork-shaped blade root.

[0042]Threaded holes are evenly distributed on the opposite sides of the clamping surfaces of the three left clamping bodies 2, 10, 12, and the hexagonal bolt 5 passes through the left wall of the clamping body 1 to clamp the left clamping body 1. An anti-loosening wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com