FRP template for building and manufacturing method thereof

A construction and formwork technology, which is applied in the on-site preparation of building components, construction, building construction, etc., can solve the problems of low reuse rate, difficult demoulding, and difficult assembly, etc. Convenient and easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

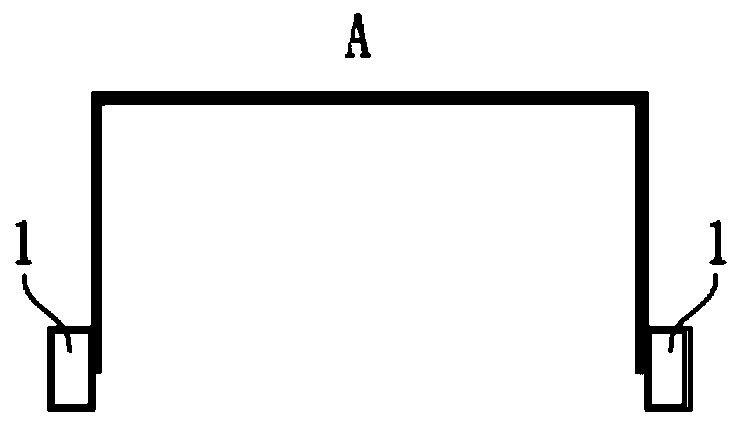

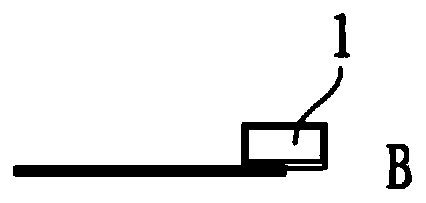

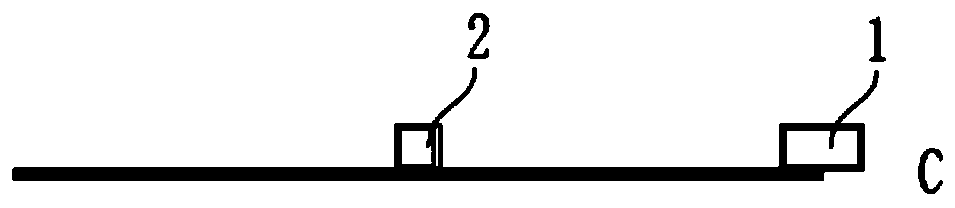

[0029] Such as Figure 1 to Figure 7 As shown, each FRP plate in this embodiment is 206*103*3 channel type FRP plate A, 100*3 flat FRP plate B, 300*3 flat FRP plate C, 400*3 flat FRP plate D , 600*3 flat FRP plate E, 100*100*3-angle FRP plate F, 103*103*3-angle FRP plate G, (units are mm).

[0030] in, figure 1 Shown is a channel-type FRP plate A, which is used to support the formwork of the entire wall thickness. The outside of any end of the notch is connected by pressing or thermosetting epoxy structural adhesive or hot-melt adhesive or mechanical connection. Any one or a combination of several fixes a 40×25×1.8 galvanized flat steel pipe 1. The 40×25×1.8 galvanized flat steel pipe is placed flat and stretched out halfway for connecting adjacent FRP flat plates. In this embodiment, the groove Profile type FRP flat plate A all fixes described galvanized flat steel pipe 1 at both ends.

[0031] Figure 2 to Figure 5 The flat FRP plates B, C, D, and E of different lengths ...

Embodiment 2

[0036] refer to Figure 9 , this embodiment illustrates a kind of FRP formwork for construction, wherein the FRP slabs are made of the same material as the FRP slabs used in Embodiment 1, but the formwork and specification selection are changed according to the construction needs.

[0037] It consists of 2 pieces of 206*103*3 channel type FRP panels A, 4 pieces of 100*3 flat FRP panels B, 2 pieces of 400*3 flat FRP panels D, 4 pieces of 600*3 flat FRP panels E, 2 A 100*100*3-angle FRP flat panel F, two 103*103*3-corner FRP flat panels G, are made by splicing support molds such as Figure 9 FRP formwork (for walls) for construction shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com