Co-extrusion mould capable of replacing identification strip online

A technology for identifying strips and dies, which is applied in the field of plastic processing, can solve the problems of increased production costs of silicon core tubes, increased labor intensity of employees, waste of labor and energy consumption, etc., to save labor and power consumption, reduce labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

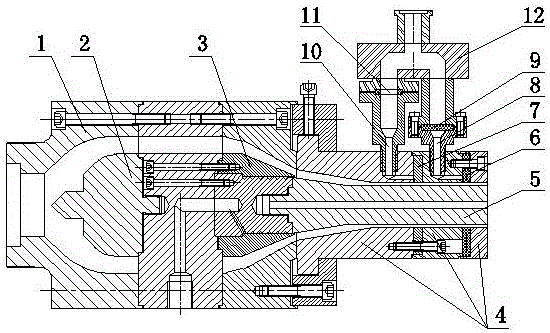

[0010] The co-extrusion mold with on-line replaceable identification bar consists of a pipe head body 1, a shunt shuttle 2, an inner mold 3, a die assembly 4, a mandrel 5, an identification bar rib plate a6, an identification bar rib plate b7, a connecting nozzle a8, The stop valve a9, the connecting nozzle b10, the stop valve b11 and the identification strip head body 12 are composed of a die assembly 4 fixedly connected to the right end of the pipe head body 1, and inside the cavity of the pipe head body 1 Shuttle shuttle 2 and inner mold 3 are installed sequentially from left to right, a core mold 5 is fixedly connected to the right end of inner mold 3, and the outer end of core mold 5 is placed in die assembly 4; said die assembly 4 There are two identification ribs a6 and identification ribs b7 of different types embedded in it; the upper part of the die assembly 4 is equipped with a connecting nozzle a8 and a connecting nozzle b10, and the connecting nozzle a8 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com