Upper cover mould

A mold and body technology, applied in the field of the upper cover mold, can solve the problems of affecting the mold maintenance speed, poor cooling effect, troublesome mold removal, etc., and achieve the effect of facilitating the mold removal operation, ensuring the cooling effect, and speeding up the work speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

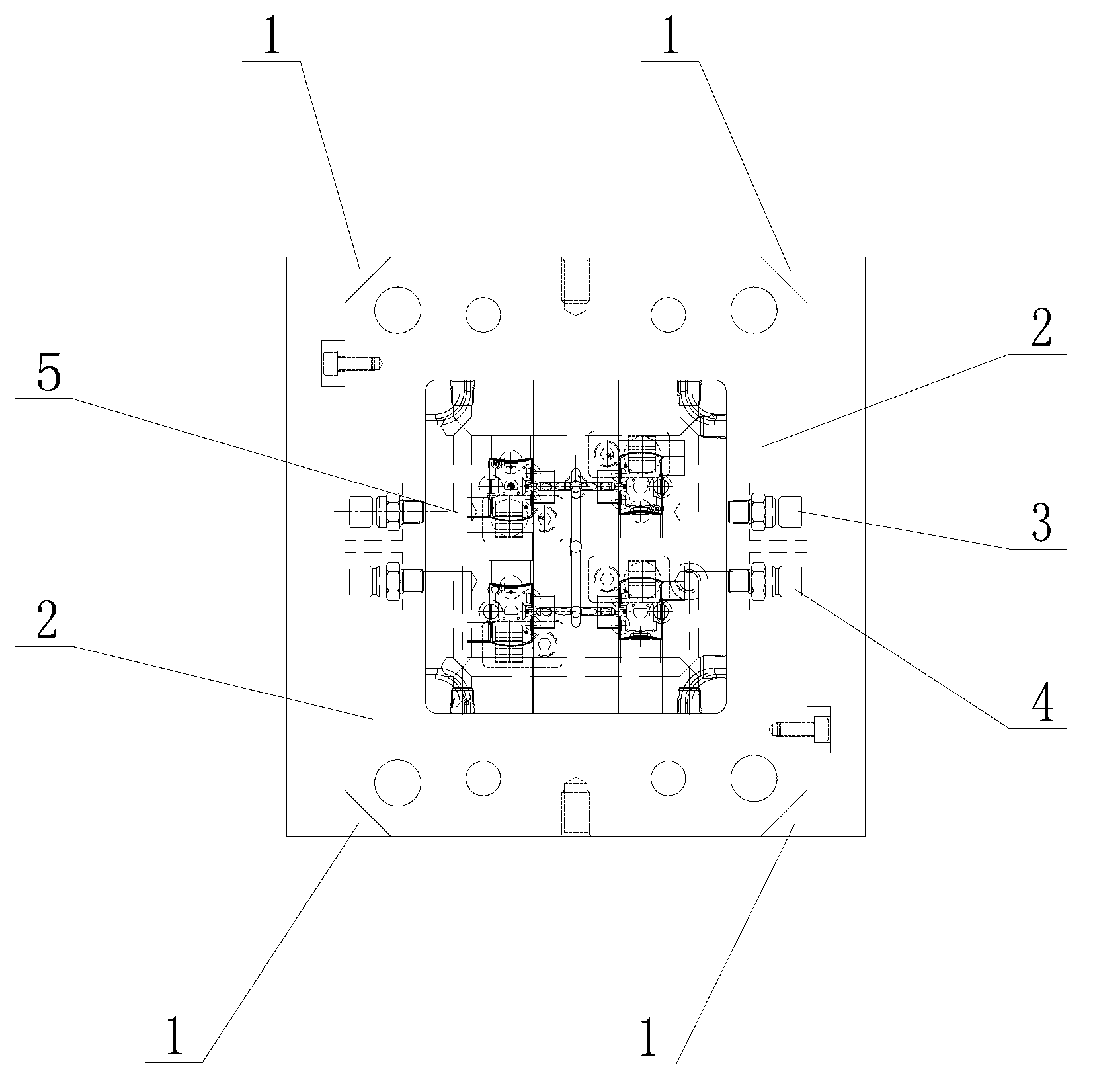

[0017] Such as figure 1 As shown, a mold for the upper cover includes a mold body 2, several demoulding devices are arranged on the same side of the mold body 2, and several water cooling devices are arranged in the mold body 2.

[0018] In this embodiment, the water cooling device includes a water inlet 3 and a water outlet 4 arranged on the mold body 2 , and a cooling pipeline 5 is arranged between the water inlet 3 and the water outlet 4 .

[0019] In actual use, there are four water cooling devices in total, which are evenly distributed in the mold body, so as to ensure the maximum cooling effect.

[0020] In this embodiment, the demoulding device is a pick 1 designed on the outer surface of the mold body. The prying piece 1 is in the shape of an equilateral right triangle, wherein the right angle corresponds to the right angle of the mold body.

[0021] The four corners of the mold body are provided with pryers, which are in the shape of an equilateral right triangle, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com