Hollow floor construction method using opening composite core mold

A technology of hollow floor and construction method, which is applied in the direction of floors, building components, buildings, etc., can solve the problems of difficult high-rise or super-high-rise transportation, cavity self-heavy, self-heavy, etc., to shorten the construction period, reduce construction difficulty, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the invention.

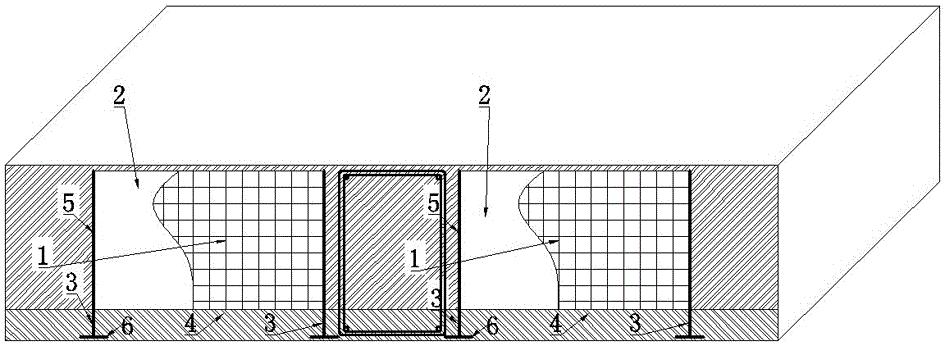

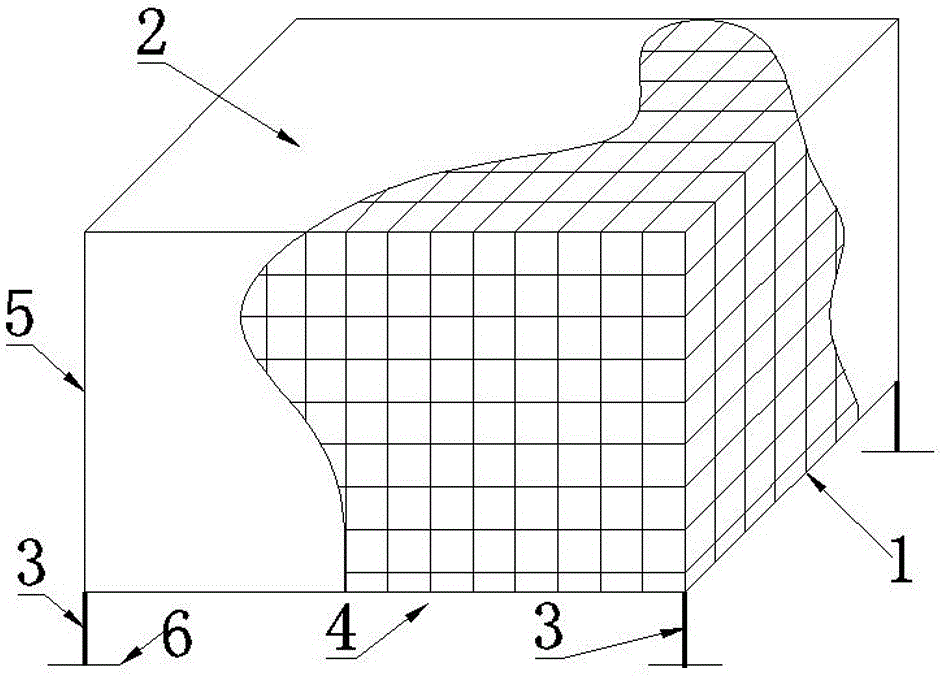

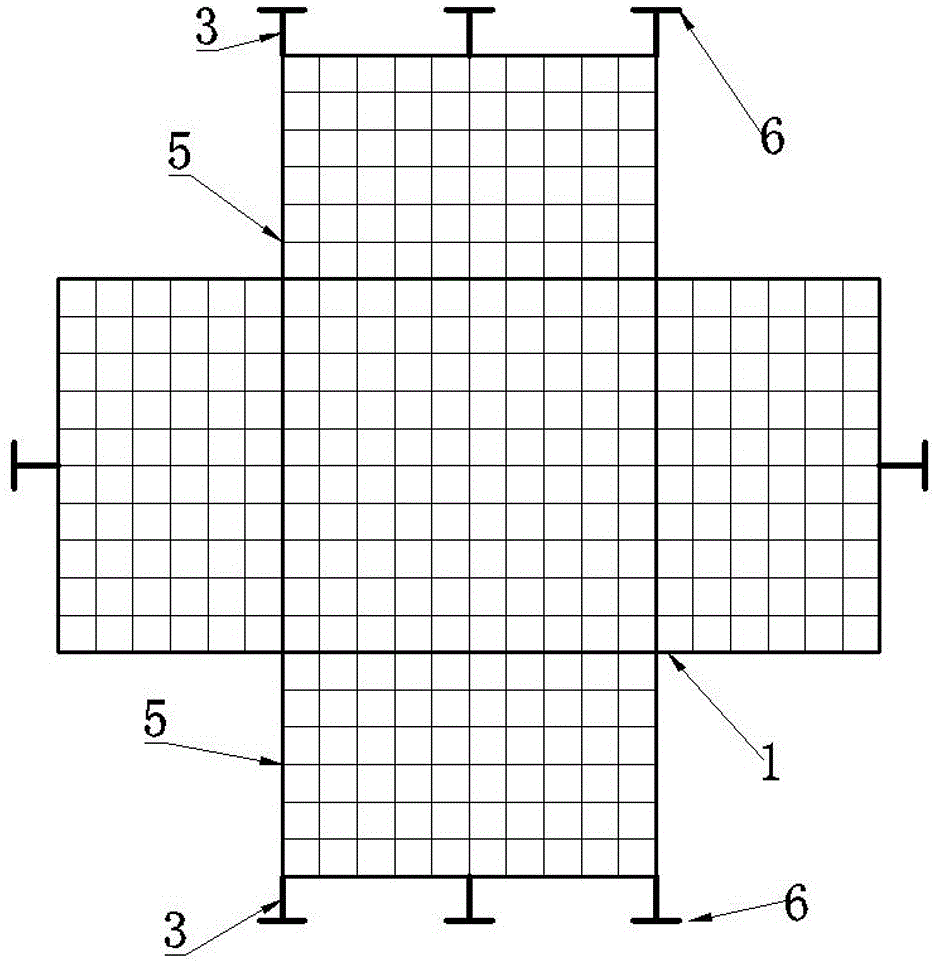

[0033] Such as figure 1 and figure 2 The embodiment shown is an open composite mandrel. The composite mandrel is composed of a grid-like skeleton 1, a surface layer 2 and four foot supports 3. The surface layer 2 and the skeleton 1 together form a geometric body, which is hollow. And there is an opening 4 at the bottom, and the foot support 3 is located on the lower side of the opening 4 and exposed outside the surface layer 2 . The concrete steps of this method are as follows:

[0034] a. formwork, according to the design requirements, the formwork is set at the bottom of the concealed ribbed floor or only at the bottom of the rib;

[0035] b. Line setting, used to precisely position ribs by drawing lines on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com