Mould structure for precast concrete column

A technology of prefabricated concrete and concrete columns, which is applied in the direction of molds, columns, pier columns, etc., can solve the problems of single purpose of concrete prefabricated parts and single structure of concrete prefabricated parts, and achieve the effect of fast and convenient assembly, saving materials and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

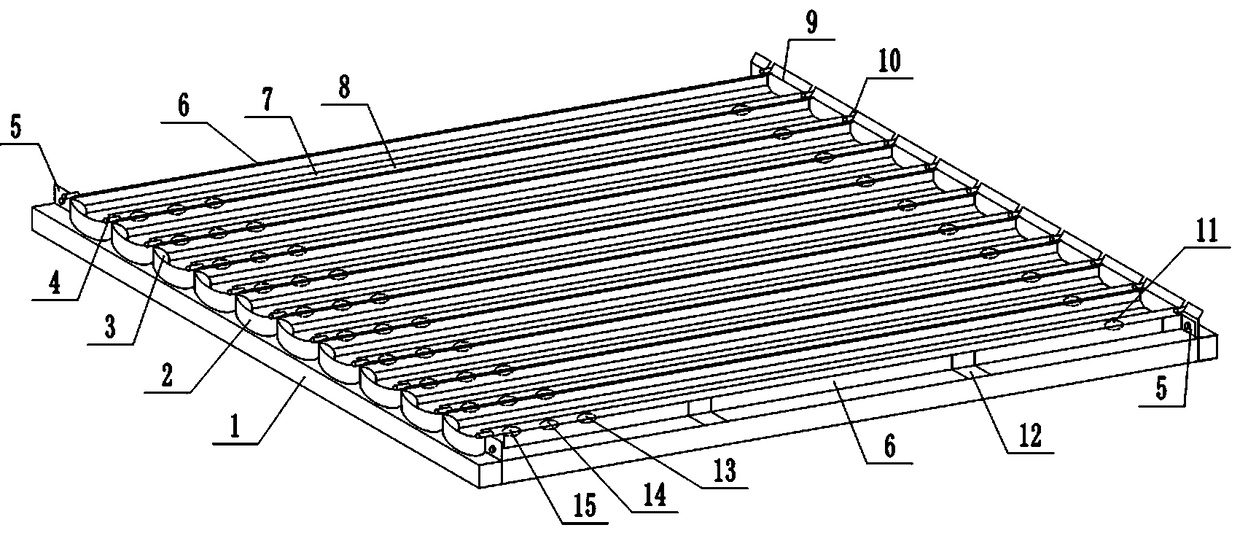

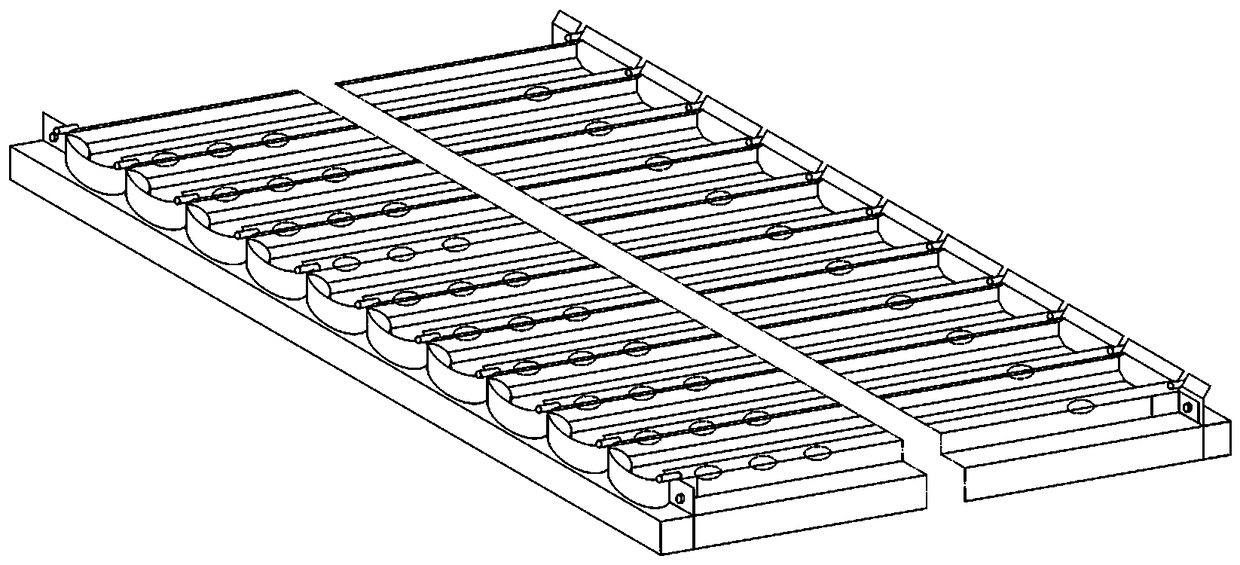

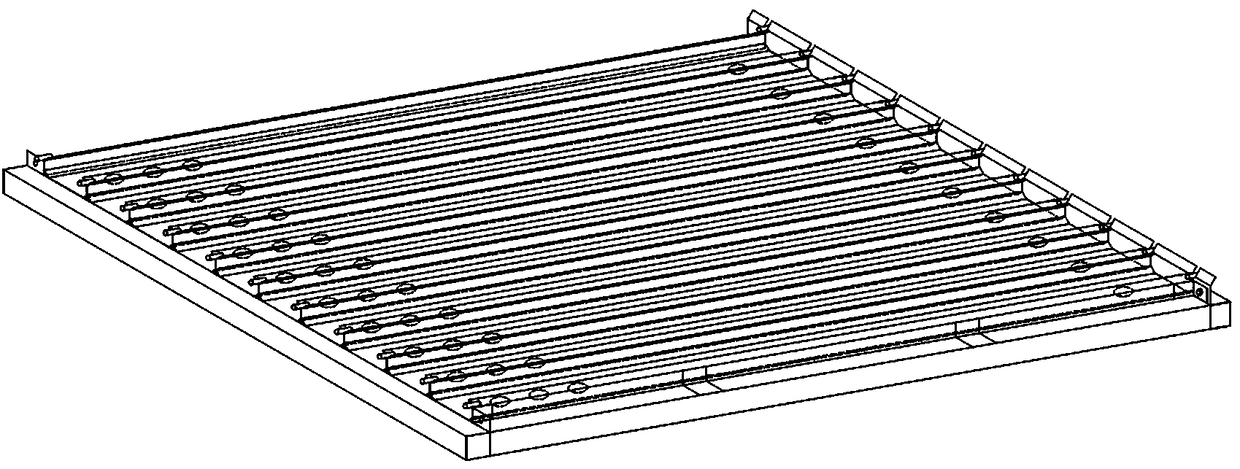

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] Such as Figures 1 to 10 As shown, a mold structure for prefabricated concrete columns includes a support frame 1, a top formwork 2, a side formwork 6, a bottom formwork 7, a middle formwork 8 and a bottom formwork 9; the support frame 1 is arranged side by side Bottom formwork 7, middle formwork 8 is installed between described bottom formwork 7, and the bottom formwork 7 that is positioned at support frame 1 both side edges installs side formwork 6, and top formwork 2 and bottom formwork 9 are respectively installed at both ends; The concrete column poured through the mold structure is suitable for column support, such as being used in orchards, vegetable gardens or temporary places to build canopies or awnings as column support.

[0044]The upper section of the side formwork 6 is bent at a bending angle of 30° to 60°. After bending, the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com