Gas-liquid parallel current guide floating valve

A float valve and gas-liquid technology, applied in the field of guided float valves, can solve the problems of incomplete elimination of reverse airflow against airflow, unsatisfactory energy consumption and mass transfer efficiency, increased energy consumption, etc., to achieve increased specific surface area, increased gas Opportunities for liquid contact and reduction in operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

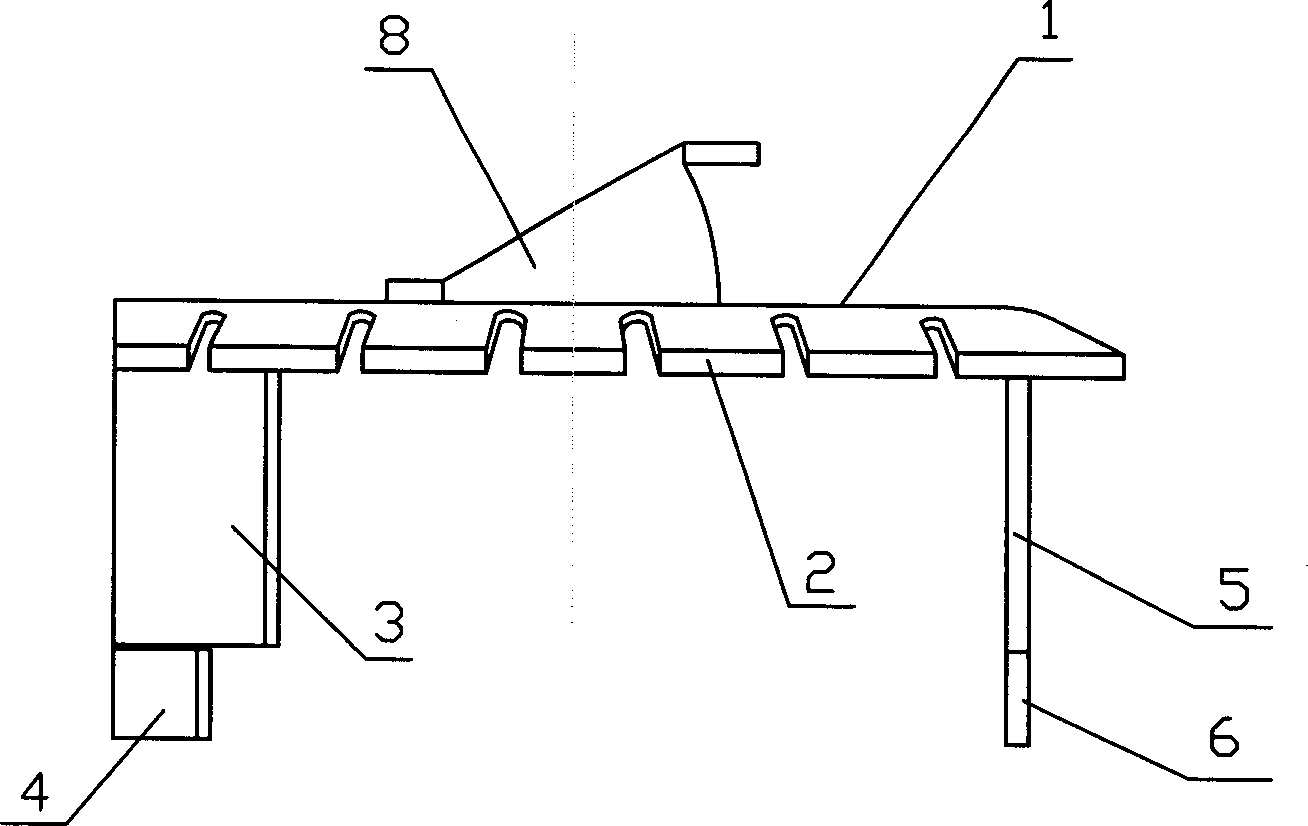

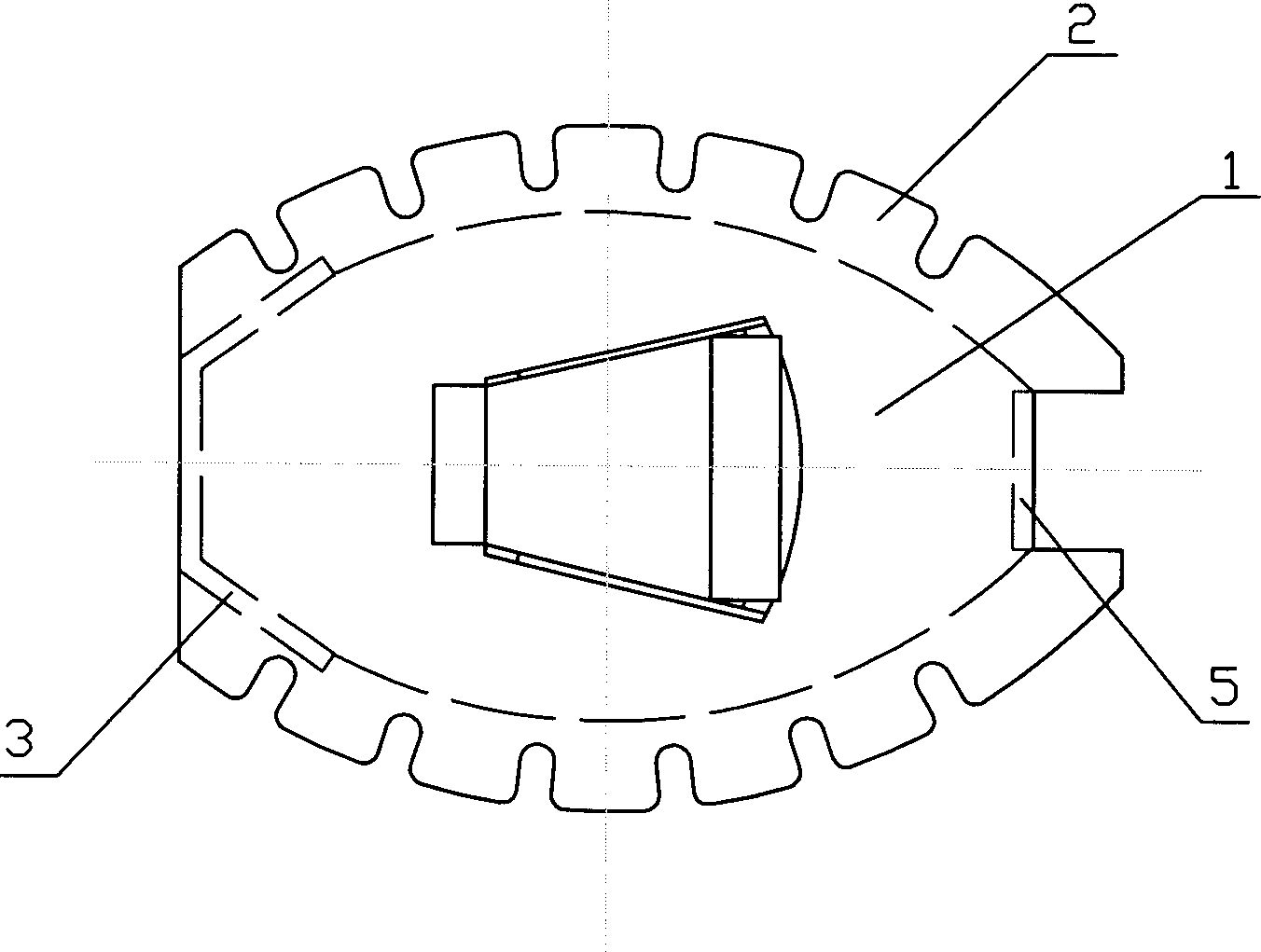

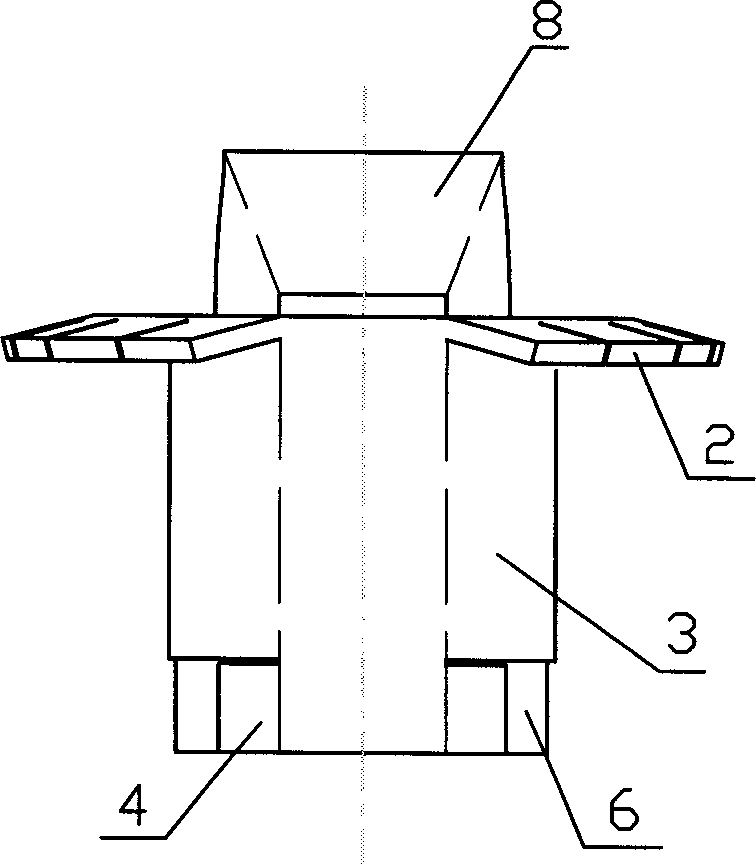

[0036] see Figure 1~4 , 9. The float valve has an elliptical bonnet 1, on both sides of the short axis of the bonnet there are flower-toothed guide pieces 2 bent and pressed down, and on one end of the long axis of the bonnet is provided with a vertical downward bend The liquid-receiving plate 3, the liquid-receiving baffle in this example is made in this way: the small arc surface at one end of the long axis of the elliptical bonnet is bent vertically downward, and a rectangular vertical plate is below the bending line, and the folded Cut a section symmetrically on both sides of the bending line, and then bend the vertical plate of the cut part toward the valve cover to form a trapezoidal liquid-receiving plate with a small front and a large rear. Avoid edges and corners as much as possible to reduce the resistance to the liquid; there is a valve stirrup 4 at the lower end of the liquid-receiving plate 3, before the valve body is installed, the valve stirrup bends toward the...

Embodiment 2

[0040] see Figures 13 to 16 In this example, a grid bar 2' bent vertically downwards is added between the petals of the tooth-shaped guide piece 2, the grid bar is formed by retaining the spacer between the petals and then vertically bent, and the grid bar can be The gas rushing out from both sides of the valve body is cut to refine the bubbles and further improve the mass transfer efficiency. In addition, this example presents a structure in which the center of gravity of the small float valve 8 shifts toward the direction of the liquid-receiving plate, so as to realize the gradual opening function of the main float valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com