Patents

Literature

38results about How to "Reduce banding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

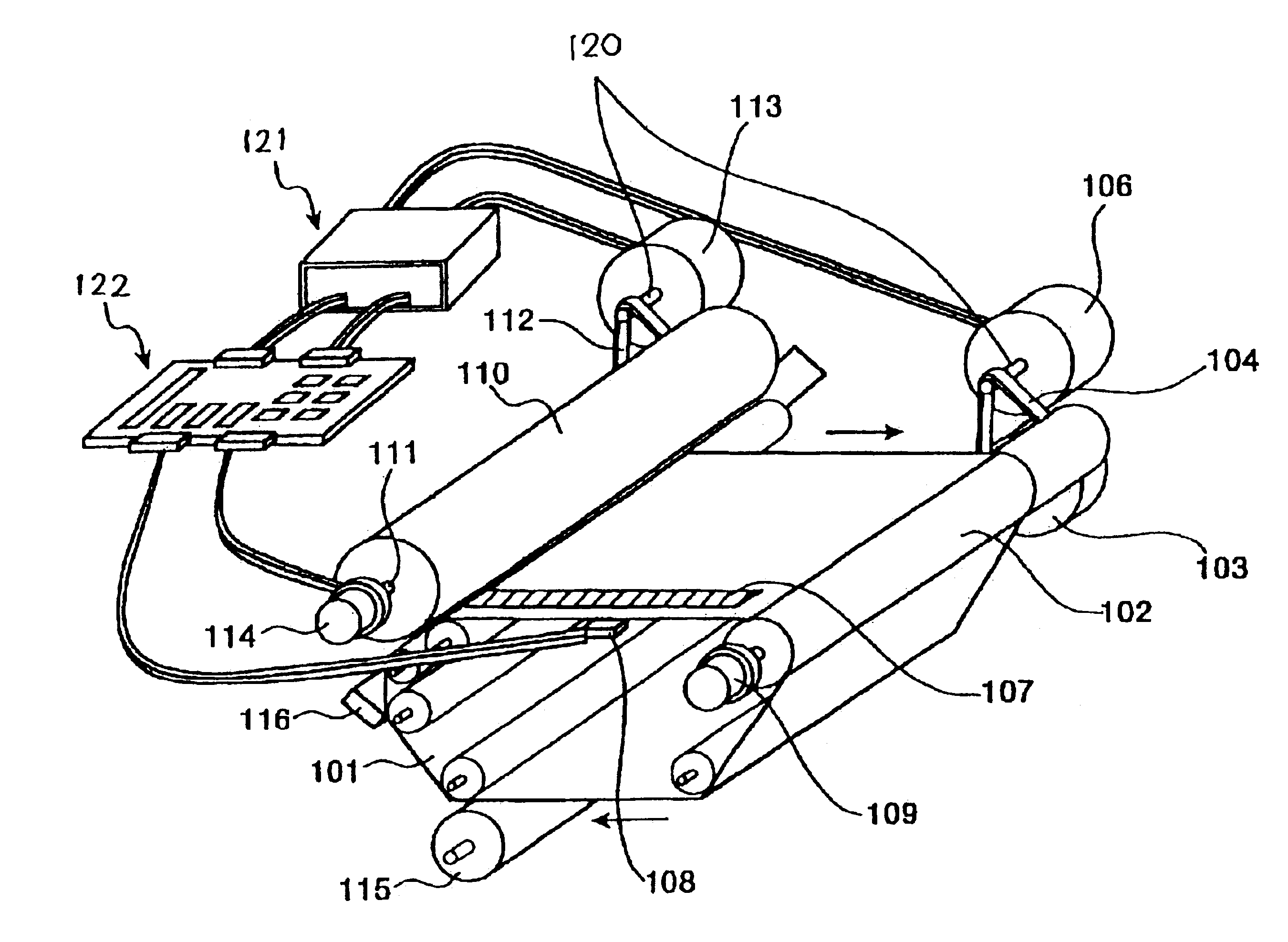

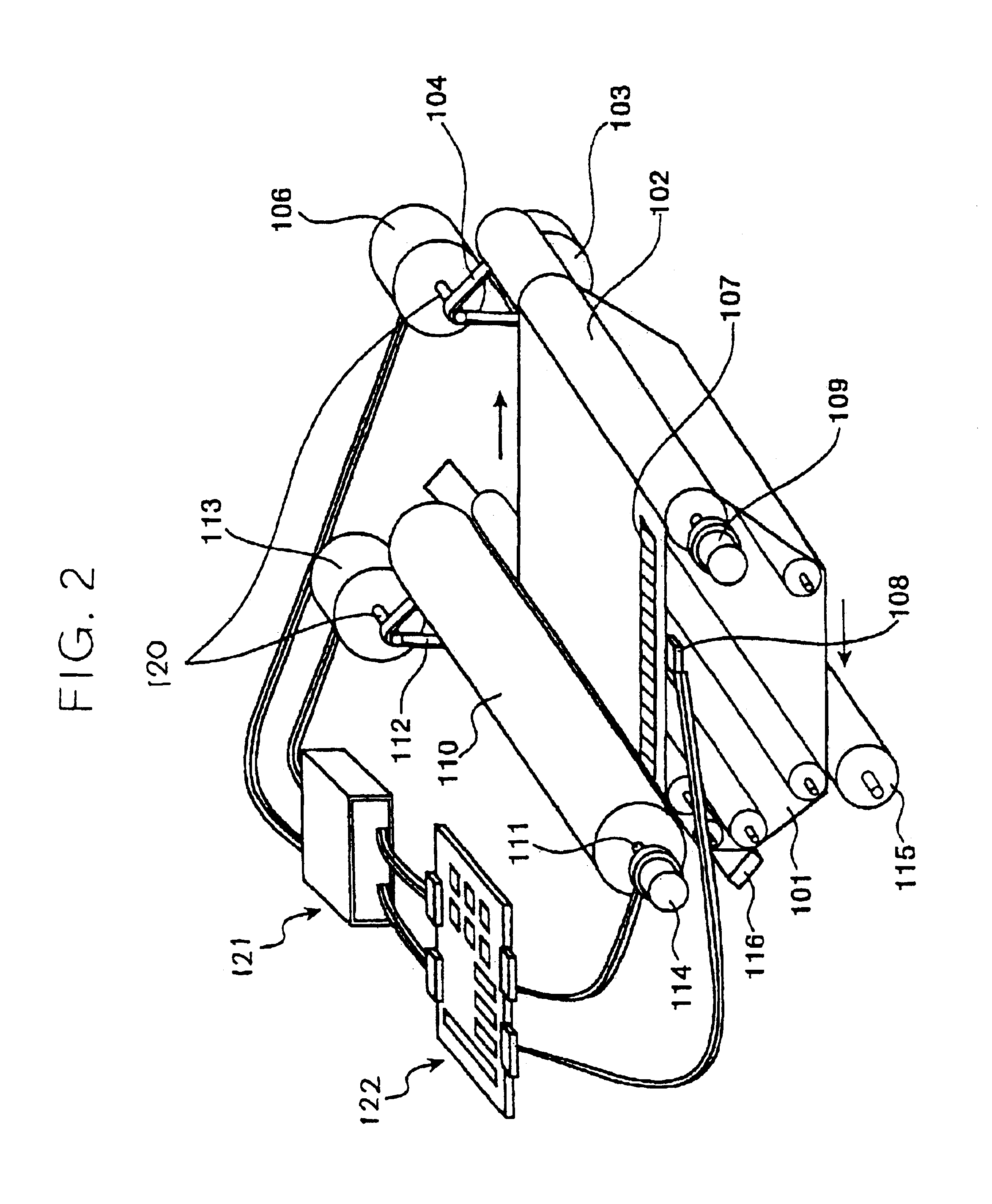

Belt moving device and image forming apparatus including the same

InactiveUS6925279B2Highly accurate position controlReduce bandingElectrographic process apparatusInformation controlDrive shaft

A belt moving device of the present invention includes a drive shaft for moving the belt and a drive transfer line for transferring the output torque of a motor to the drive shaft. A marker sensor senses a marker positioned on the belt to thereby determine the position of the belt in the direction of movement. A rotation condition sensor senses the rotation condition of the drive shaft. A first correction information generating circuit generates, based on the output of the marker sensor, correction information for correcting the position of the belt. A second correction information generating circuit generates, based on the output of the rotation condition sensor, correction information for correcting the rotation condition of the drive shaft. A controller controls the movement of the motor in accordance with the correction information output from the first and second correction information generating circuits.

Owner:RICOH KK

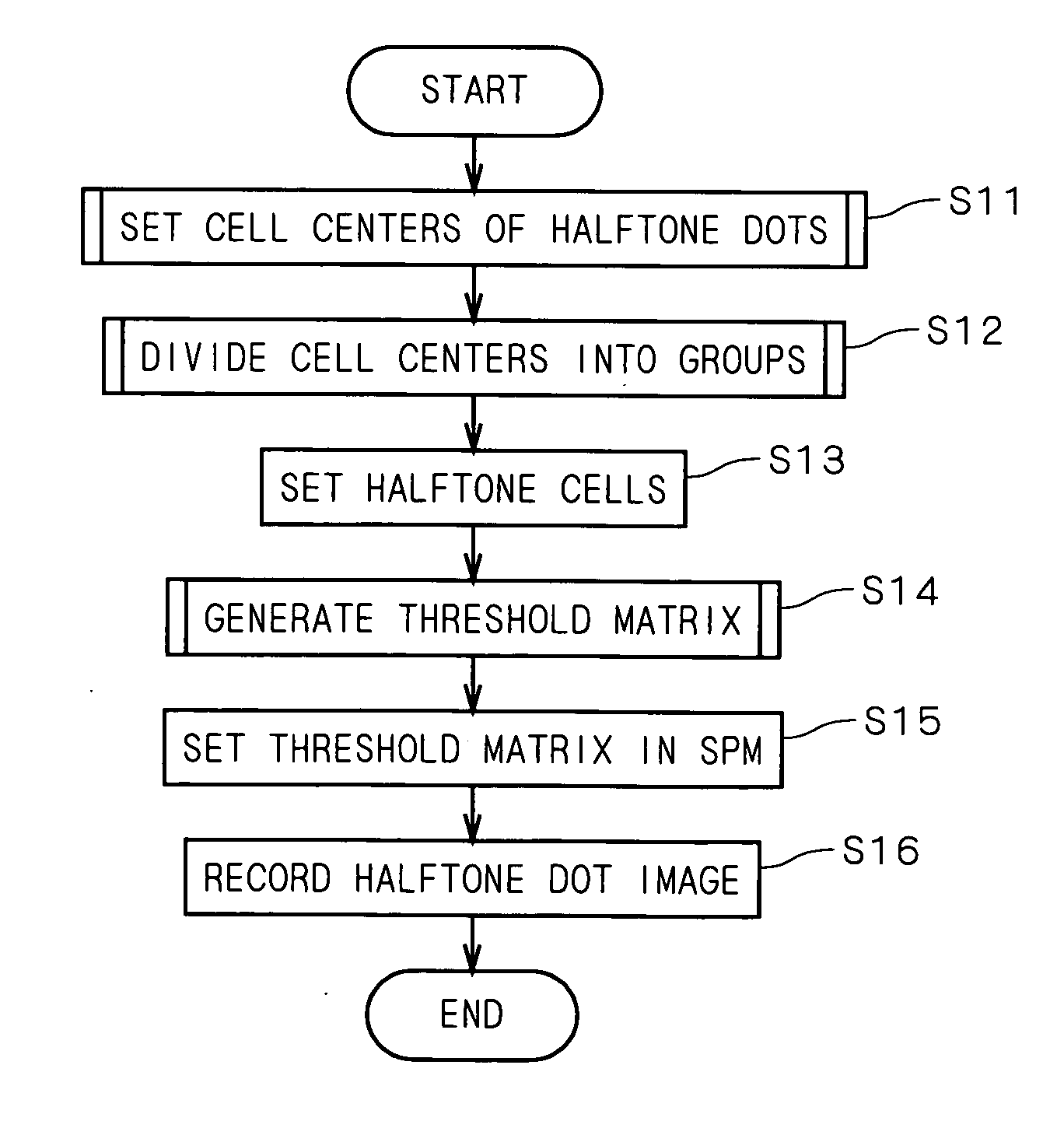

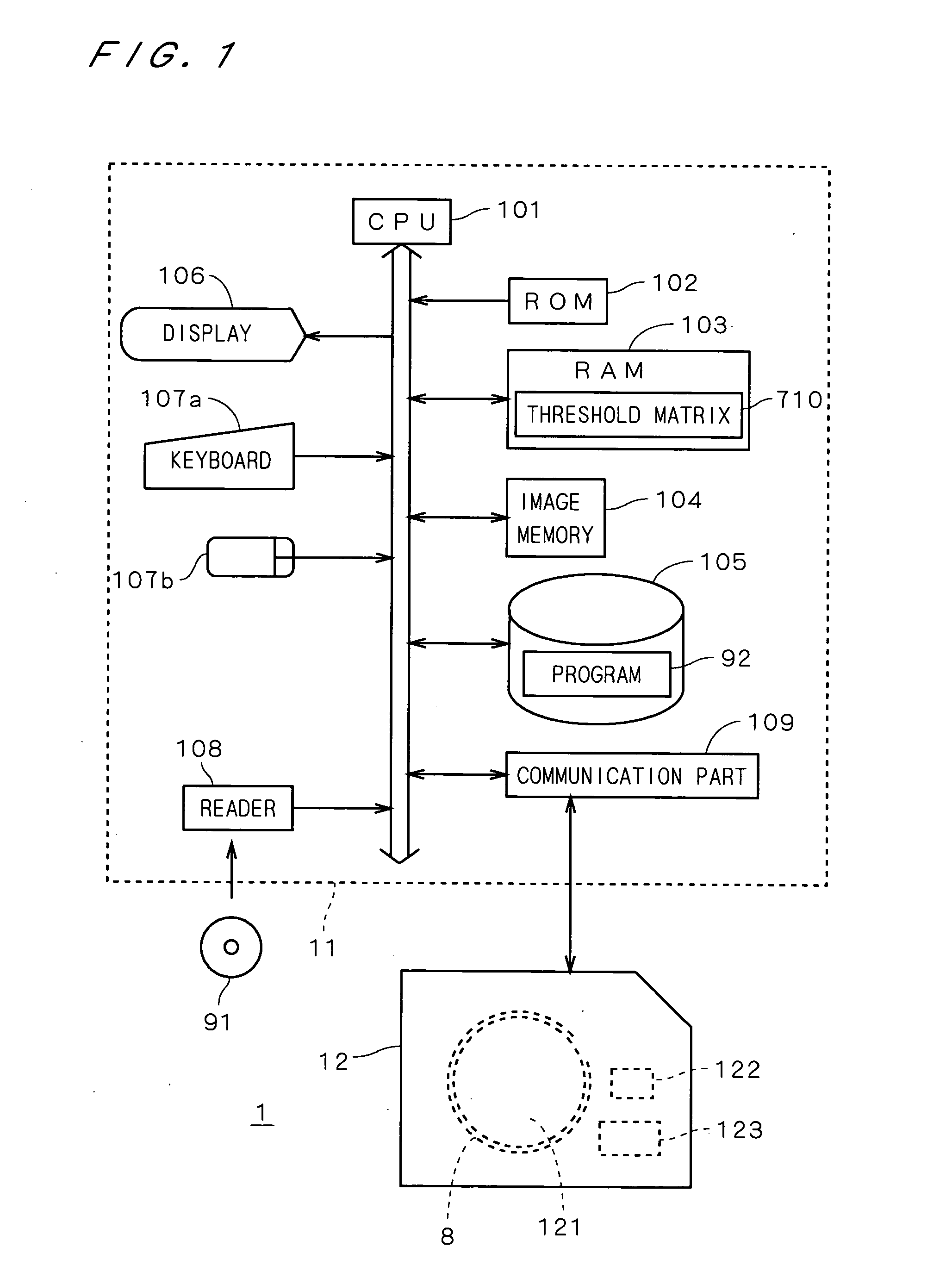

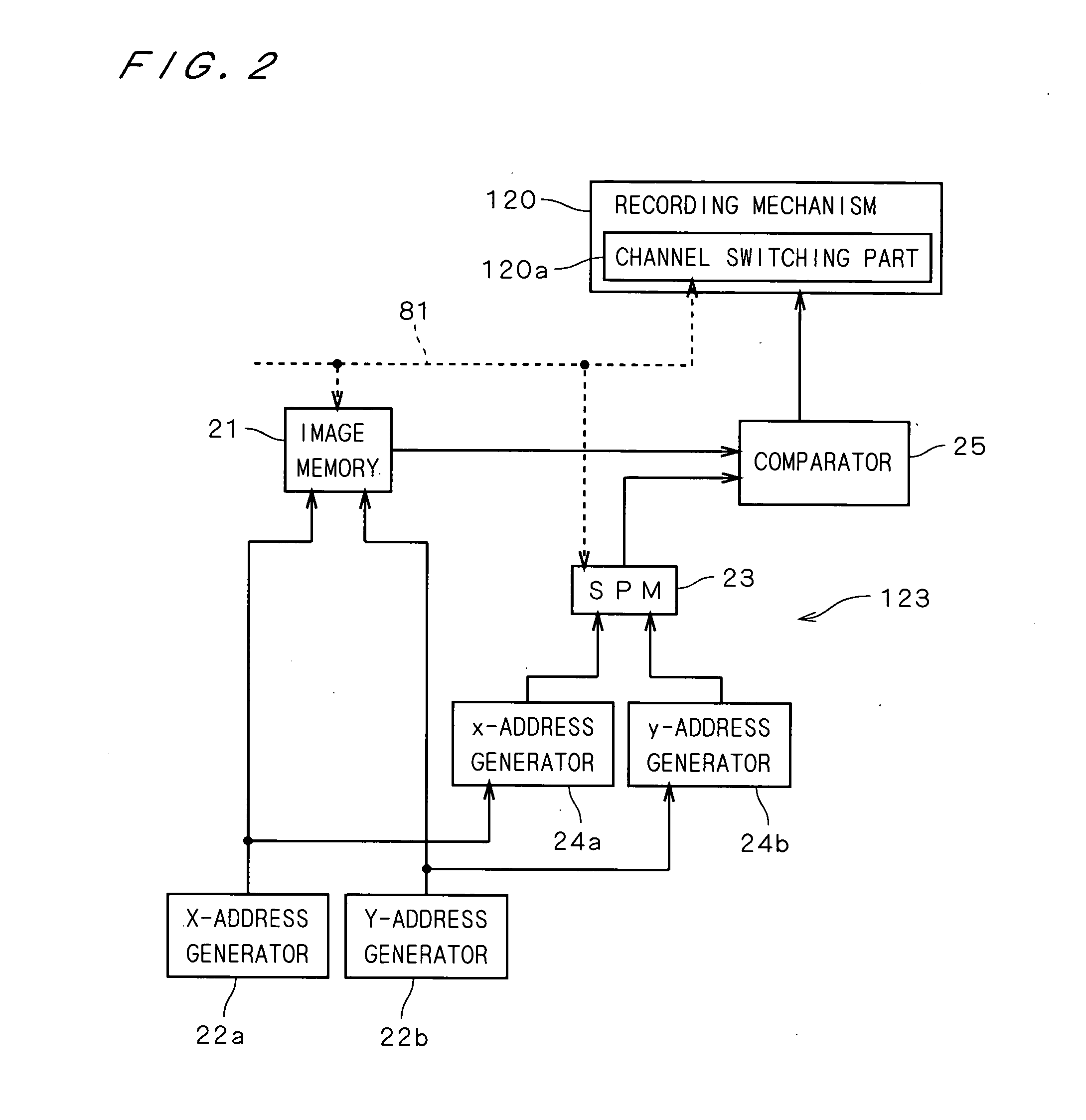

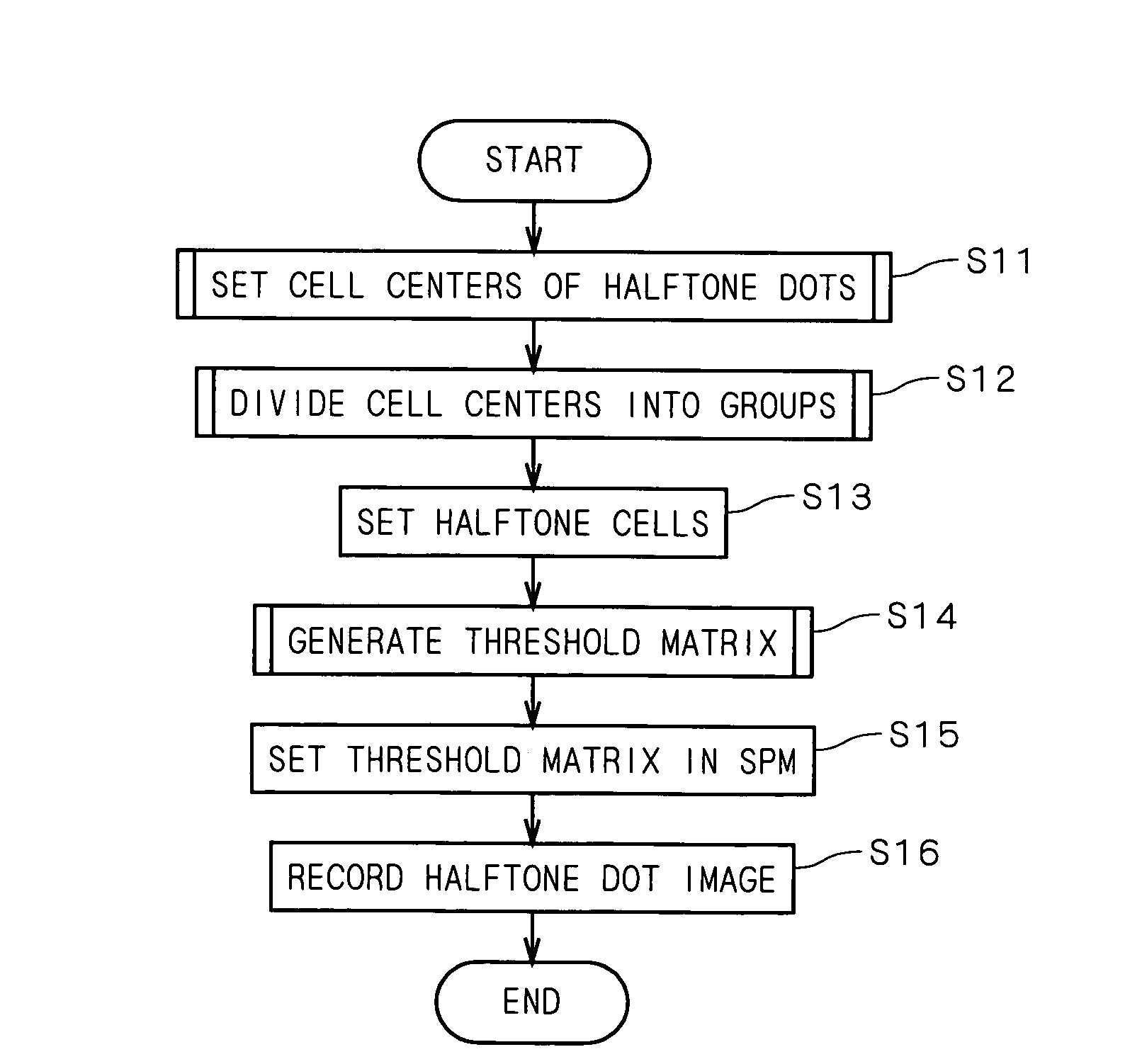

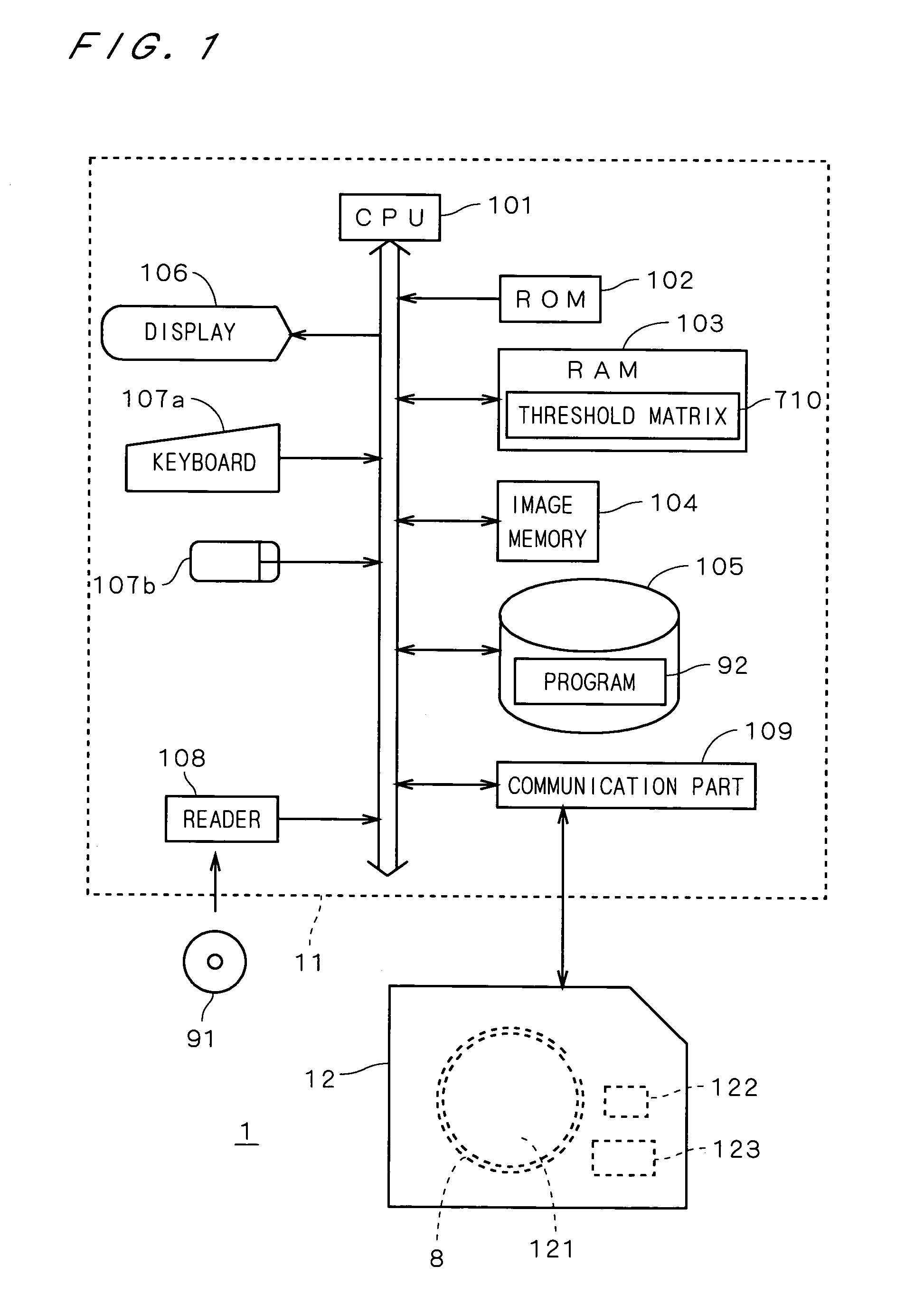

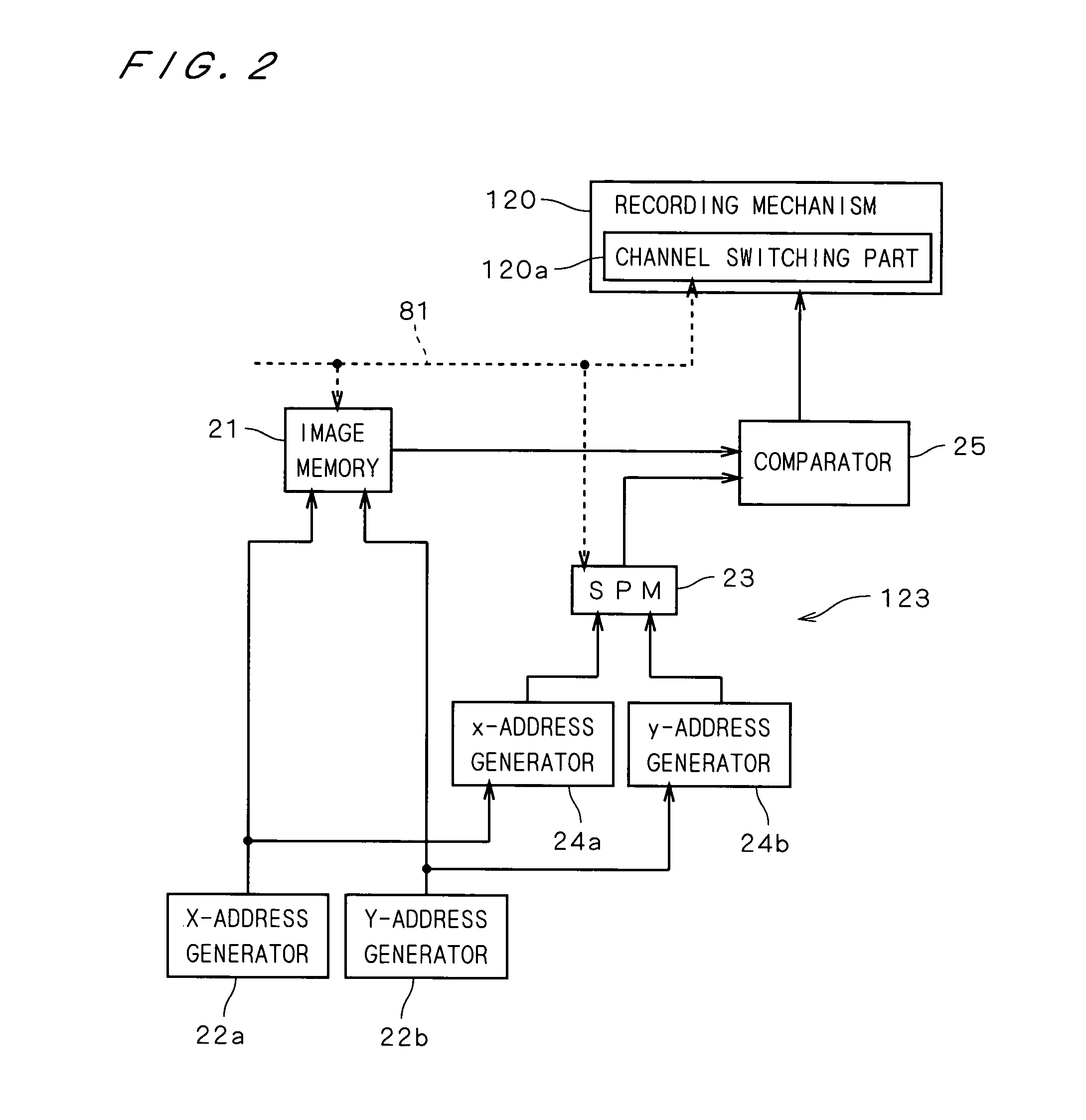

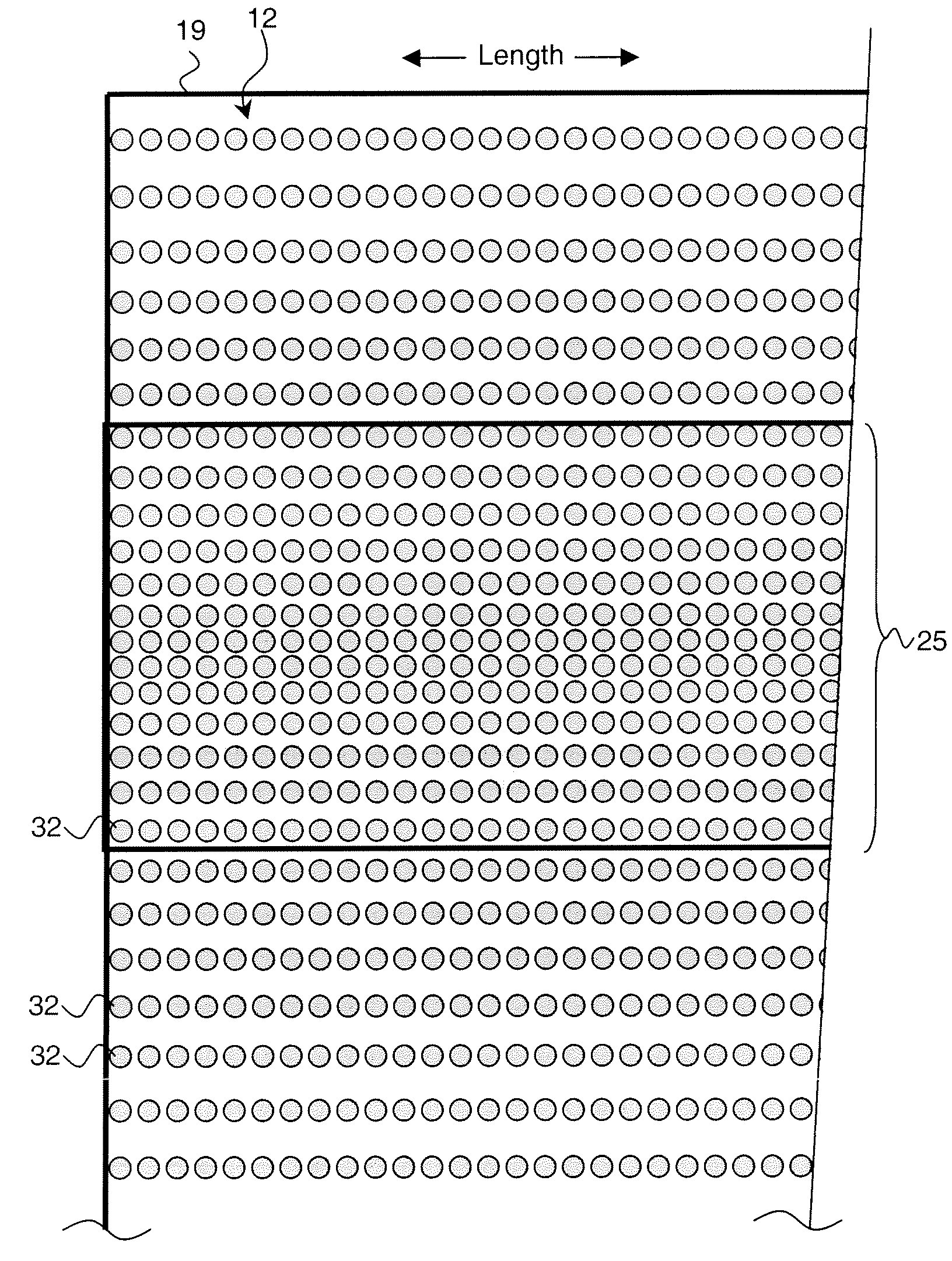

Halftone dot formation method, halftone dot formation apparatus, threshold matrix generation method used therefor and halftone dot recording medium

Halftone cells each serving as a unit for formation of a dot are arranged in irregular shapes at random and divided into two groups. The halftone cells (720) in the first group are fewer than the halftone cells (730) in the second group and dispersed, and the area of each of the halftone cells (720) in the first group is set larger than that in the second group. The dot growth speed of the halftone cells (720) in the first group is higher than that of the halftone cells (730) in the second group. This allows formation of fine halftone dots consisting of the halftone cells in the first and second groups, and it is possible to reduce banding appearing in a main scan direction during recording of the halftone dots, with low-frequency components in spatial frequency of the halftone dots caused by the halftone cells (720) in the first group.

Owner:DAINIPPON SCREEN MTG CO LTD

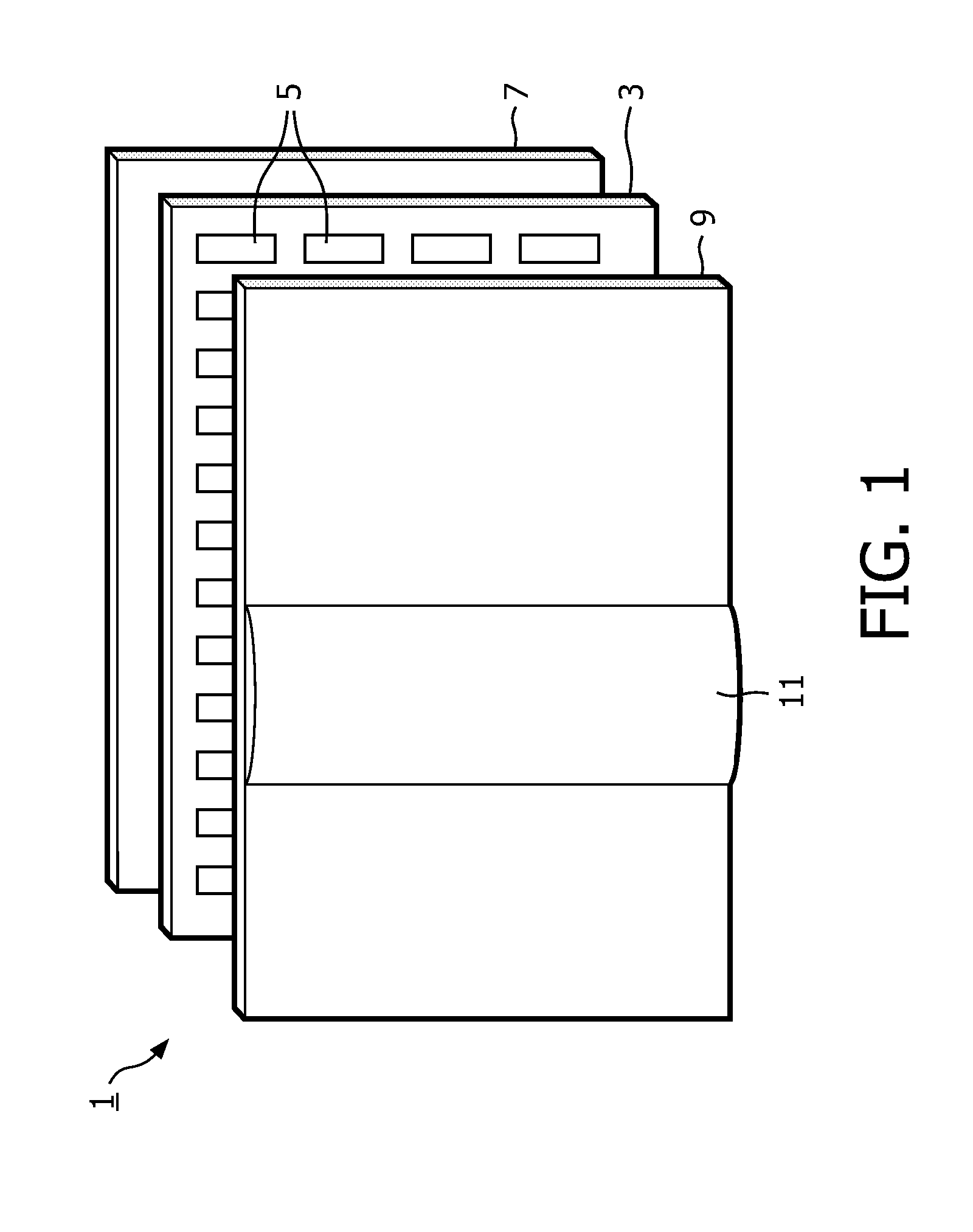

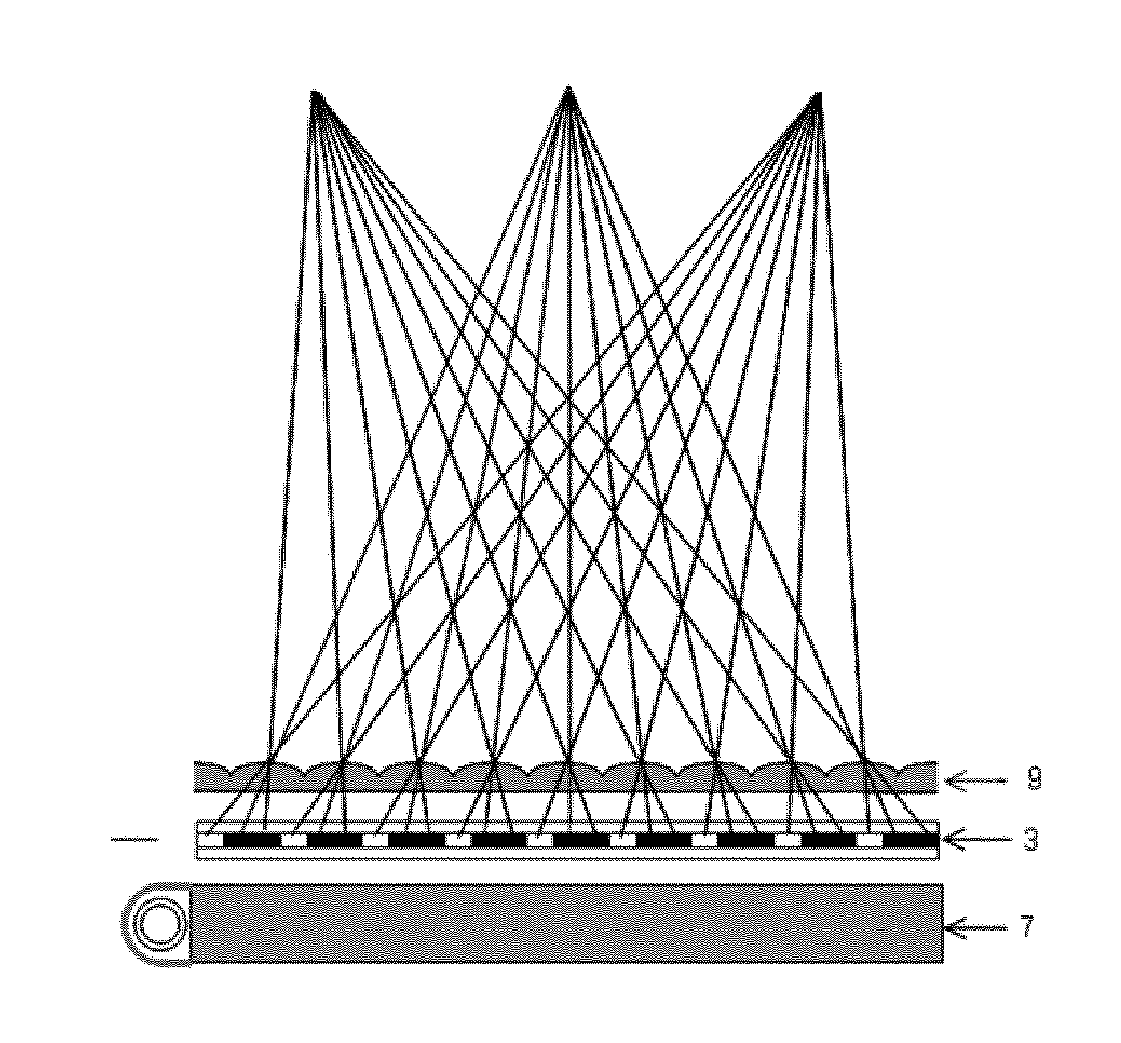

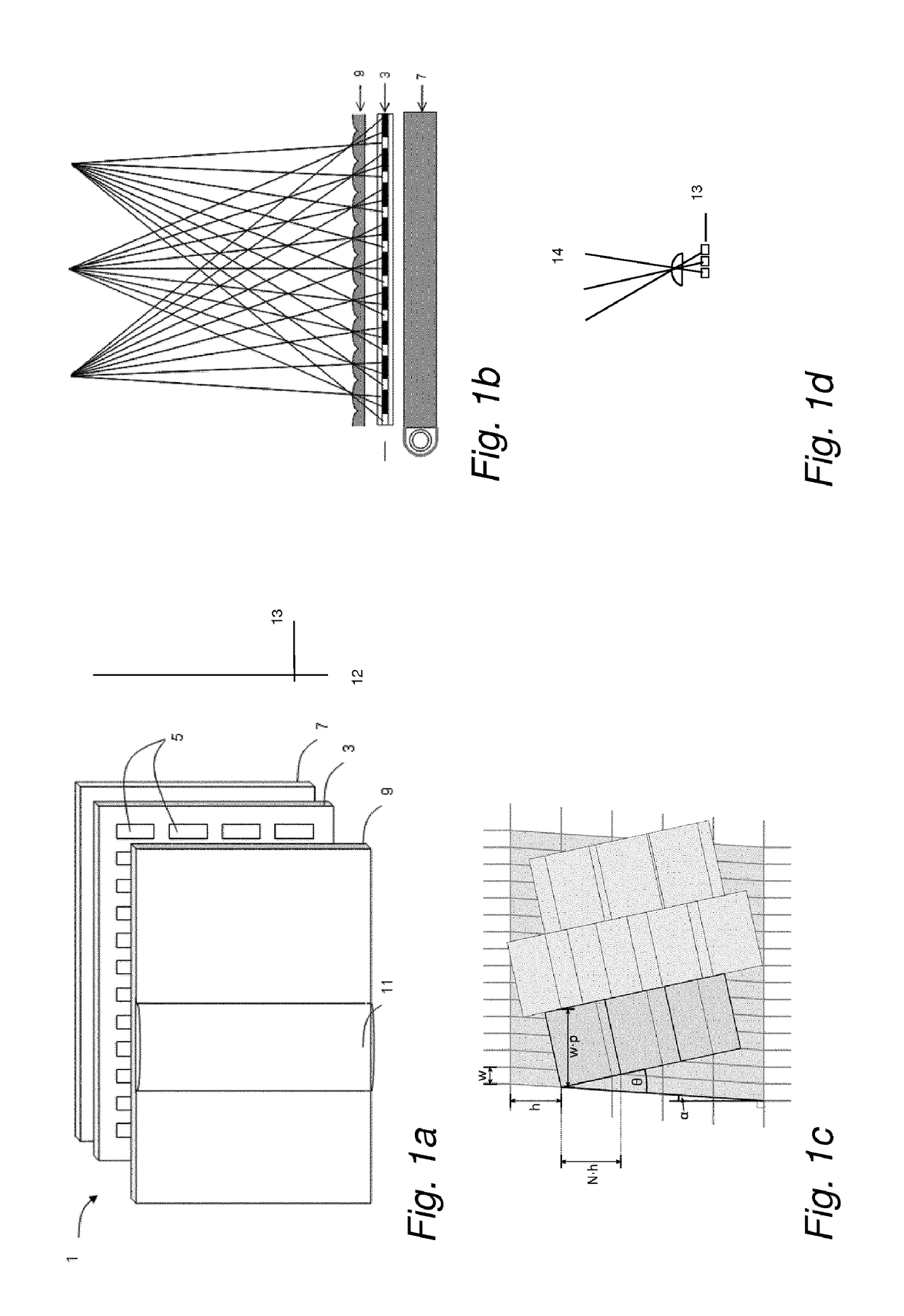

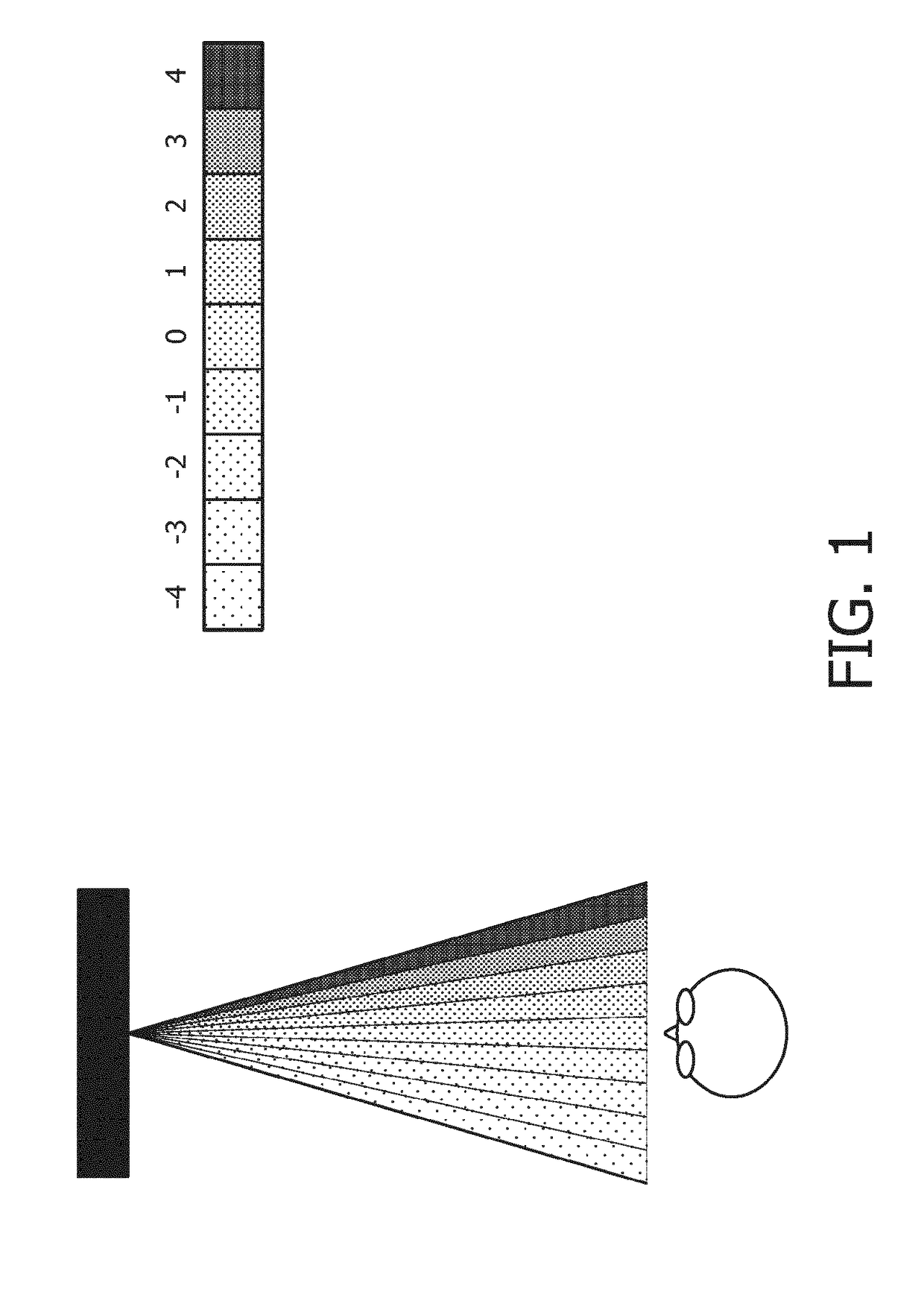

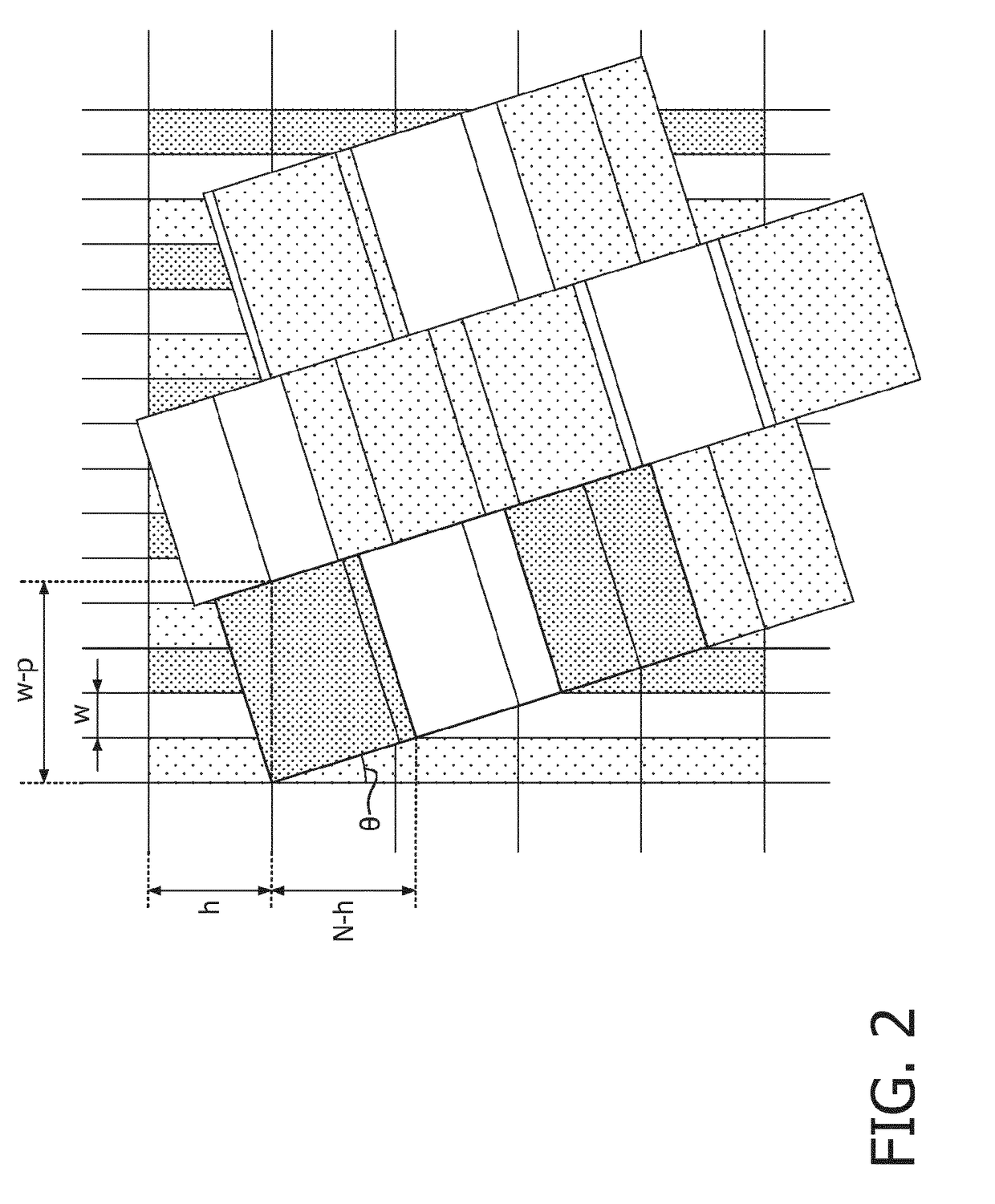

Multi-view autostereoscopic display device

InactiveUS20120092339A1Increase output resolutionReduce bandingSteroscopic systems3D-image renderingImage resolutionComputer graphics (images)

An autostereoscopic display device comprises a display panel (3) having an array of display pixel elements (5) for producing a display, the display pixel elements being arranged in rows and columns. An imaging arrangement (9) directs the output from different pixel elements to different spatial positions to enable a stereoscopic image to be viewed. The imaging arrangement comprises first and second polarization-sensitive lenticular arrays (50,52), wherein the light incident on the imaging arrangement is controllable to have one of two possible polarizations, and wherein each of the two possible polarizations gives a different 3D mode. These multiple modes can be used to increase the resolution, or increasing the number of views, or provide additional functionality to the display device.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

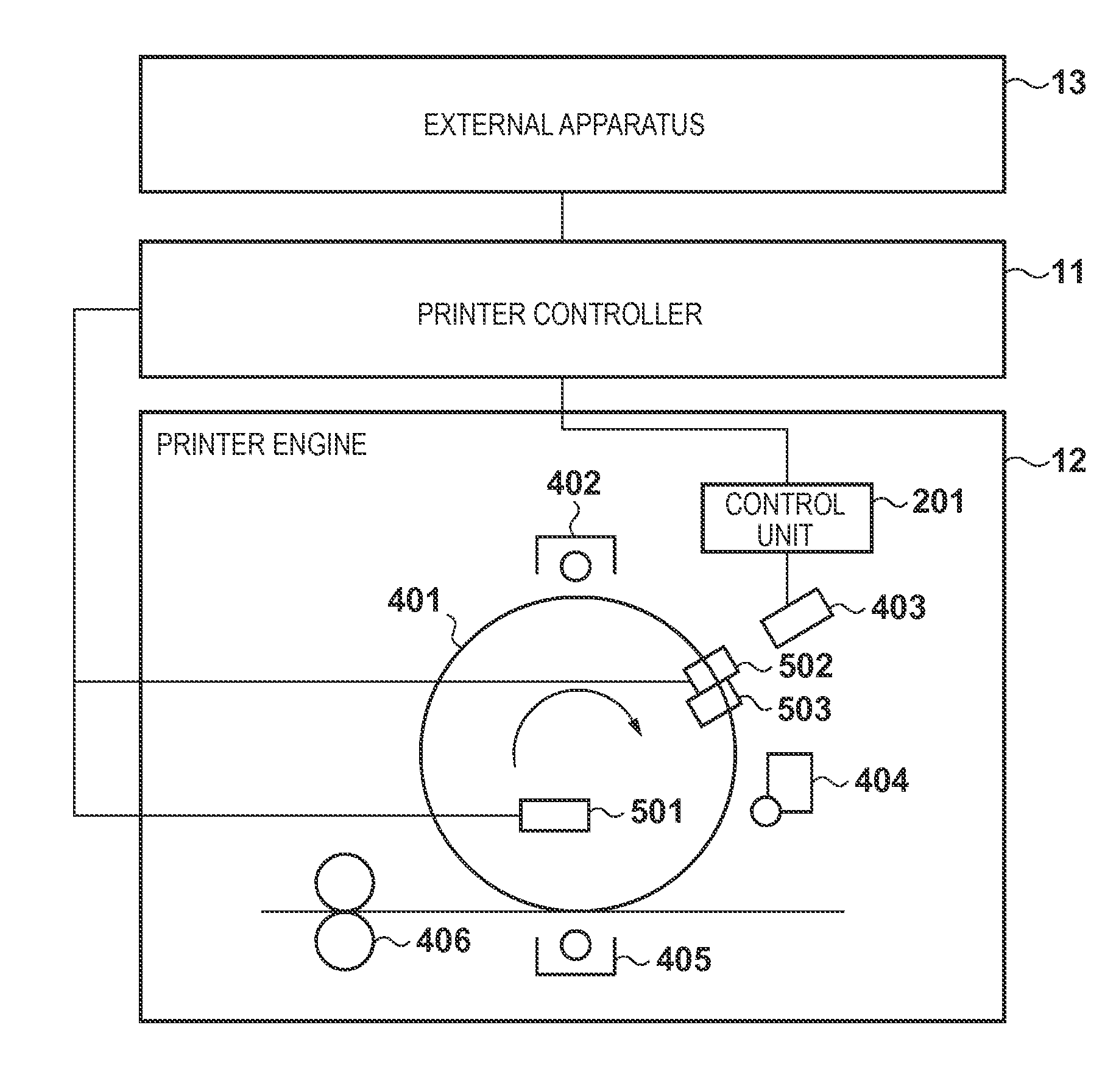

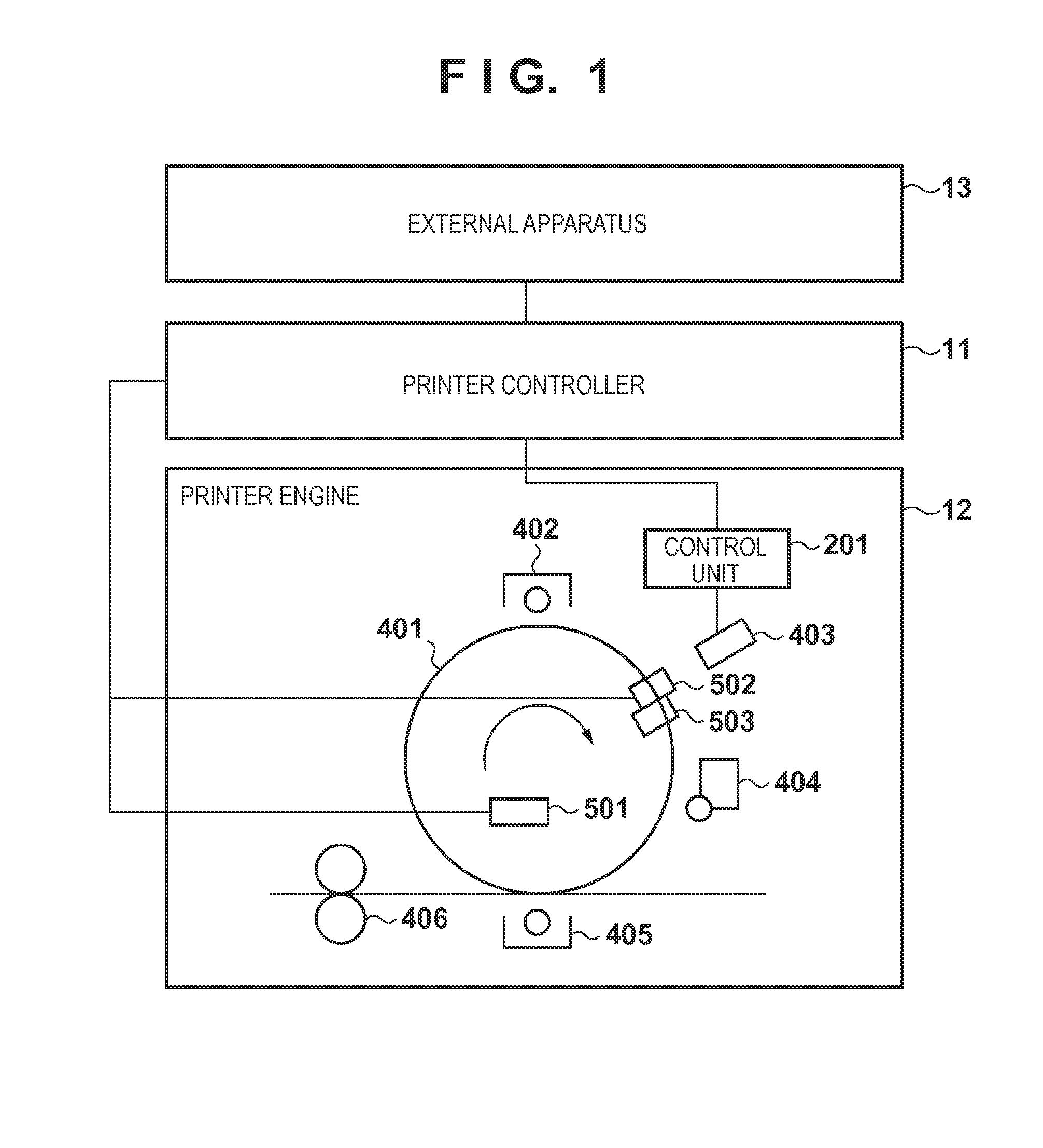

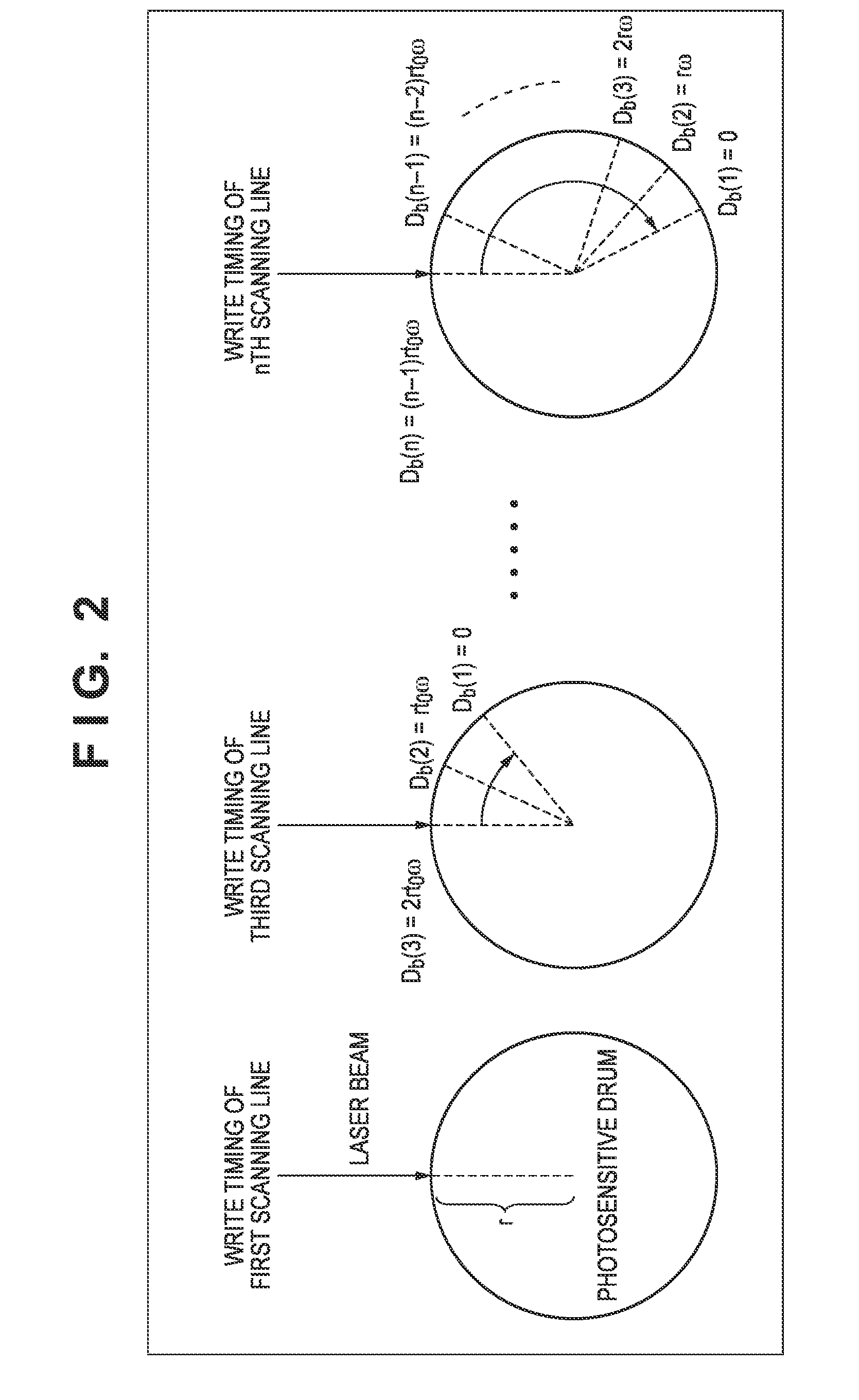

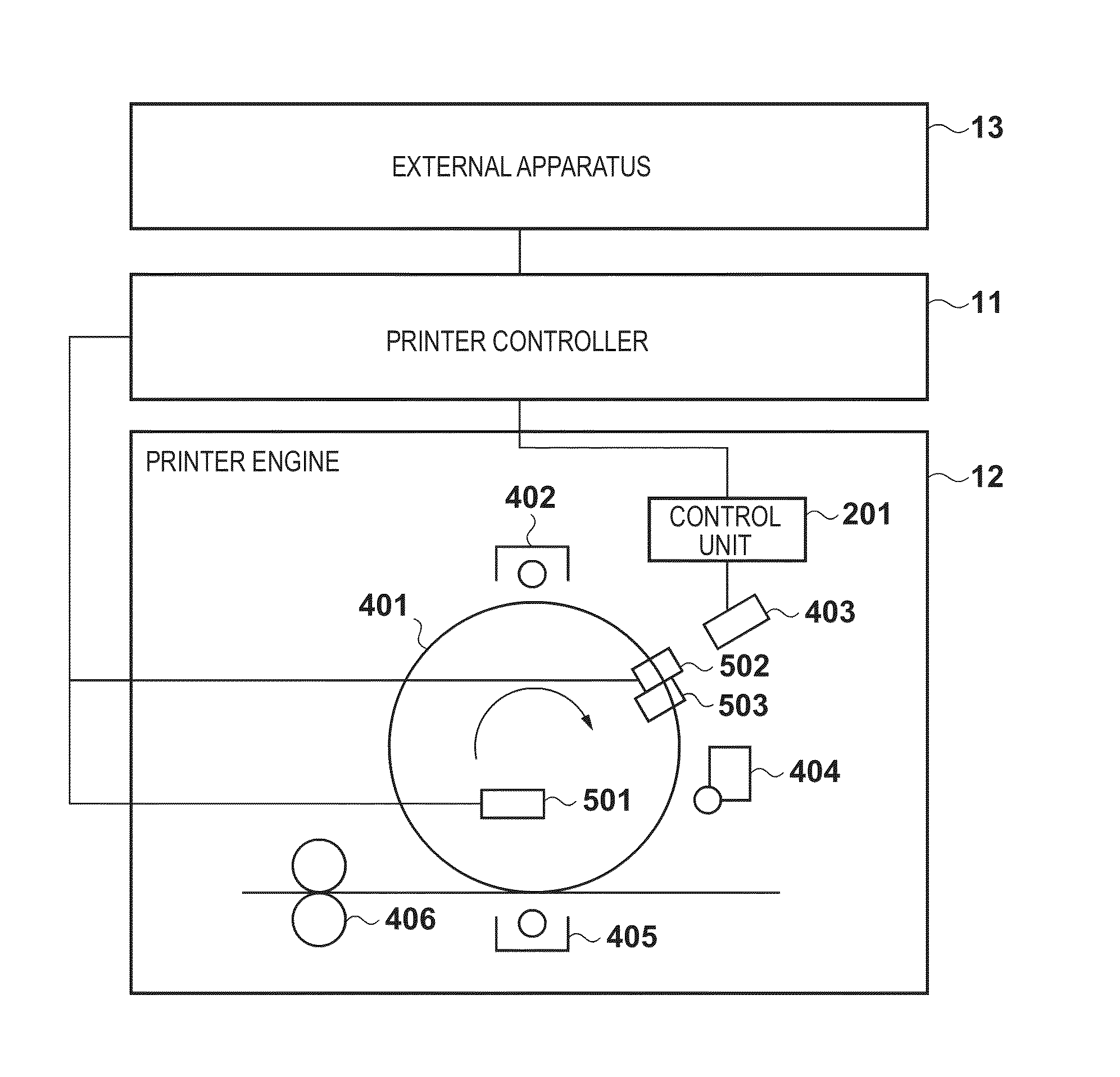

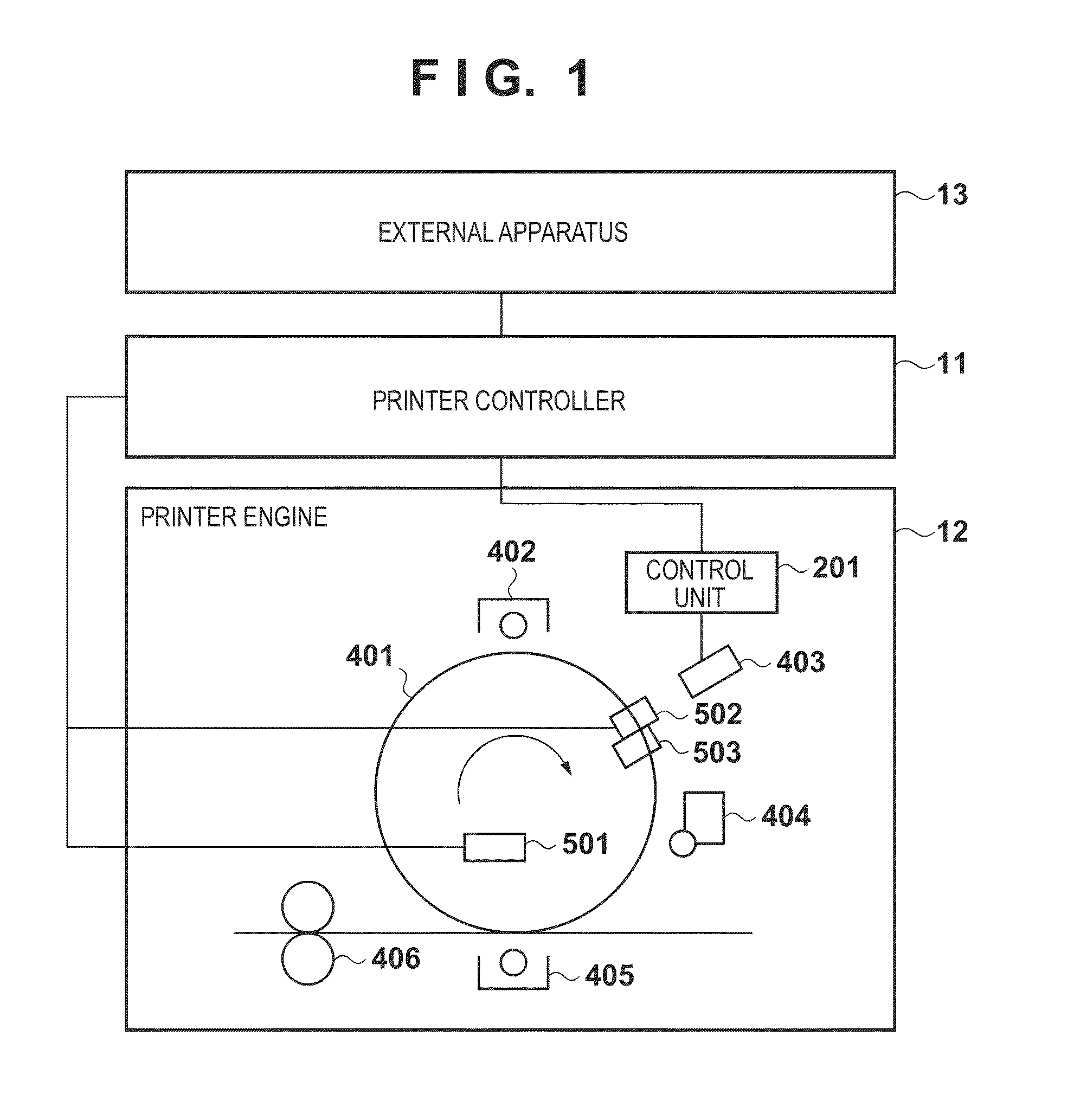

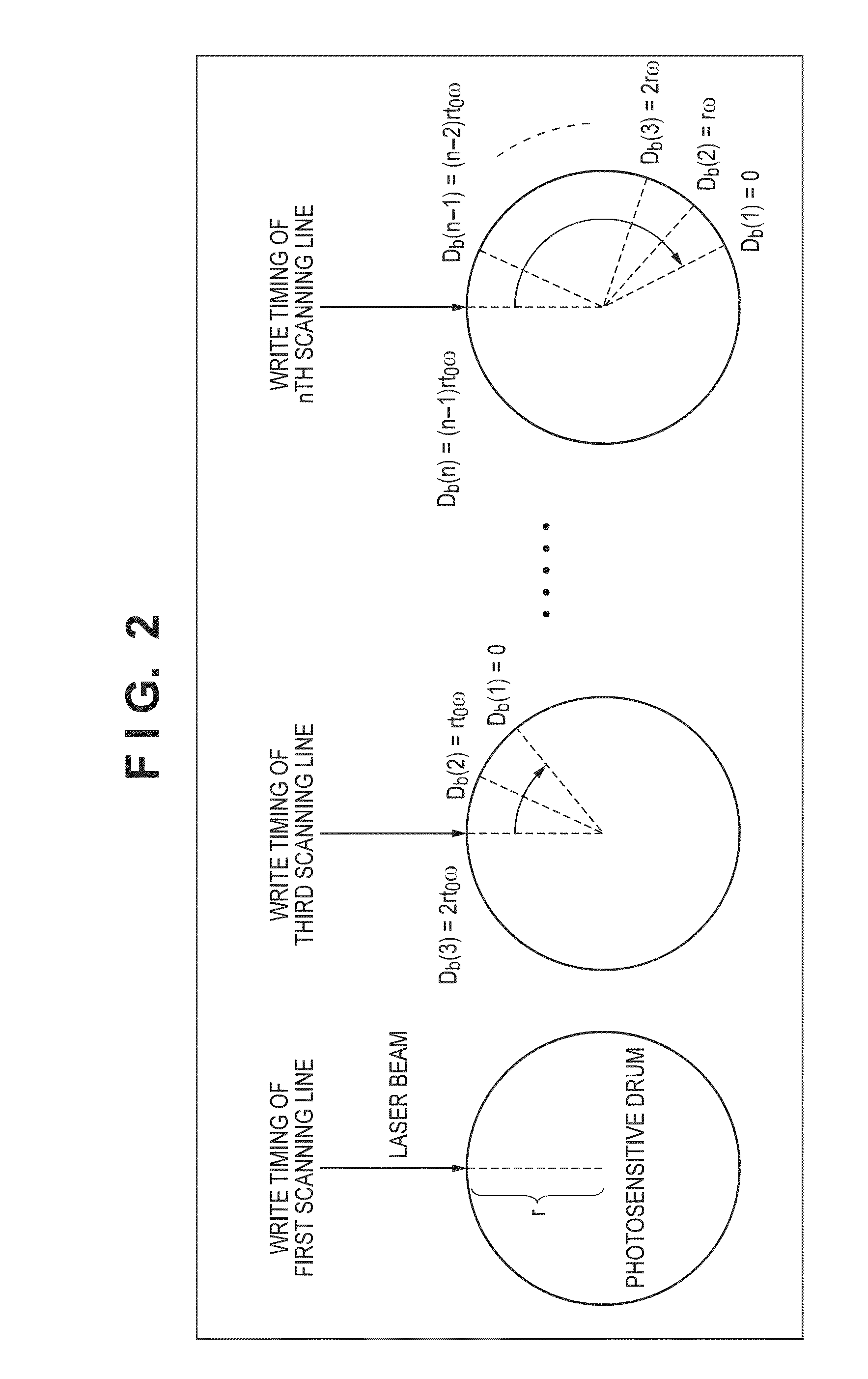

Image processing apparatus, image processing method and program

InactiveUS20130229696A1Low densityReduce bandingVisual presentationElectrographic process apparatusRadiologyImage formation

There is provided an image forming apparatus comprising: detection means for detecting position information eating a scanning position; interval prediction means for predicting a first scanning line interval indicating a distance in the sub-scanning direction between the scanning line of interest and a succeeding scanning line to be scanned after the scanning line of interest; interval calculation means for calculating, by using the position information held by the holding means, a second scanning line interval indicating a distance in the sub-scanning direction between the scanning line of interest and the scanned scanning line; and rate calculation means for calculating a correction rate on an exposure amount for the scanning line of interest so that a predicted density calculated using the first scanning line interval and the second scanning line interval matches with a predicted density calculated using a predetermined reference scanning line interval.

Owner:CANON KK

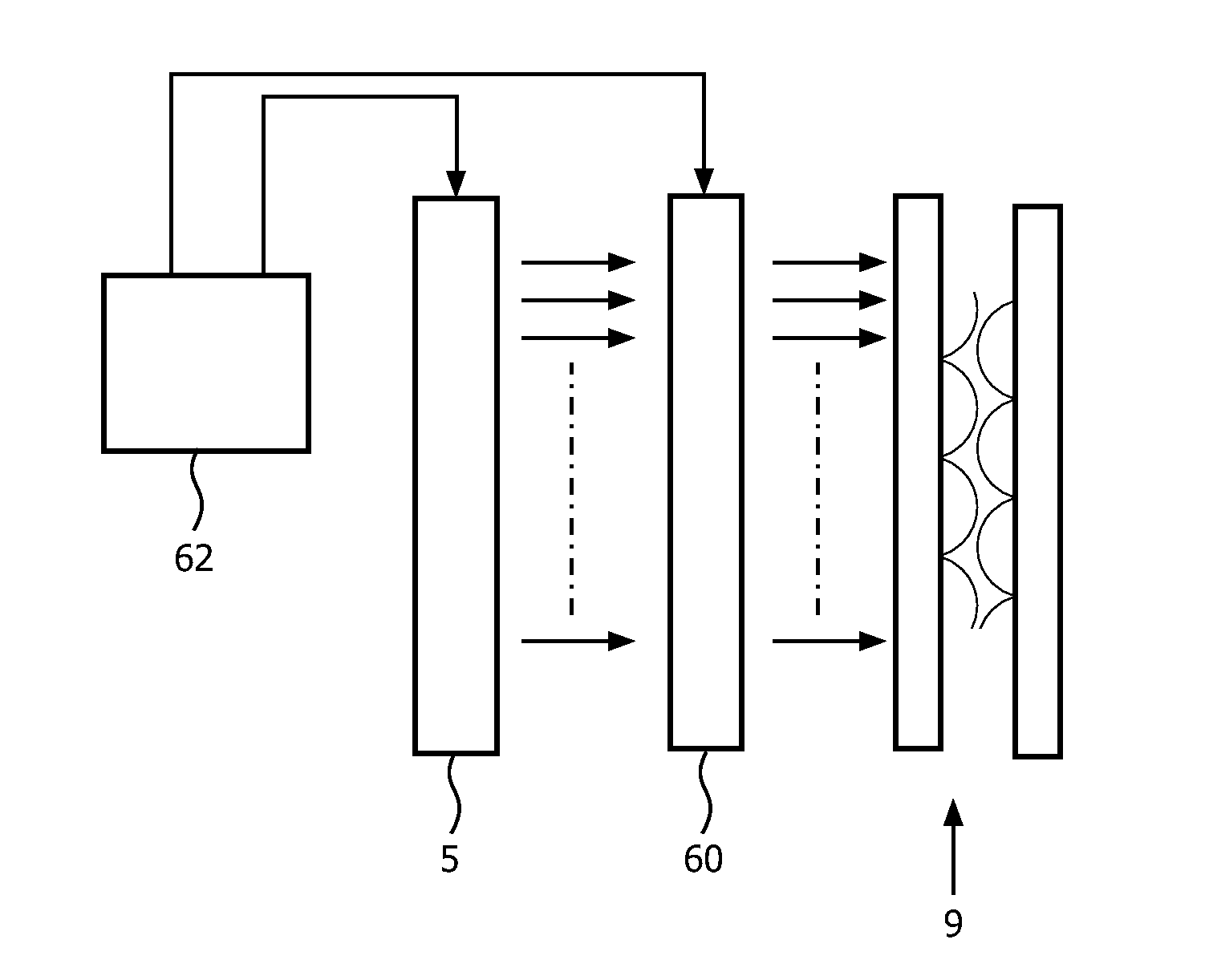

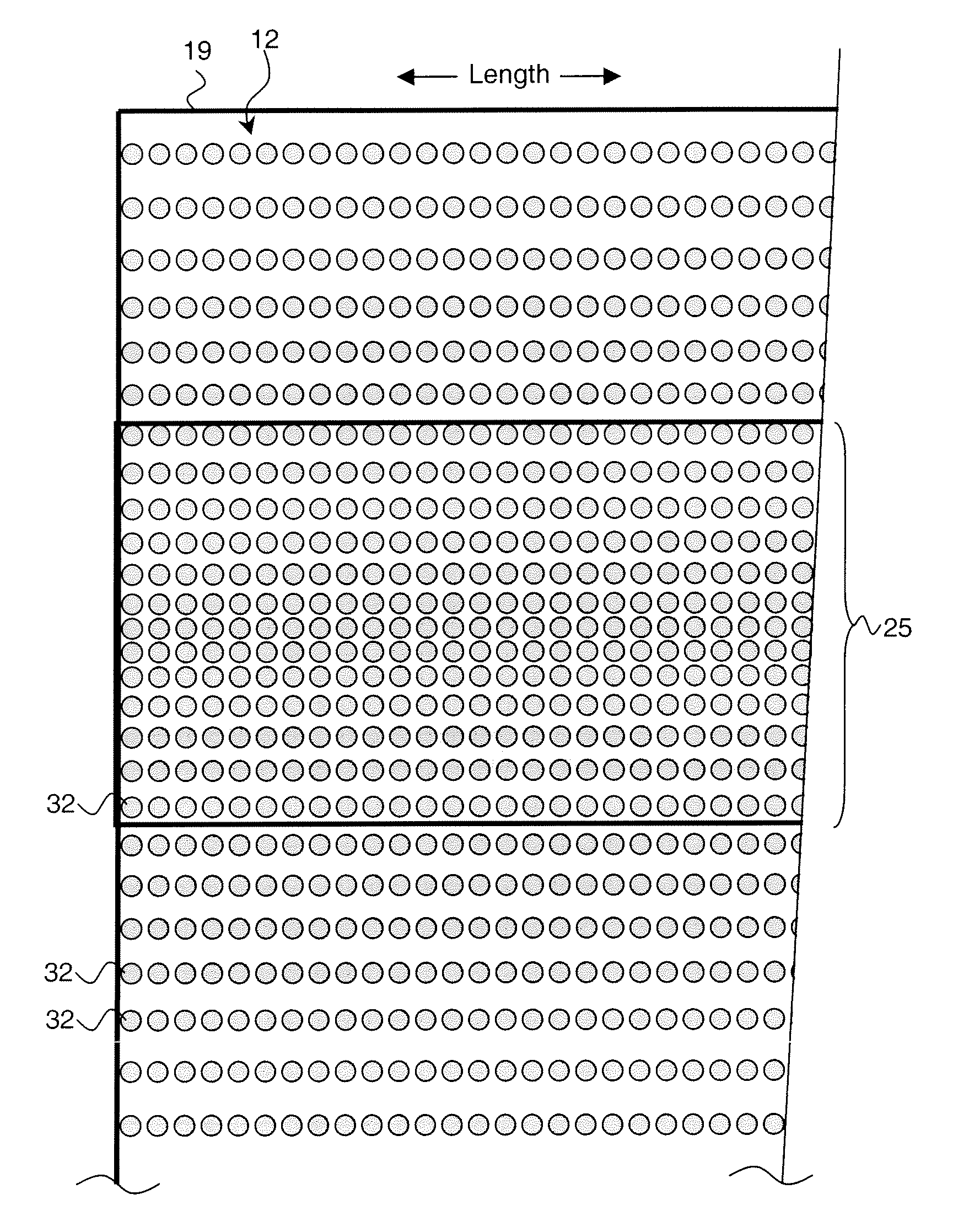

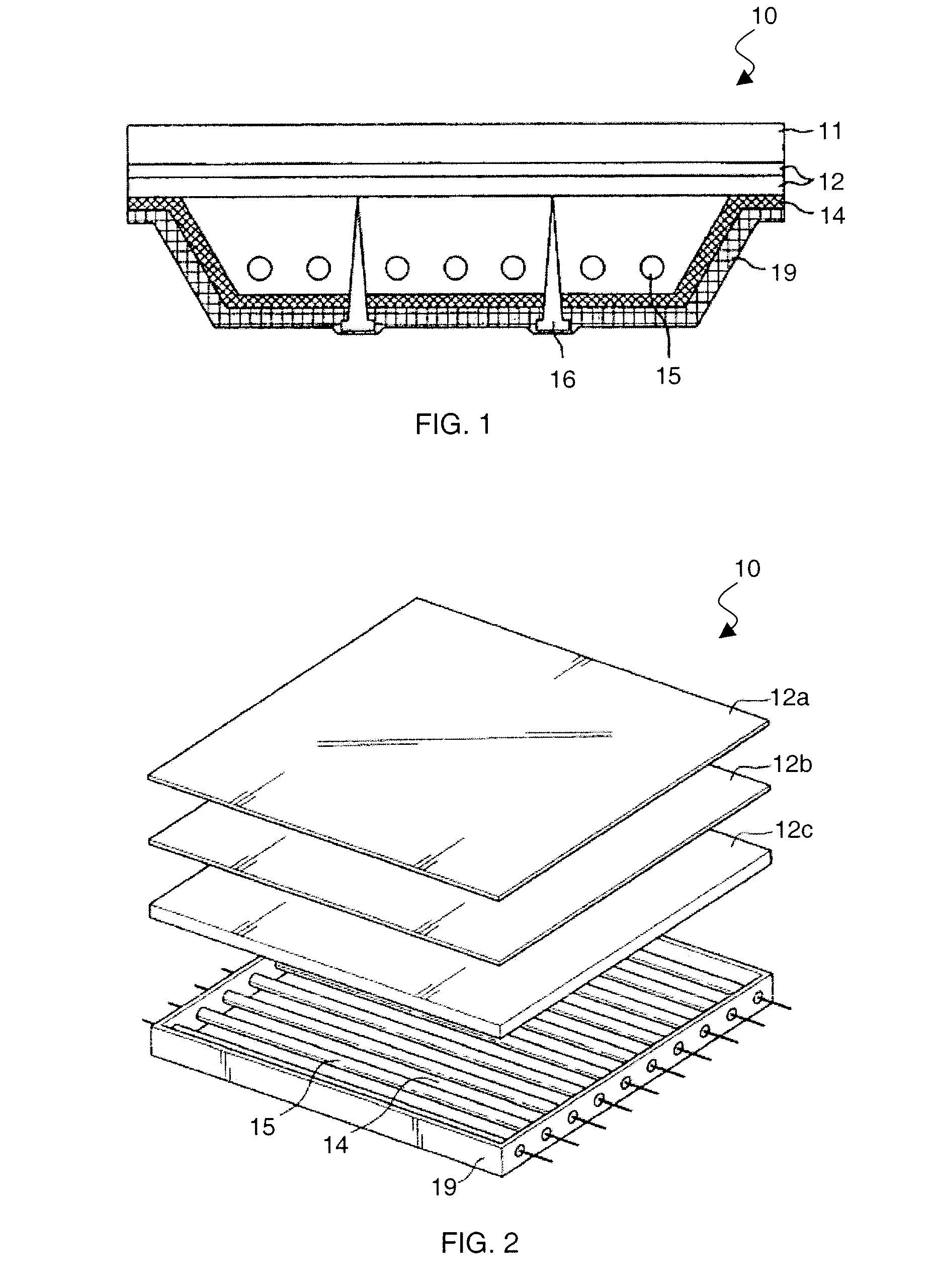

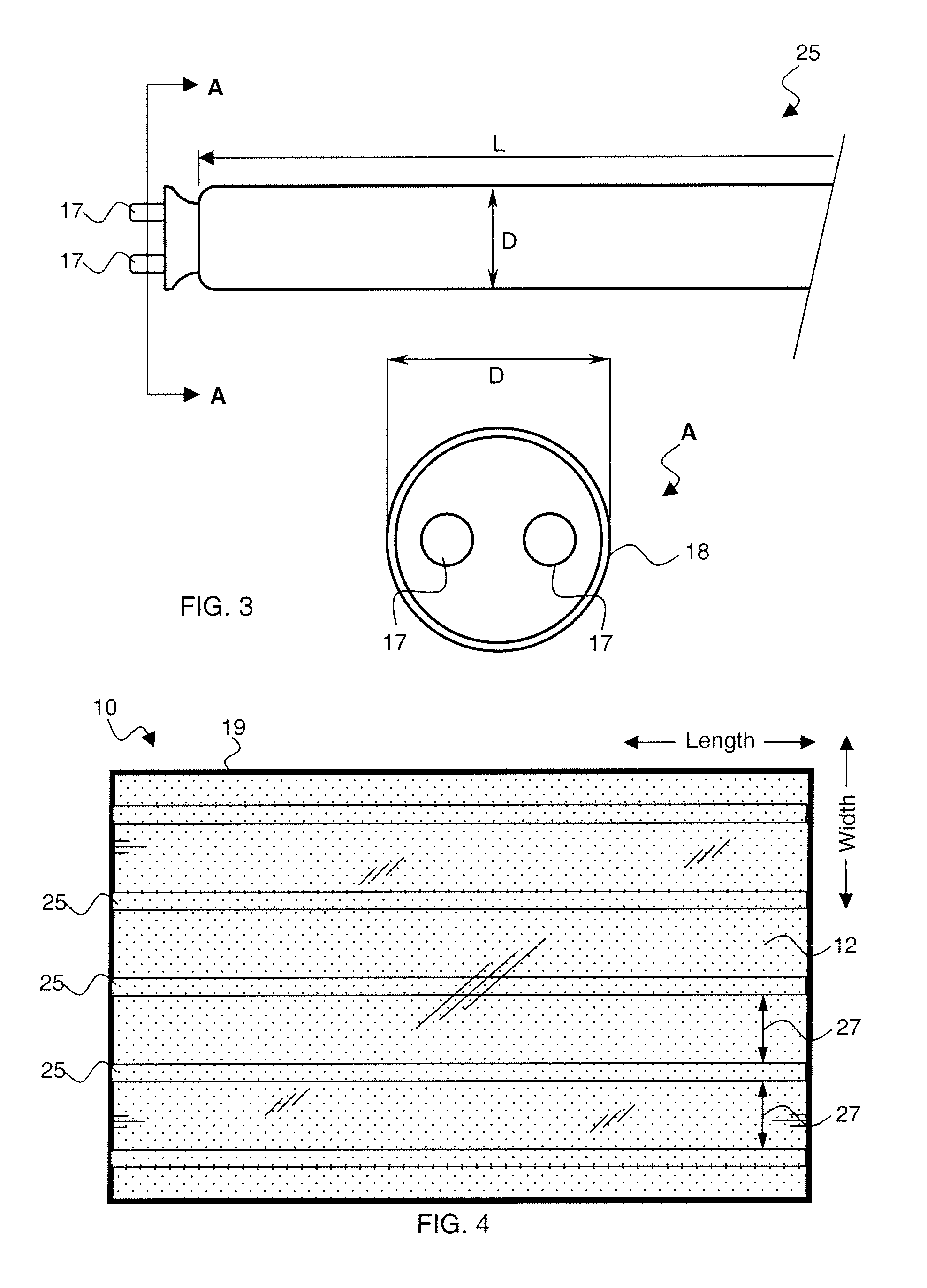

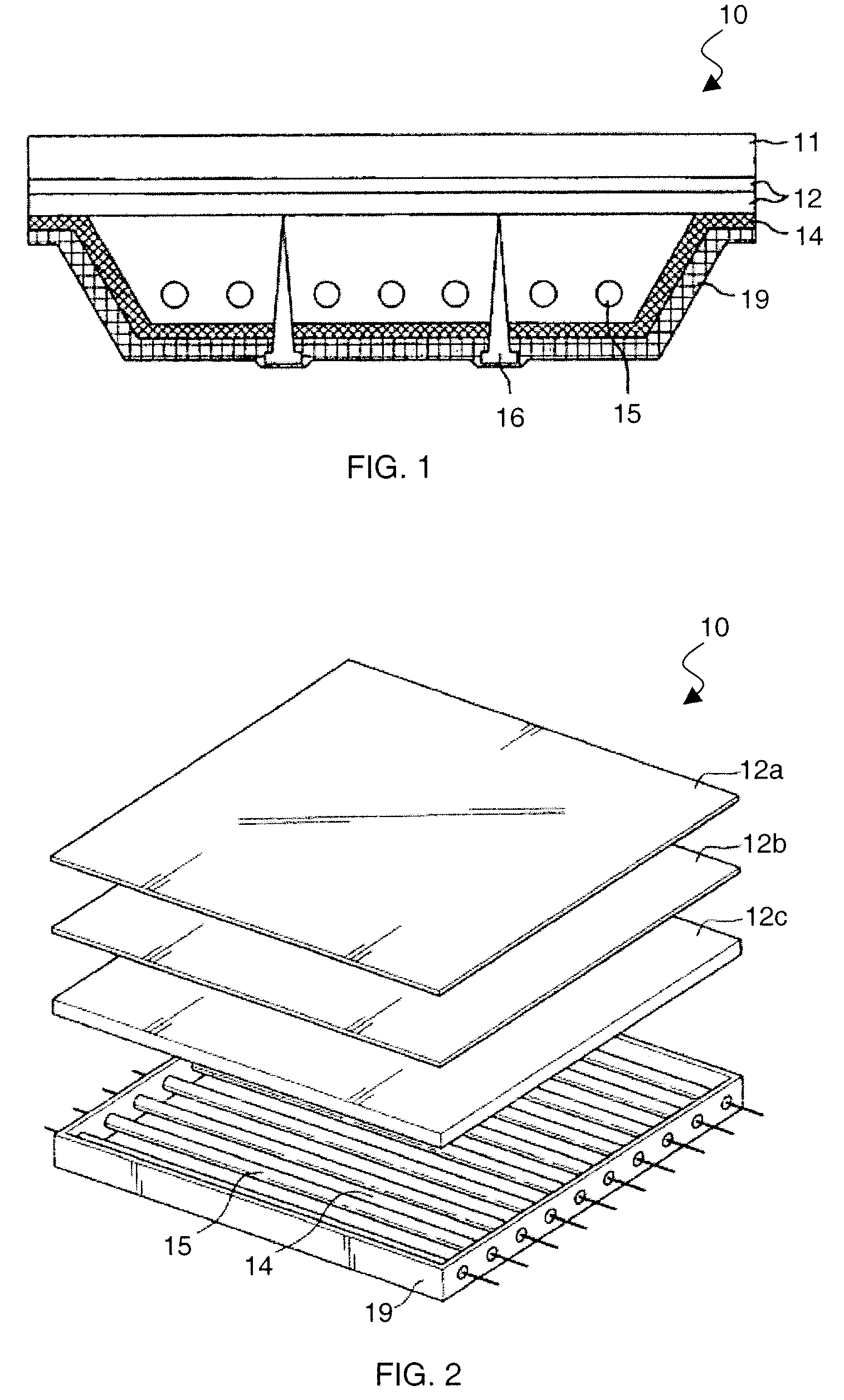

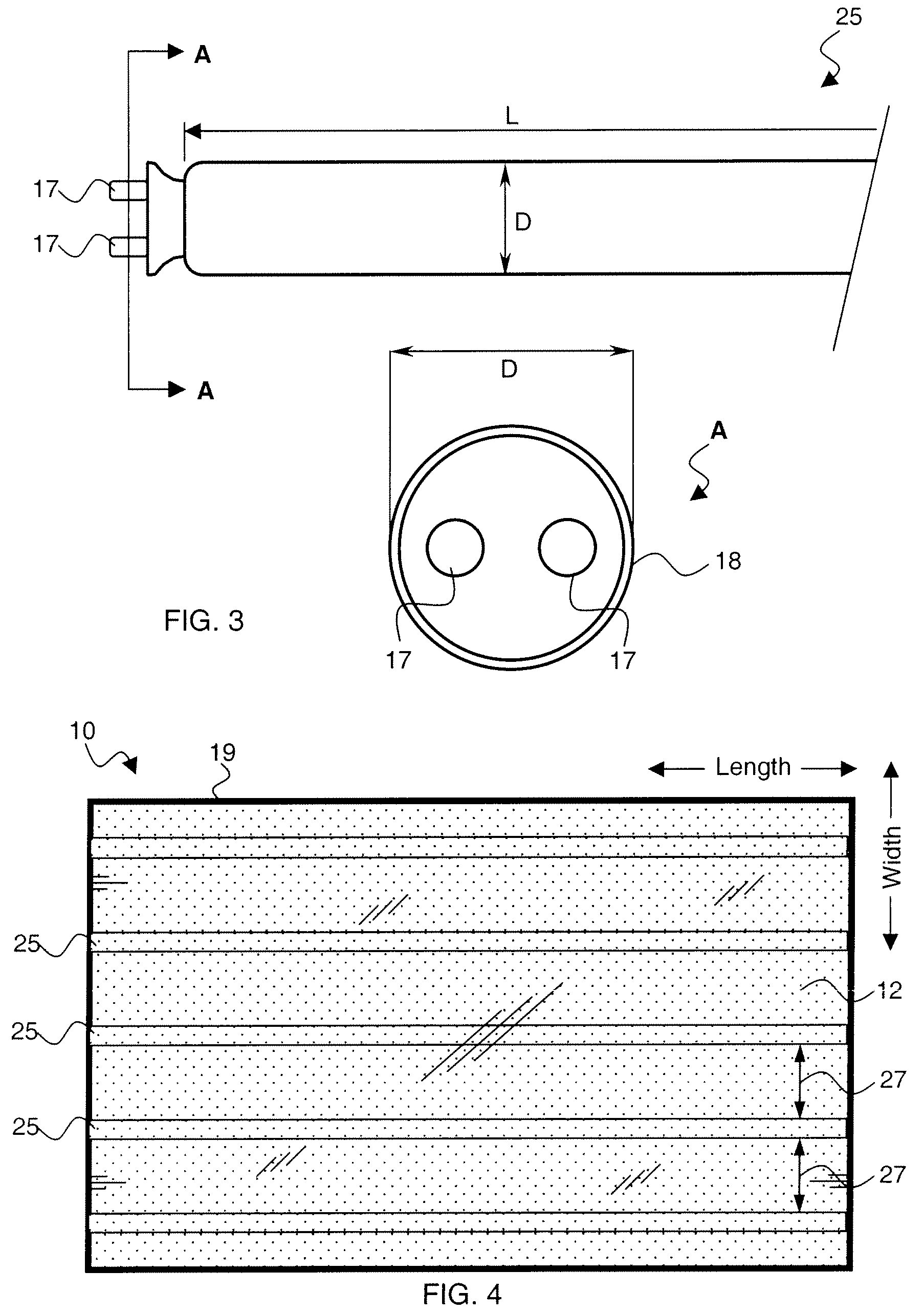

System for improved backlight illumination uniformity

InactiveUS20080117630A1Improve brightness uniformityReduce bandingNon-linear opticsRefractorsOptoelectronicsLighting system

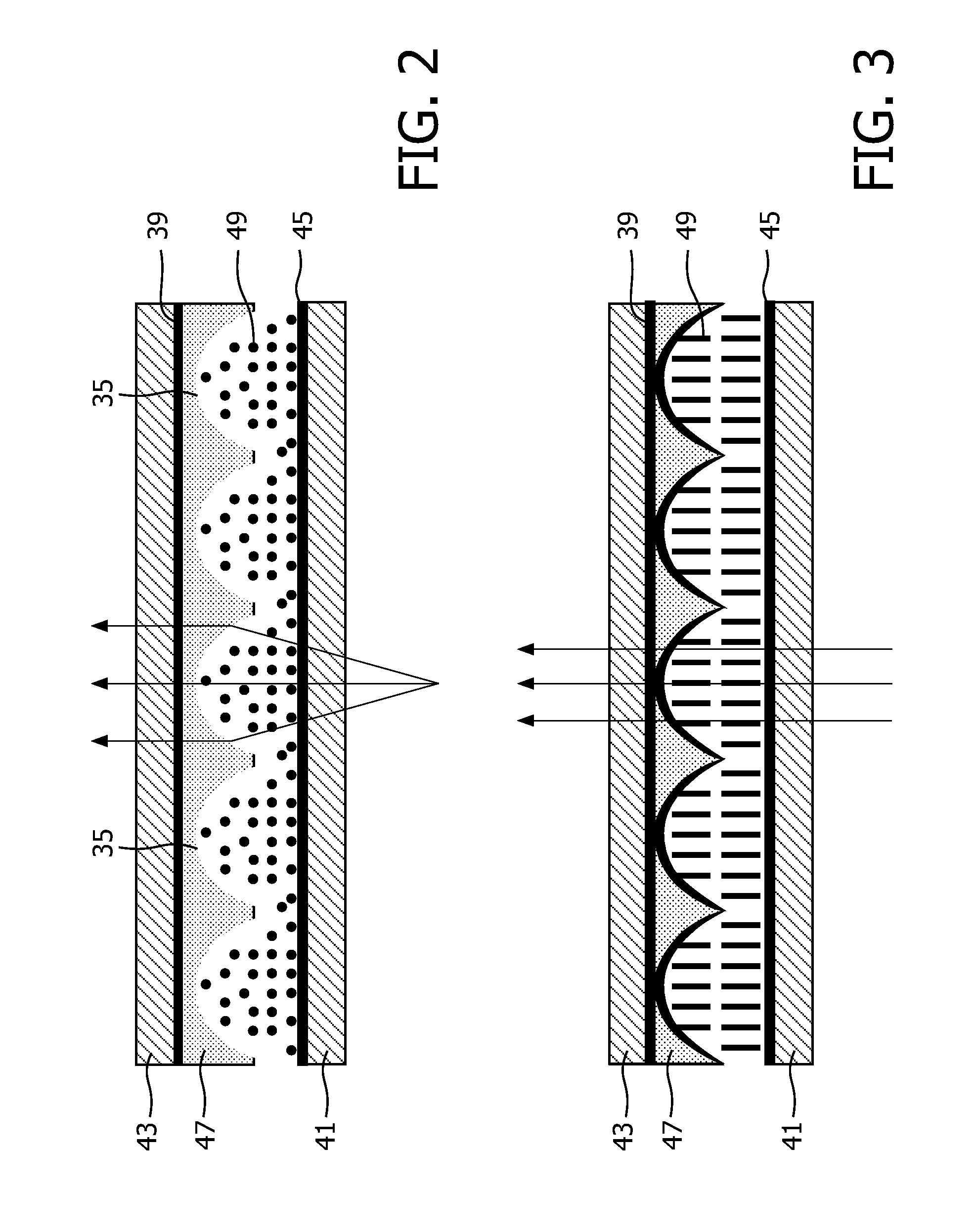

An illumination system includes a backlight housing, a plurality of light valves coupled to the backlight housing, and a plurality of light sources arranged in the backlight housing and optically coupled to the light valves. The illumination system may further include a light-scattering substrate optically coupled between the plurality of light sources and the light valves, and a plurality of light modulating dots patterned on the substrate to modulate transmitted intensity of light from the plurality of light sources to achieve increased luminance uniformity by decreasing banding caused by the separated light sources. The light modulating dots may include comprise reflective dots, transmissive dots, absorptive dots, or a combination thereof.

Owner:GENERAL ELECTRIC CO

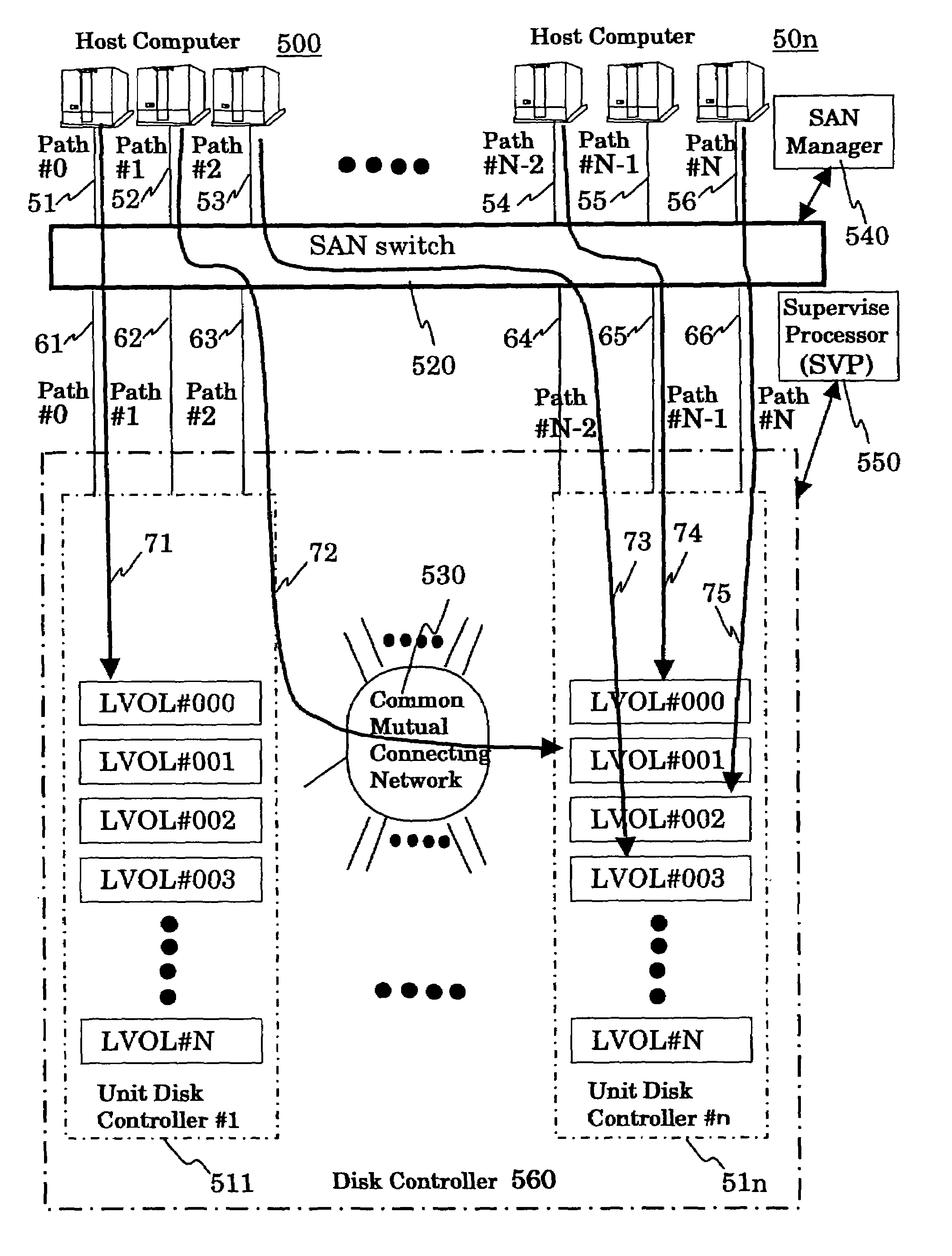

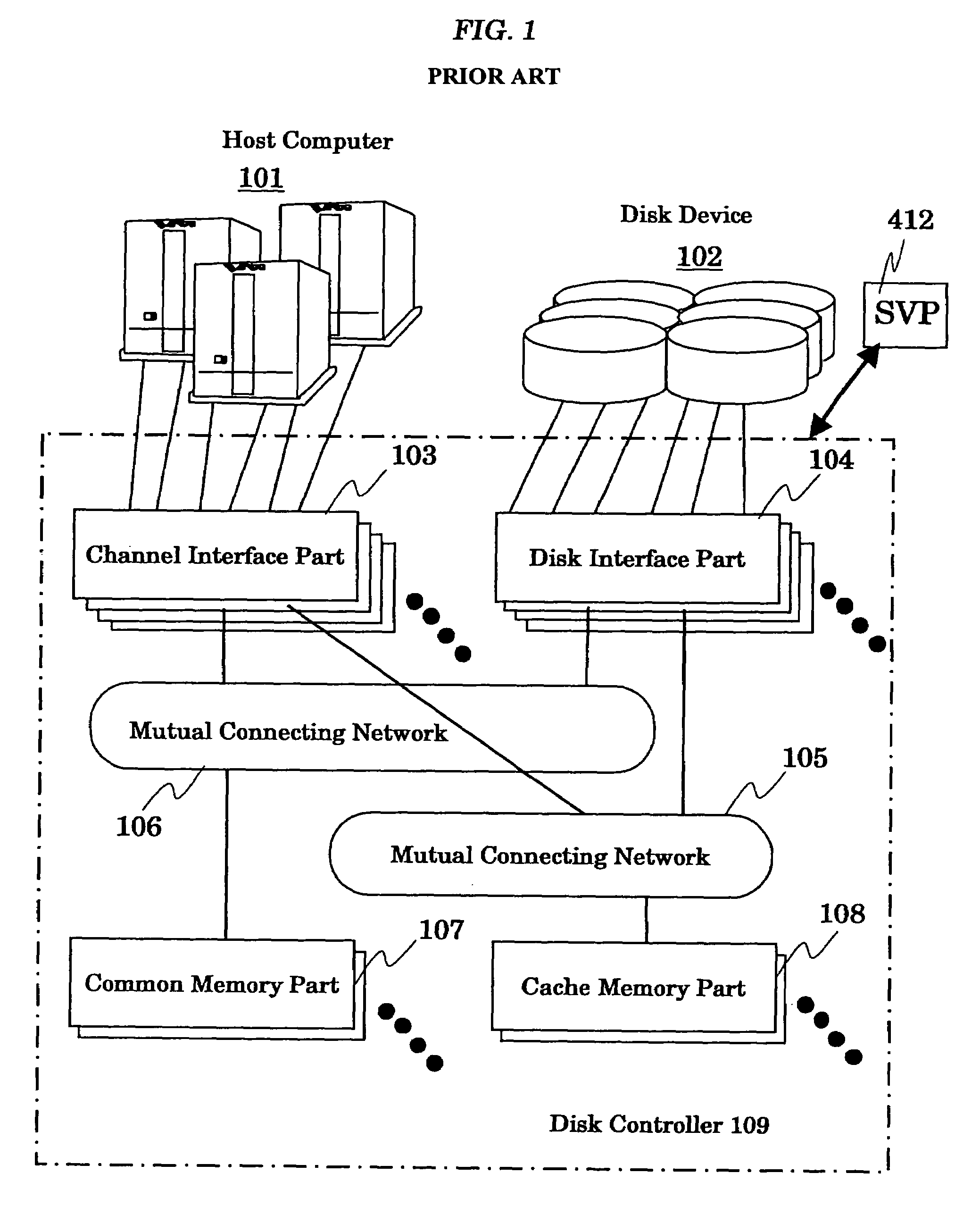

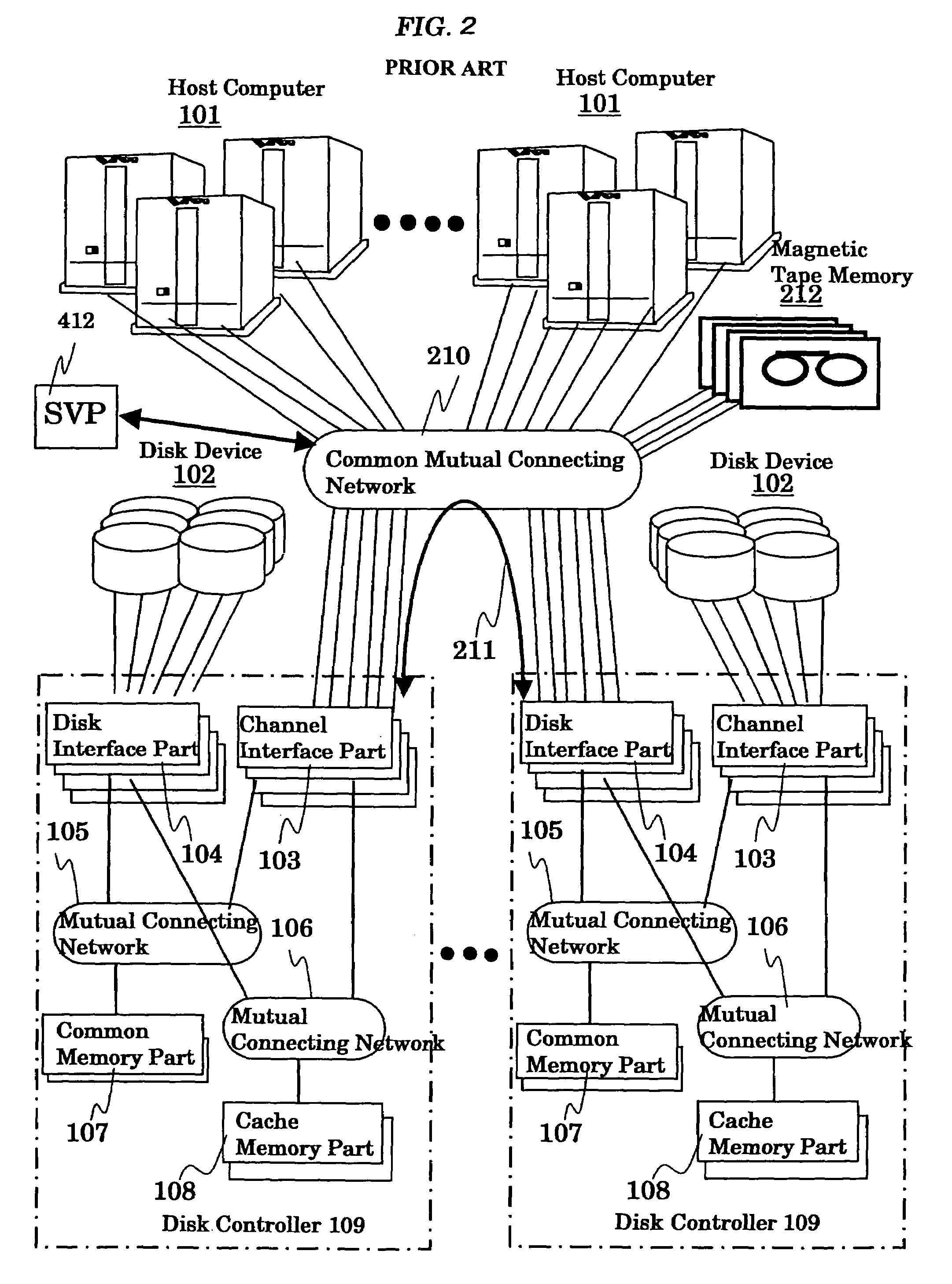

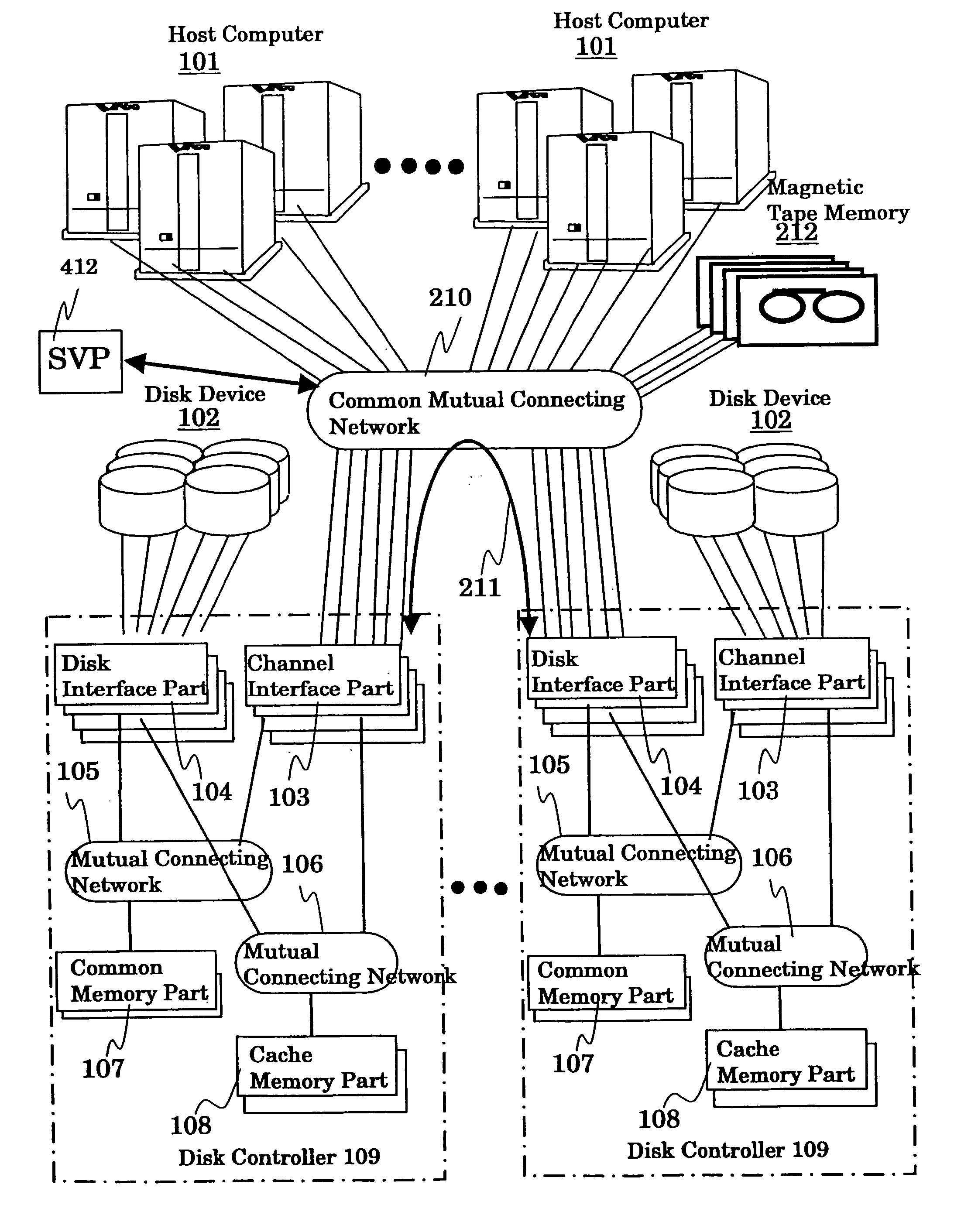

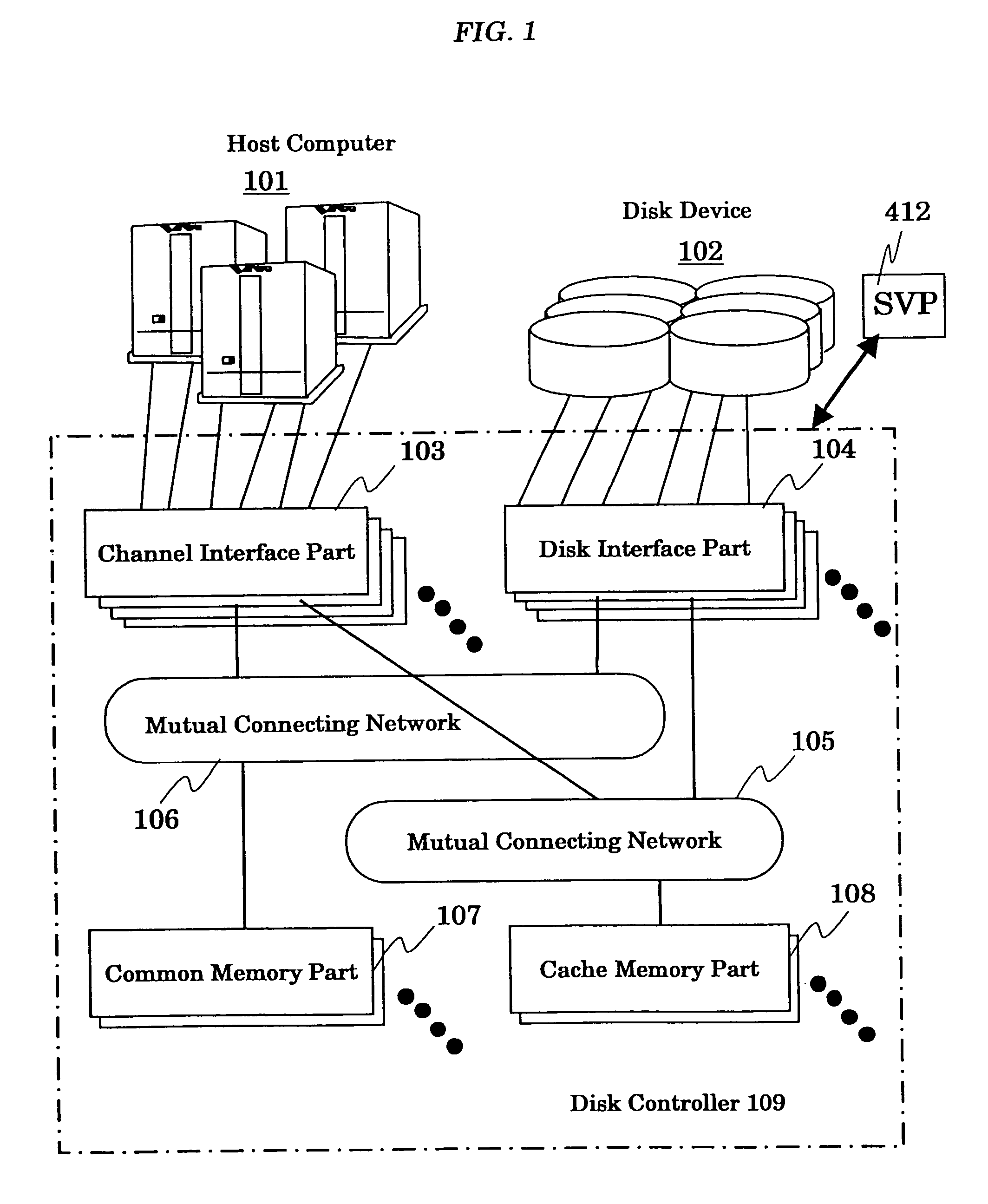

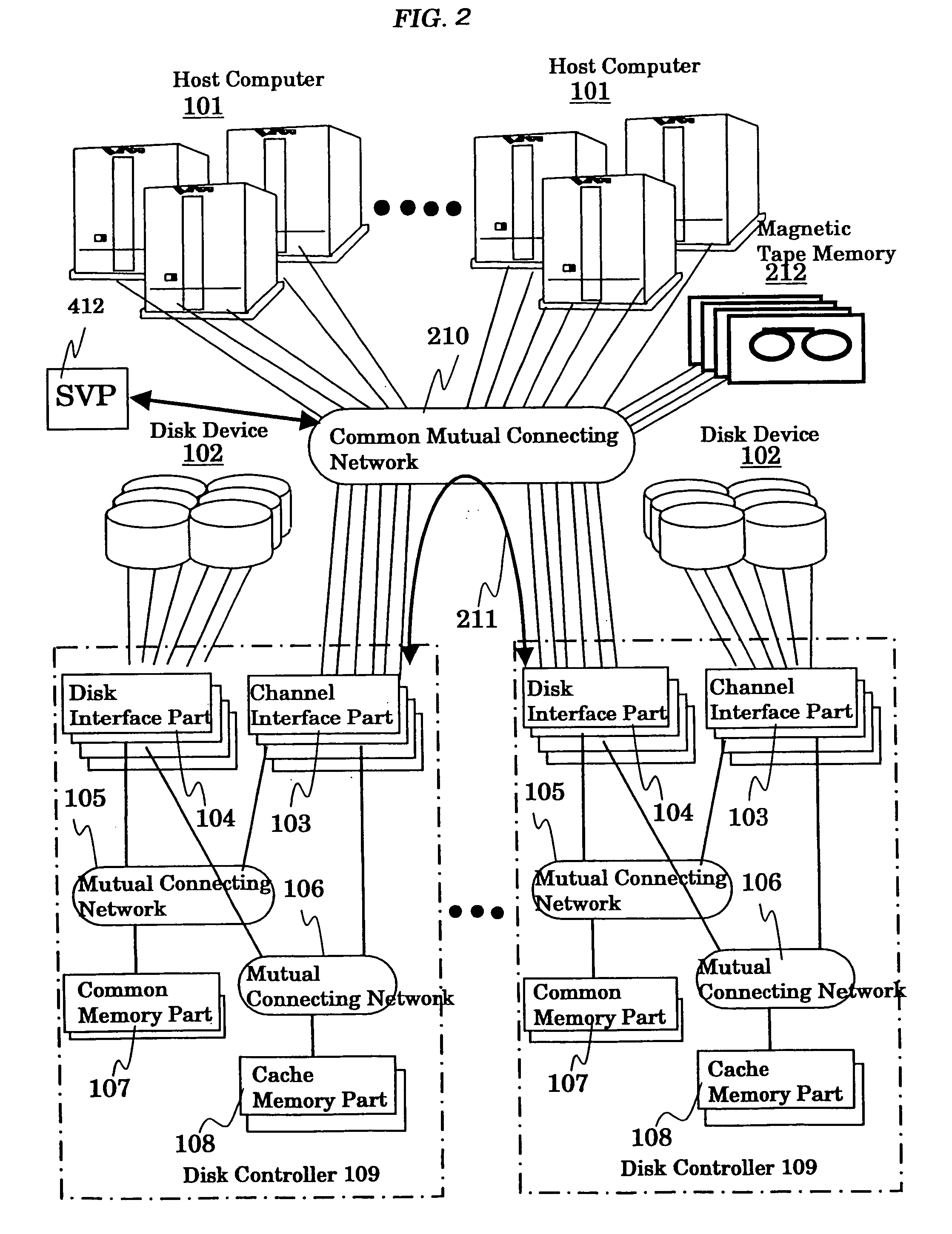

Computer system using disk controller and operating service thereof

InactiveUS7149886B2Lower initial costGuaranteed uptimeEnergy efficient ICTInput/output to record carriersDisk controllerComputerized system

When there is an access passing between unit disk controllers, the band of a mutual connecting network must be very large in order to exhibit the performance sufficiently, so that the cost is increased. In the present invention, the access number of a logical volume is monitored, the change of an access path is suggested to an upper class device, and the logical volume is moved or copied to each unit disk controller, so that the mutual connecting network is used mainly for copy of the logical volume, thereby reducing the necessary band.

Owner:HITACHI LTD

Pigmented inks formed using microfiltration

InactiveUS20050139122A1Stable and reliable jettabilityHigh optical densityInksOrganic dyesPorosityFiltration

The invention relates to a pigment-based ink composition for inkjet printing the ink composition pigment particles, wherein said ink composition has a filterability of at least 80% wherein filterability is determined by the following test; a sample of said pigment-based ink is divided into four 100 ml aliquots and a first aliquot is filtered through a chemically inert membrane having a porosity of 1.0 μm and a diameter of 47 mm and using a vacuum of 20 inches of Hg and measuring the time it takes to complete the filtration, T1, a second and third aliquot are sequentially passed through the same filter under the same filtering conditions, the fourth aliquot is then passed through the same filter under the same conditions while measuring the time it takes to complete the filtration of the fourth aliquot, T4, the time of T1 is divided by T4 and multiplied by 100 to obtain the filterability.

Owner:EASTMAN KODAK CO

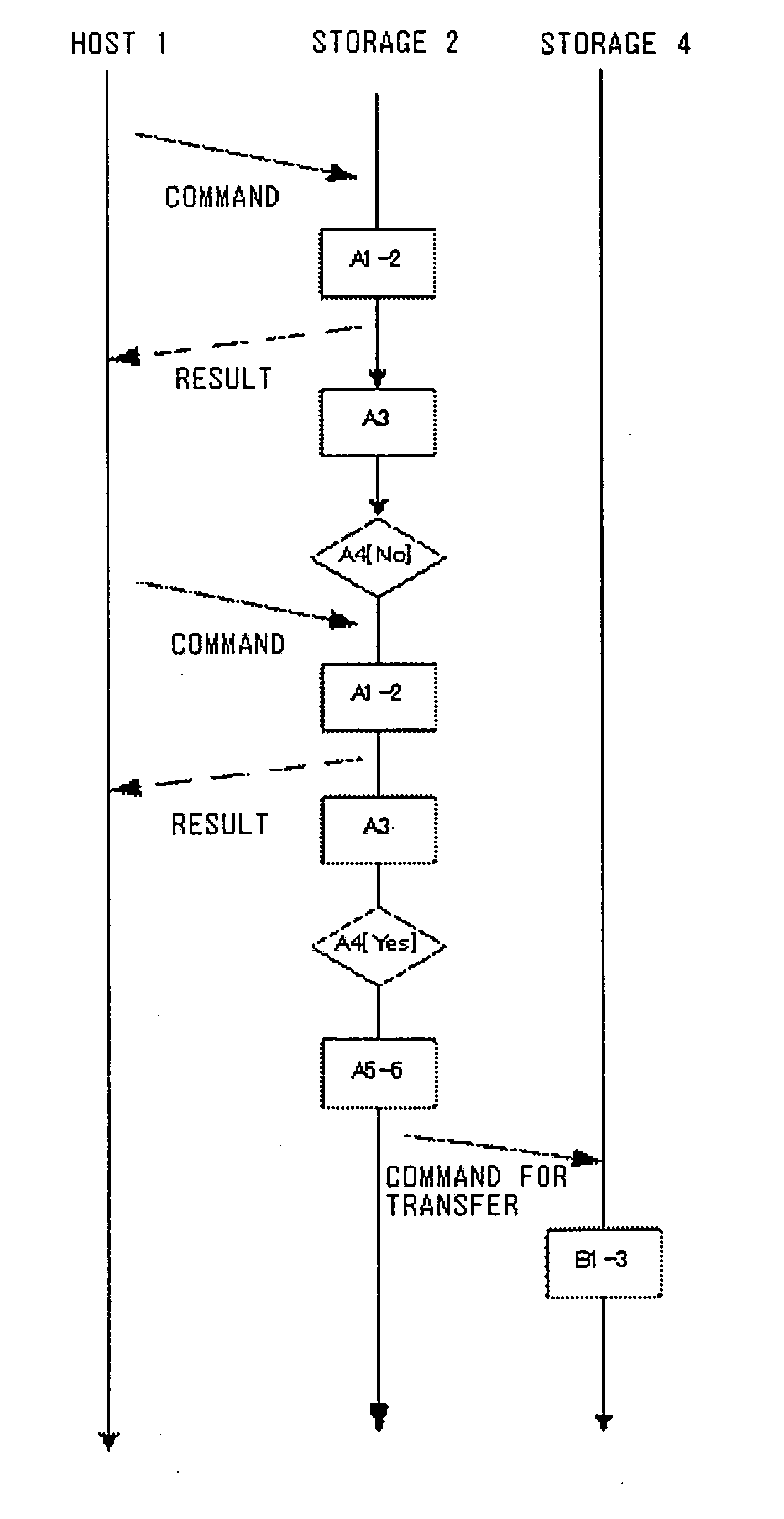

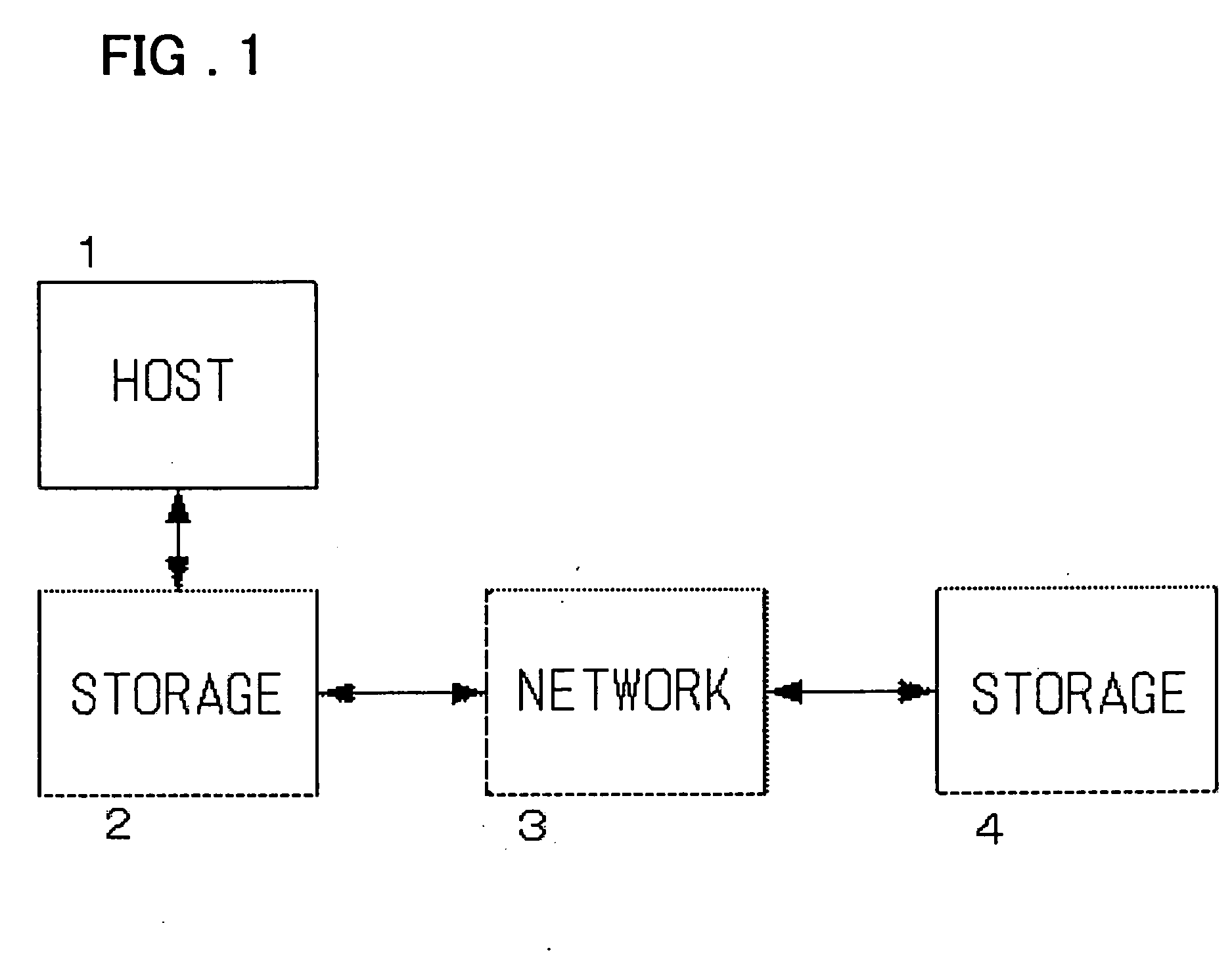

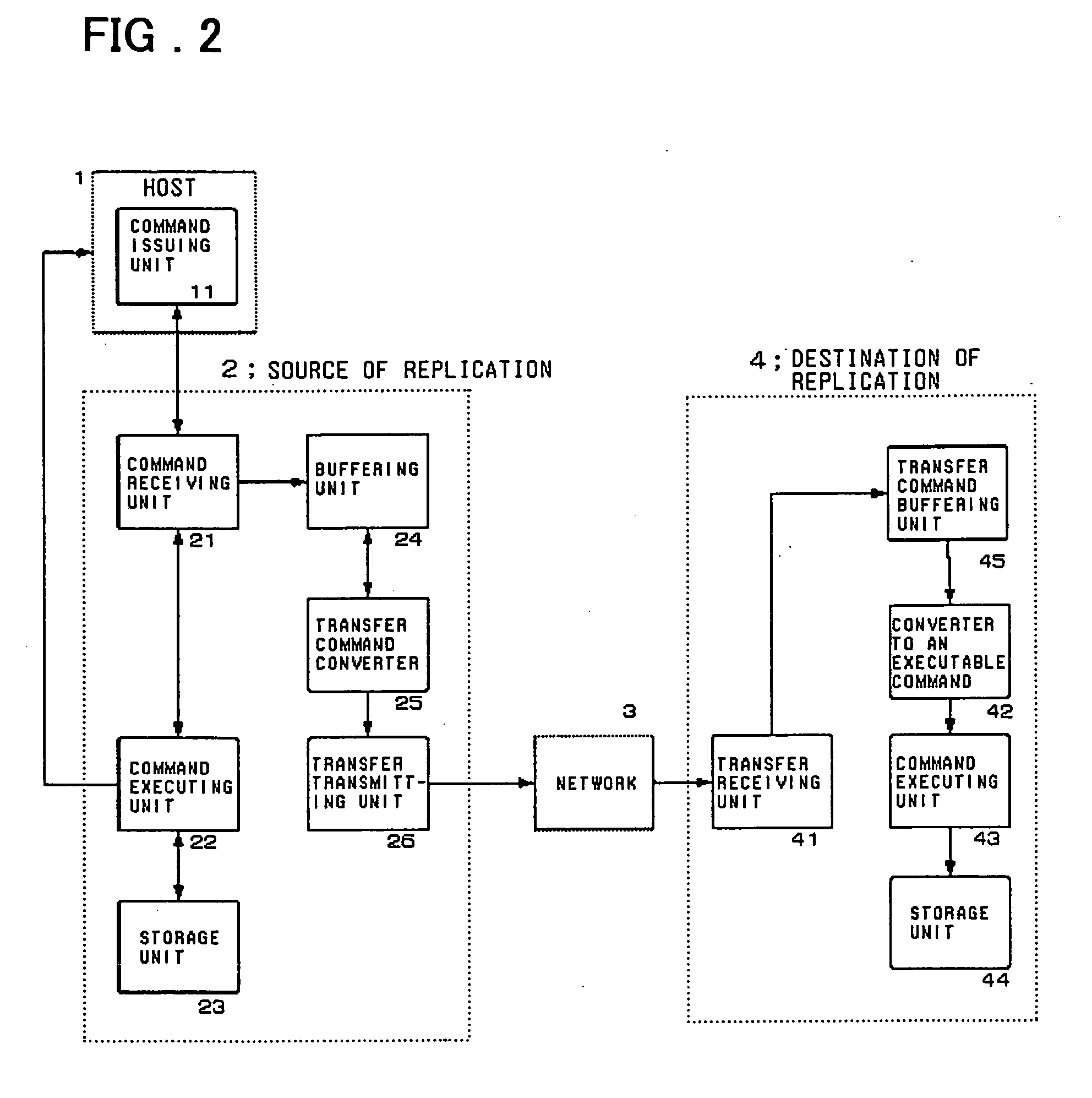

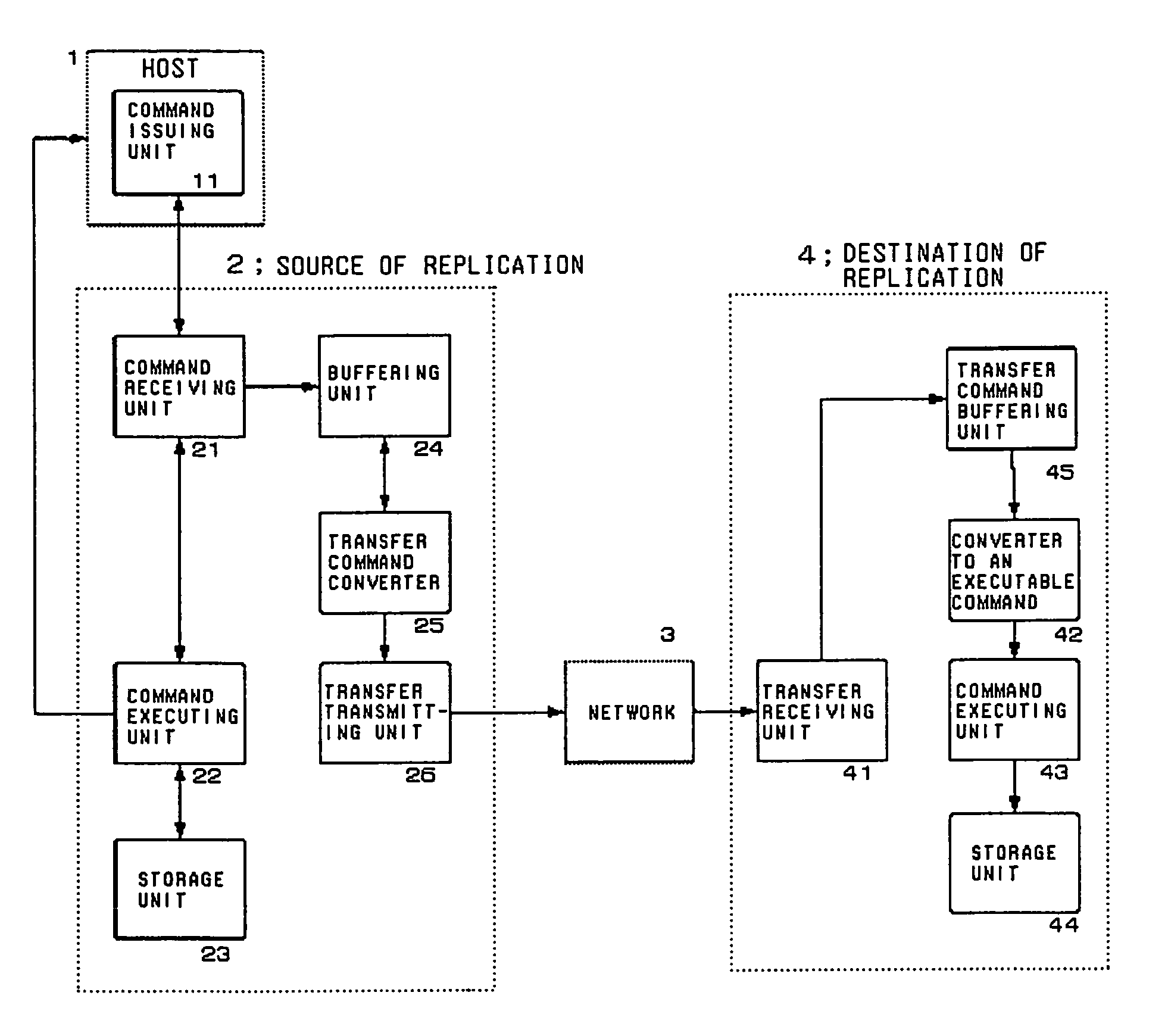

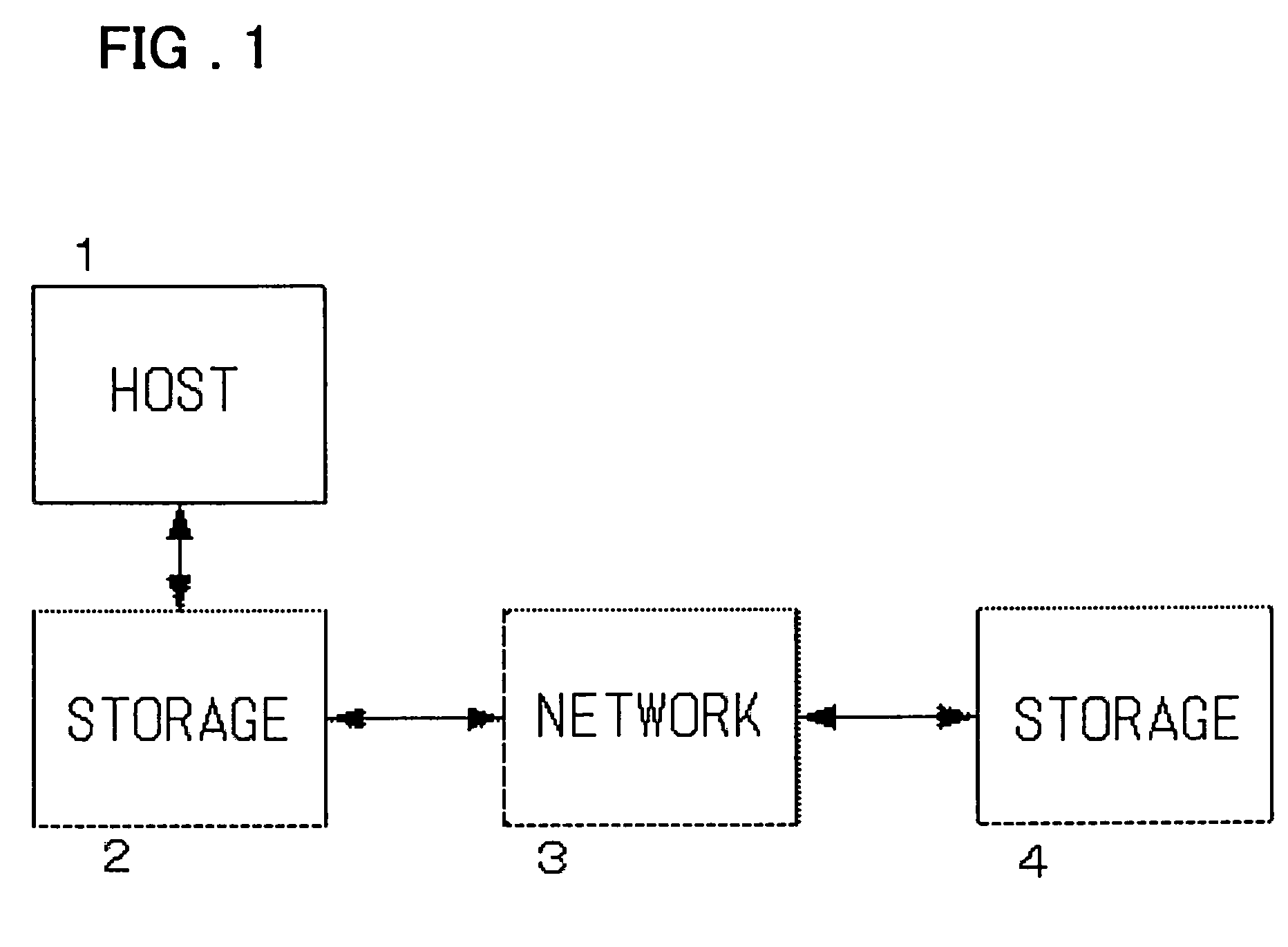

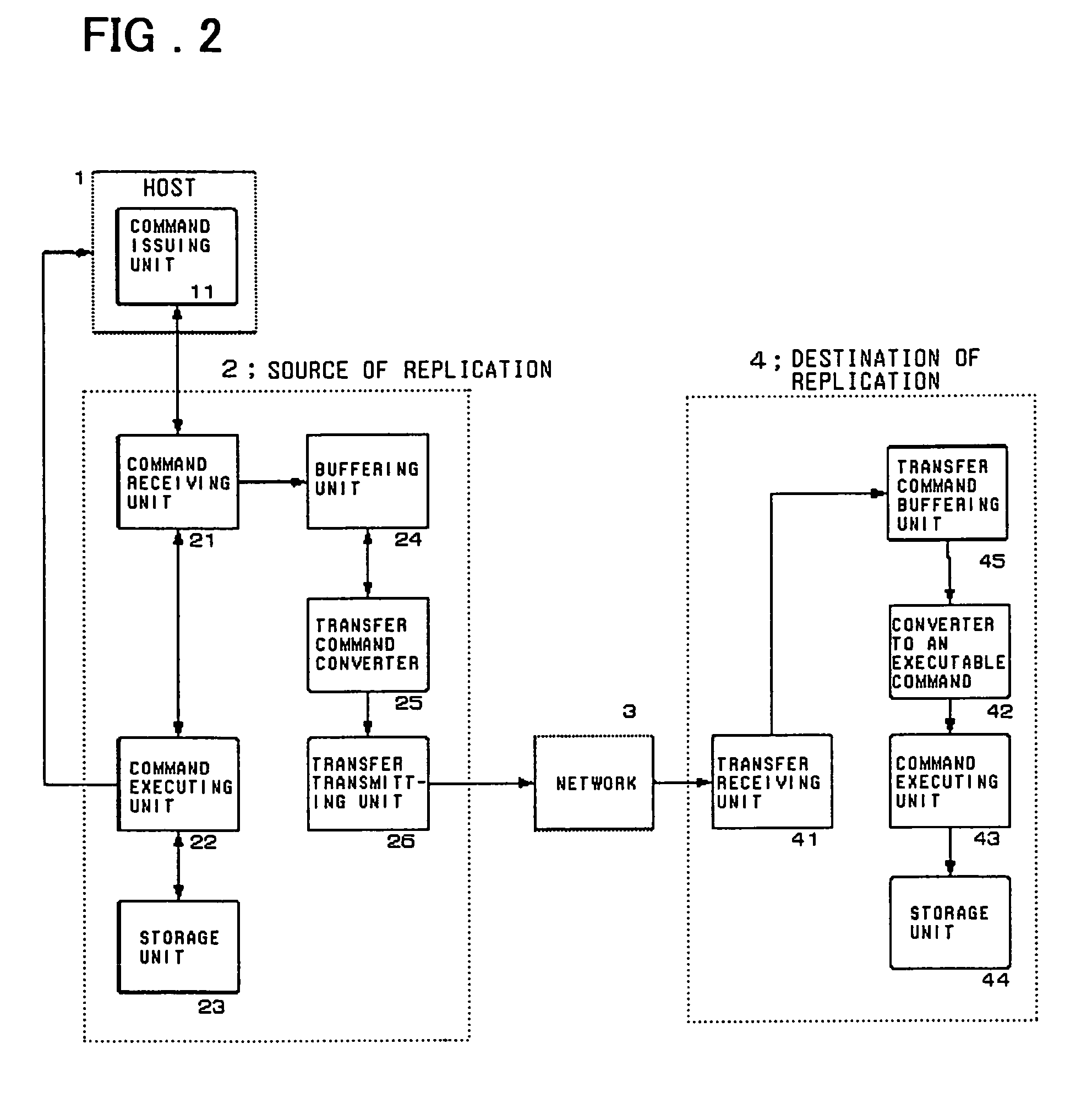

Storage system, method for replication thereof and program

ActiveUS20060112149A1Process can be minimizedReduce amount of data transferredError detection/correctionDigital data processing detailsData transmissionMonitor unit

As in a normal storage system, an application run on a host issues a data write command or a data read command. A monitor unit monitors the host and a command issued by the host to detect a re-startable point to issue the re-startable point notification to a source storage system. Using the re-startable point as a momentum, the source storage system converts a command stored in a buffering unit into a command for transfer in which redundant data transfer has been curtailed to transfer the command for transfer to a destination storage system. The destination storage system applies the received command to a storage unit. At this time, the command for transfer is restored to an ordinary command which is applied.

Owner:NEC CORP

Halftone dot formation method, halftone dot formation apparatus, threshold matrix generation method used therefor and halftone dot recording medium

Owner:DAINIPPON SCREEN MTG CO LTD

Storage system and method for data replication with reduced redundant data transfer

ActiveUS7698308B2Reduce dataReduce bandingDigital data processing detailsError detection/correctionMomentumData transmission

As in a normal storage system, an application run on a host issues a data write command or a data read command. A monitor unit monitors the host and a command issued by the host to detect a re-startable point to issue the re-startable point notification to a source storage system. Using the re-startable point as a momentum, the source storage system converts a command stored in a buffering unit into a command for transfer in which redundant data transfer has been curtailed to transfer the command for transfer to a destination storage system. The destination storage system applies the received command to a storage unit. At this time, the command for transfer is restored to an ordinary command which is applied.

Owner:NEC CORP

System for improved backlight illumination uniformity

InactiveUS7690811B2Improve brightness uniformityReduce bandingNon-linear opticsRefractorsOptoelectronicsLighting system

Owner:GENERAL ELECTRIC CO

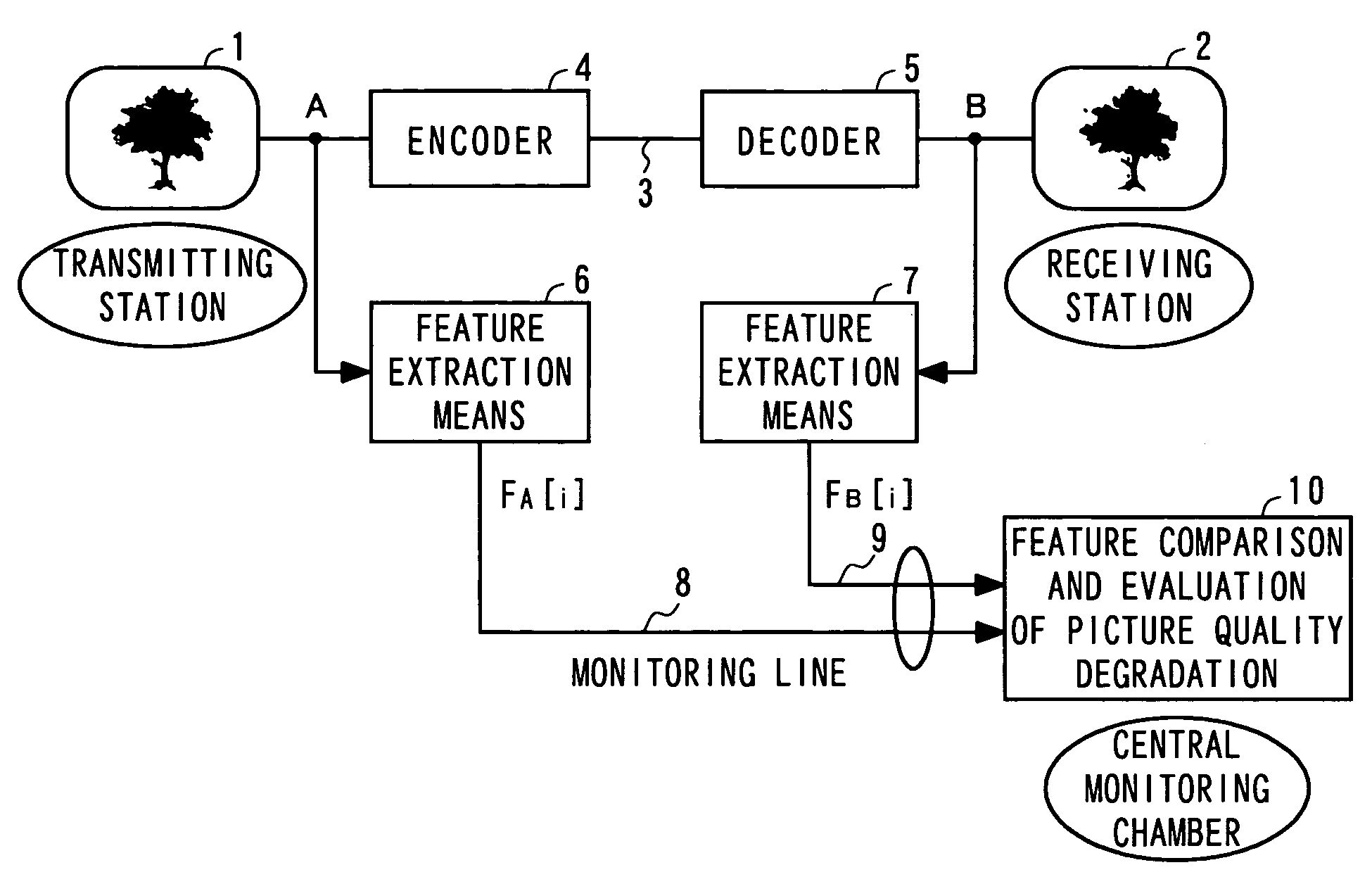

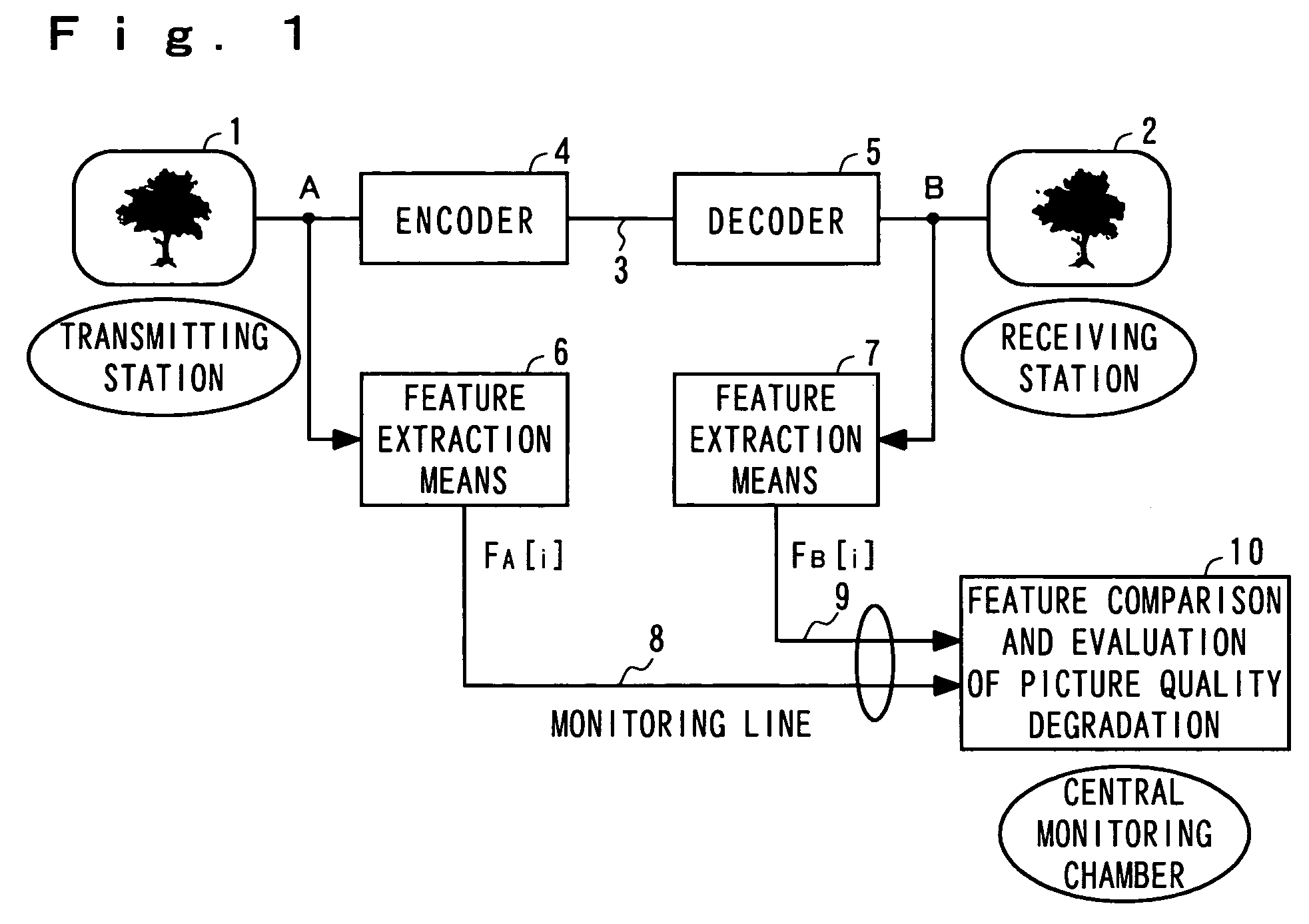

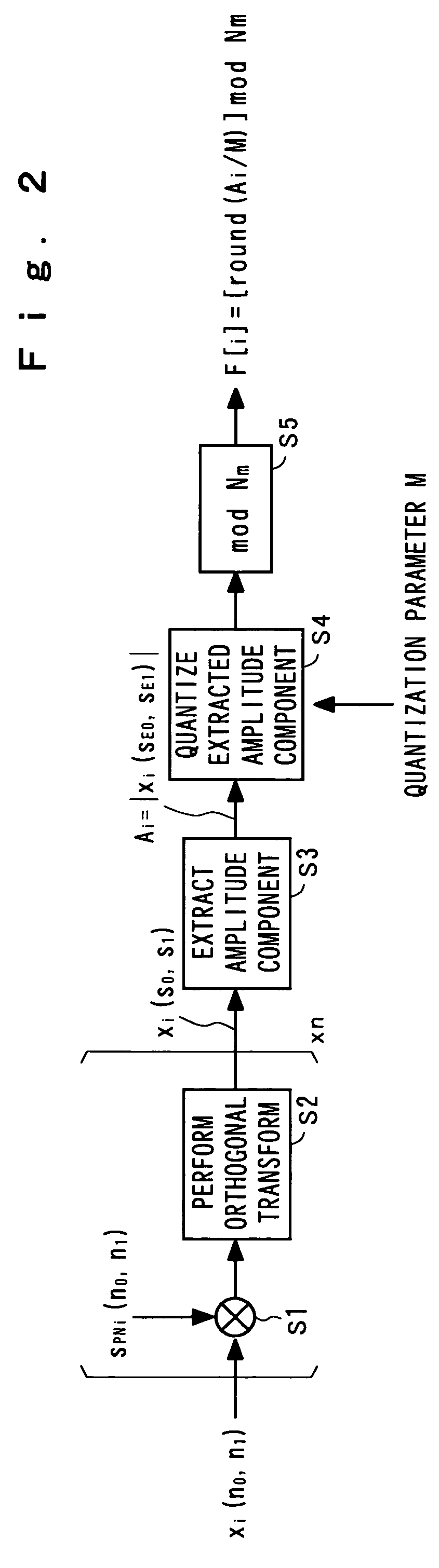

Picture feature extraction system and picture quality evaluation system

InactiveUS7385627B2Reduce the amount requiredReducing a line rate of each monitoring line necessaryCode conversionCharacter and pattern recognitionFeature extractionEvaluation system

This invention is intended to reduce a line rate of a monitoring line necessary for transmission of a picture feature without complicating a system. A video signal xi (n0, n1) of each block is subjected to spread spectrum by multiplying the video signal xi(n0, n1) by a PN sequences SPN1 (n0, n1) (in a step S1). The resultant video signal is orthogonally transformed by DFT, DCT, WHT, or the like (in a step S2). An amplitude component Ai=|Xi(SE0, SE1)| of an arbitrary component (SE0, SE1) in a coefficient Xi(S0, S1) obtained by the steps S1 and S2 is extracted (in a step S3), and the extracted amplitude component is quantized with a step size M (in a step S4). The picture feature F[i] is given as a residue obtained under a modulus Nm of a quantized typical value obtained by the quantization (in the step S4) (in a step S5).

Owner:KDDI CORP

Image processing apparatus, image processing method and program

InactiveUS8837011B2Low densityReduce bandingUltrasonic/sonic/infrasonic diagnosticsVisual representatino by photographic printingImaging processingImage formation

There is provided an image forming apparatus comprising: detection means for detecting position information indicating a scanning position; interval prediction means for predicting a first scanning line interval indicating a distance in the sub-scanning direction between the scanning line of interest and a succeeding scanning line to be scanned after the scanning line of interest; interval calculation means for calculating, by using the position information held by the holding means, a second scanning line interval indicating a distance in the sub-scanning direction between the scanning line of interest and the scanned scanning line; and rate calculation means for calculating a correction rate on an exposure amount for the scanning line of interest so that a predicted density calculated using the first scanning line interval and the second scanning line interval matches with a predicted density calculated using a predetermined reference scanning line interval.

Owner:CANON KK

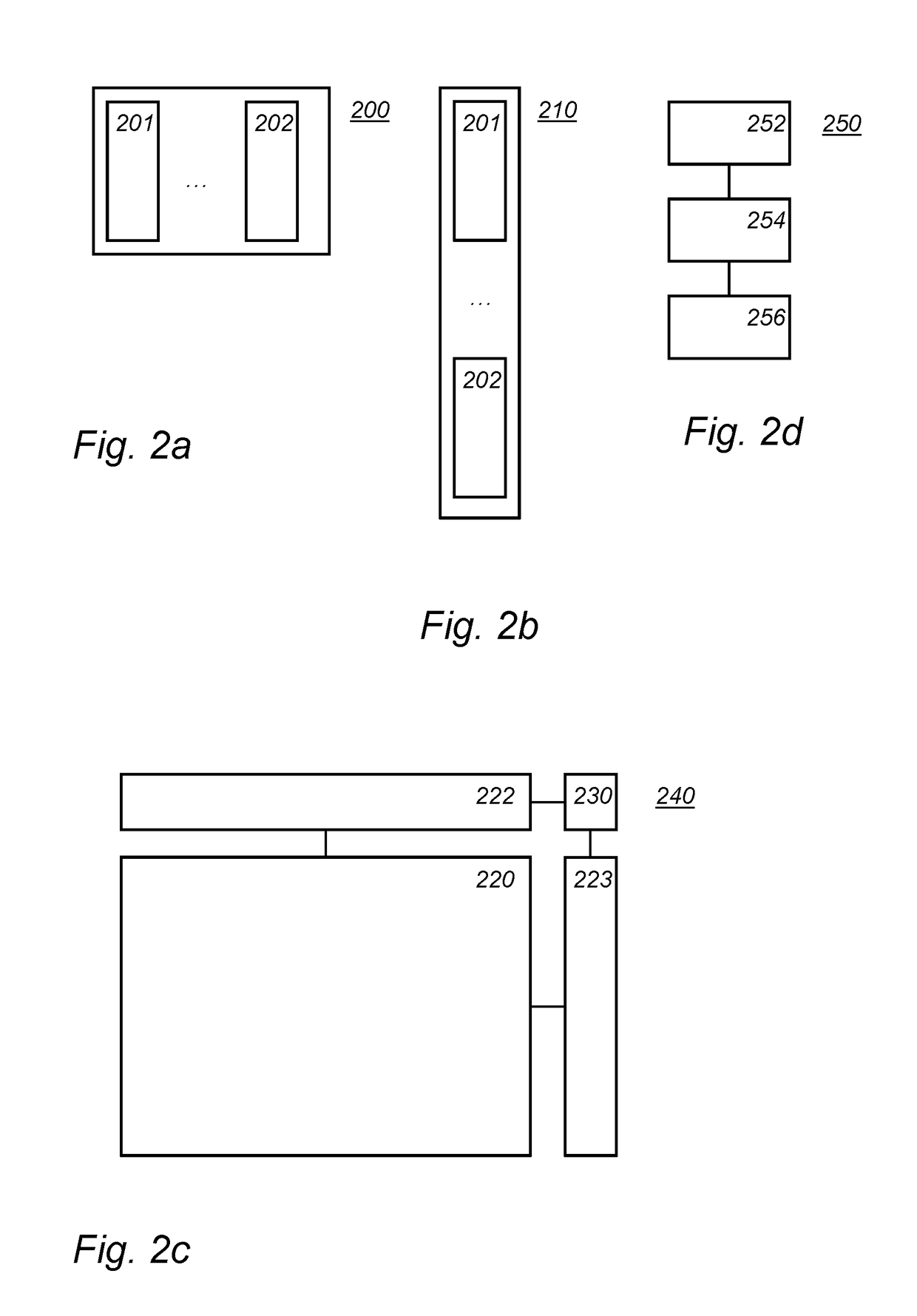

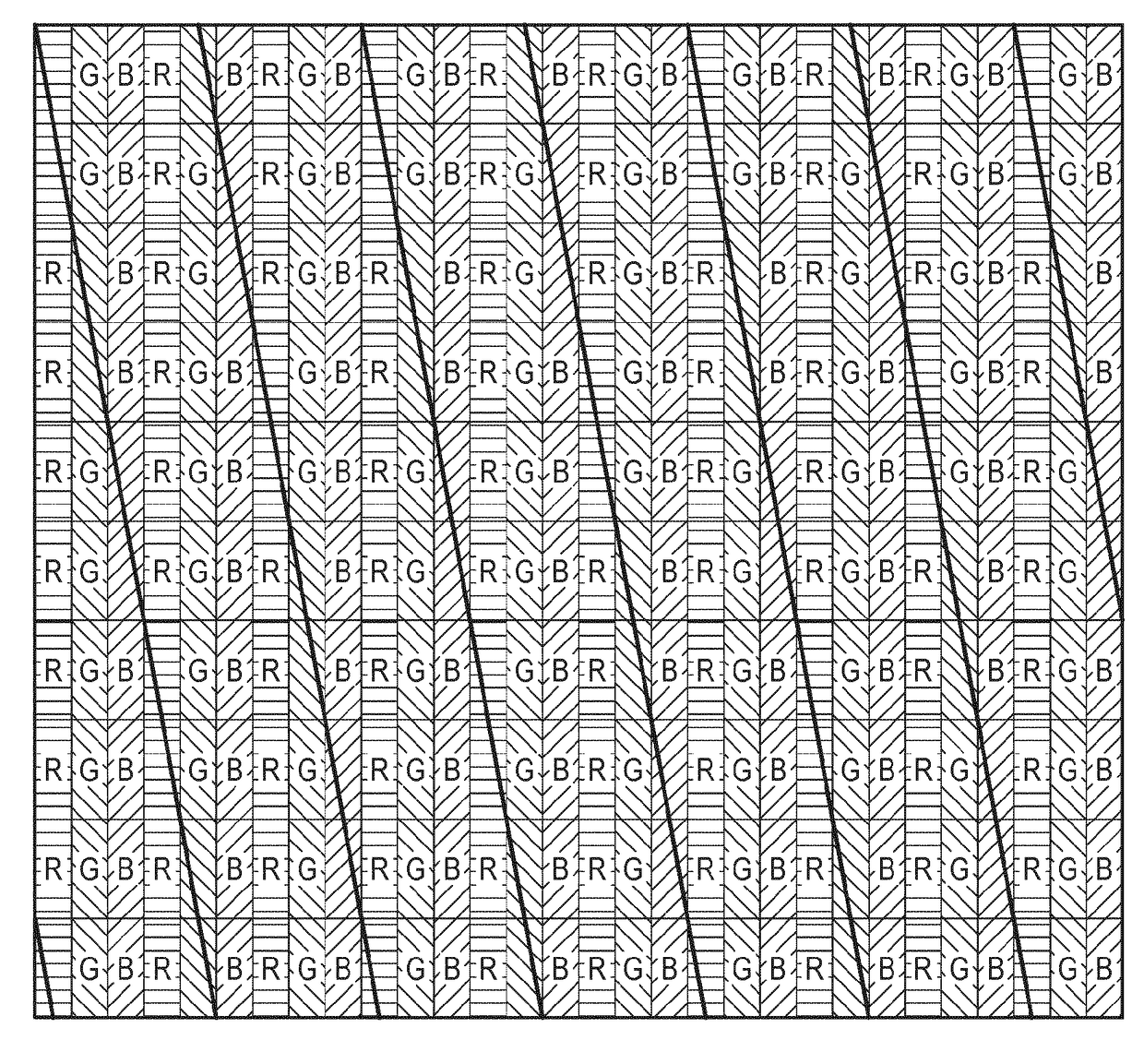

Autostereoscopic display system

InactiveUS20170150131A1Reduce viewing-angle dependencyReduce bandingStatic indicating devicesSteroscopic systemsHigh intensitySurface plate

An autostereoscopic display system (240) arranged to display an autostereoscopic image, the display system comprising a display panel (400, 500) comprising multiple sub-pixels. The multiple sub-areas of a sub-pixel comprising a high-intensity sub-area, wherein the high-intensity sub-area is arranged to provide light of a higher intensity than the other sub-areas in the multiple sub-areas of the sub-pixel for at least one image value received in the sub-pixel. The high-intensity sub-area may be arranged in the sub-pixel to reduce banding, inter alia, by splitting the multiple sub-areas along a direction parallel to the direction of the columns.

Owner:KONINKLJIJKE PHILIPS NV

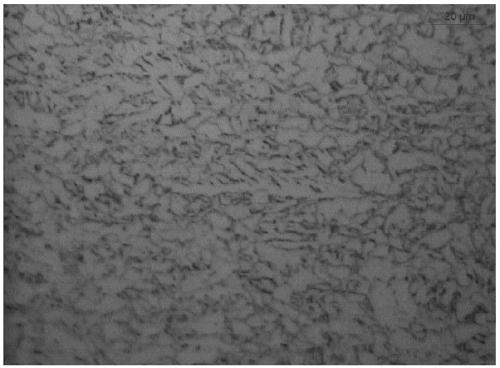

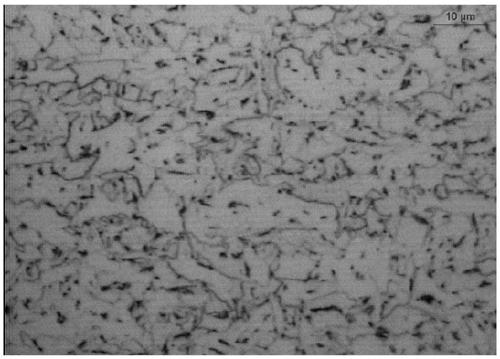

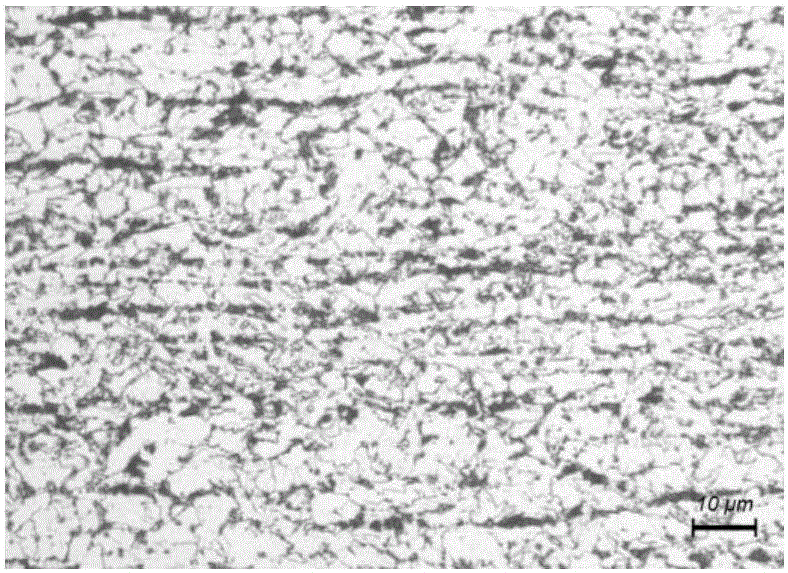

Production method of high H2S corrosion-resistant petroleum well casing pipe J55

InactiveCN109023045AImprove low temperature toughnessImprove corrosion resistanceFurnace typesHeat treatment furnacesHydrogenToughness

The invention discloses a production method of a high H2S corrosion-resistant petroleum well casing pipe J55. The production method comprises the processes of steel making, continuous casting, heating, rolling, coiling, uncoiling, pipe making and heat treating. According to the production method of the high H2S corrosion-resistant petroleum well casing pipe J55, on the component design, low-content C, low-content P and low-content S are adopted to reduce banded segregation, and cracking and temper brittleness tendency are reduced; the low-temperature toughness and the welding corrosion resistance of steel are improved through low-content O, low-content N and low-content H; Nb, Cr and Mo are added to form a passivation film, hydrogen is prevented from entering the passivation film, and thenthe effect of effectively inhibiting the hydrogen sulfide corrosion rate is achieved; and a TMCP rolling technology is adopted and combined with a low-temperature rolling technology, therefore, it isguaranteed that austenite phase transformation is generated at low temperature, ultrafine ferrite structures are obtained, and then production of the high H2S corrosion-resistant petroleum well casing pipe J55 is achieved. According to the production method, the safety performance of the petroleum well casing pipe industry is greatly improved, and the production method has the characteristics ofbeing low in product cost, excellent in comprehensive performance and the like.

Owner:HANDAN IRON & STEEL GROUP +1

Generation of drive values for a display

InactiveUS20170155895A1Improve the display effectImprove image qualityStatic indicating devicesSteroscopic systemsDisplay deviceComputer science

An apparatus is arranged to generate sub-pixel drive values for sub-pixels of an autostereoscopic display. The display comprises a display panel (503) with the sub-pixels, and further comprises a view forming optical element (509), such as a lenticular screen, overlaid the display panel (503). The apparatus comprises a receiver (903) for receiving light output values for pixels of at least one image to be presented. A driver (905) generates the sub-pixel drive values. Specifically, it generates a first drive value for a first sub-pixel in response to a light output value for a pixel of which the first sub-pixel is a part, a sub-pixel value of at least one other sub-pixel and a cross-talk pattern reflecting sub-pixel cross-talk characteristics for sub-pixels of the autostereoscopic display. In addition, the sub-pixel drive values are biased towards extreme drive values, i.e. towards fully-on or fully-off values.

Owner:KONINKLJIJKE PHILIPS NV

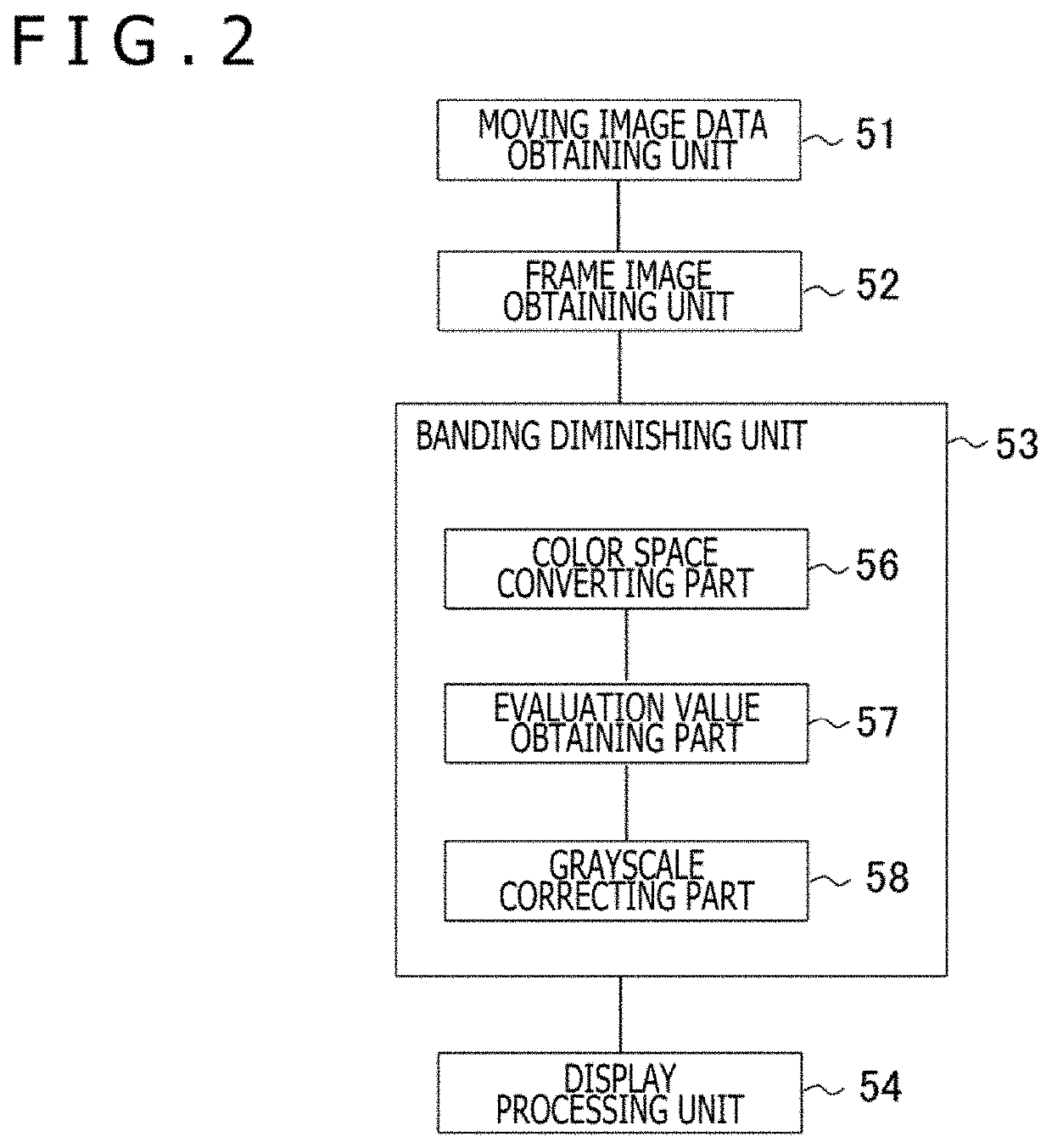

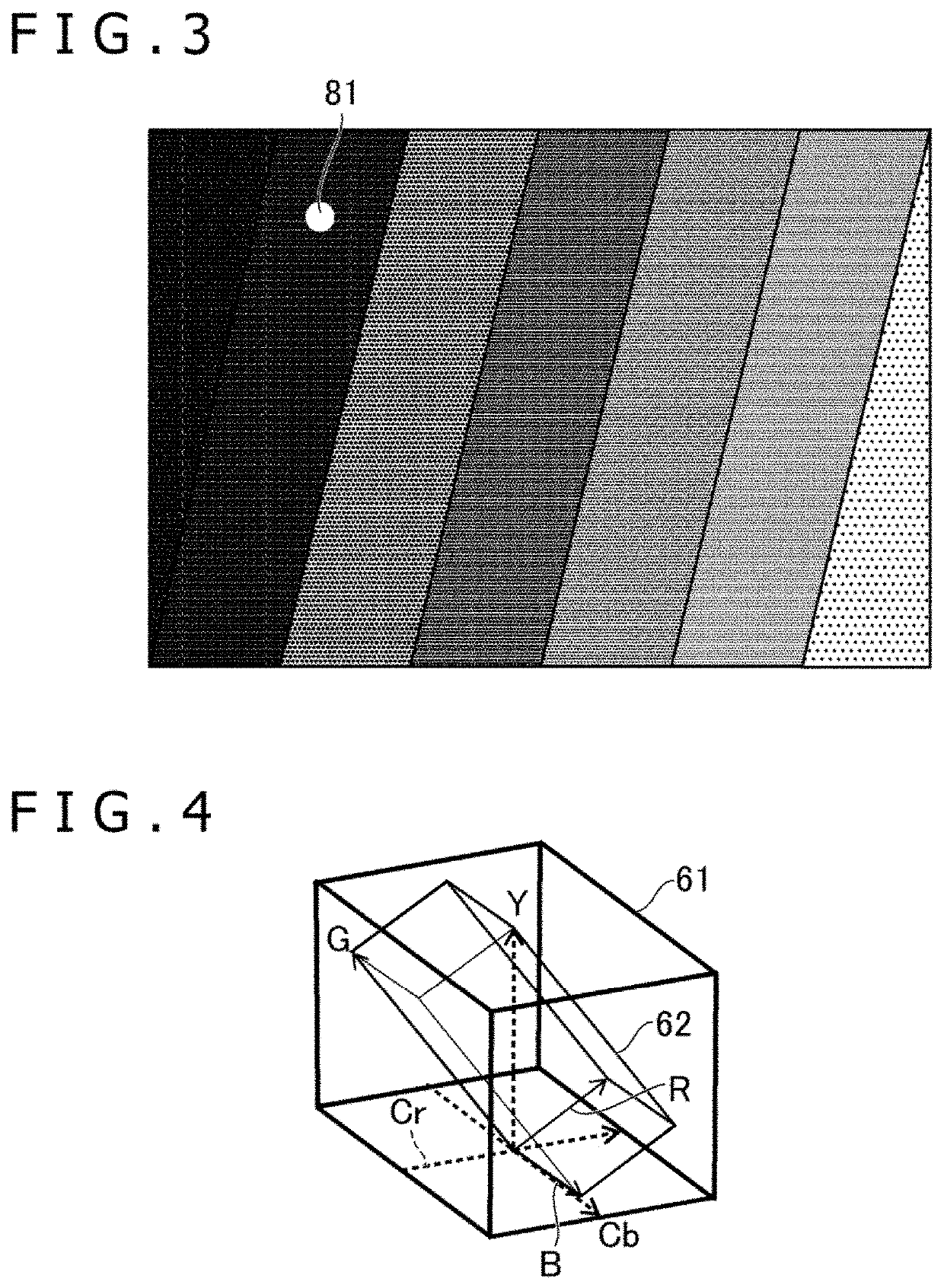

Image processing device, image processing method, and program

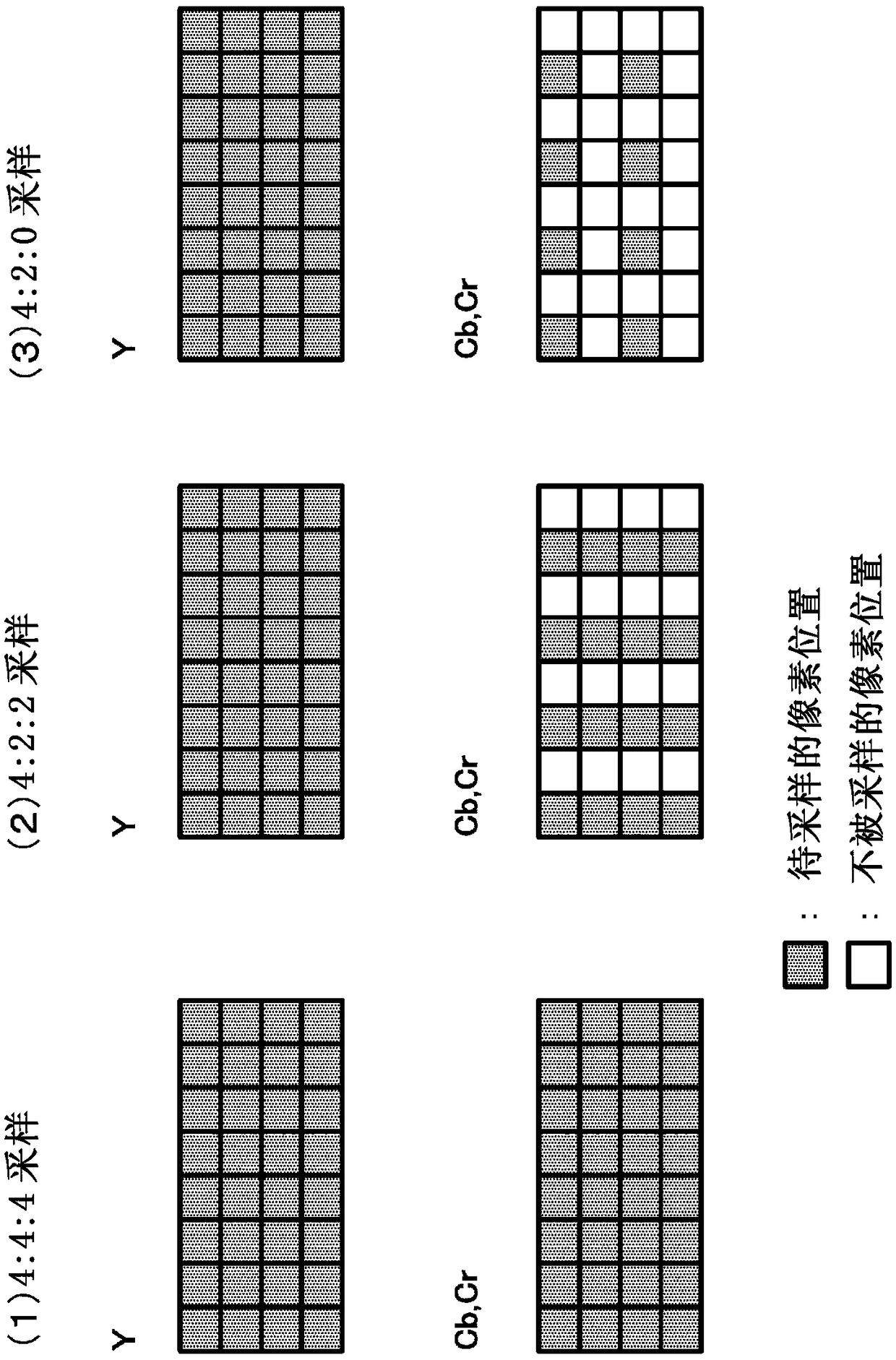

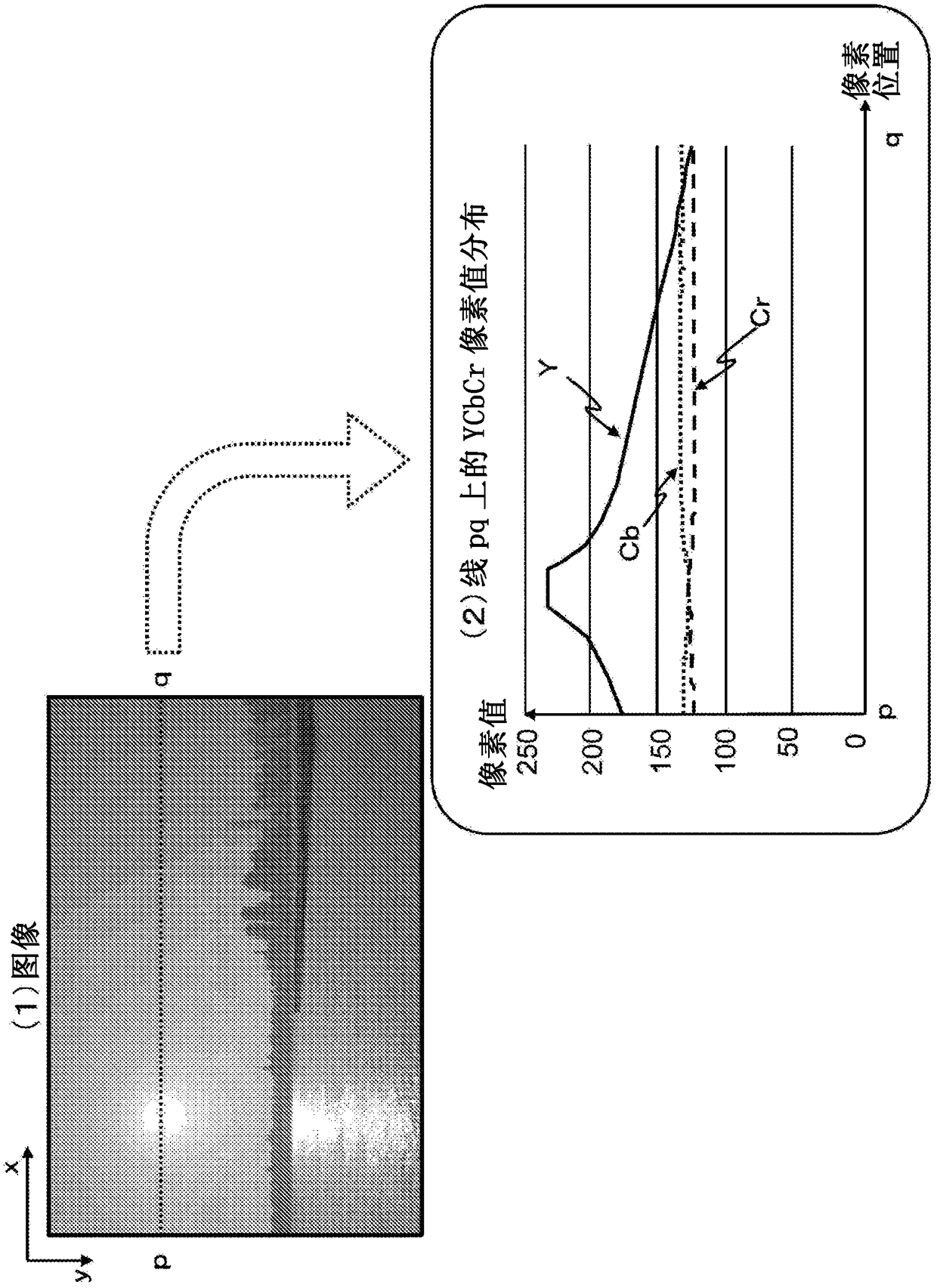

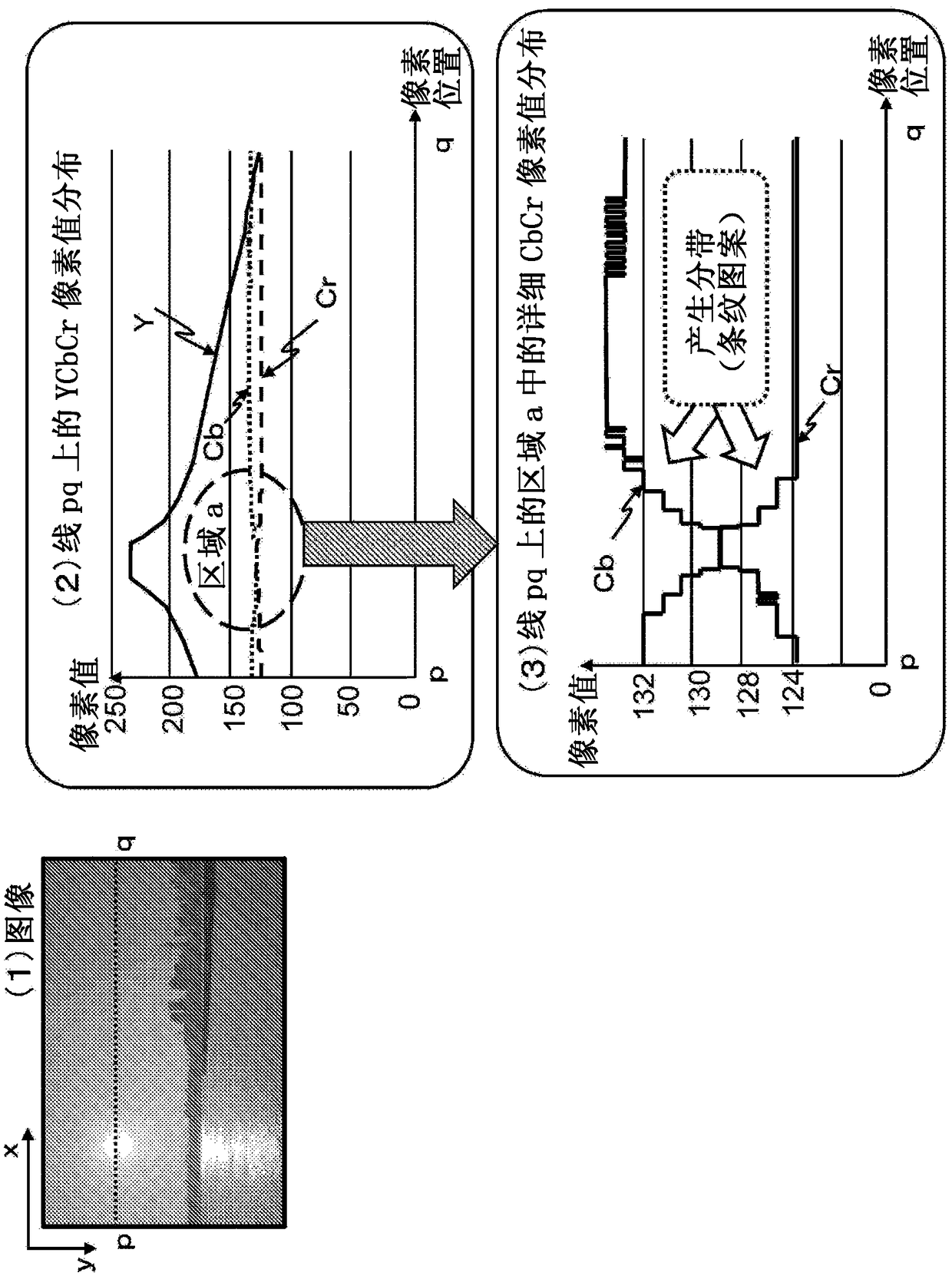

ActiveCN109155845AReduce bandingImprove image qualityColor signal processing circuitsBrightness and chrominance signal processing circuitsImaging processingBrightness perception

Provided are a device and method for reducing the banding phenomenon in subsampled images, and that achieve high picture quality. A subsampled image to which an adjoining pixel value is copied at thesubsampling position of the pixel value is made to serve as an input image, and global gain for the signal to be corrected, which is the ratio of the inclination of the signal to be corrected for theglobal area comprising a plurality of consecutive pixels including the pixel position of the pixel to be corrected in the input image to the inclination of the brightness signal, is calculated, localinclination of brightness, which is the inclination of the brightness signal of a local area smaller than the global area, which is within the global area and includes the pixel position of the pixelto be corrected of the input image, is calculated, local inclination of brightness is multiplied by the global gain of the signal to be corrected, and the multiplication results are applied to calculate the corrected pixel value for the pixel to be corrected. For example, the signal pixel value subject to correction on the edge of the local area is added to the multiplied value to calculate the corrected pixel value.

Owner:SONY CORP

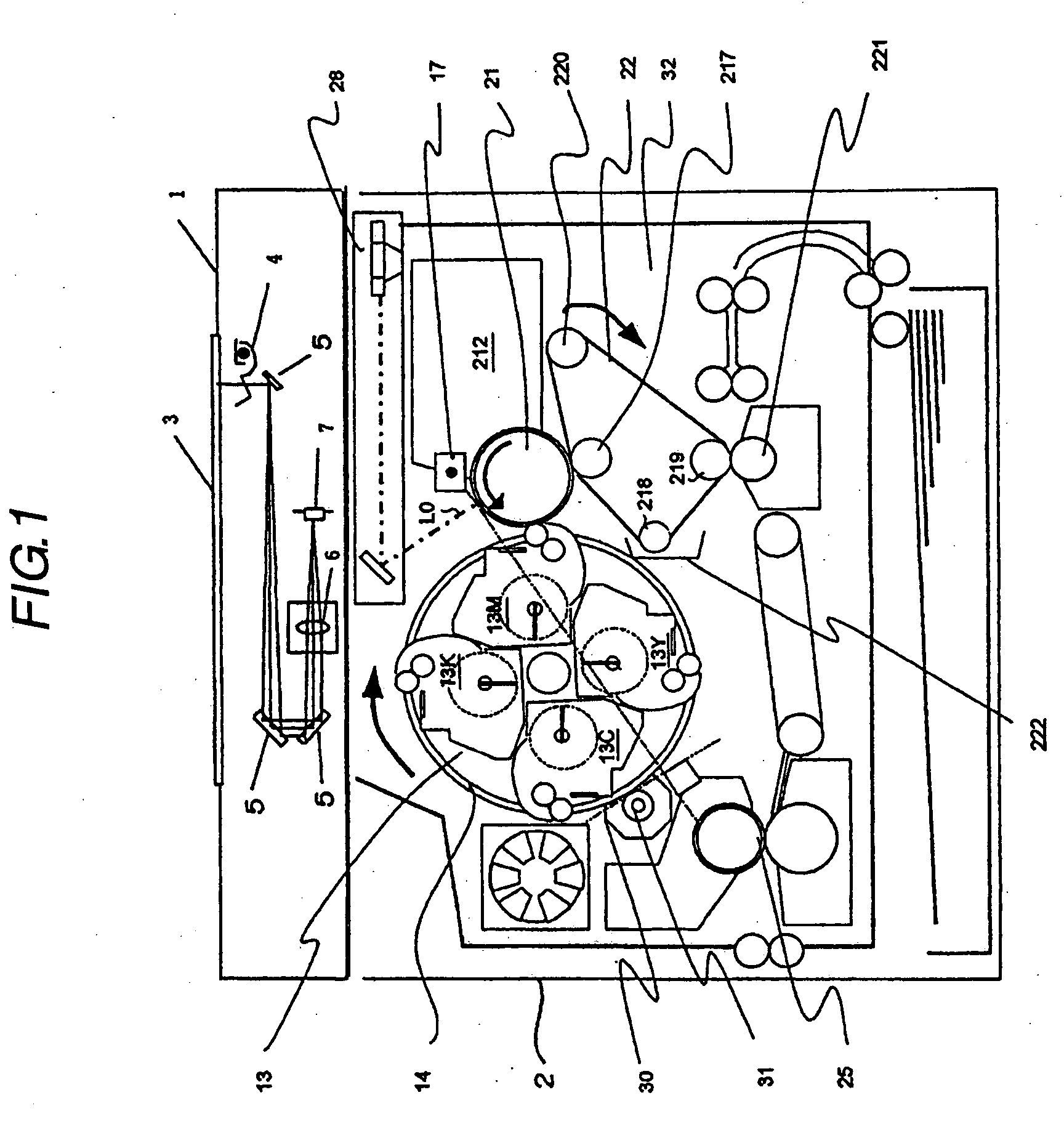

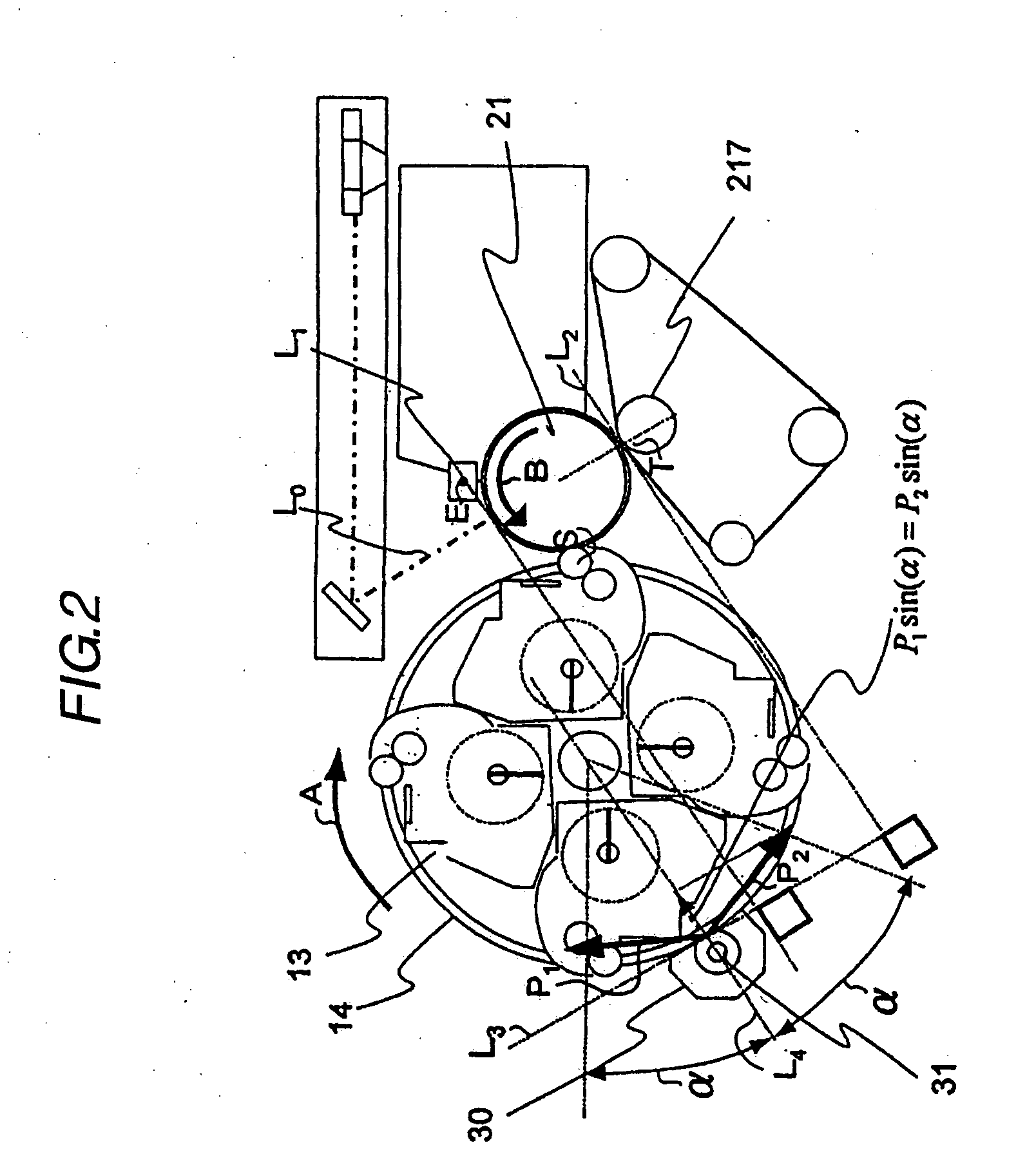

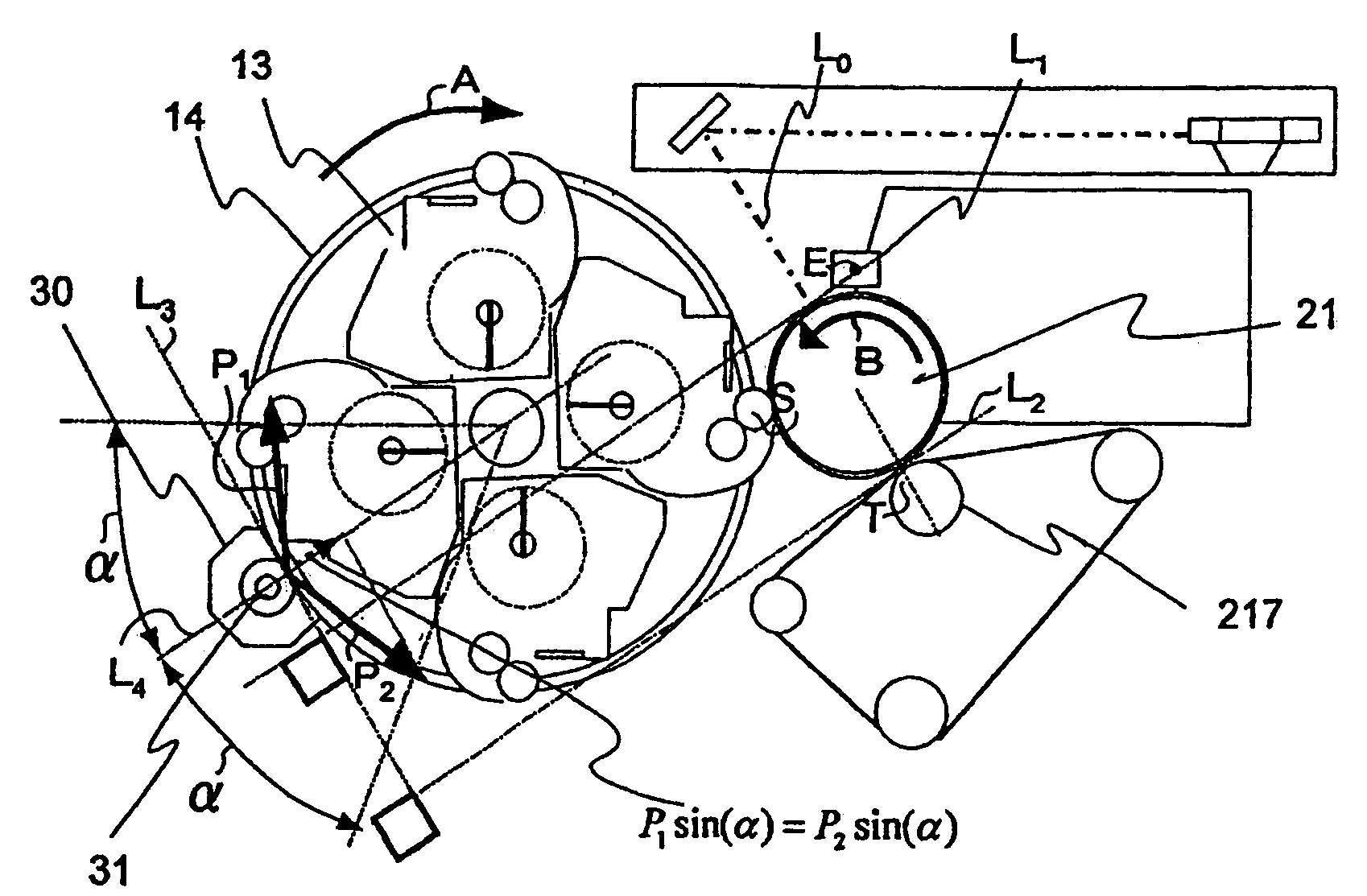

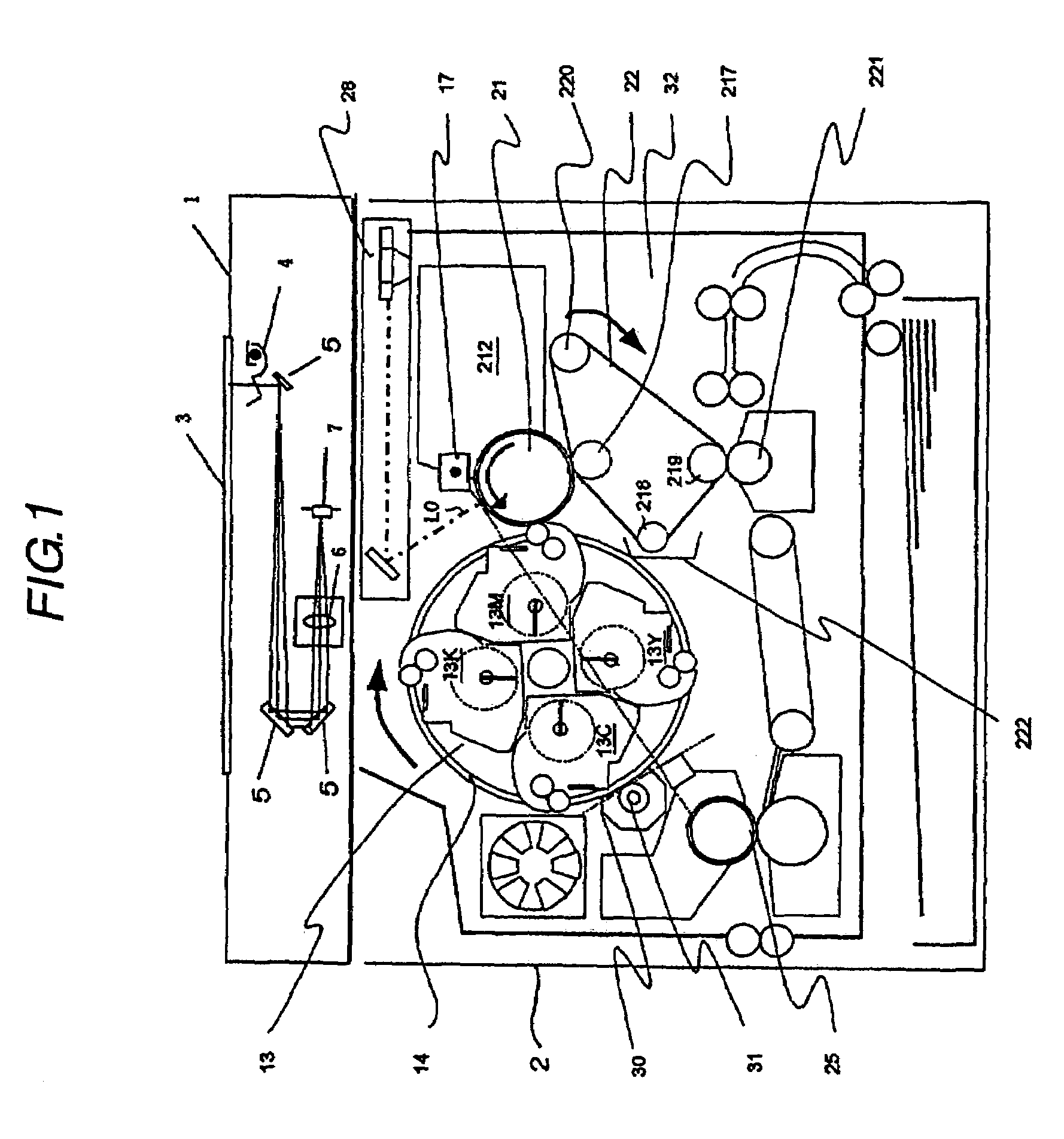

Image forming apparatus

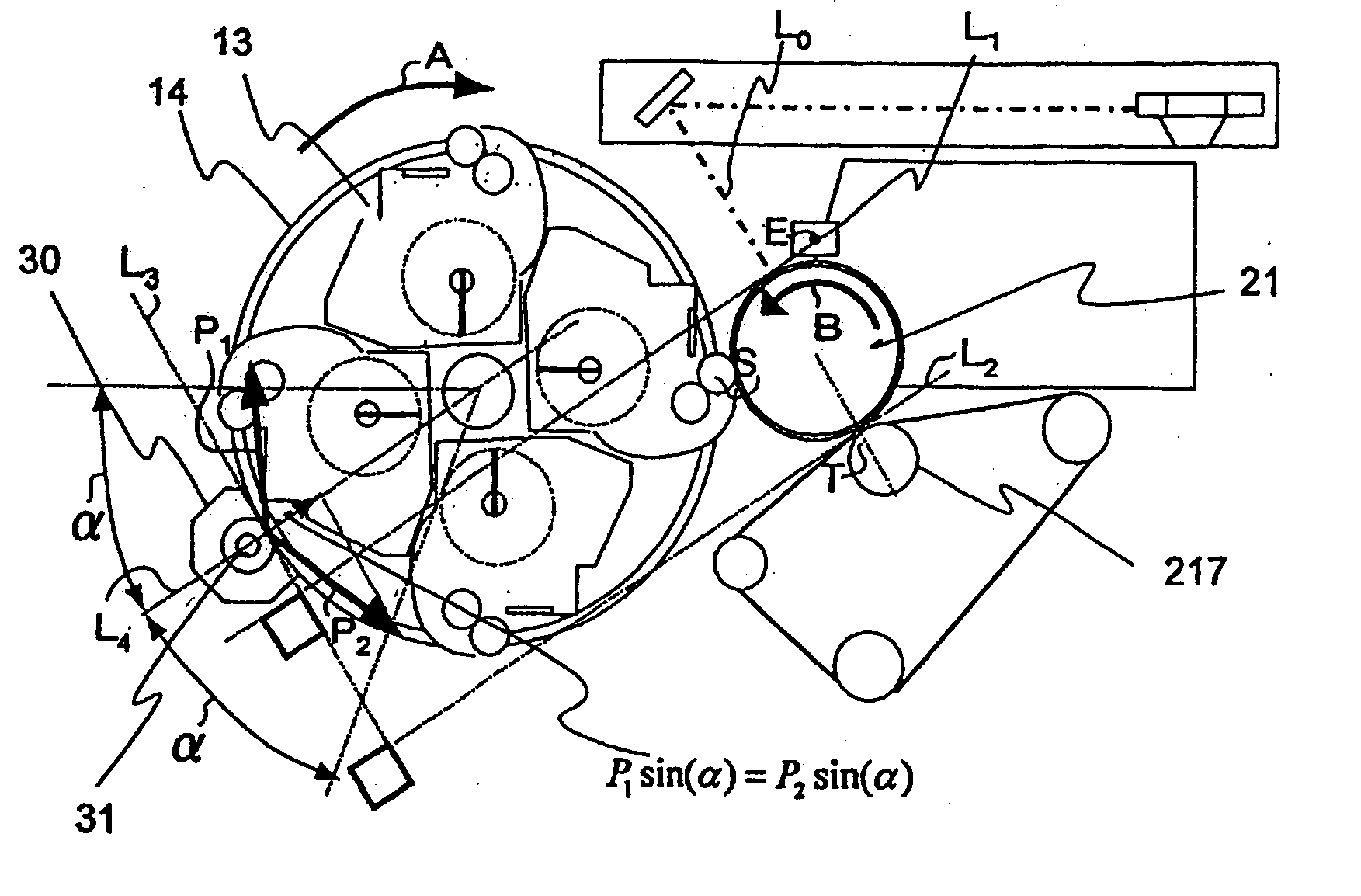

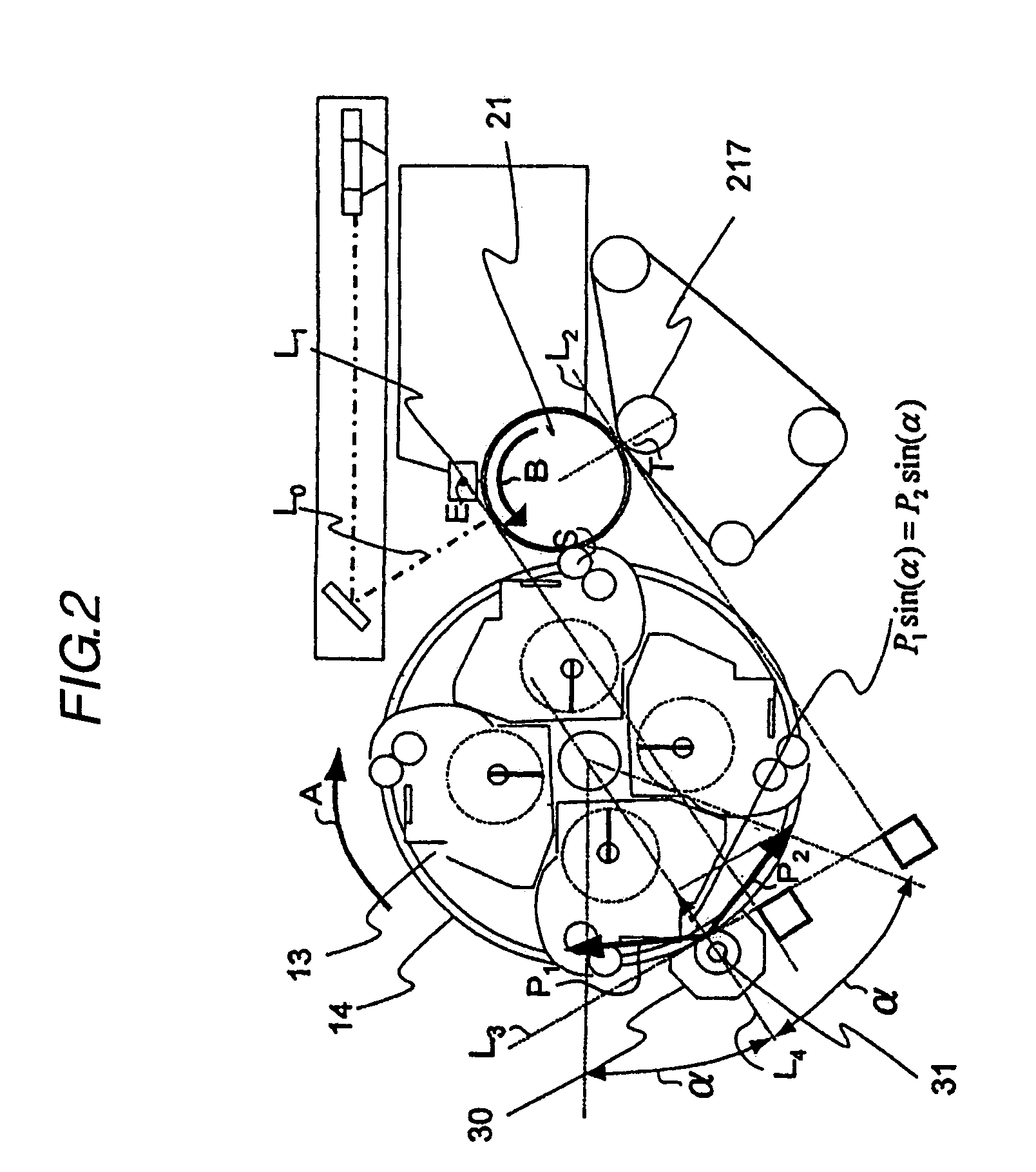

The present invention relates to an image forming apparatus comprising: an exposing means and a developing means. The developing means comprises a plurality of developing devices, a rotating member rotatable while supporting the plurality of the developing devices, and a driving means for the rotation drive of the rotating member for selectively moving the plurality of the developing devices to the developing position such that the driving means transmits driving force to the rotating member via a gear at a drive transmitting position. An angle θe(°) formed by a straight line linking the rotation center of the rotating member and the drive transmitting position and the tangent of the image bearing member at an exposing position in the image bearing member moving direction satisfies the following relationship with the premise that an pressure angle of the gear is α(°) and the image bearing member rotating direction is positive: −α≦θe≦α.

Owner:CANON KK

Image forming apparatus

The present invention relates to an image forming apparatus comprising: an exposing means and a developing means. The developing means comprises a plurality of developing devices, a rotating member rotatable while supporting the plurality of the developing devices, and a driving means for the rotation drive of the rotating member for selectively moving the plurality of the developing devices to the developing position such that the driving means transmits driving force to the rotating member via a gear at a drive transmitting position. An angle θe(°) formed by a straight line linking the rotation center of the rotating member and the drive transmitting position and the tangent of the image bearing member at an exposing position in the image bearing member moving direction satisfies the following relationship with the premise that an pressure angle of the gear is α(°) and the image bearing member rotating direction is positive: −α≦θe≦α.

Owner:CANON KK

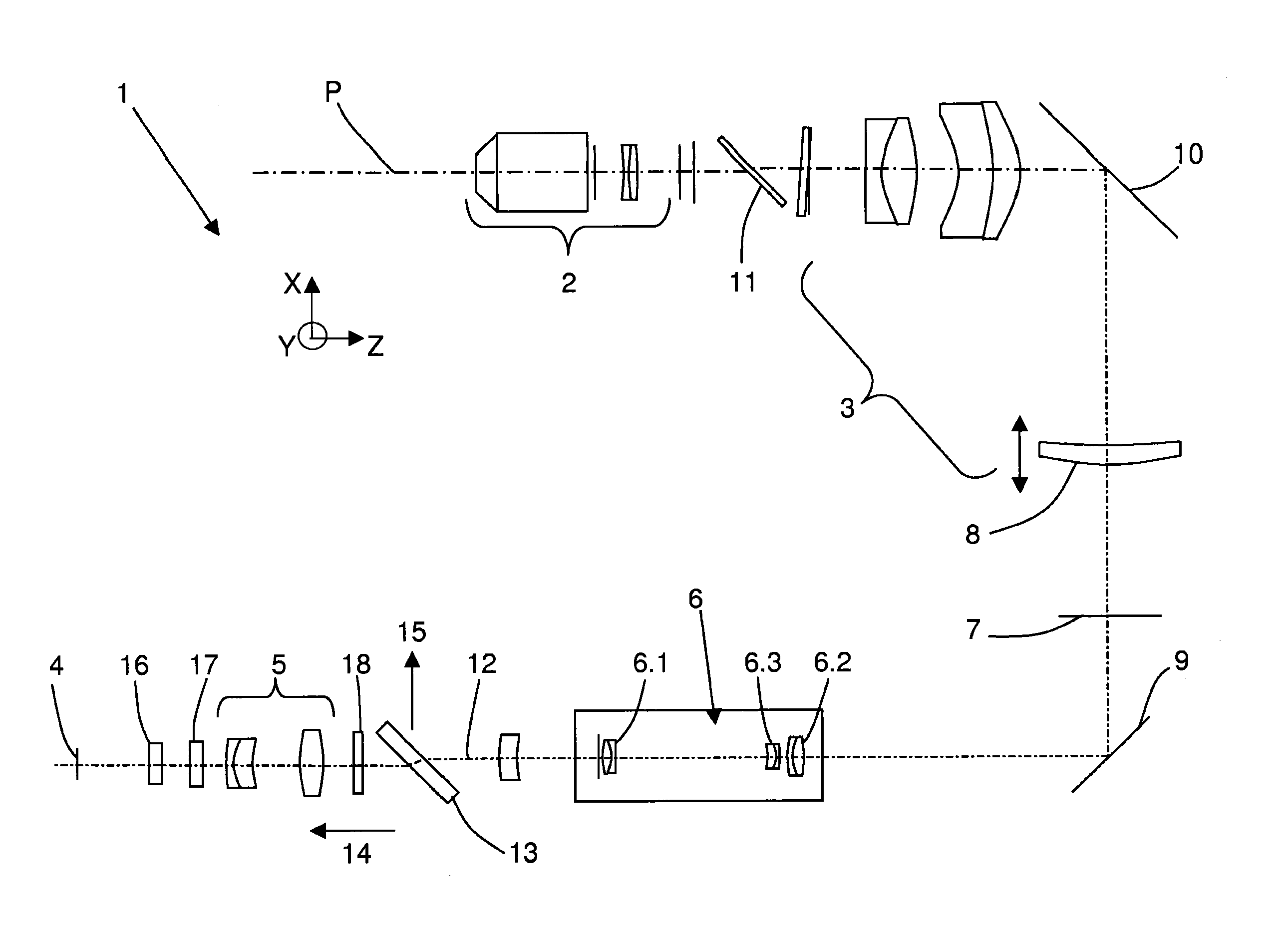

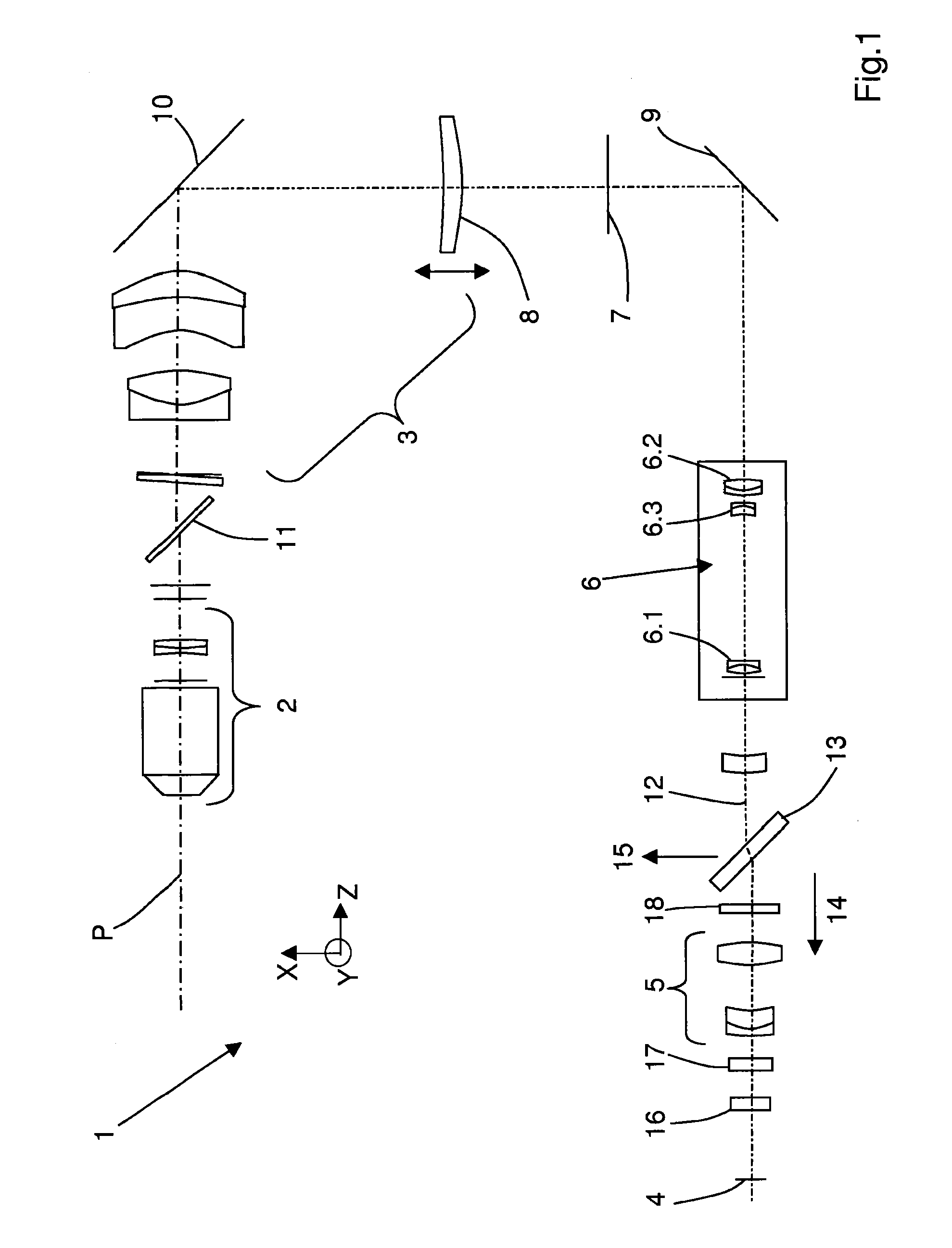

Microscope with light sheet illumination

A family of microscopes include an illumination device which produces a planar light sheet along an illumination axis of an illumination beam path and a transverse axis normal to the illumination axis. A detection device detects light emitted from the sample region along an axis of detection of a detection beam path. The illumination and detection axes as well as the transverse axis and the axis of detection being oriented relative each other at an angle unequal to zero. A light sheet generator also produces rotationally symmetrical light and includes structure and control for rapidly scanning the sample region along the transverse axis. The illumination device includes a second light sheet generator having a first astigmatically active optical element with at least one astigmatic lens for producing a static sheet of light. Selection elements used to select either the first or the second light sheet or both together to produce the sheet of light.

Owner:CARL ZEISS MICROSCOPY GMBH

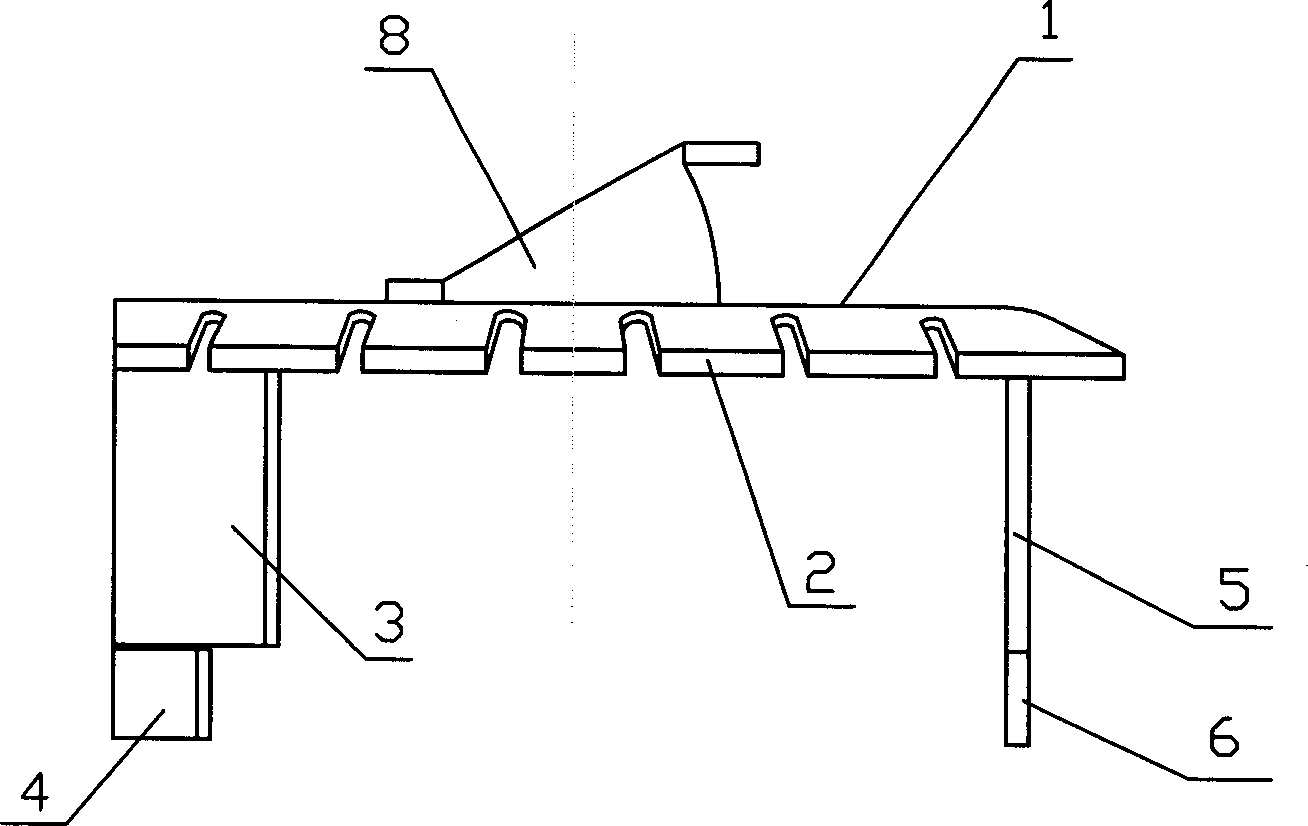

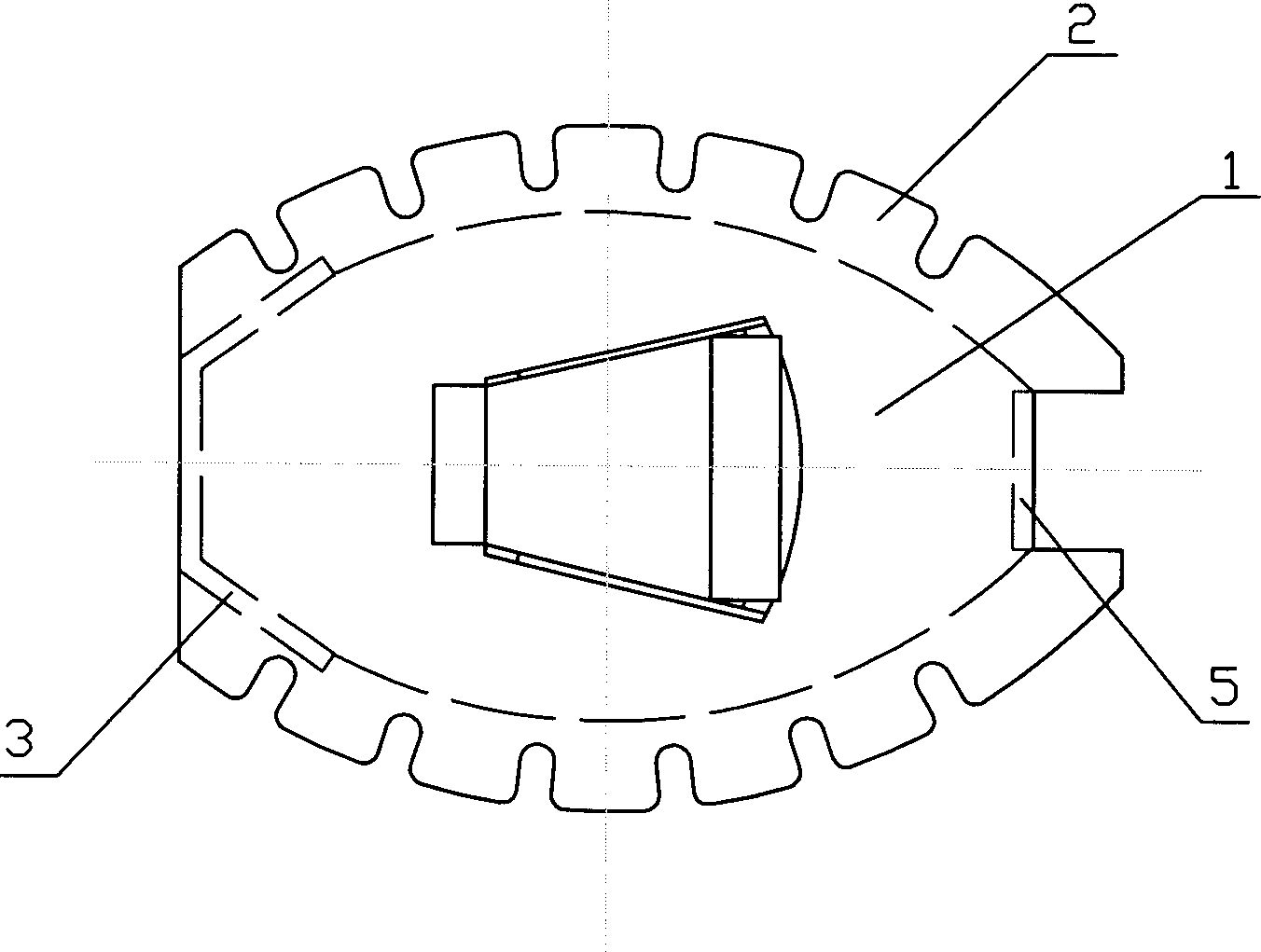

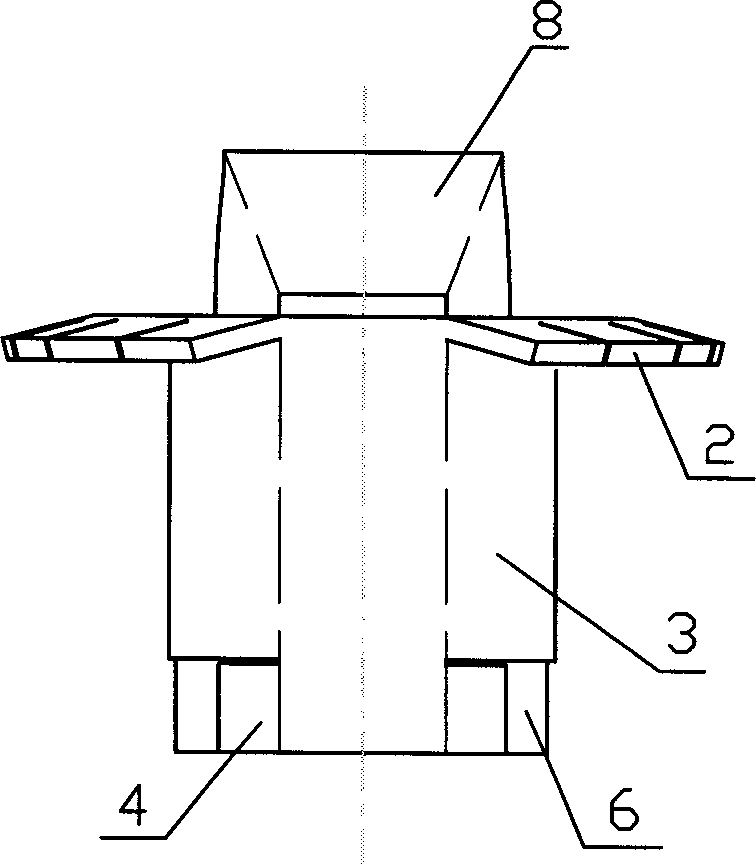

Gas-liquid parallel current guide floating valve

InactiveCN1907530AIncrease motivationGreat driving forceDistillation separationConvective overshootEngineering

The invention relates to a guide float valve, which comprises: an ellipses valve cover whose short axle has spindle guide plate bended at two sides, and long axle has one ellipses liquid plate at one end, wherein the lower end of liquid plate has one valve stop pin; another end of said long axle has a vertical bended valve leg; the lower end of said leg has another valve stop pin; the valve leg has a ventilate hole; the valve cover has a guide small float valve; the liquid plate can completely block the airflow reversed to the liquid, and via using liquid plate and guide small float valve to guide the gas, the gas will be guided out, and the convective overshooting between valves can be avoided, to reduce the liquid gradient and reduce the energy consumption.

Owner:西安汉术化学工程股份有限公司

Continuous pipe resistant to H2S corrosion and manufacturing method thereof

The invention discloses a continuous pipe resistant to H2S corrosion and a manufacturing method thereof. The continuous pipe comprises following material by mass percent such as C of 0.03-0.06 %, Si less than or equal to 0.152 %, Mn of 0.15-0.55%, P less than or equal to 0.01, S less than or equal to 0.003, Cr of 0.2-0.6 %, Mo less than or equal to 0.02, Ni of 0.1-0.27%, V of less than or equal to 0.06%, Ti of less than or equal to 0.03%, Nb of 0.05-0.09%, and the balance Fe. The continuous pipe resistant to H2S corrosion helps to solve the problem that an existing steel continuous pipe loses efficacy at a quick pace in an acid environment.The low-carbon low-manganese continuous pipe resistant to H2S corrosion has great intensity, plasticity and corrosion resistance.While meeting the mechanical properties of tubular products in the first place, banded segregation of parent material is substantially reduced by the low-carbon low-manganese alloying composition design so that defects are effectively reduced and H collection is prevented. The formation and expansion of cracks do not easily occur so that corrosion resistance of tubular products is remarkably improved. In the meantime, residual stress of tubular products by optimizing weld seams and carrying out thermal processing technology of parent material so that corrosion resistance is further enhanced.

Owner:BAOJI PETROLEUM STEEL PIPE

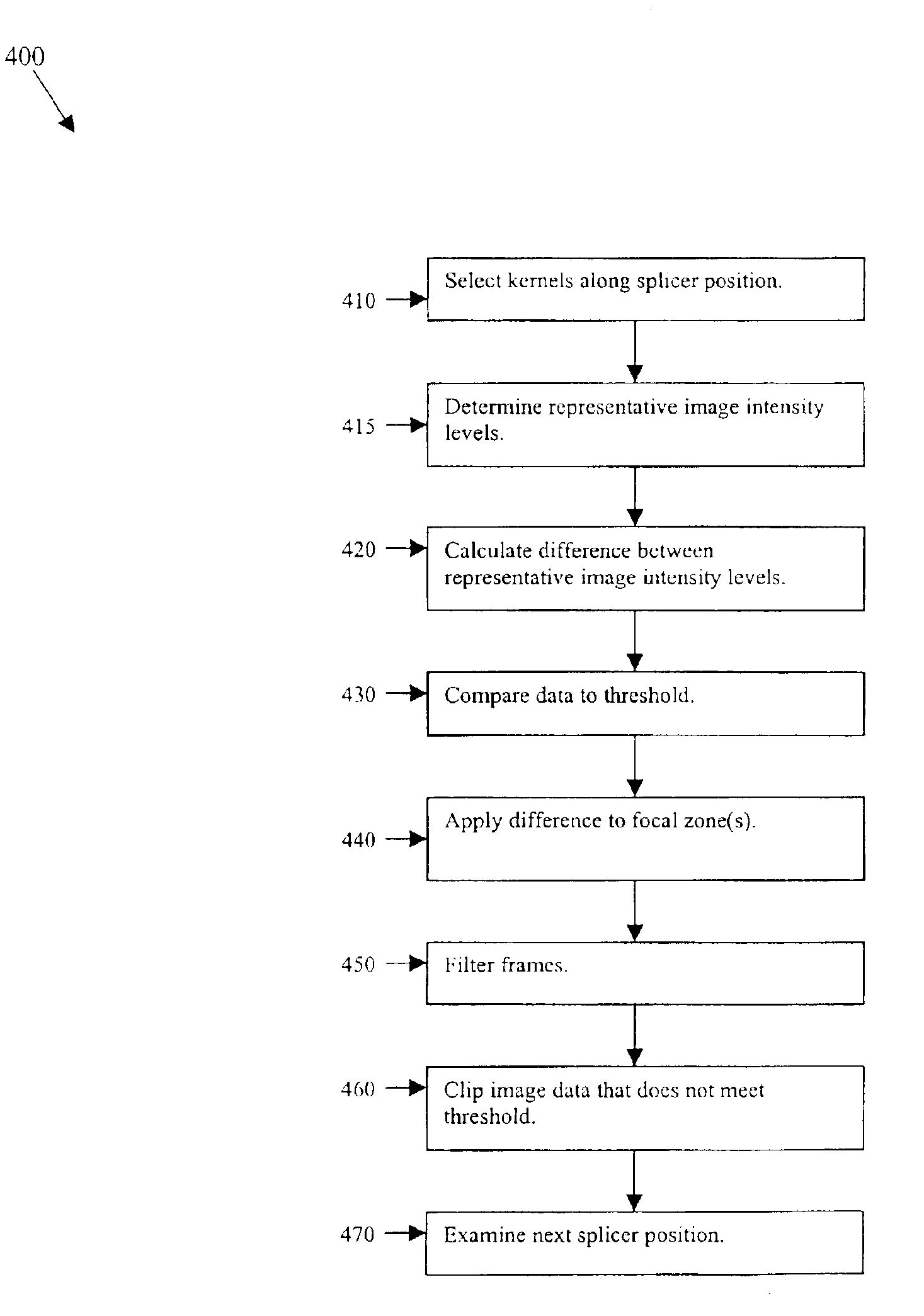

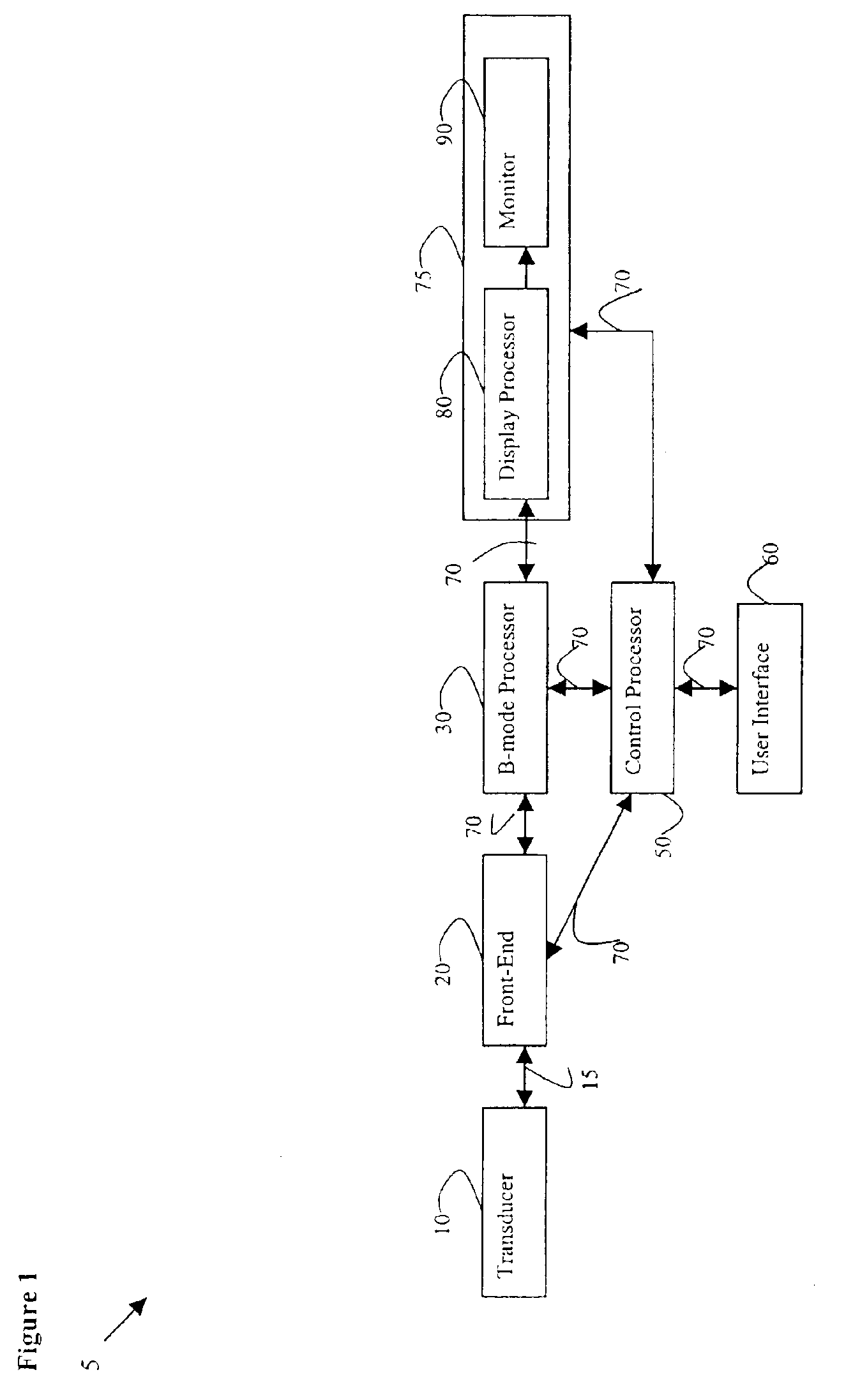

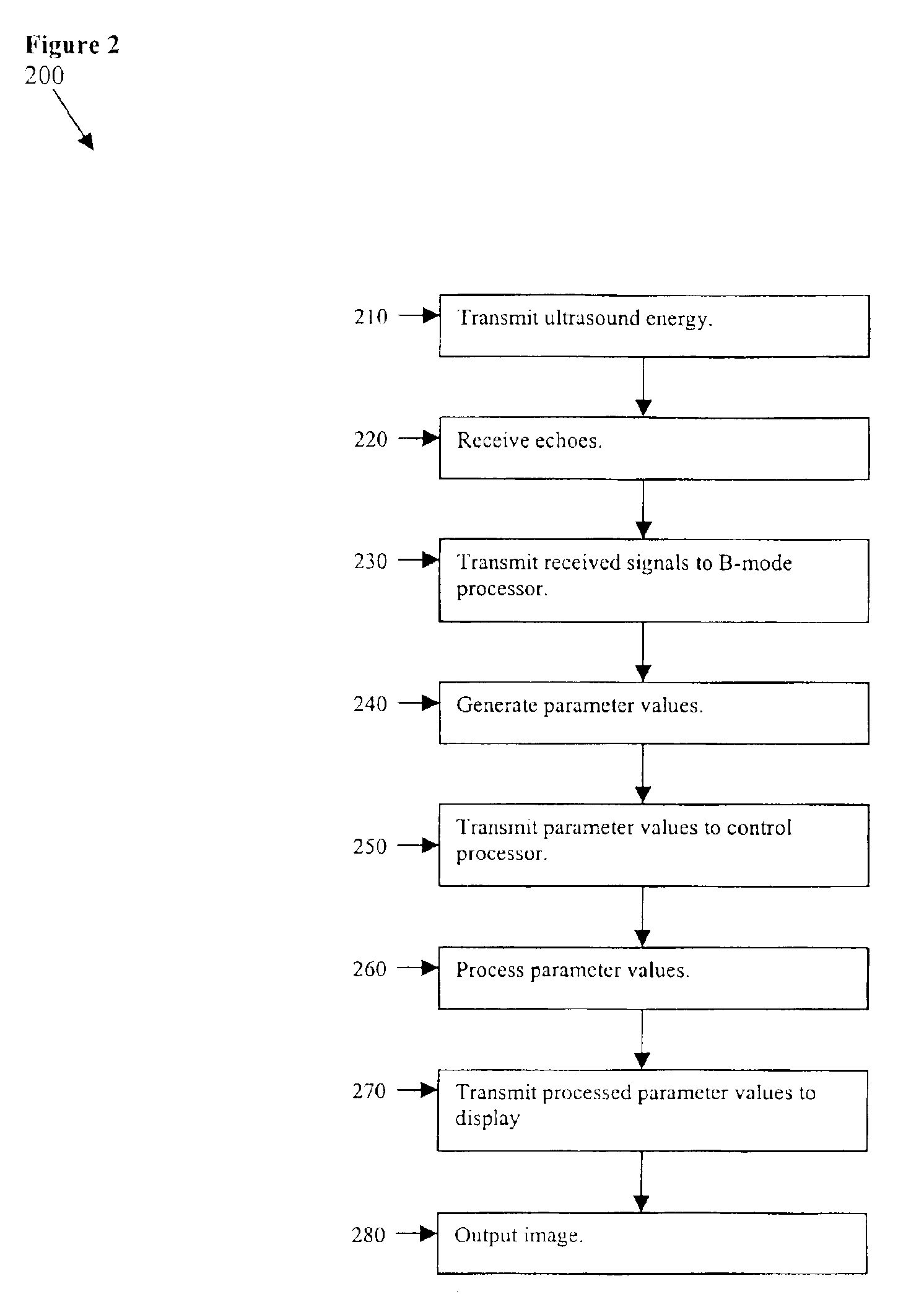

Method and apparatus for B-mode image banding suppression

InactiveUS6893399B2Reduce bandingUltrasonic/sonic/infrasonic diagnosticsWave based measurement systemsB mode ultrasoundFocal zone

Certain embodiments include a system and method for banding suppression in a B-mode ultrasound image. Banding occurs in a diagnostic image when two or more focal regions having different waveforms and / or frequencies, for example, are combined. The resulting difference in intensity between the focal regions produces banding in the final image. For purposes of illustration only, the method below will be described with two focal zones. Certain embodiments of the present invention reduce banding in a diagnostic image including a plurality of focal zones by processing the first focal zone, determining intensity around the border or “stitch line” between the two focal regions, and adjusting the second focal region based on the difference in intensity. Preferably, processing is done in real time as image frames are updated.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

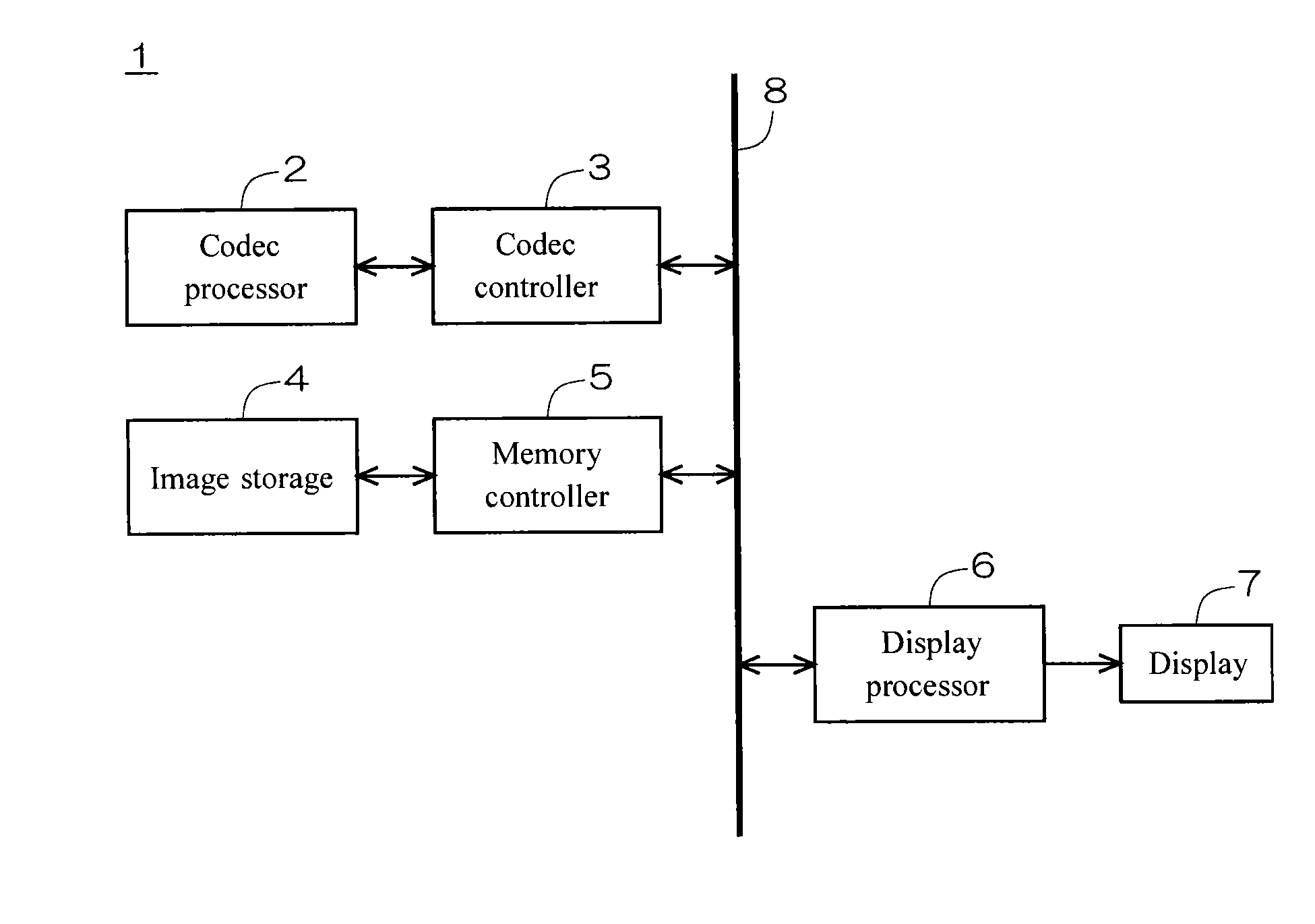

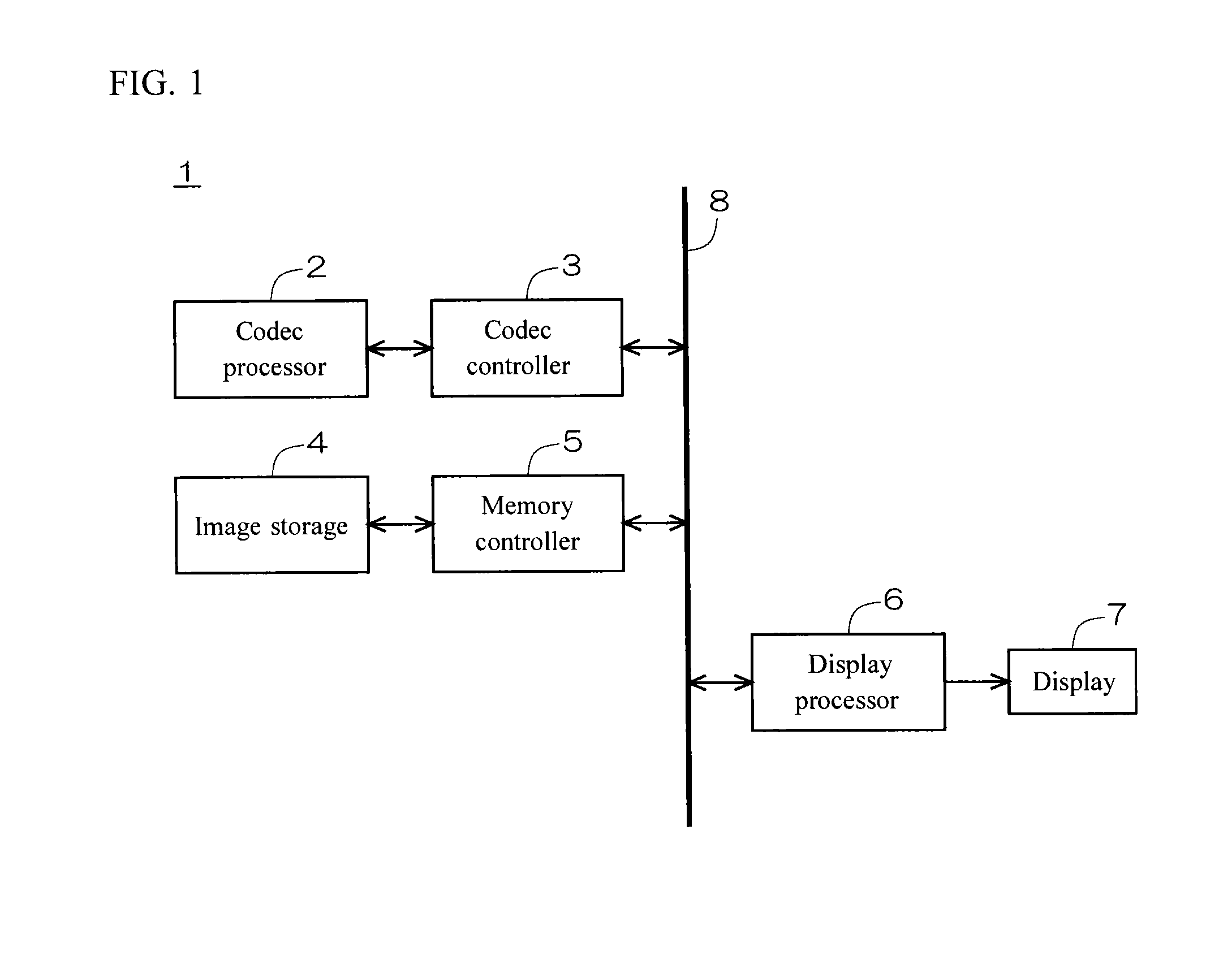

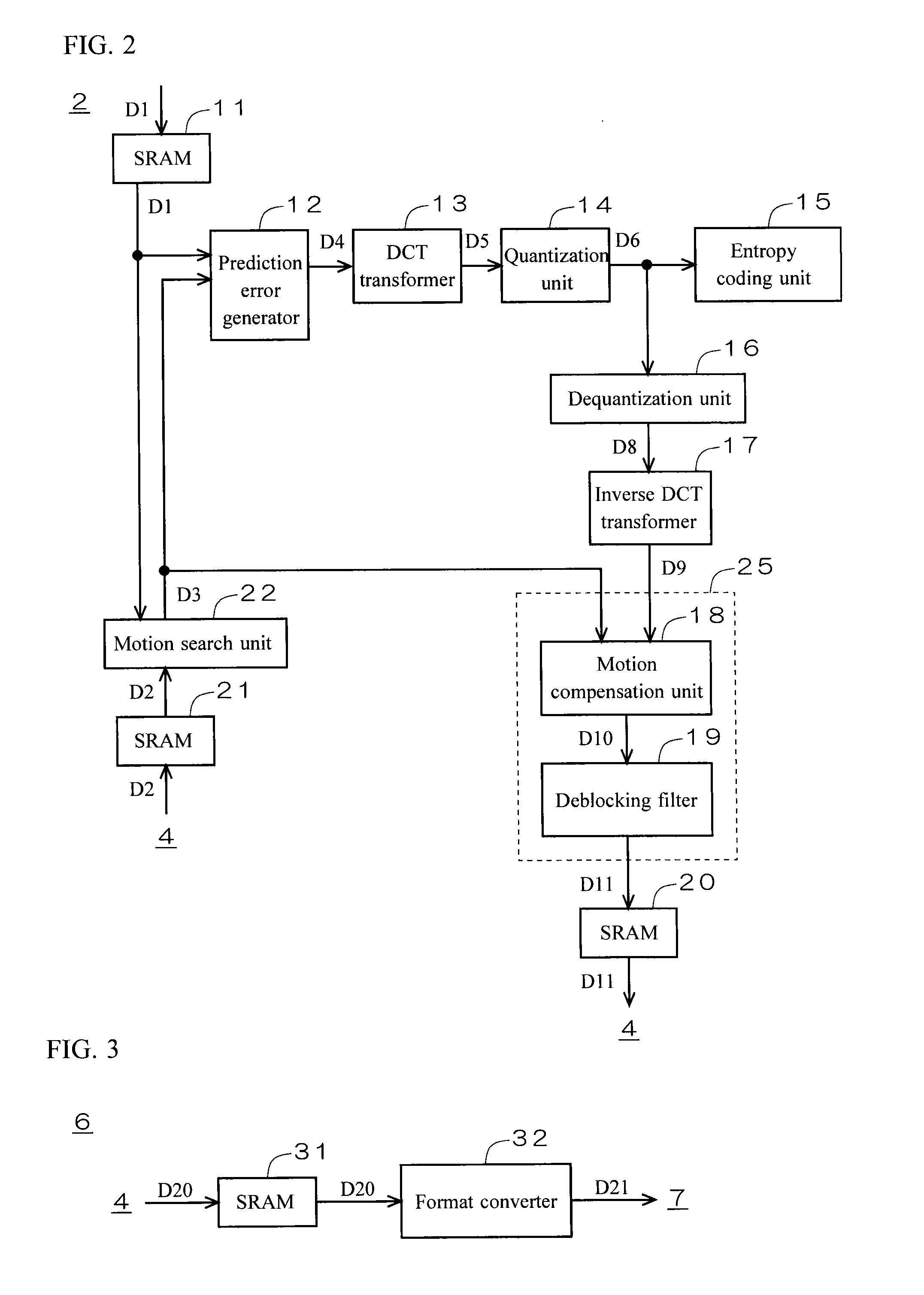

Image processor

ActiveUS20150172706A1Increase cache hit ratioProcessing time be shortenColor television with pulse code modulationColor television with bandwidth reductionVertical motionImage storage

The codec processor includes an SRAM that holds a reference image read from an image storage, and a motion search unit that performs motion search on the basis of a reference image held in the SRAM to generate a prediction block for a target block in an input image. The SRAM holds a reference image having a horizontally equivalent number of pixels to a horizontal number of pixels of the input image and a number of pixels vertically larger than or equal to a vertical motion search range.

Owner:MEGACHIPS

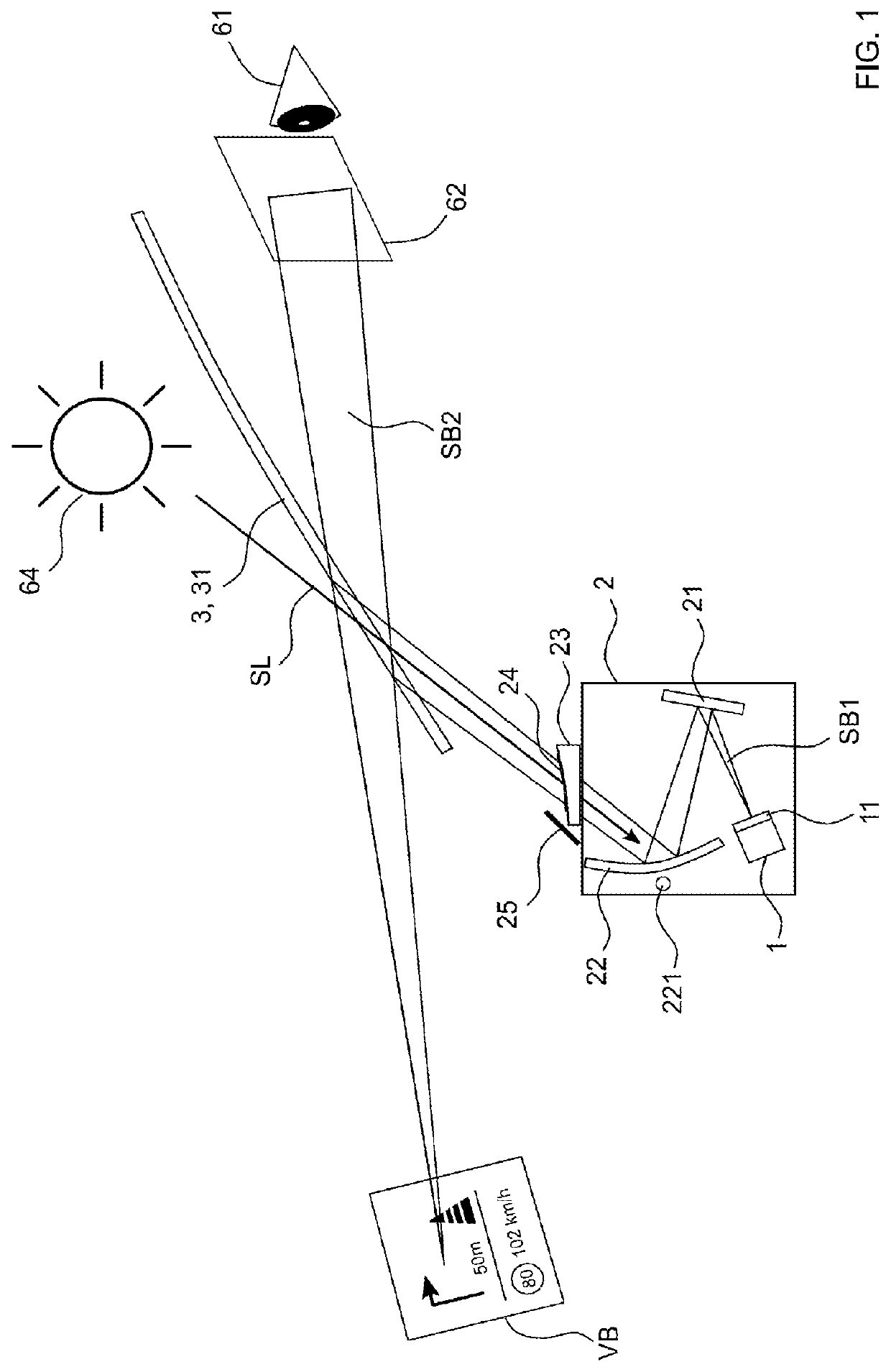

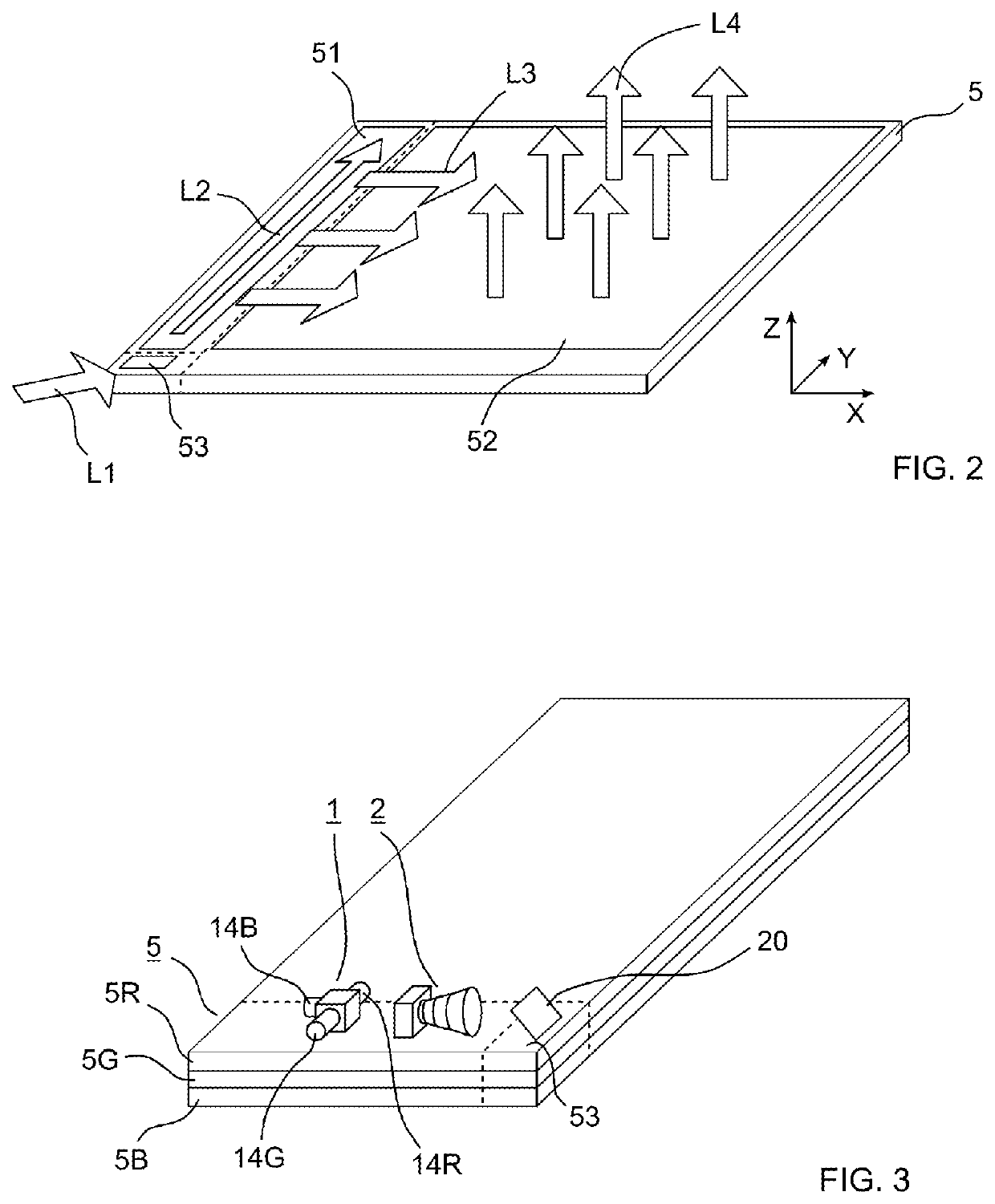

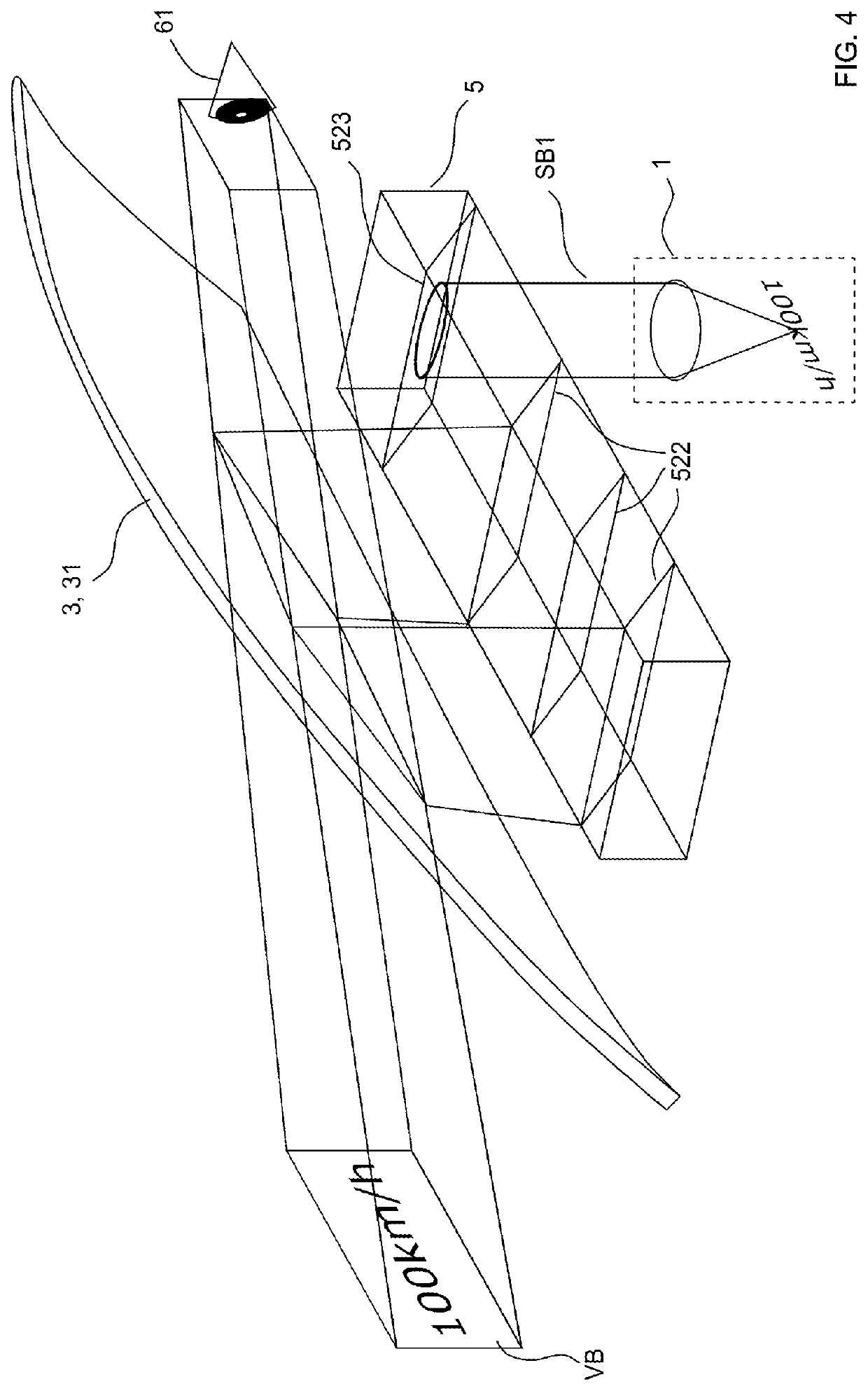

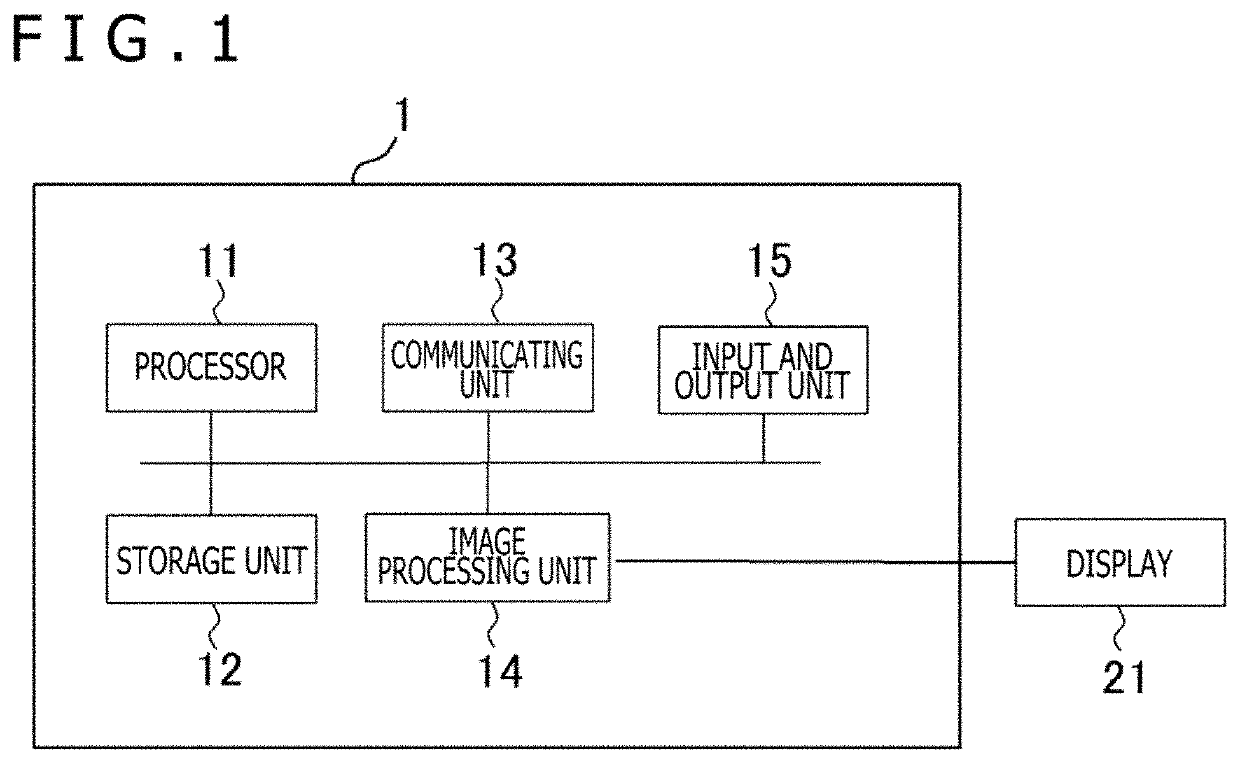

Device for producing a virtual image having a field-point-dependent aperture

PendingUS20210141222A1Simple wayReduce bandingMechanical apparatusPlanar/plate-like light guidesExit pupilLight beam

The invention relates to a device for generating a virtual image with scanning image production. The device has at least one light source for producing a light beam, an image-generating unit for producing an image, and an optical waveguide for expanding an exit pupil. The optical waveguide has an input coupling hologram. With the imaging unit in connection with the input coupling hologram, a field-point-dependent aperture for the optical waveguide is implemented.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Image processing device, image processing method, and program

ActiveUS20200059573A1Reduce bandingThe right amountImage enhancementTelevision system detailsPattern recognitionImaging processing

To prevent any variation of the grayscale to be originally present from becoming unclear, diminishing banding that is generated when an image including a gradation is displayed. An image processing device obtains image data of an original image including plural pixels, obtains an evaluation value that represents the possibility of the generation of the banding on the basis of the color distribution of a noted area including a target pixel that is any one of the plural pixels, produces an intermediate image of which the color of the target pixel is corrected on the basis of the evaluation value, and causes a corrected image to be output on the basis of the produced intermediate image. A correction amount of the color of the target pixel is varied in accordance with the evaluation value, in the correction of the color.

Owner:SONY COMPUTER ENTERTAINMENT INC

Computer system using disk controller and operating service thereof

InactiveUS20060277403A1Reduce data transferIncrease probabilityEnergy efficient ICTInput/output to record carriersDisk controllerNetsniff-ng

When there is an access passing between unit disk controllers, the band of a mutual connecting network must be very large in order to exhibit the performance sufficiently, so that the cost is increased. In the present invention, the access number of a logical volume is monitored, the change of an access path is suggested to an upper class device, and the logical volume is moved or copied to each unit disk controller, so that the mutual connecting network is used mainly for copy of the logical volume, thereby reducing the necessary band.

Owner:HITACHI LTD

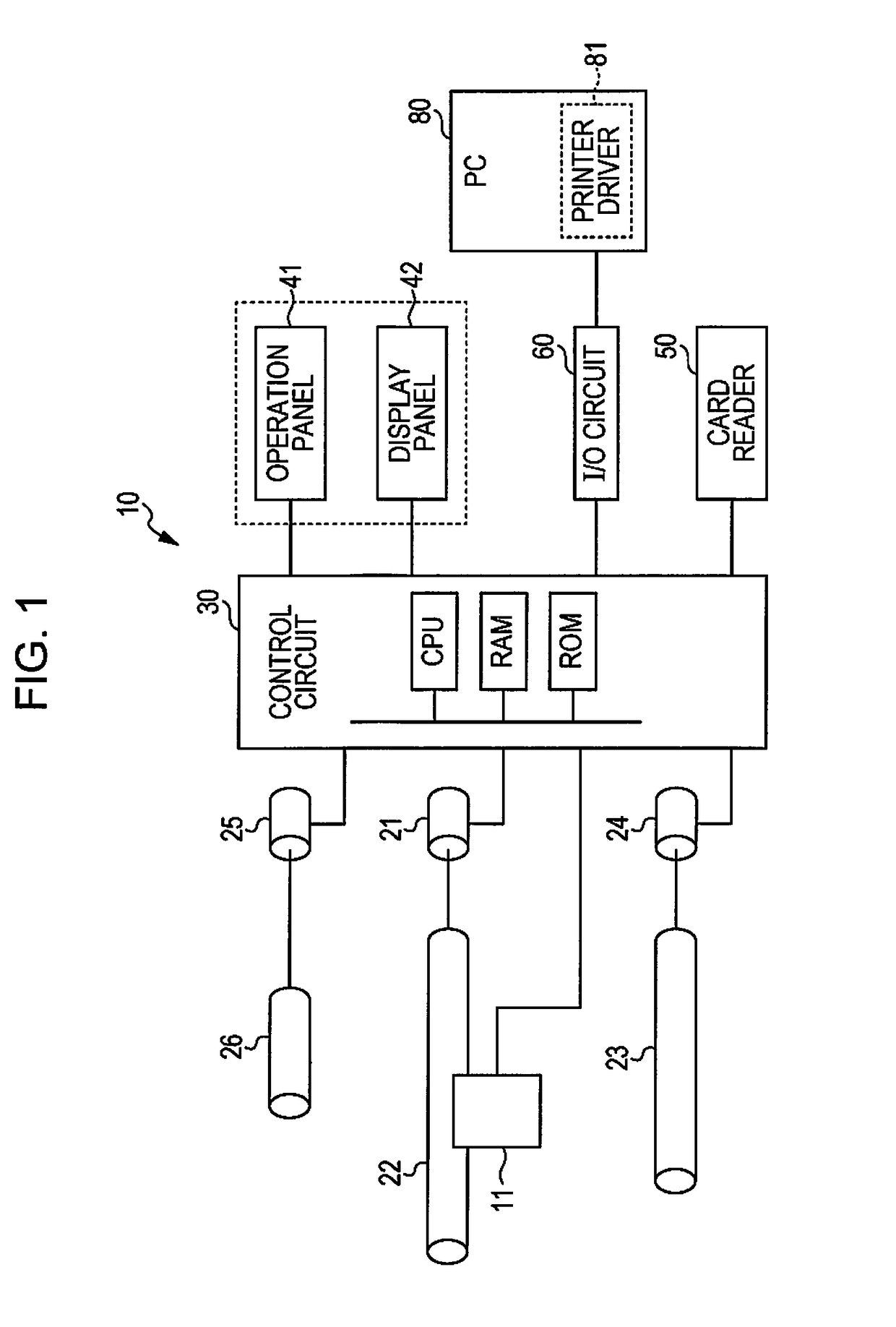

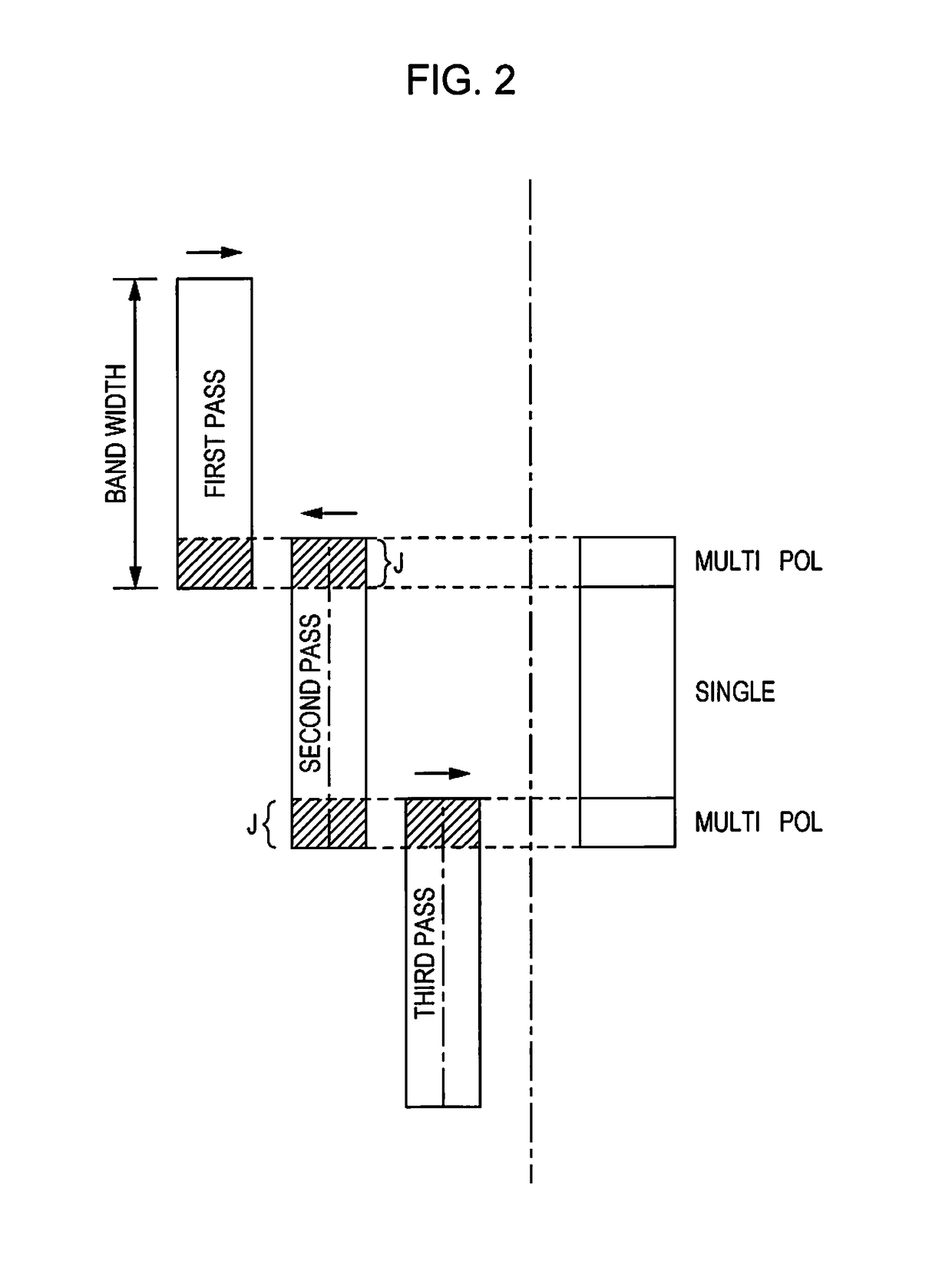

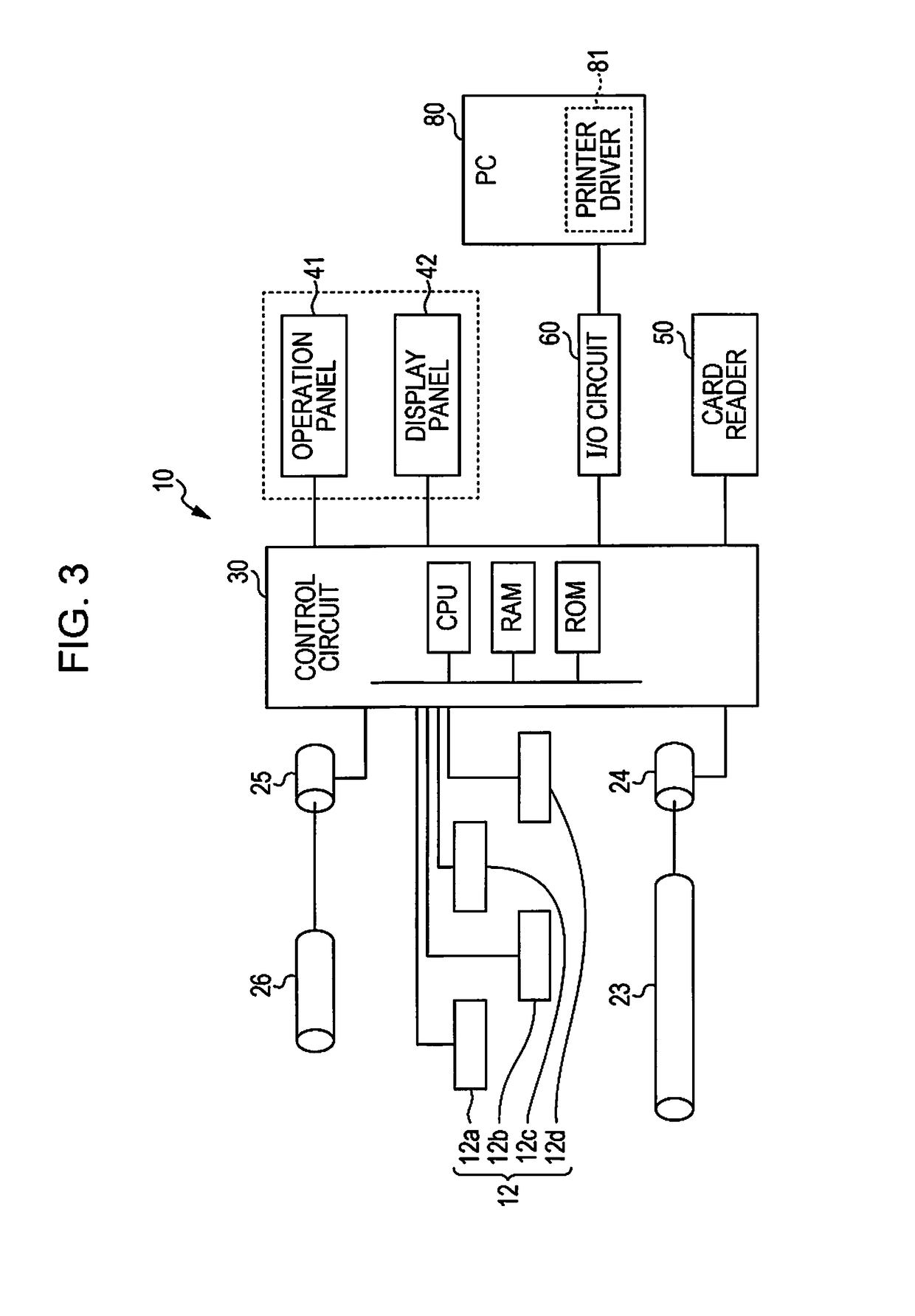

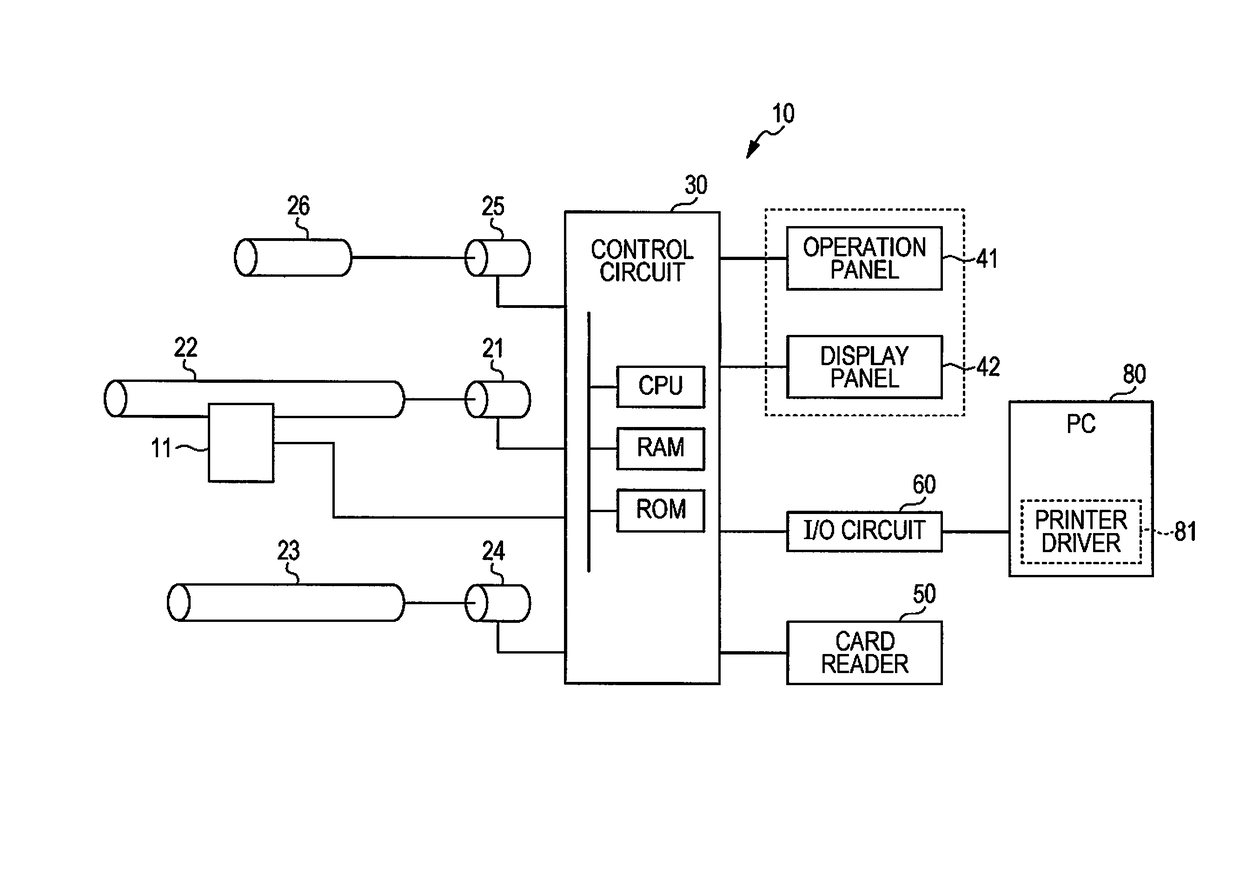

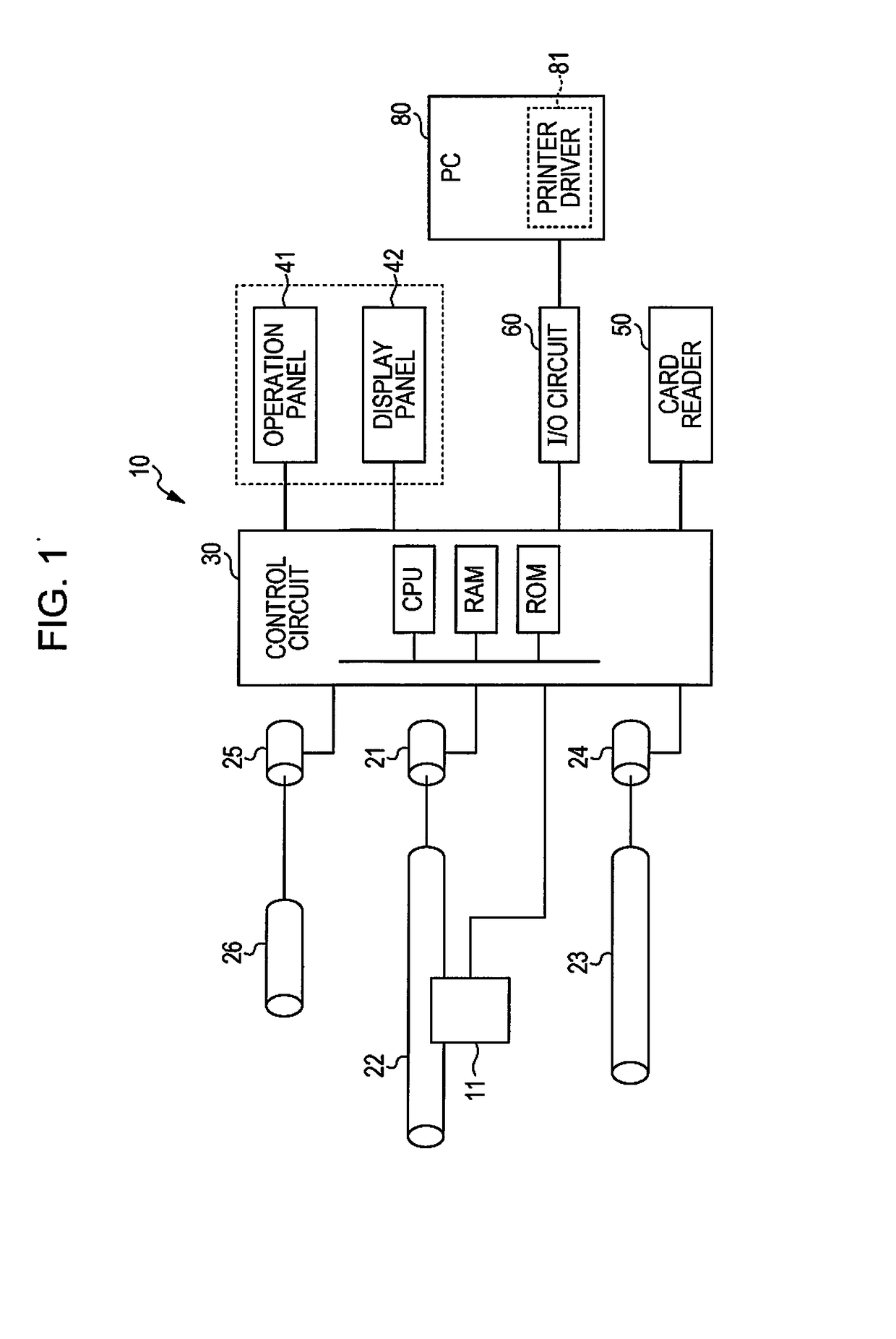

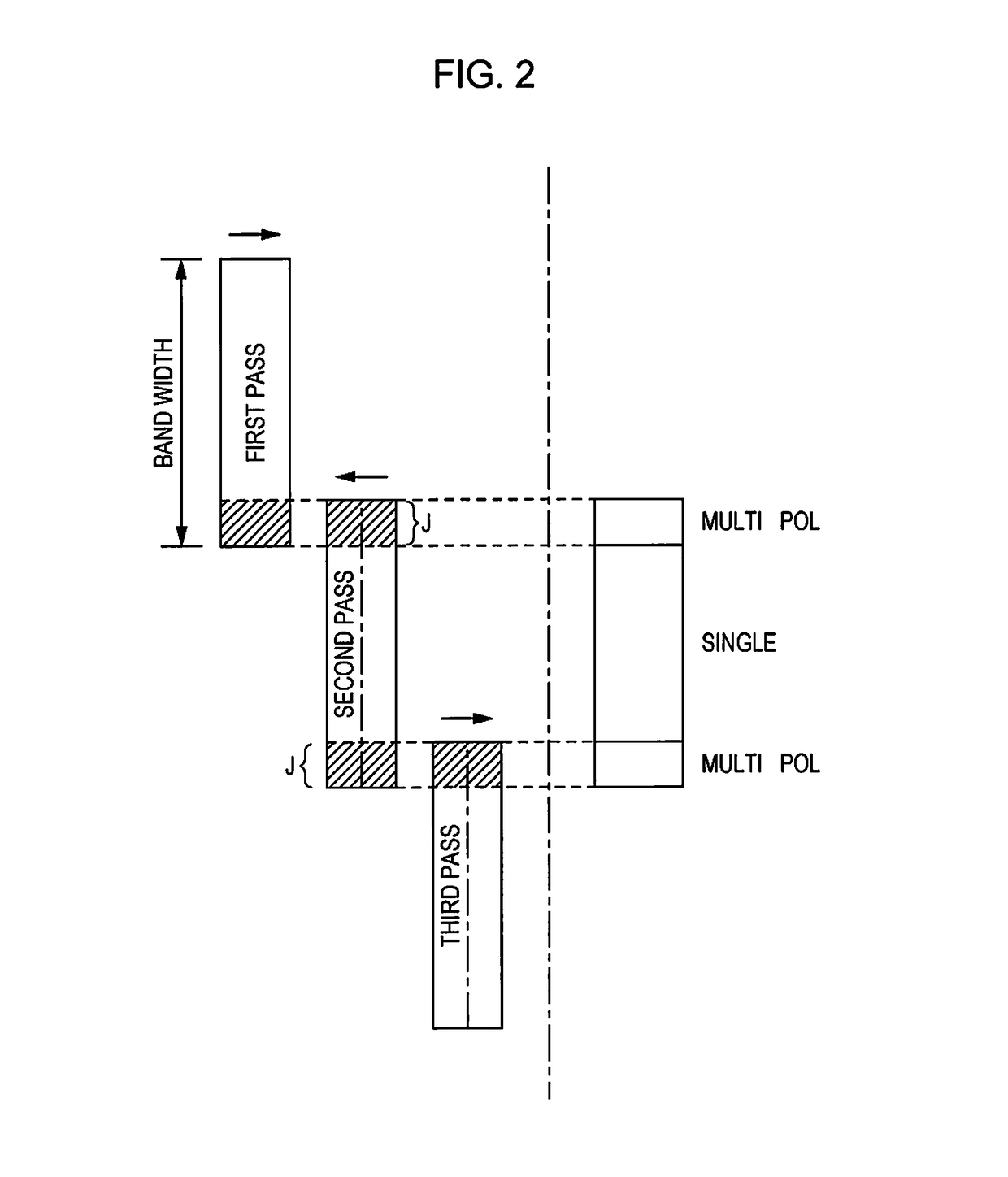

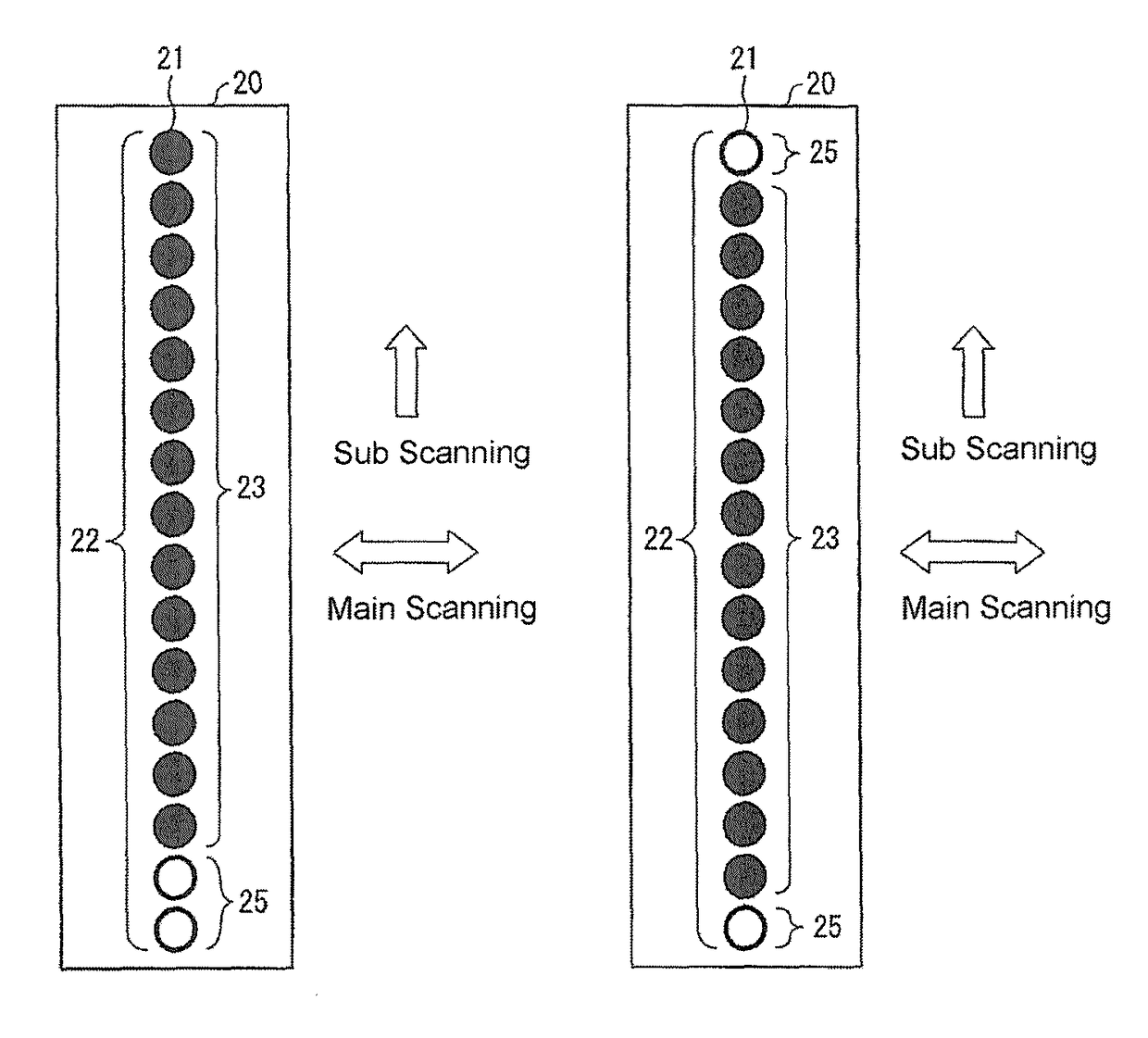

Droplet ejection control apparatus, droplet ejection control method, and droplet ejection control program

ActiveUS10232608B2Reduce bandingBanding can be reducedVisual presentationPrintingControl circuitRaster data

Droplet ejection amounts are adjusted during a process of generating raster data, and this process is realized by a control circuit. The sum total of droplet ejection amounts exceeds 100% as for three nozzles while the sum total of droplet ejection amount is below 100% as for one nozzle, which is repeated at some nozzle numbers. The sum total of droplet ejection amounts is 100% in a normal portion. As such, in the case where this sum total is taken as a reference amount, the sum total of droplet ejection amounts for each raster in a region where overlap printing is performed is sequentially changed to be equal to or greater than the reference amount in the normal region where the overlap printing is not performed, and to be equal to or smaller than the above reference amount.

Owner:SEIKO EPSON CORP

Droplet ejection control apparatus, droplet ejection control method, and droplet ejection control program

ActiveUS20170253025A1Reduce bandingImpact precisionVisual presentationPrintingControl circuitRaster data

Droplet ejection amounts are adjusted during a process of generating raster data, and this process is realized by a control circuit. The sum total of droplet ejection amounts exceeds 100% as for three nozzles while the sum total of droplet ejection amount is below 100% as for one nozzle, which is repeated at some nozzle numbers. The sum total of droplet ejection amounts is 100% in a normal portion. As such, in the case where this sum total is taken as a reference amount, the sum total of droplet ejection amounts for each raster in a region where overlap printing is performed is sequentially changed to be equal to or greater than the reference amount in the normal region where the overlap printing is not performed, and to be equal to or smaller than the above reference amount.

Owner:SEIKO EPSON CORP

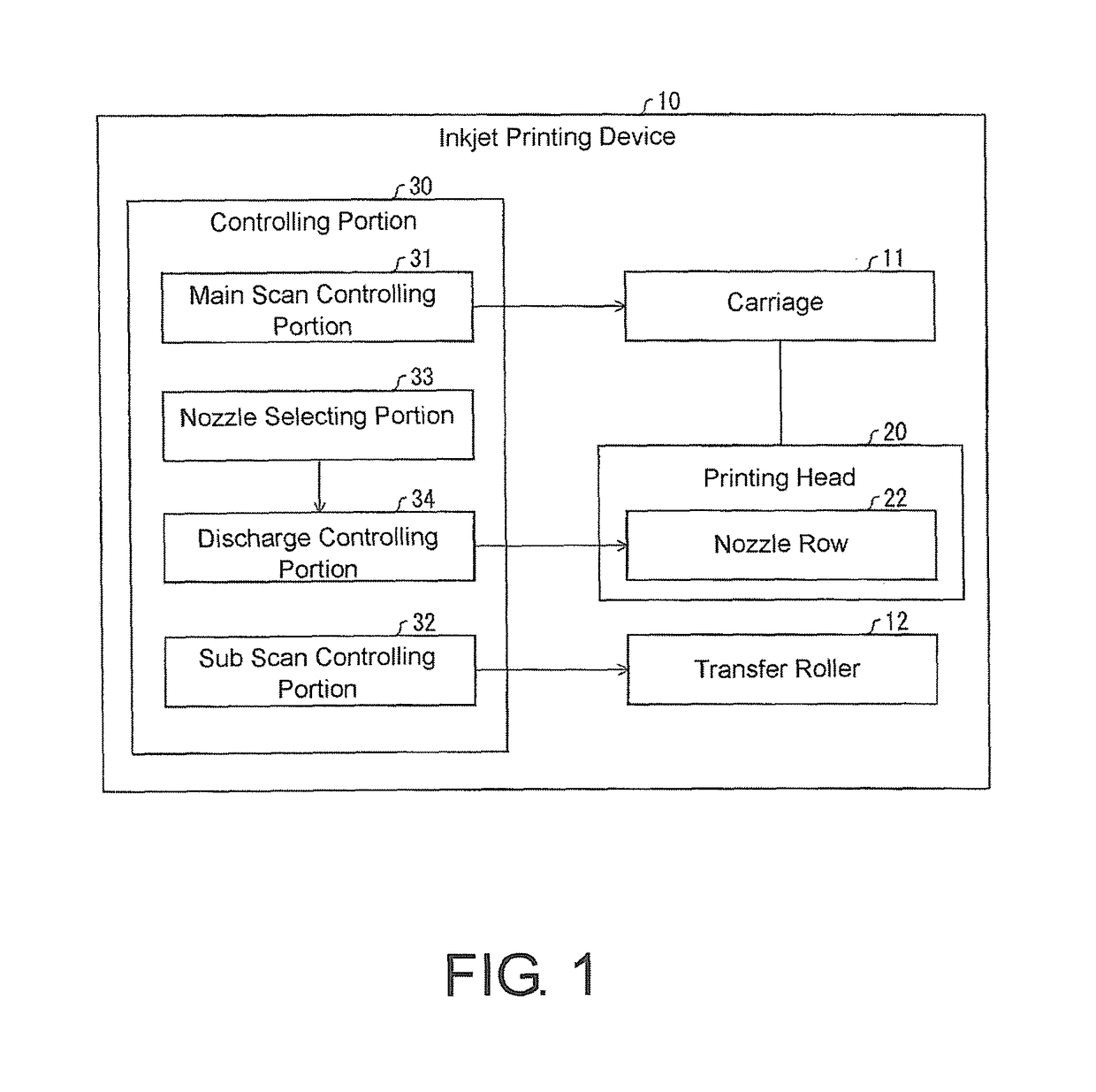

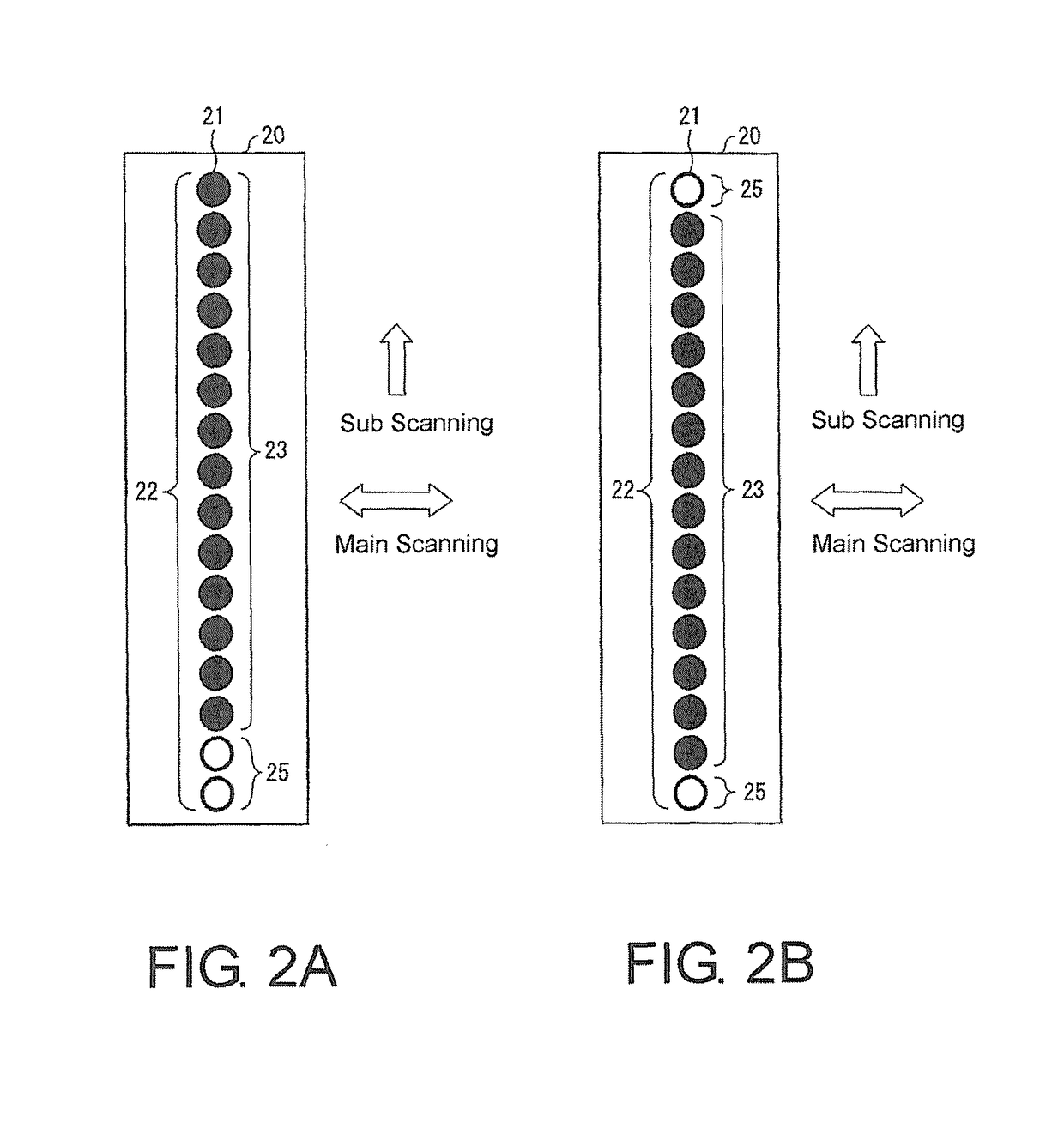

Inkjet printing device and printing method

ActiveUS9776426B2High quality print imageReduce bandingPower drive mechanismsImage resolutionEngineering

An aim is to provide a technique for obtaining a higher quality print image by reducing a banding caused upon printing using a printing head having nozzle rows. As a solution, an activated nozzle row is reselected each time when the activated nozzle row has discharged ink for a preset number of times, and in each scan, an interval by which the activated nozzle row discharges ink in a main scanning direction is set to be an integer multiple of a resolution of an image to be printed on a print medium in the main scanning direction.

Owner:MIMAKI ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com