Continuous pipe resistant to H2S corrosion and manufacturing method thereof

A manufacturing method and technology for coiled tubing, which are applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of overall mechanical properties decline, coiled tubing failure, structural defects, etc., and achieve the formation and expansion of cracks. Optimize the heat treatment process and reduce the effect of band segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]

[0038] The steel designed with the above composition is rolled into a steel coil with a size of 1100×3.18mm, a weight of 20t, and a length of about 700m.

[0039] The main properties of the steel: yield strength 550MPa, tensile strength 642MPa, elongation 34%, hardness 228HV 0.5 . The grain size is at ASTM E112NO.11 level, and the band structure is at level 1.0.

[0040] 2) Slitting the steel coil into 9 steel strips with a width of 120.2 mm. The steel belts are butted into a steel belt with a total length of 6300 meters. A steel pipe with a size of Φ38.1×3.18mm is formed by a row of rollers. After heat treatment of the weld seam and stress relief treatment of the whole pipe body, a plate of 4000 meters long H 2 S corrodes coiled tubing products.

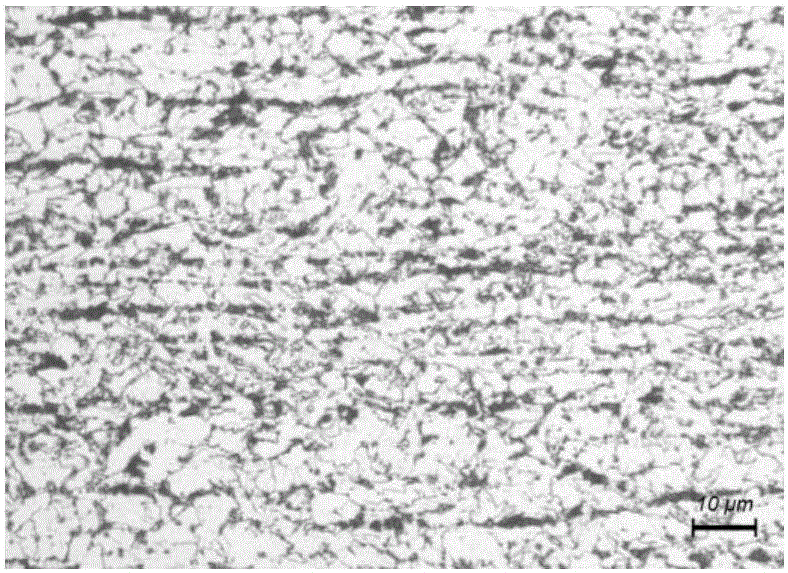

[0041] The main properties of the coiled tubing: the yield strength is 595MPa, the tensile strength is 668MPa, and the maximum hardness is 232HV 0.5 . organizational profile see Picture 1-1 and Figure 1-2 .

[...

Embodiment 2

[0048]

[0049] The steel designed with the above composition is rolled into a steel coil with a size of 1120×4.0mm, a weight of 20t, and a length of about 570m.

[0050] The main properties of the steel: yield strength 470MPa, tensile strength 575MPa, elongation 32%, hardness 219HV 0.5 . The grain size is at ASTM E112 NO.11 level, and the band structure is at level 1.0.

[0051] 2) The steel coil was longitudinally cut into seven steel strips with a width of 158.1 mm. The steel belts are butted into a steel belt with a total length of 3990 meters. A steel pipe with a size of Φ50.8×4.0mm is formed by a row of rollers. After heat treatment of the weld seam and stress relief treatment of the whole pipe body, a 3500-meter-long H 2 S corrodes coiled tubing products.

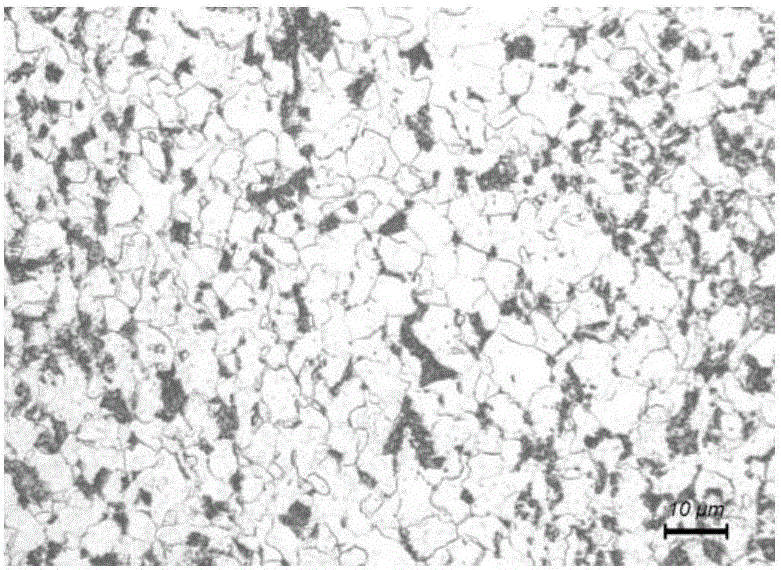

[0052] The main properties of the coiled tubing: the yield strength is 515MPa, the tensile strength is 595MPa, and the maximum hardness is 226HV 0.5 . organizational profile see Pic 4-1 and Figure 4-2 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com