Microscope with light sheet illumination

a microscope and light sheet technology, applied in the field of microscopes, can solve the problems of limiting the use of spim technology in the commercial market, affecting the quality of light sheets, so as to reduce the banding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

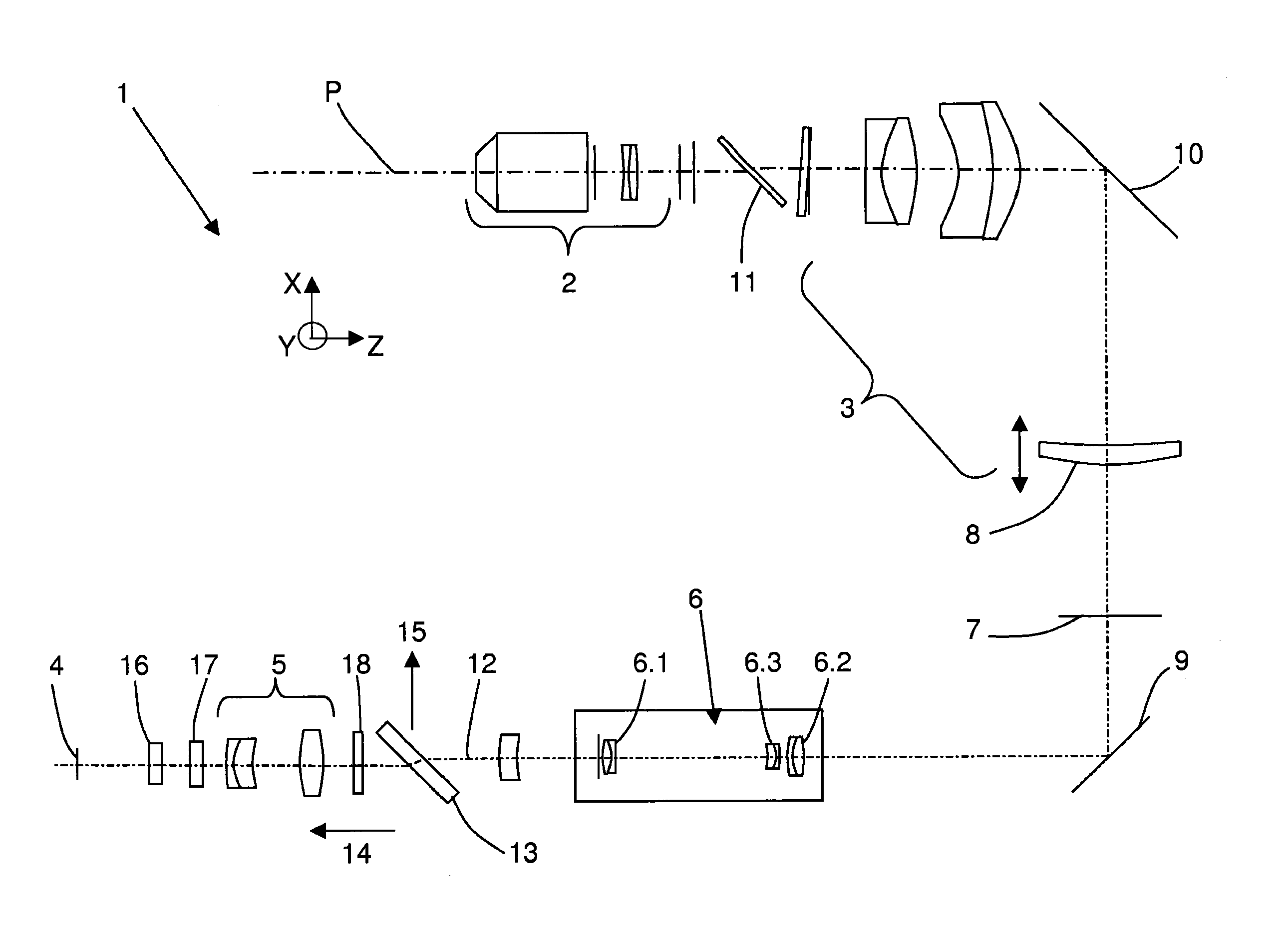

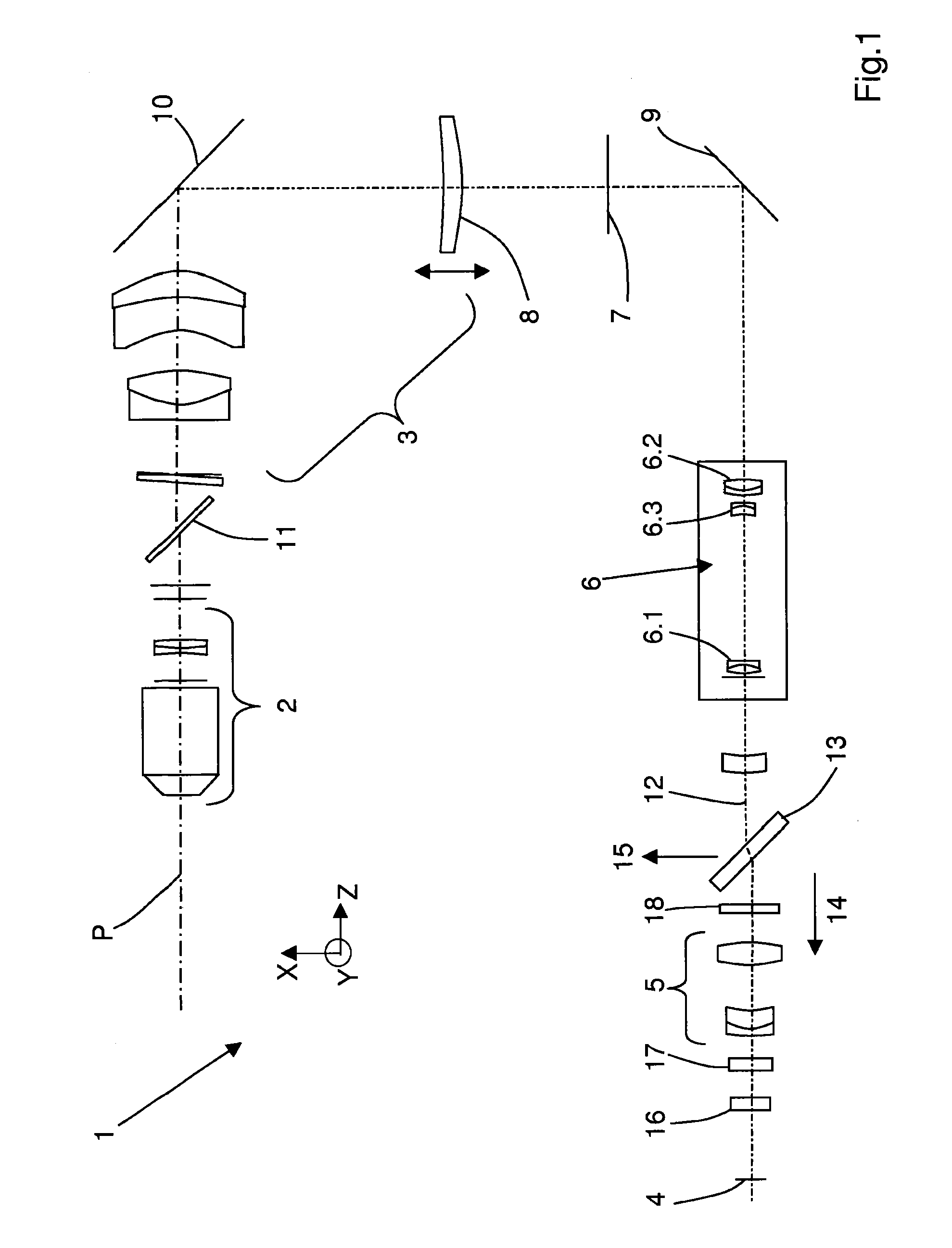

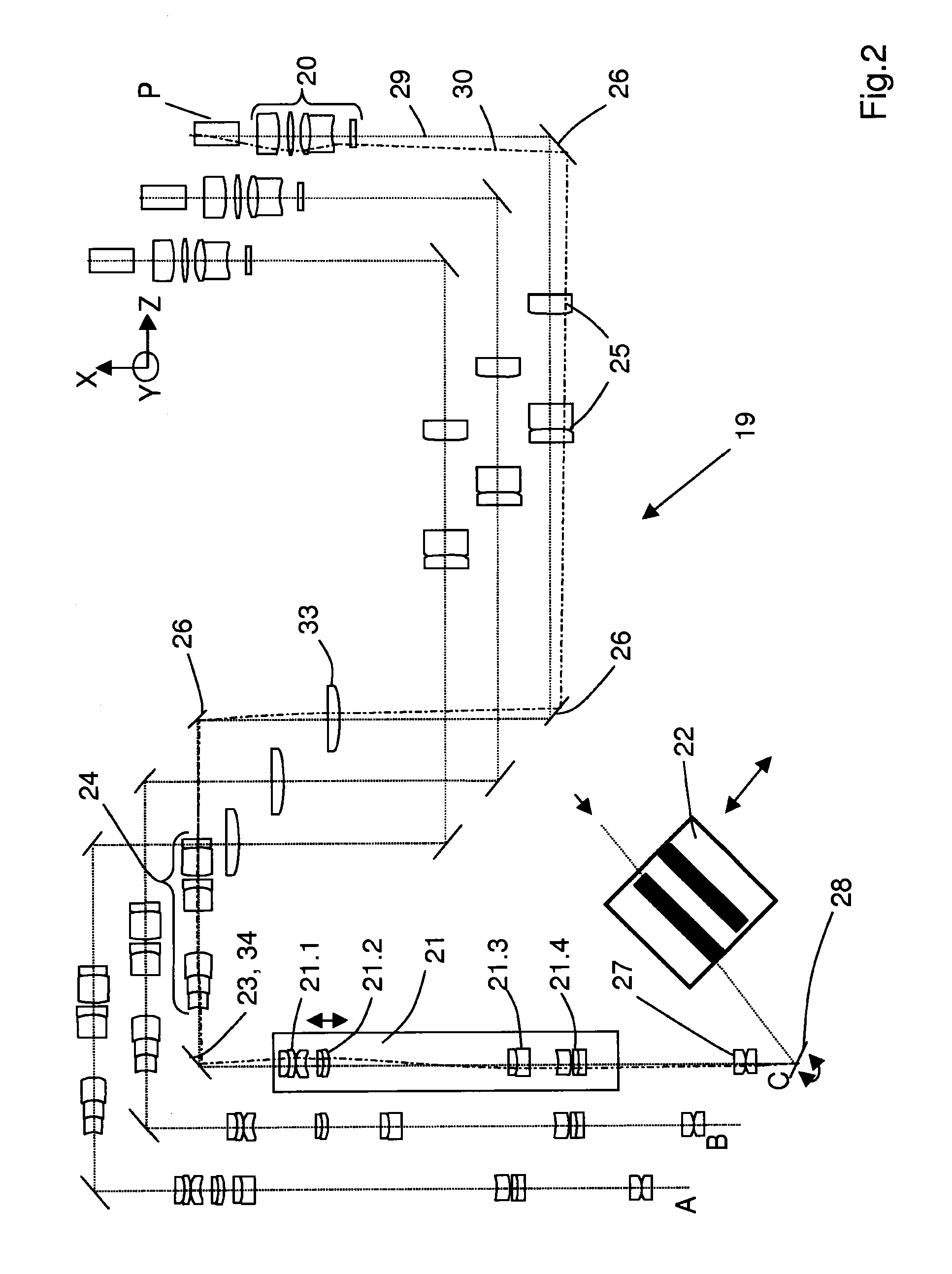

[0037]FIG. 1 shows a detection beam path of a microscope operating by the principle of SPIM technology. Pertaining to it, though not shown in FIG. 1, is an illumination device of the microscope, with which a light sheet for illuminating a sample region P is generated. In the direction of an illumination axis X of an illumination beam path and in the direction of a transverse axis Y lying at a right angle to the illumination axis X, the light sheet has an approximately planar form. Shown along the detection beam path are elements of a detection device 1 used to detect light that is radiated by the sample region P along a detection axis Z. The illumination axis X and the detection axis Z are approximately perpendicular to each other, as are the transverse axis Y and the detection axis Z.

[0038]The detection device 1 comprises a detection objective 2 arranged in the detection beam path. Other essential elements in the detection beam path 1 are a tube lens unit 3 and a spatially resolvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com