A processing method for concrete column mold structure

A technology of concrete columns and processing methods, which is applied in the direction of molds, etc., can solve the problems of no processing method, single structure of concrete prefabricated parts, single use of concrete prefabricated parts, etc., and achieve the effect of fast processing speed, fast and convenient assembly, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

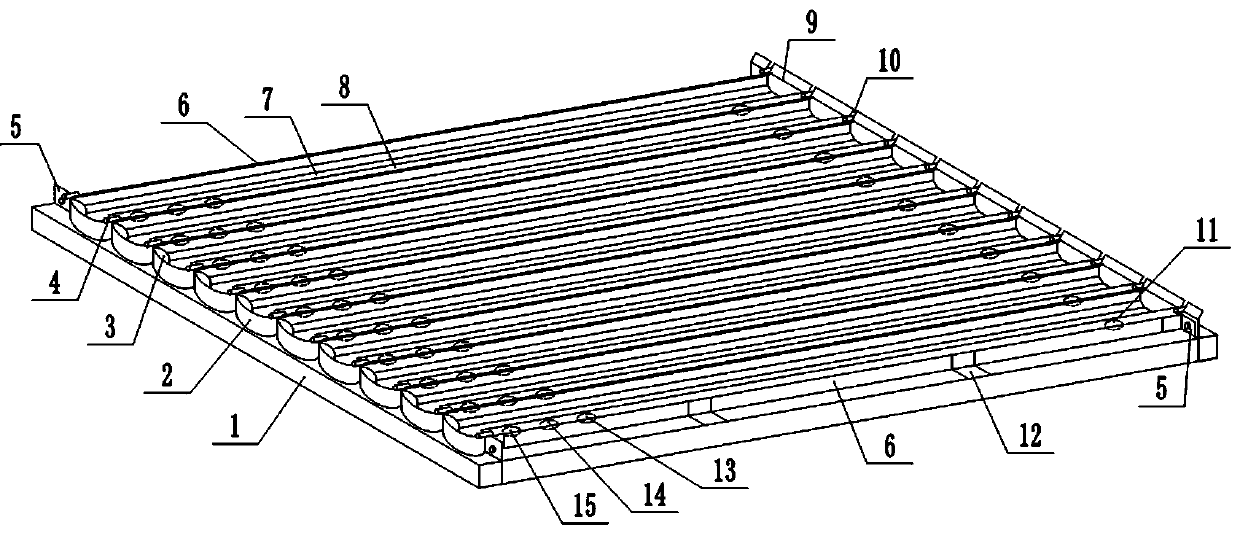

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] A processing method for concrete column mold construction, said processing method comprising the following steps:

[0043] (1) Blanking of each component according to the design drawings;

[0044] (2) Assemble the support frame and install and connect the blanked sections;

[0045] (3) Prefabricate the bottom formwork, the material plate of the bottom formwork is punched and formed by a punching machine at one time, and the cross-sectional shape is inverted trapezoid after stamping;

[0046] (4) Prefabricate the bottom formwork, punch out the notch on one side of the material plate of the bottom formwork through the punching machine, and then use the bending machine to bend the side that has been punched out of the notch, and the bending angle is 30-60° °;

[0047](5) Prefabricate the side plate formwork, and bend the material plate side of the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com