Mould segment ring (well wall) prefabrication device and mould segment ring (well wall) prefabrication method

A segment and model technology, which is applied in the field of model segment ring (well wall) prefabrication device and prefabrication, can solve the problems of small simulation range and large test piece size, and achieve the effect of protection strength and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is further described.

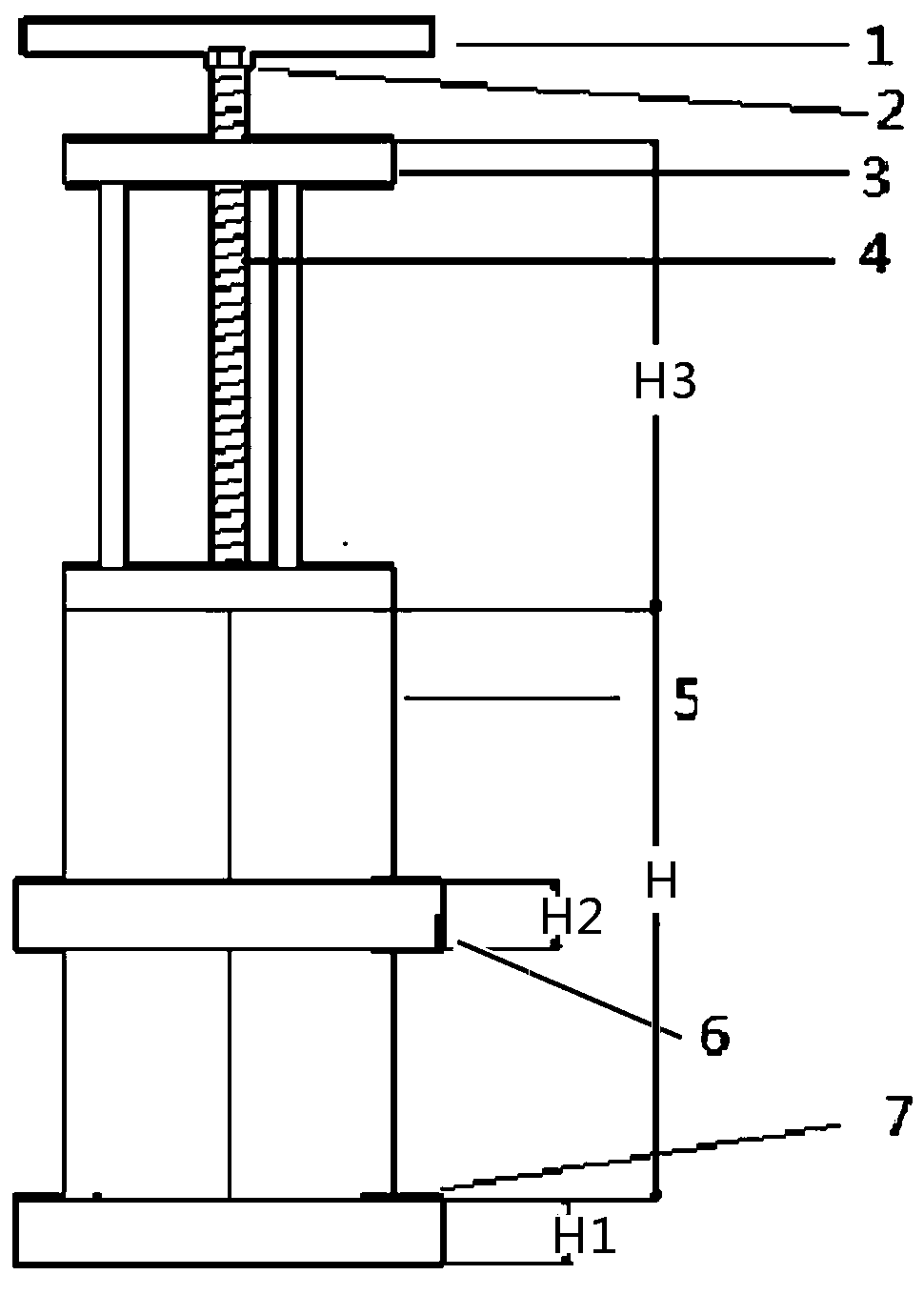

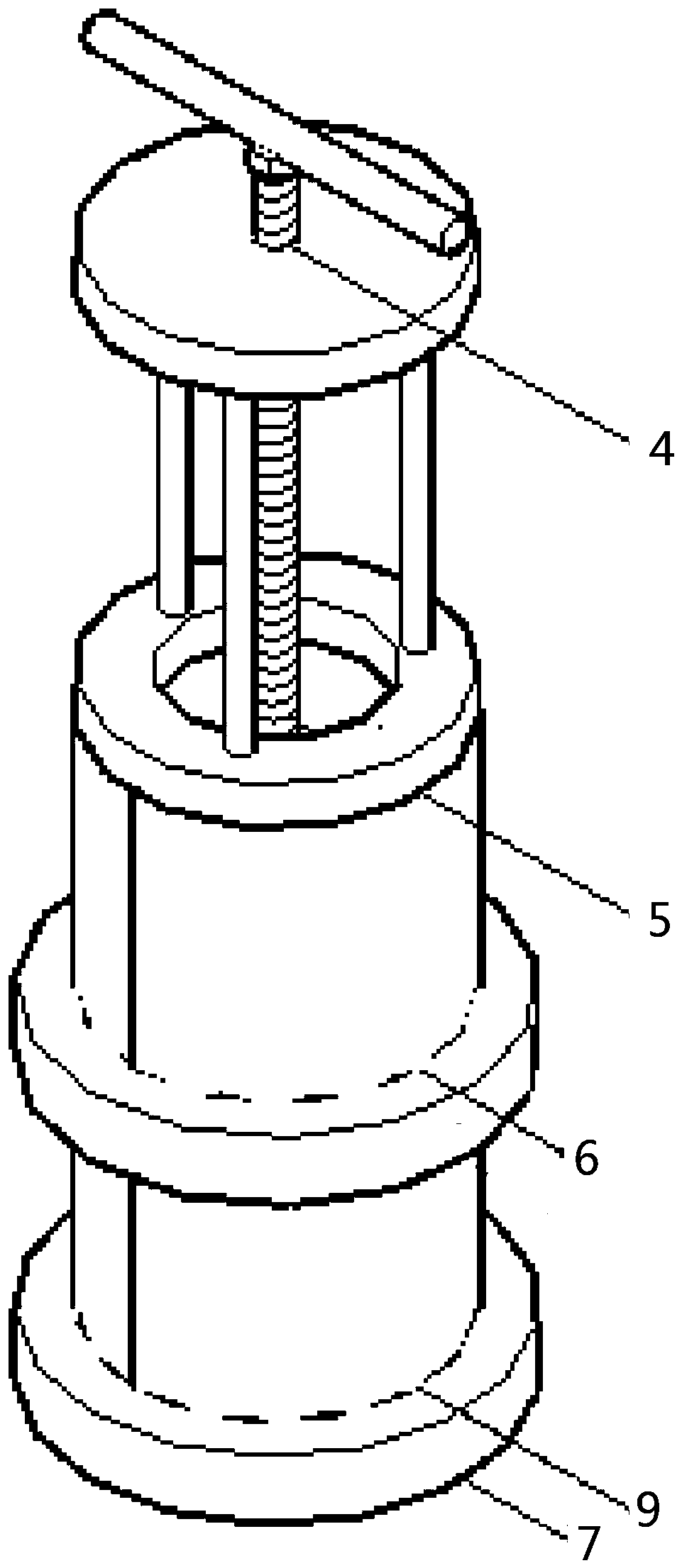

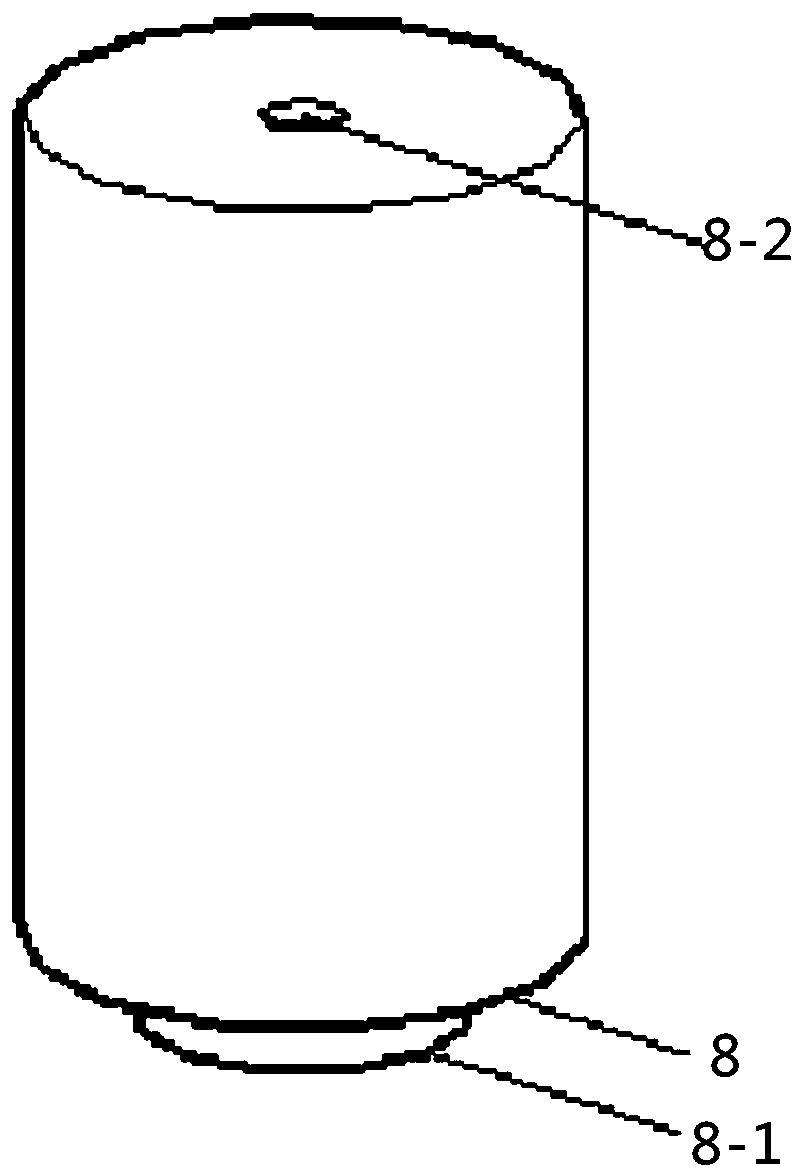

[0029] Such as Figure 1-Figure 9 A model segment ring (well wall) prefabrication device shown includes a casting mold 5 and a form removal device; the casting mold 5 includes a cylinder 8, a base 7 and two semicircular formwork 9, and the cylinder The center of 8 is provided with a threaded hole 8-2 penetrating along the axis, the center of the bottom of the cylinder 8 is fixed with a cylindrical positioning protrusion 8-1, and there is a circular groove 7-1 in the middle of the base 7. There is a center hole 7-2 in the center of the groove 7-1, and the center hole 7-2 matches the radius and height of the cylindrical positioning protrusion 8-1, and the bottom of the cylinder 8 is located on the circle of the base 7. On the groove 7-1, the cylindrical positioning protrusion 8-1 is inserted into the central hole 7-2; two semicircular templates 9 are wrapped around the outer ring of the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com