Manufacture method for random micro-fissure rock mass physical model

A technology of physical model and manufacturing method, which is applied in the field of geotechnical engineering, can solve problems such as large density difference between tin bar and mortar, tin bar floating or sinking, large density difference between crack material and matrix material, etc., and achieves wide application prospects, Wide range of applications, convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

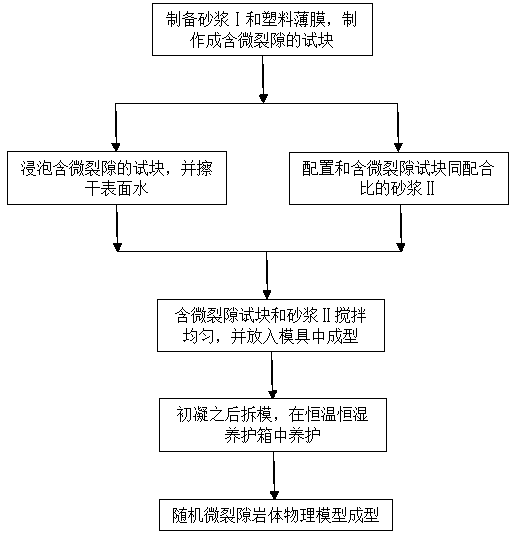

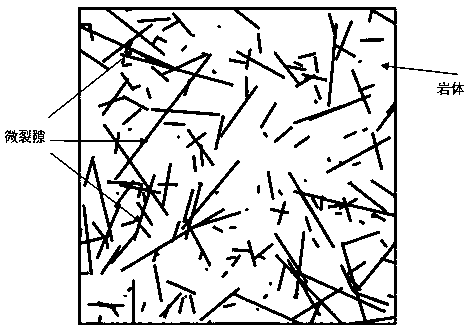

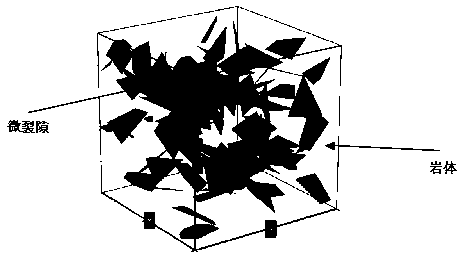

[0035] combine Figure 1 to Figure 3 As shown, a method for making a random micro-cracked rock mass physical model, the steps are as follows:

[0036] Step 1: Prepare mortar I and plastic films of different shapes;

[0037] Plastic film: Cut plastic films of different shapes manually or mechanically, and make 200 pieces of plastic films with a thickness of 0.1mm-0.5mm. The geometric shape and quantity of the plastic films are determined according to the crack density of the rock mass to be simulated;

[0038] Mortar Ⅰ: Made of 52.5 ordinary Portland cement, quartz sand with a particle size of 0-4mm and water, the mix ratio is: water: cement: sand = 1:2.5:6.8.

[0039] Step 2: Lay a layer of mortar I with a thickness of 5mm first, then lay a layer of 0.1mm-0.5mm plastic film on the mortar I, and finally lay a layer of mortar I with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com