Butt joint structure with replaceable assembly and continuous clip applier for surgical robot

The technology of a clip applier and a docking mechanism is applied in the field of continuous hair clip appliers for surgical robots, which can solve the problems of high cost, contamination of the actuator of the surgical robot, inconvenient addition of tissue clips, etc., and achieves easy adjustment and convenient organization. The number and type of clips, the effect of improving the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

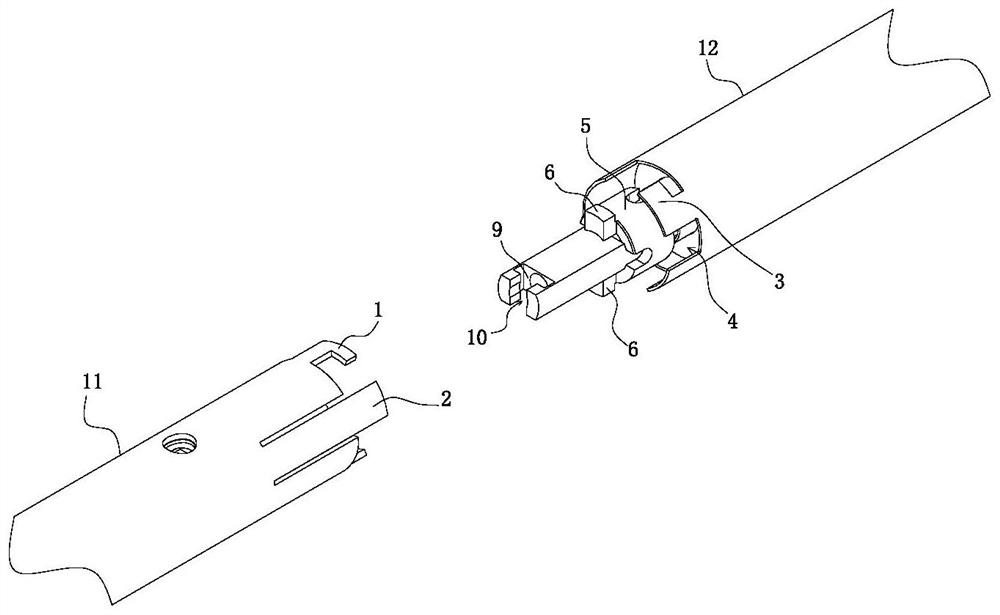

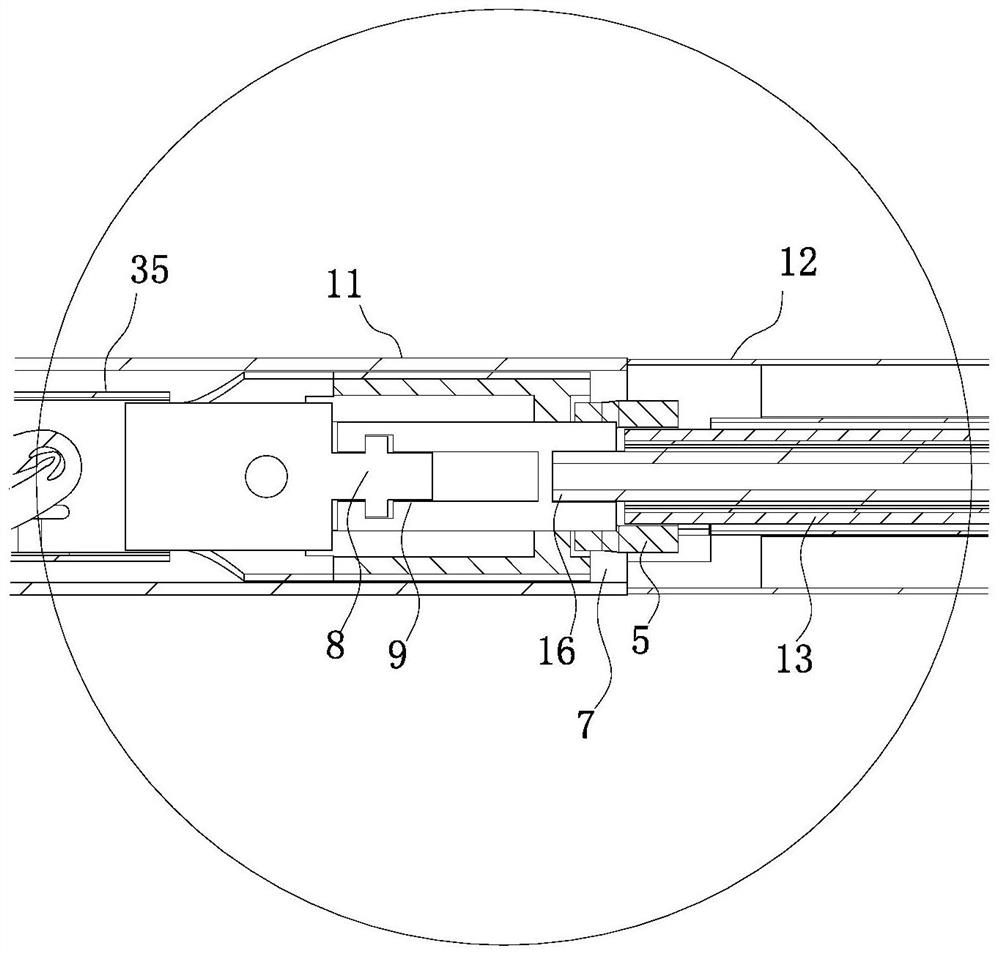

[0055] Such as Figures 1 to 8 shown, refer to the attached Figures 9 to 19 , the docking structure of the replaceable components is disclosed in this embodiment. It includes a first docking mechanism and a second docking structure, and the first docking mechanism and the second docking structure are respectively fixedly connected with the two ends that need to be docked in the process of replacing components.

[0056] Such as figure 2 As shown, the first docking mechanism includes a first hook 1 and an anti-rotation shrapnel 2 . The second docking mechanism includes a second hook 3 and an anti-rotation groove 4 . Such as Figure 6 As shown, when the two ends are butted, the first hook 1 is hooked with the second hook 3 , and the anti-rotation shrapnel 2 is fitted into the anti-rotation groove 4 .

[0057] Refer to attached figure 2 and 6 , during the butt joint process of the two ends, the first hook reaches the hooking position of the second hook from the channel, ...

Embodiment 2

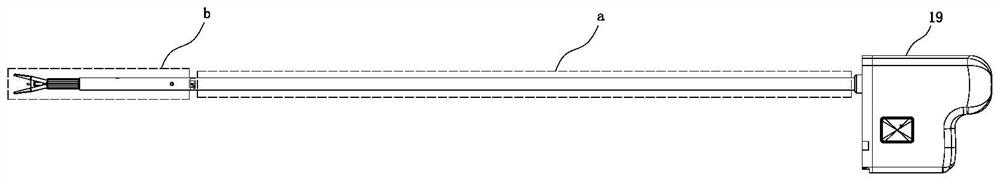

[0067] Such as Figures 9 to 19 As shown, with reference to other drawings in the accompanying drawings, the front part of the shaft part a of the continuous clamp applicator for the robot disclosed in this embodiment is docked with a replaceable component b, and the docking structure adopted is the one used in Embodiment 1. Open docking structure.

[0068] The continuous clip applier for surgical robots disclosed in this embodiment includes a replaceable component b located at the front of the clip applier, and the replaceable component b and the shaft part a of the clip applier pass through the replaceable component b. The docking structure is connected.

[0069] In this embodiment, the two ends that need to be butted in the process of replacing the components described in Embodiment 1 are the front end of the shaft portion a of the clamp applier and the rear end of the replaceable component b respectively.

[0070] Refer to attached Figure 6 , the first docking mechanis...

Embodiment 3

[0101] This embodiment is further optimized on the basis of embodiment 2:

[0102] Refer to attached Figures 1 to 19 ,Such as Figure 14 As shown, the body base 19 includes a base 51, a middle bracket 52 and a top bracket 53, the middle bracket 52 and the top bracket 53 are fixedly connected with the base 51 respectively, and the top of the first columnar body 25 is rotatable with the top bracket 53. Connected, the bottom of the second columnar body 26 is rotatably connected with the middle bracket 52; the third columnar body 24 of the continuous clip applier pliers is rotatably connected with the base 51. In this embodiment, the structures that are rotatably connected to each other are connected by bearings. The first chuck 20, the second chuck 22 and the third chuck 46 of the body base 19 stretch out to the outside of the base 51 respectively, and the first chuck 20, the second chuck 22, the third chuck 46 are respectively connected with A plurality of brake discs or act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com