Method for maintaining high-performance concrete under severe environment

A high-performance concrete and harsh environment technology, applied in the field of concrete, can solve problems such as hard maintenance methods to be effective, and achieve good thermal insulation, good effect, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

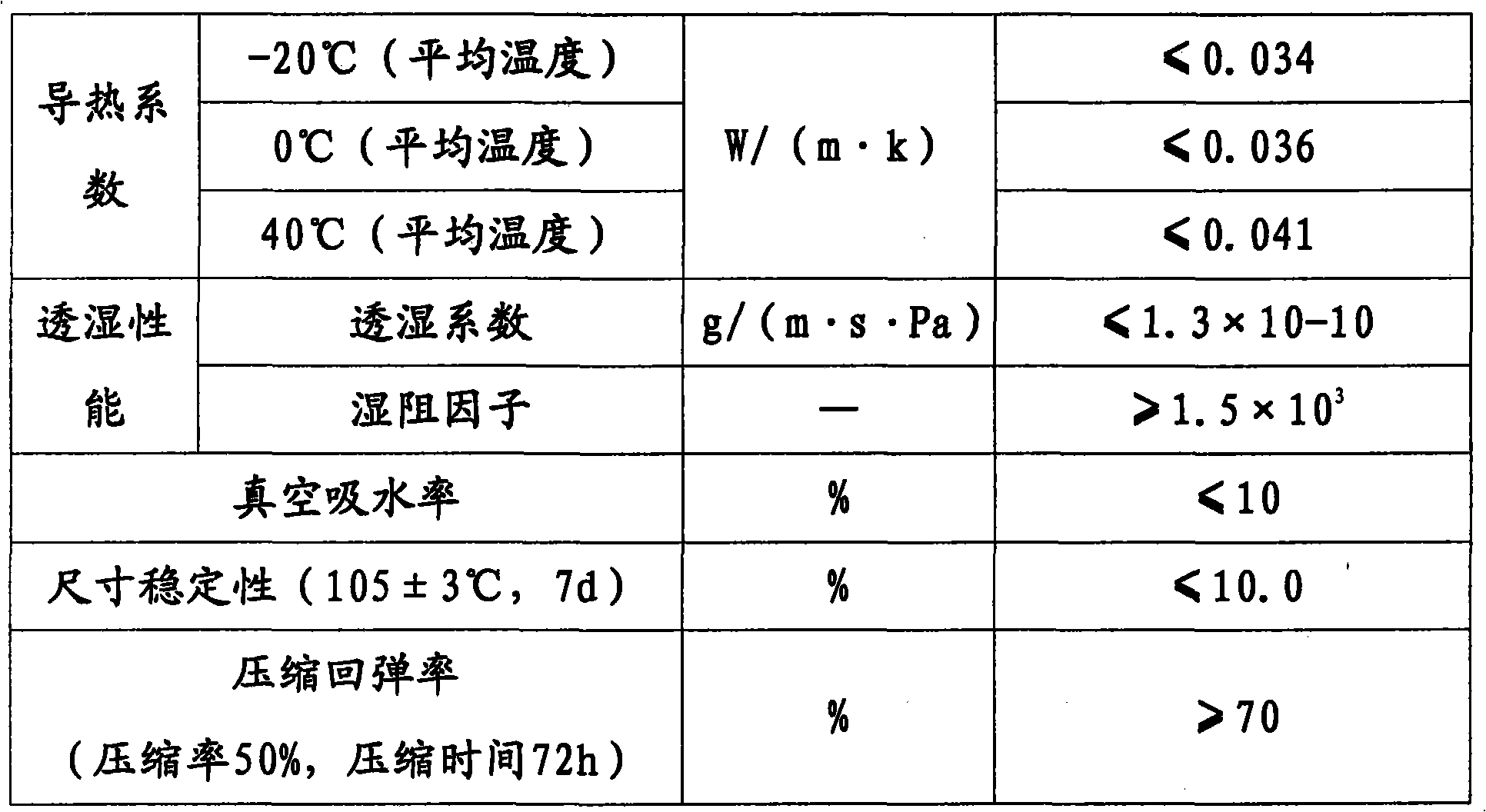

[0026] The maintenance materials used in the heat preservation and moisturizing maintenance method are: rubber-plastic board + geotextile.

[0027] Procedures and precautions of heat preservation, moisturizing and maintenance methods:

[0028] 1. After the concrete is poured, immediately cover the top surface of the concrete and the surface of the concrete exposed to the air with a rubber-plastic plate or geotextile or reserve 5cm on the top of the formwork, and water it for curing to prevent exposure to the atmosphere The moisture on the concrete surface evaporates too fast and shrinkage cracks appear;

[0029] 2. When the strength of the poured concrete meets the requirements of form removal and the temperature of the concrete center begins to drop, the form removal can be carried out; the time of form removal should not be too early or too late, and the premature removal of the form will lead to the failure of the concrete strength and elastic modulus If the design require...

Embodiment 2

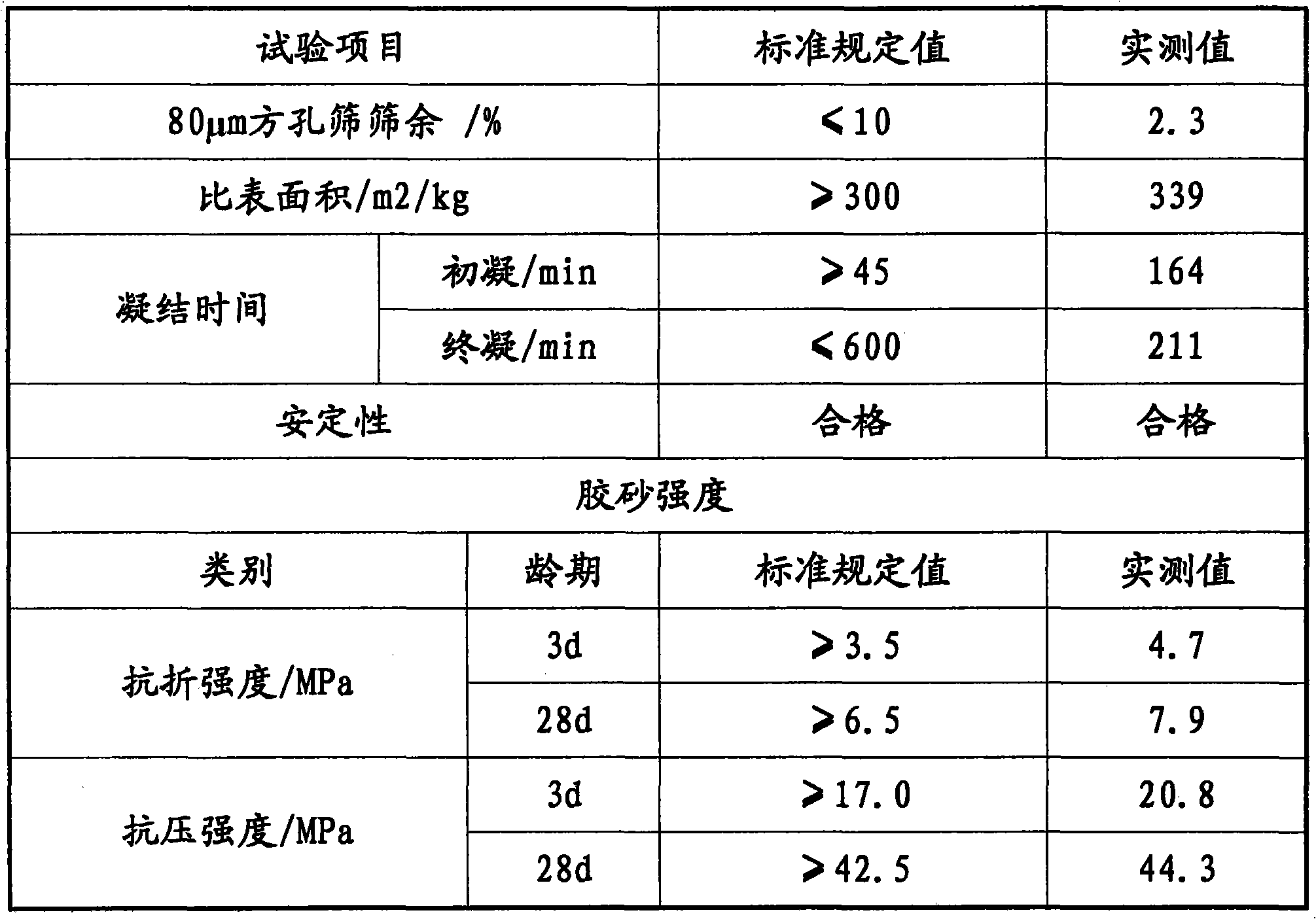

[0042] This embodiment provides a comparative test of curing using the curing method of the present invention.

[0043](1) Purpose: The L (beam) type, D (pier) type and Z (pile) type concrete mixed with anti-cracking compacting agent were prepared, and the strength and chloride ion penetration resistance test specimens were made, and tested under standard conditions. For curing, the strength value of 7d, 28d and 56d and the electric flux of 28d and 56d were tested respectively; the test results were compared with the optimized concrete without concrete anti-cracking and densifying agent, and the effect of anti-cracking and densifying agent on concrete was analyzed. Strength, compactness and crack resistance.

[0044] (2) Scheme: Curing the specimen under standard conditions for 1 day. After demoulding, wrap the plastic film for curing (denoted as CT) and wrap the heat-preserving and moisturizing film (denoted as WS) for curing. ~15℃ and -10~20℃ three kinds of curing temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com