High-strength prestressed concrete pipe pile with section and its production method

A concrete and prestressed technology, applied in sheet pile wall, construction, foundation structure engineering, etc., can solve problems such as joint cracking, and achieve the effect of improving interface strength, improving strength, and easy formwork removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Manufacture of high-strength prestressed concrete pipe pile with joints of the present invention

[0060] raw material

[0061] a) Cement: Portland cement, ordinary Portland cement, and slag Portland cement with a strength grade of not less than 42.5 are preferred. The stability of the cement must be qualified and compatible with the water reducing agent used, and the strength of the cement mortar must meet the requirements and have a certain surplus.

[0062] b) Aggregate (sand, stone): aggregate accounts for about 70% of the concrete volume in concrete. It acts as a skeleton in concrete, giving concrete greater volumetric stability and better durability than grout alone. The high content of stone powder and mud in the aggregate will directly affect the workability of the concrete mixture and adversely affect the centrifugal effect.

[0063] Sand: use clean natural medium sand with a fineness modulus of 2.3-3.4, preferably graded in zone II, with a mud content of ≤3...

Embodiment 2

[0085] On the basis of Example 1, autoclave curing is added.

[0086] As the manufacturing method of the present invention, it can be cured by autoclaving after normal pressure curing.

[0087] The autoclaving curing means that after the pipe pile is demoulded, it is put into an autoclave for autoclaving curing. Autoclaved curing can give full play to the secondary reaction of cement, and can significantly improve the strength of concrete under the same amount of cement.

[0088] The autoclaved curing conditions are carried out at 165-185° C. and 10-13 atmospheric pressure. Preferably, it is carried out at 180°C and 12 atmospheres.

[0089] Autoclave curing is an important means for pipe pile concrete to obtain high strength, and it is the only way to produce PHC piles. In the high-pressure and high-temperature saturated steam, the role of water becomes very active, and the hydrothermal effect further promotes the hydration reaction of cement and the reorganization and matu...

Embodiment 3

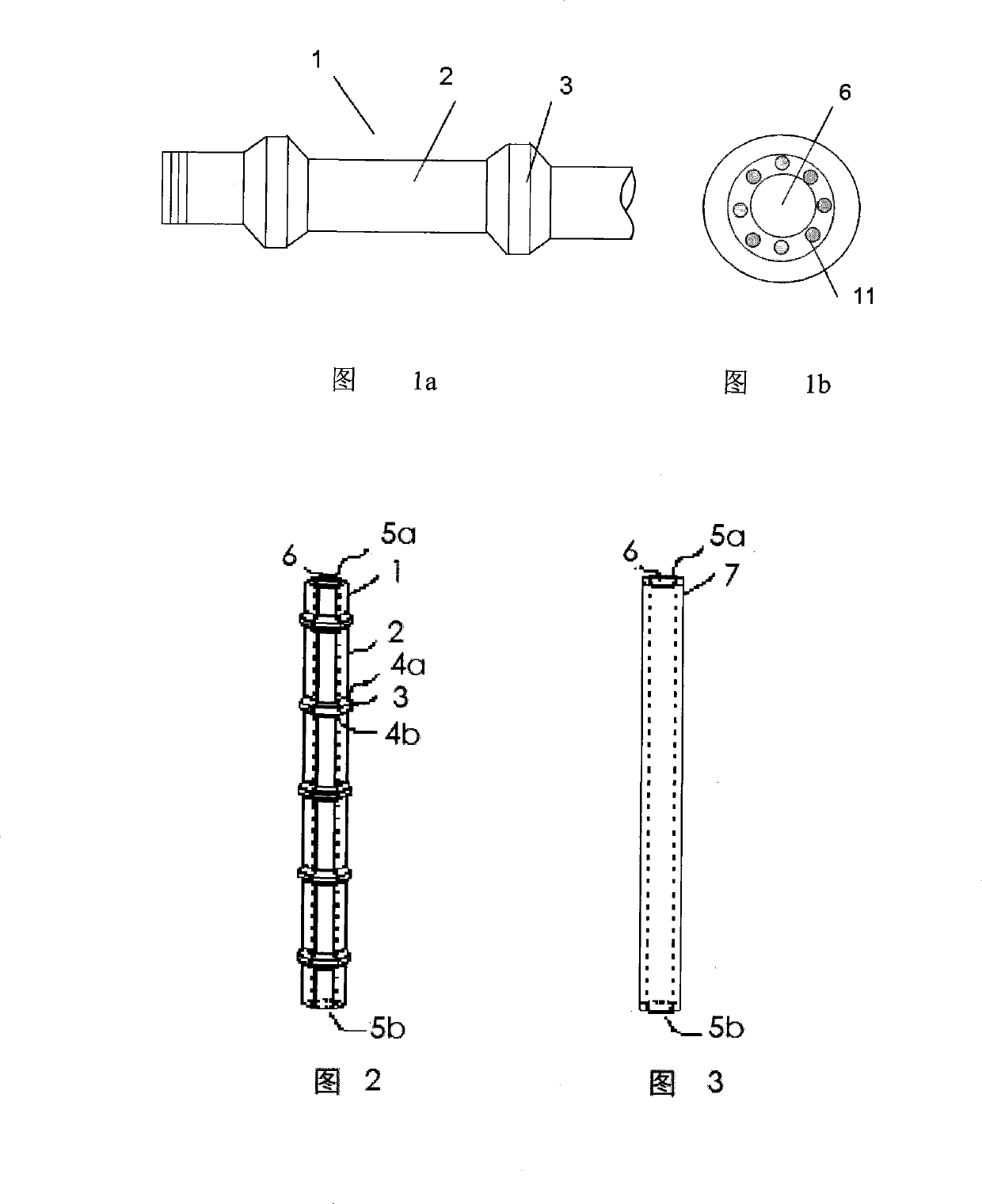

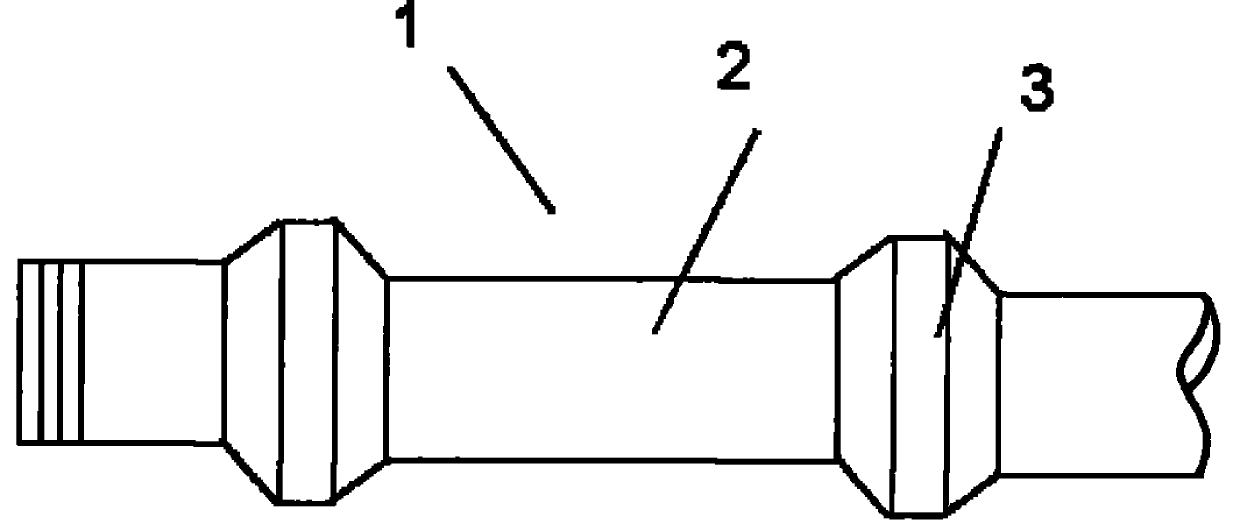

[0096] In addition to the average particle size of silica fume at 0.25 microns, the interval between the pipe piles is 8-12m to form nodes, the circumference of the nodes is 157mm, the outer diameter of the nodes is 500mm, the outer diameter of the pile shaft is 400mm, and the cross-sectional area is 684cm 2 , wall thickness 65mm, PC steel rods embedded in the concrete sectioned pipe pile, the nominal diameter of which is 9.2mm, 8 rods are set, and the cross-sectional area of each rod is 5.12cm 2 Except, others are the same as embodiment 1.

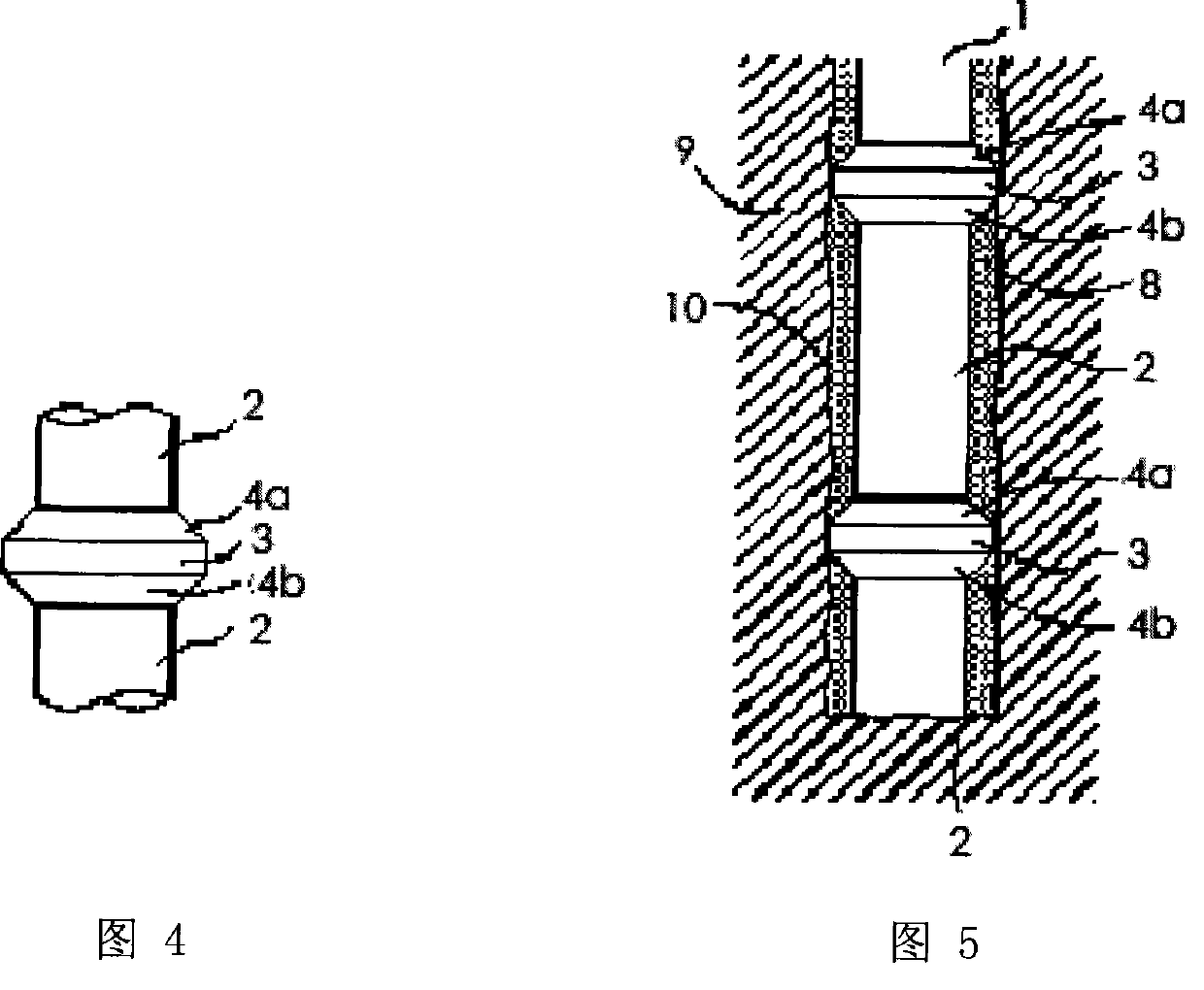

[0097] In addition, taper parts 4a, 4b are formed on the upper and lower sides of each node, and each part is integrally poured with concrete. The central hole 6 is formed during centrifugal molding, and the upper end surface 5a and the lower end surface 5b are both planar.

[0098] Figure 4 shows an enlarged view of the node. Between the pile shaft part 2 and the node part 3, the upper and lower sides are connected by a cone. The an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com