Beam and pile assembled node of precast and prestressed concrete structure

A concrete structure and prestressing technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of noise bothering surrounding residents, assembly structure application limitations, waste of construction materials, etc., to achieve strong self-recovery ability, excellent Seismic performance, reducing the effect of repair work

Inactive Publication Date: 2007-09-05

BEIJING UNIV OF TECH

View PDF0 Cites 64 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a long time, due to the unsolved technical problems of assembled structure nodes, the application of assembled structures in my country's earthquake areas has been limited. The current seismic codes generally encourage the use of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

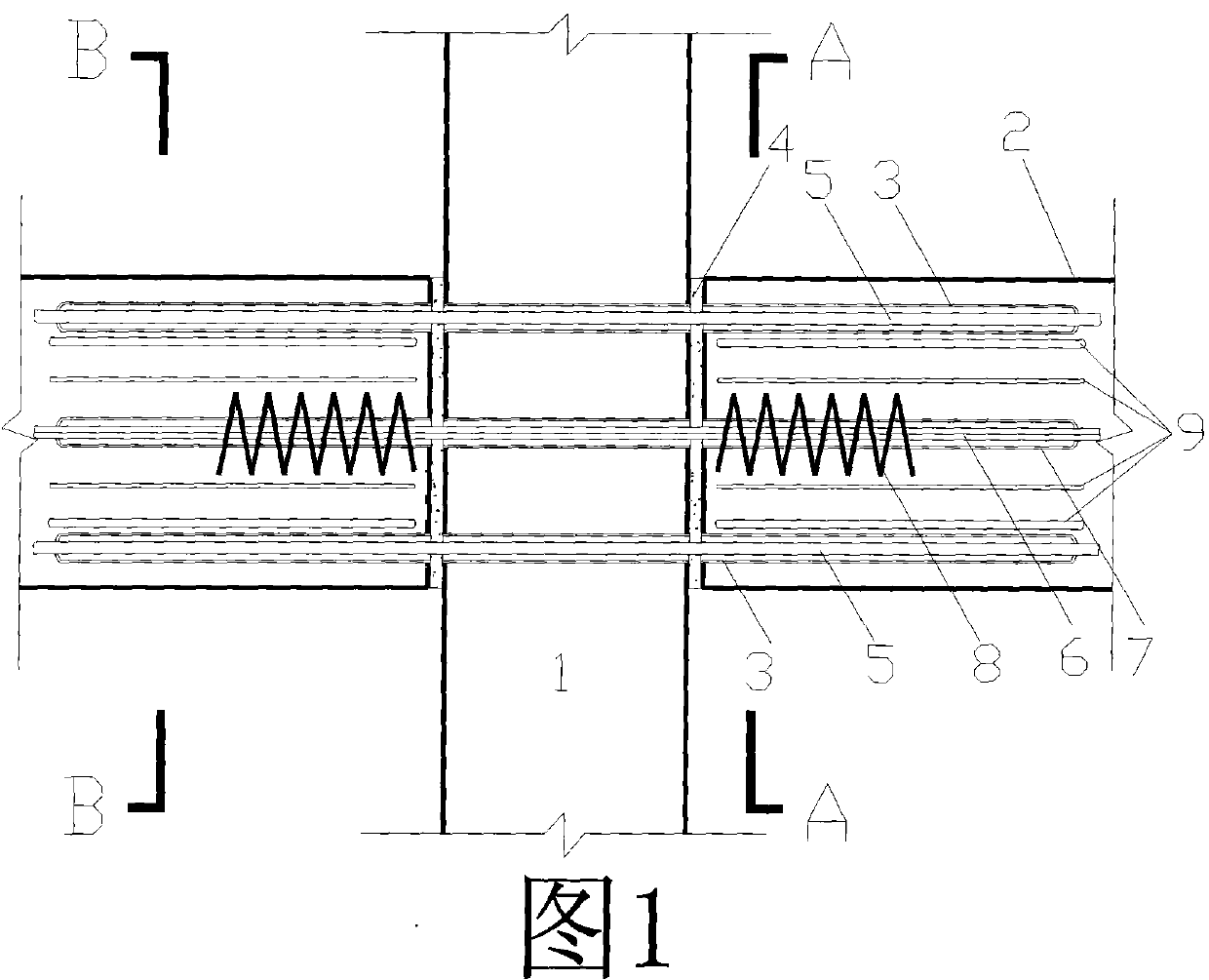

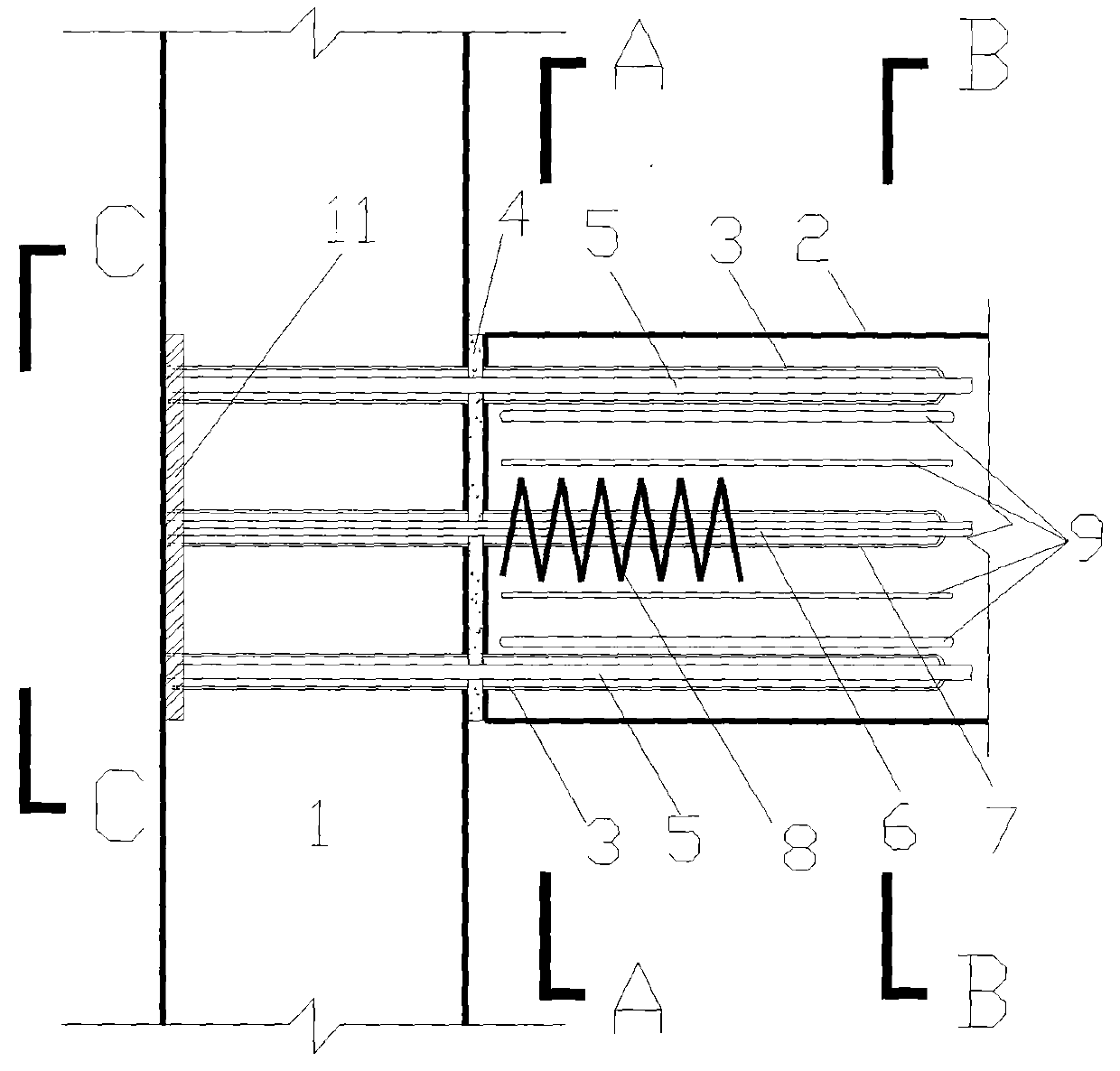

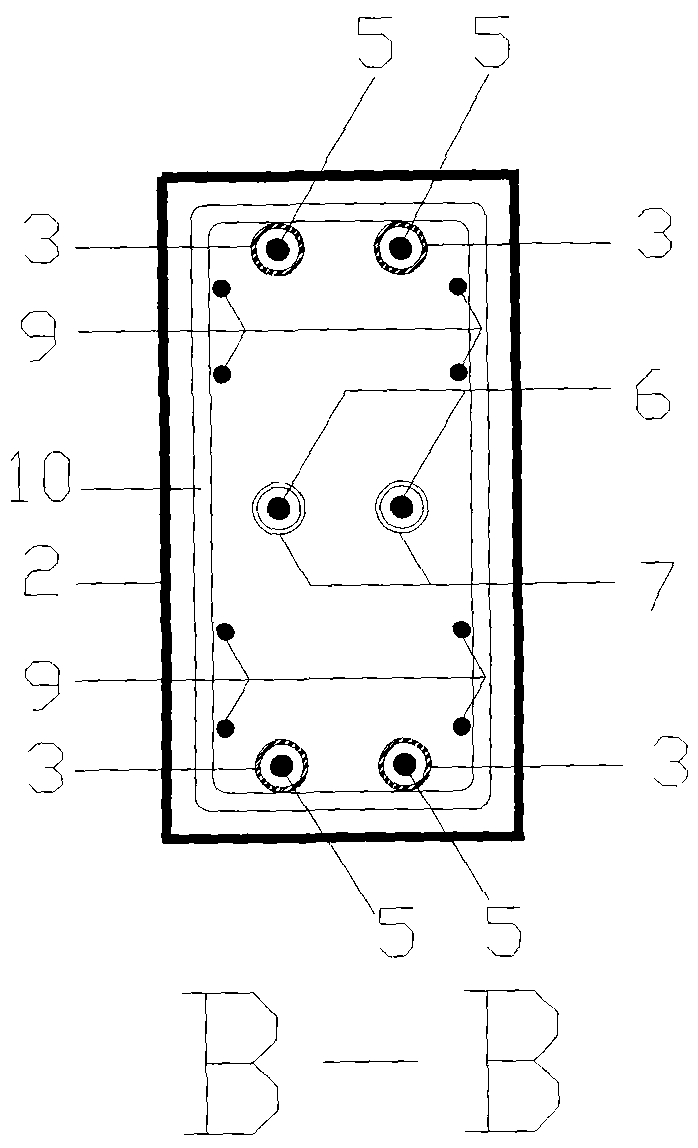

A prestressed concrete frame includes prefabricated beam and pile and integrated by prestressed reinforce. The pile is of a length over 2-3 floors. The beam is of a length for one room. Reinforce inside the beam is of a length at least equal to the short beam line. Binding reinforce concentrated in the beam center zone is of a length at least equal to the short beam line. Structure reinforce is also applied into the beam. Joint reinforce is applied to the beam ends. A distance of 30-40mm left between the beam and pile. This frame is of good stability for earthquake.

Description

technical field The prefabricated prestressed concrete structural beam and column composite joint is a form of joint processing, which belongs to the technical field of fabricated concrete structures in civil engineering. Background technique The seismic performance of prefabricated structures is determined by the connections between prefabricated components. Most areas in my country are in seismic fortified areas, so whether the connection is reliable or not directly affects the application of prefabricated structures. For a long time, due to the unsolved technical problems of assembled structure nodes, the application of assembled structures in my country's earthquake areas has been restricted. The current seismic codes generally encourage the use of cast-in-place nodes, which cause great pollution to the surrounding environment. , such as the waste of construction water and construction materials, and the noise brought by the construction also troubles the surrounding re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B1/22E04B1/21E04B1/58E04C5/01

Inventor 李振宝王冬雁韩建强马华

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com