Patents

Literature

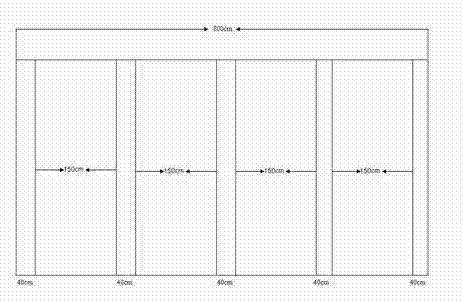

63results about How to "Save forest resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

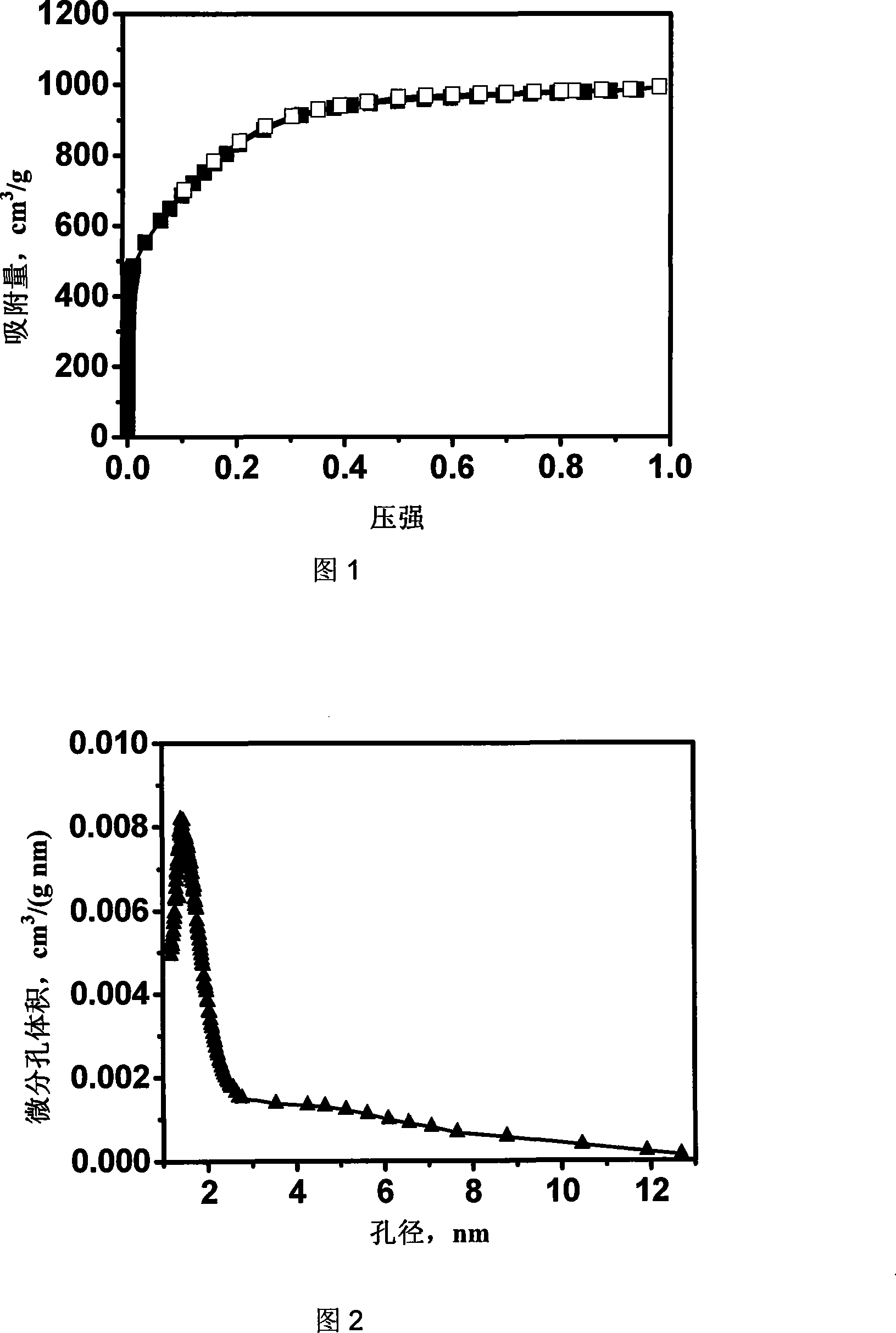

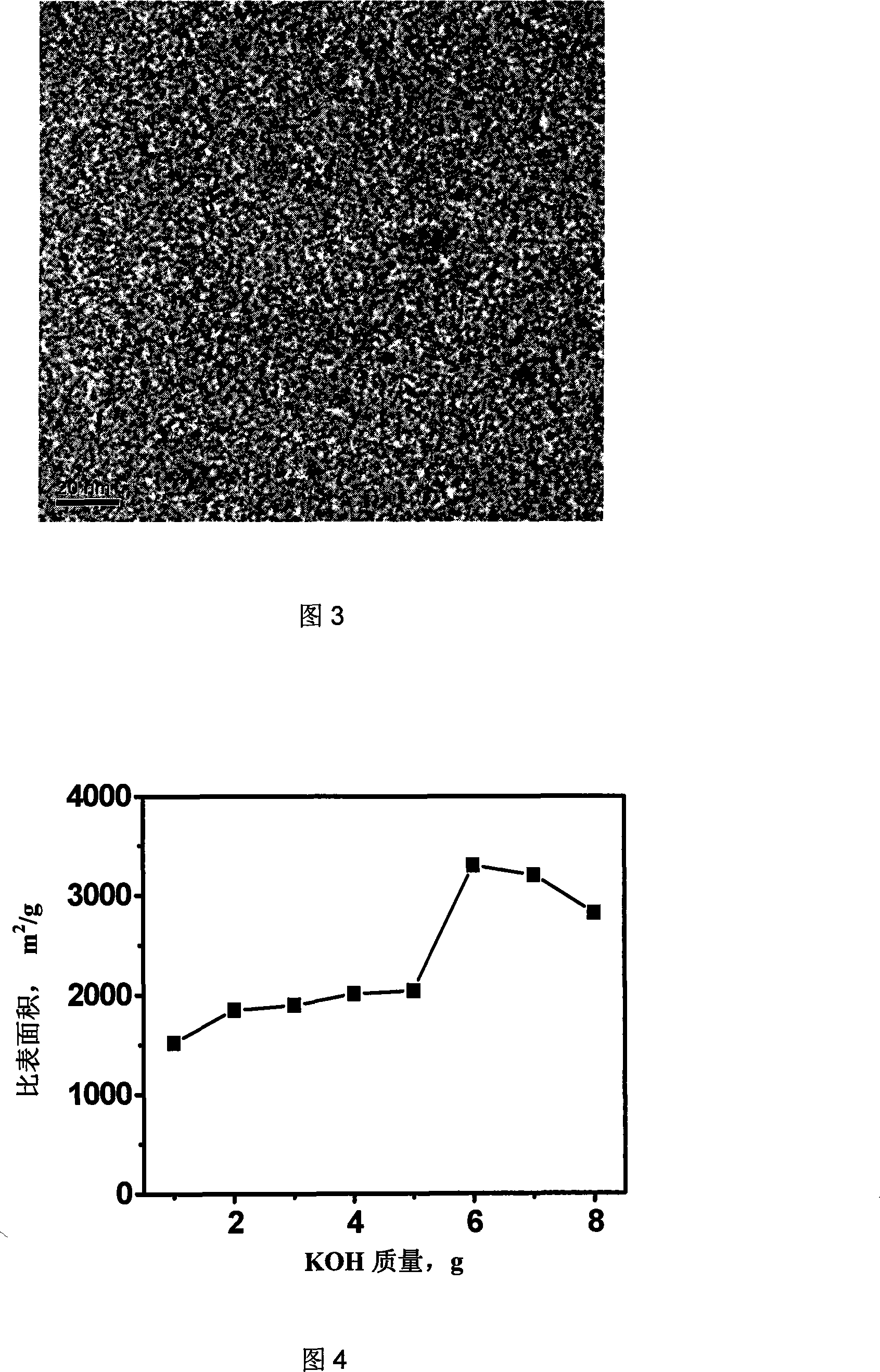

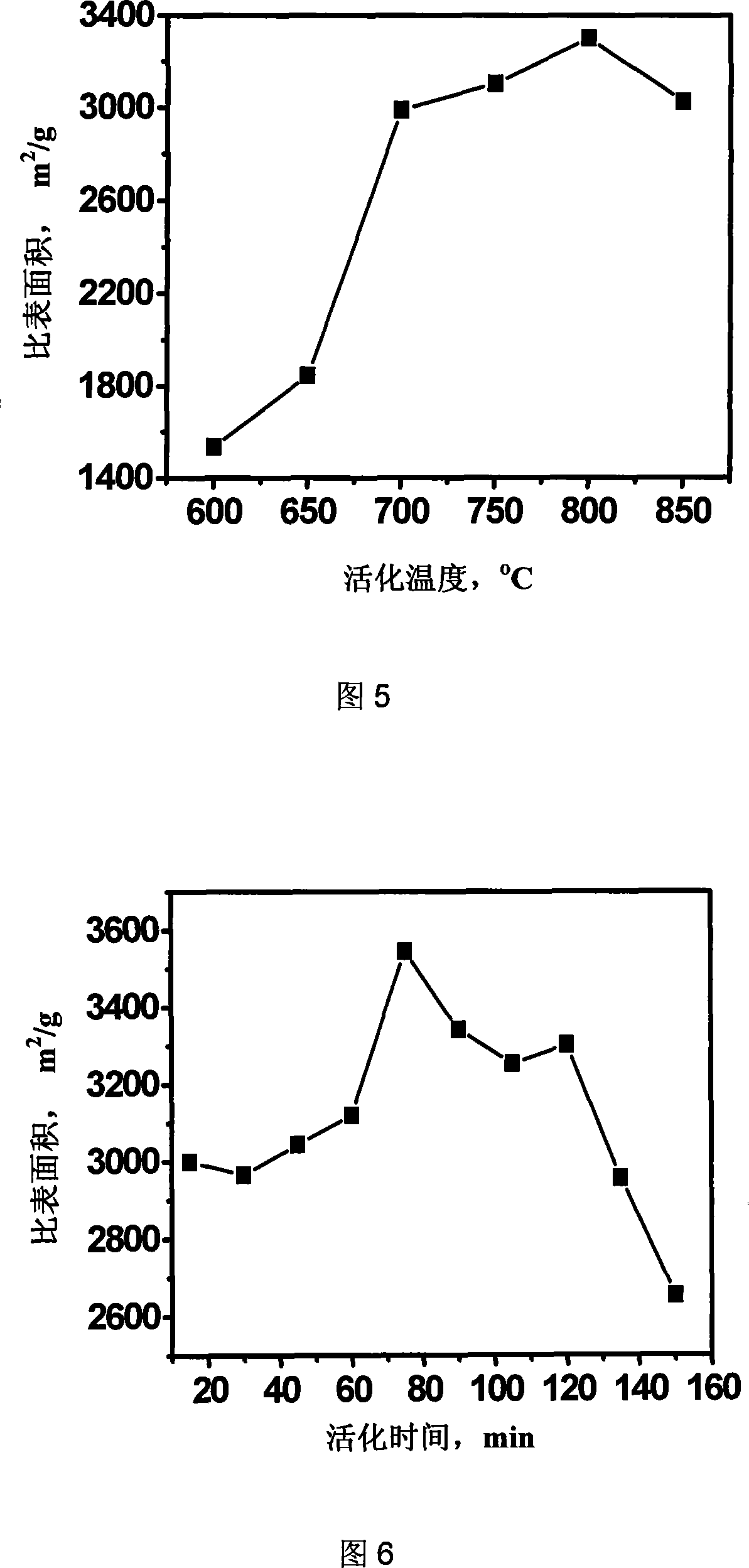

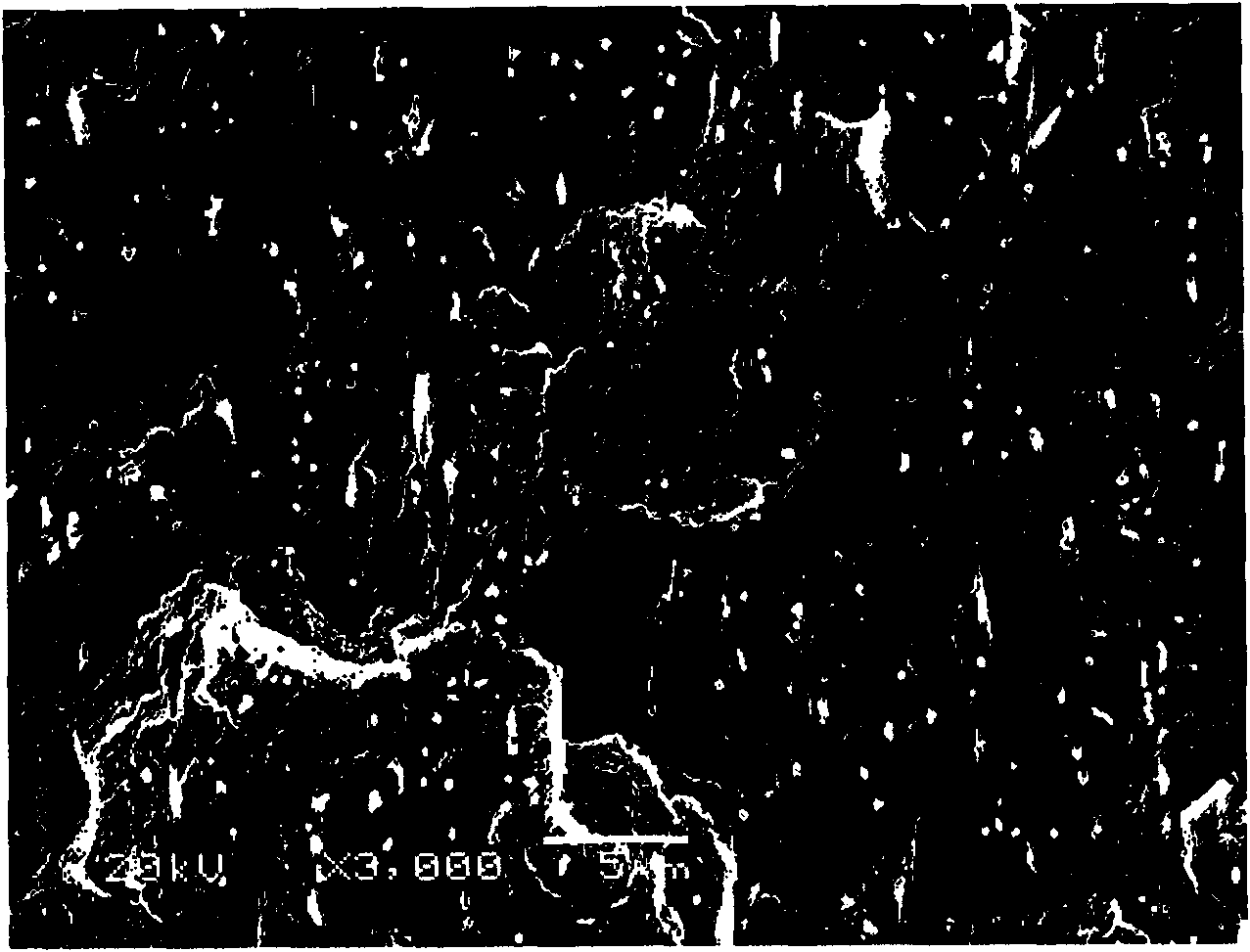

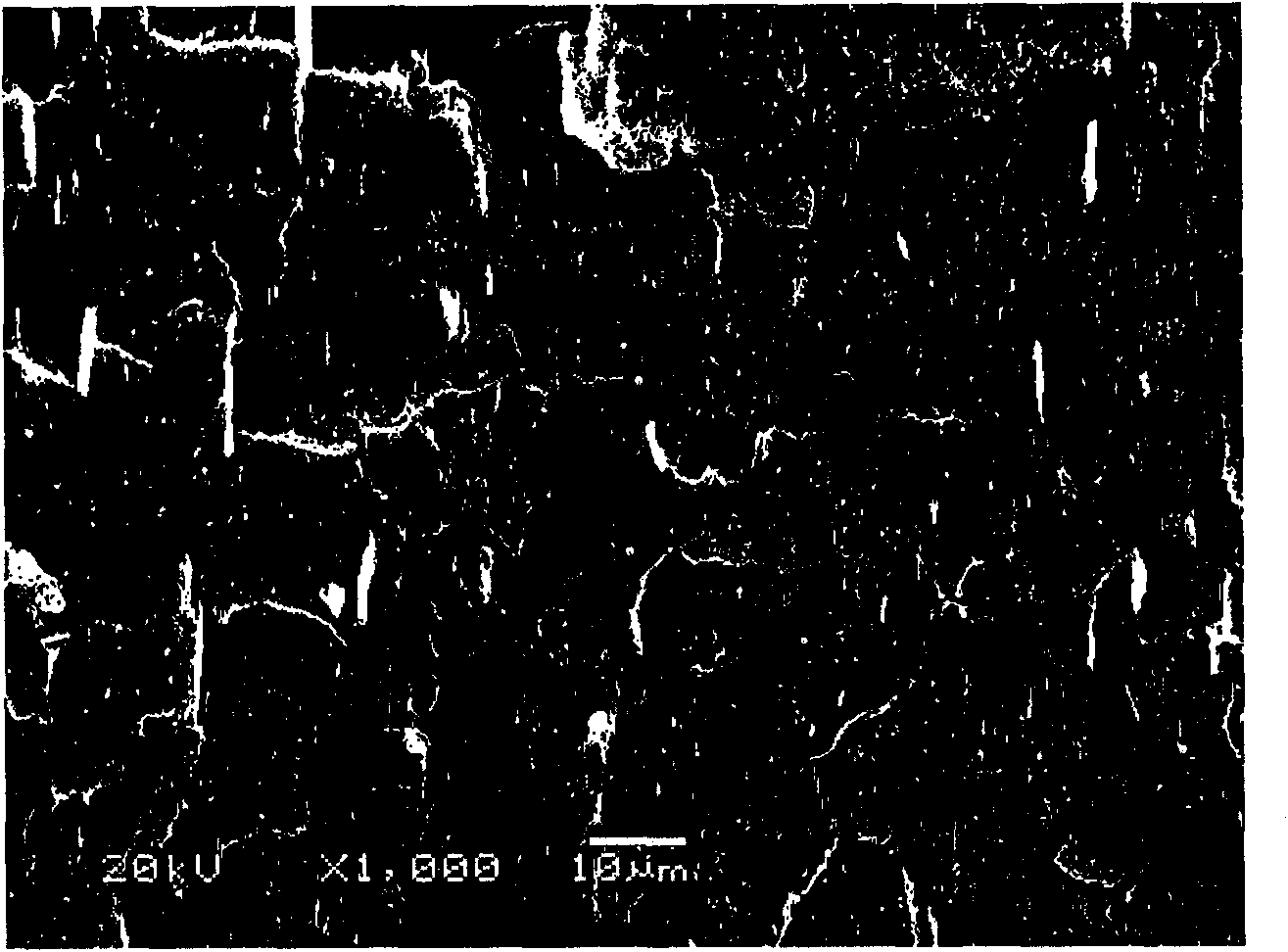

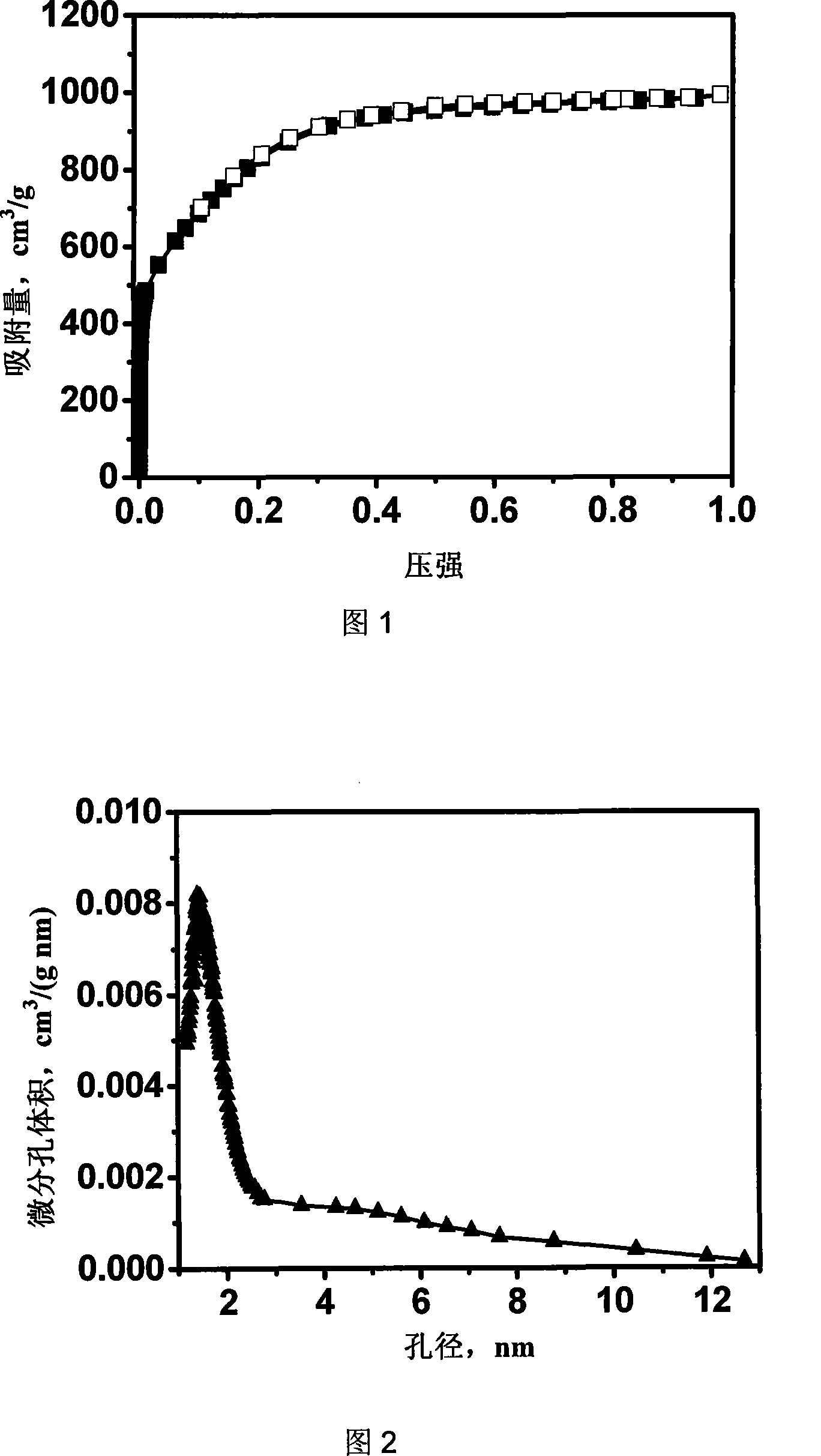

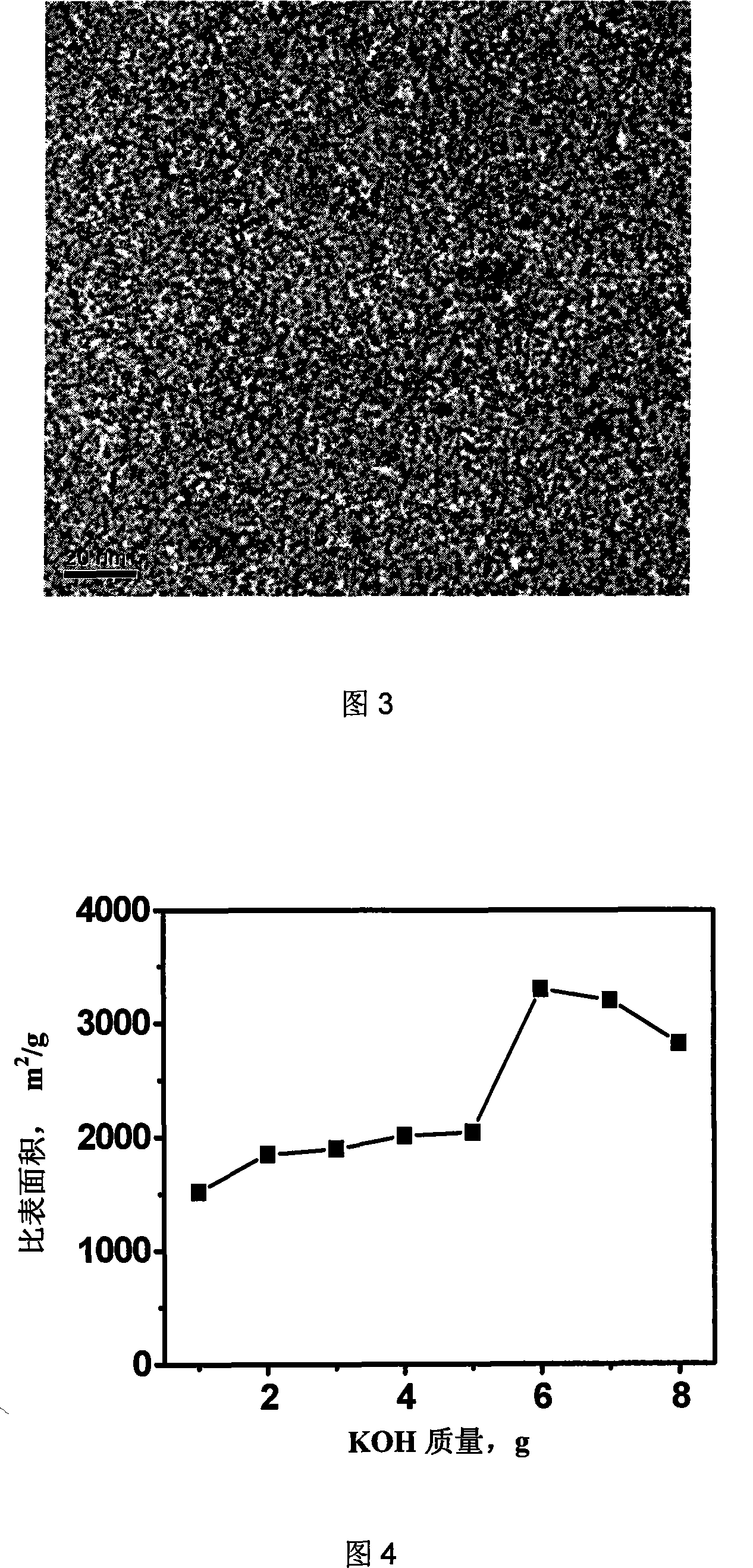

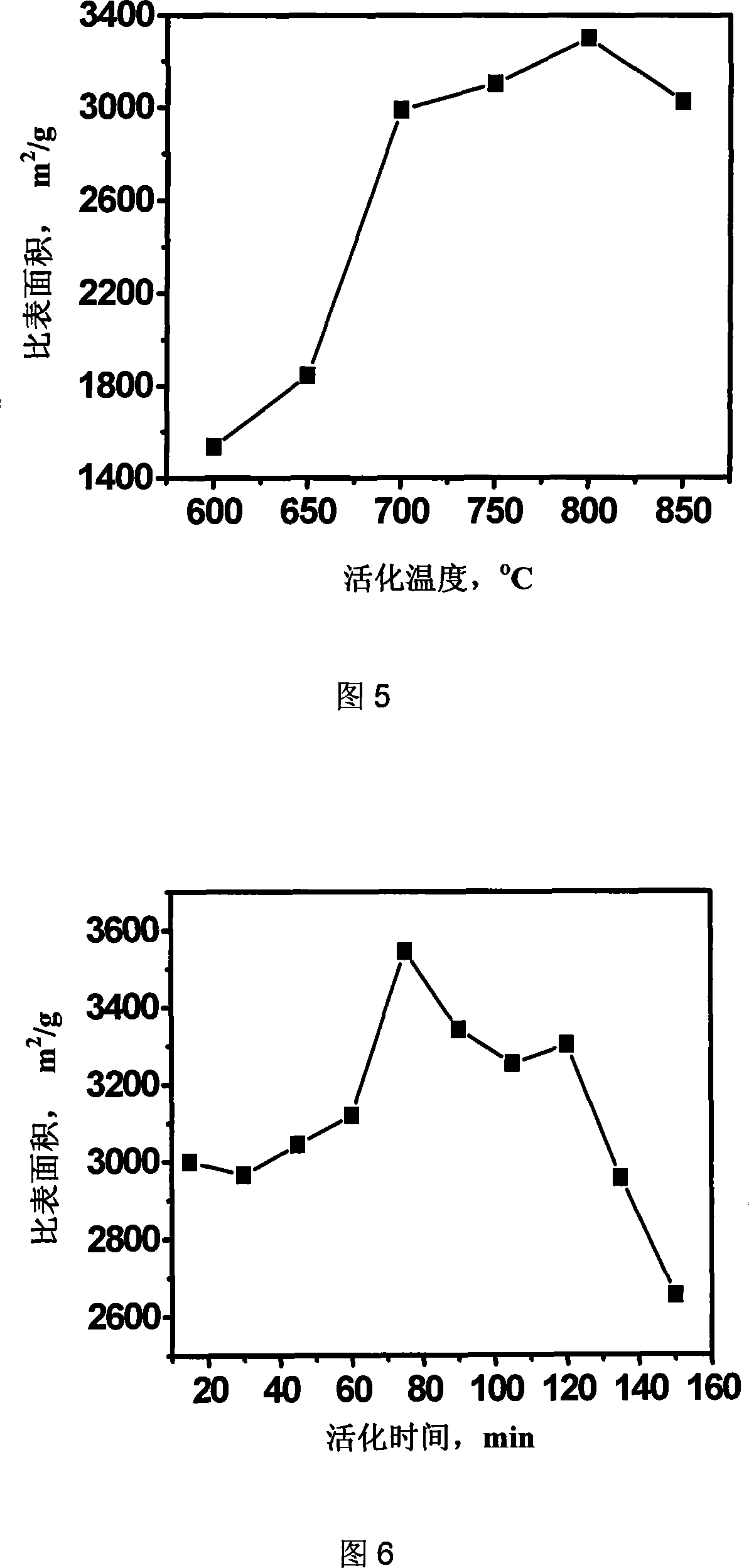

High specific surface area and narrow pore distribution porous carbon material

The invention belongs to the preparing field of porous carbon materials, which relates to a porous carbon material with high specific surface area and narrow pore distribution and which is prepared by adopting pin needles with biomass materials. The specific surface area of the porous carbon materials is capable of surpassing 3000m / 2g by adjusting activating agent dosage, activating temperature and activating time. The method of the invention has low requirement for production facilities, and has simple preparing process and low time-consumption. The main byproduct of the reaction is tar which is a product with high value in use. The washing solution of the porous carbon materials is aqueous solution which is rich in potassium ions, and is perfect potash fertilizer for agricultural industry via simple dealing. The porous carbon materials have high application prospect in the fields like the storage and separation of gas, electrode materials, catalysts or catalyst carriers in a plurality of chemical reactions, sewage disposal, recovery of noble metals and the like. The method has the advantages of cheap, plentiful and easily gained raw materials, simple preparing process, preparing condition without region limitation, thereby being adapted for large-scale industrial production.

Owner:JILIN UNIV

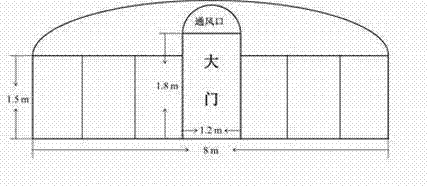

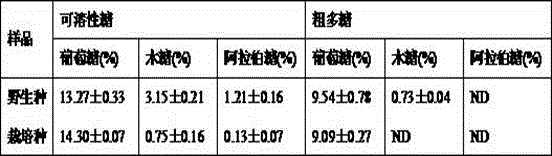

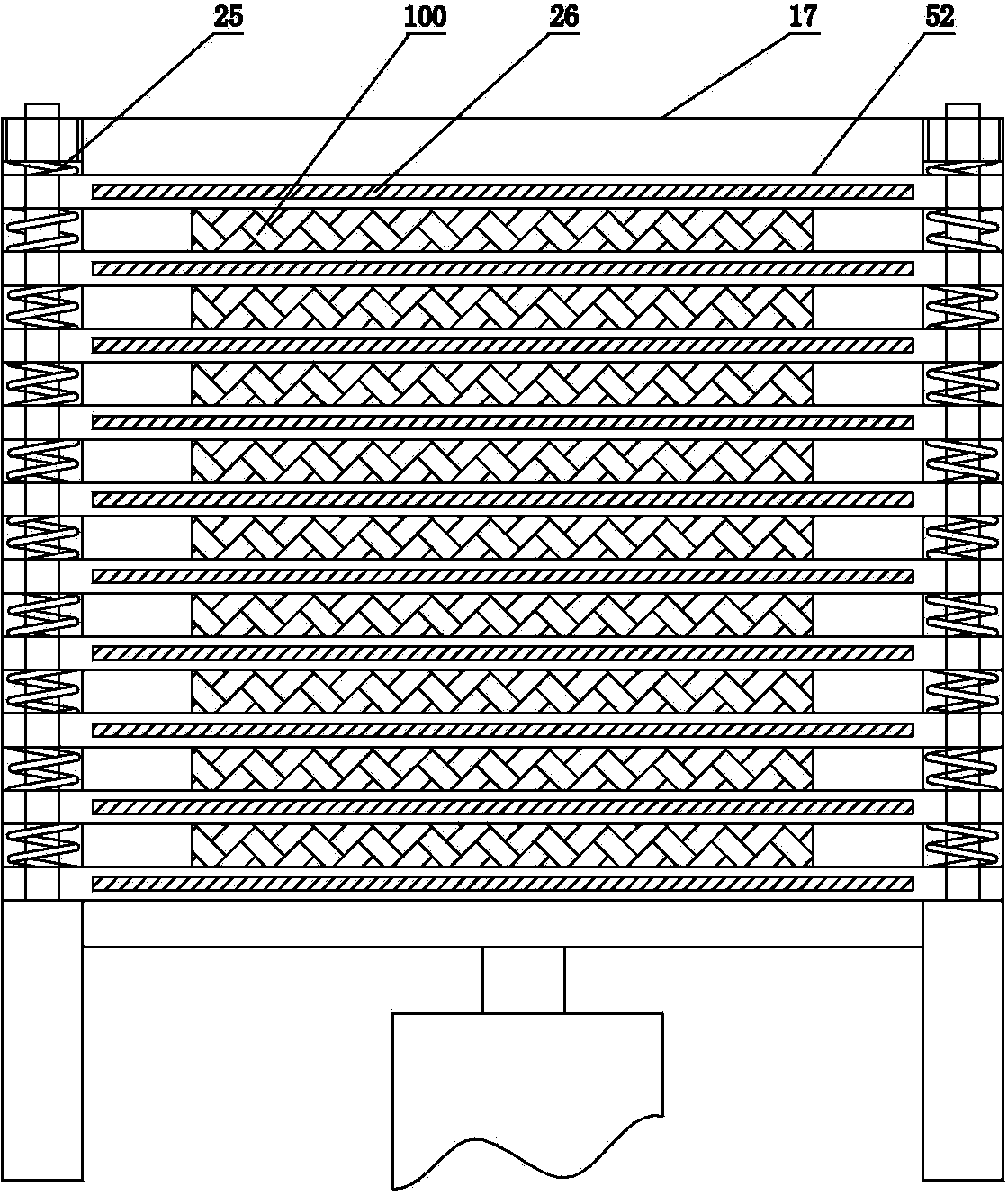

Ginseng cultivation method with nutrient blocks in greenhouse

The invention discloses a ginseng cultivation method with nutrient blocks in a greenhouse. The nutrient blocks are taken as matrixes; the temperature and humidity suitable for growth of ginseng are manually created by the greenhouse; and the growth period of the ginseng can be prolonged by two months annually, so that the ginseng can be marketed after three and a half years. According to the ginseng cultivation method, ginseng seedling raising and cultivation can be finished in one step, so that the output and the quality of the ginseng can be greatly improved when a lot of forest land resources and manpower resources are saved. The new ginseng cultivation technology can be popularized in a non-forestry land in a large scale, can be used for effectively solving the bottleneck problem that the ginseng cannot be repeatedly and continuously cropped in a forest land and a farmland, facilitates normalized and standardized cultivation and new variety breeding of the ginseng, and can be used for alleviating a physiological disease of the ginseng and eliminating adverse effects of slow land freezing and great temperature fluctuation in early spring on growth of the ginseng. The technology accords with the development direction of medicinal plant planting industry and facility agriculture production at home and abroad, and is a technical revolution on ginseng cultivation.

Owner:NORTHEAST NORMAL UNIVERSITY

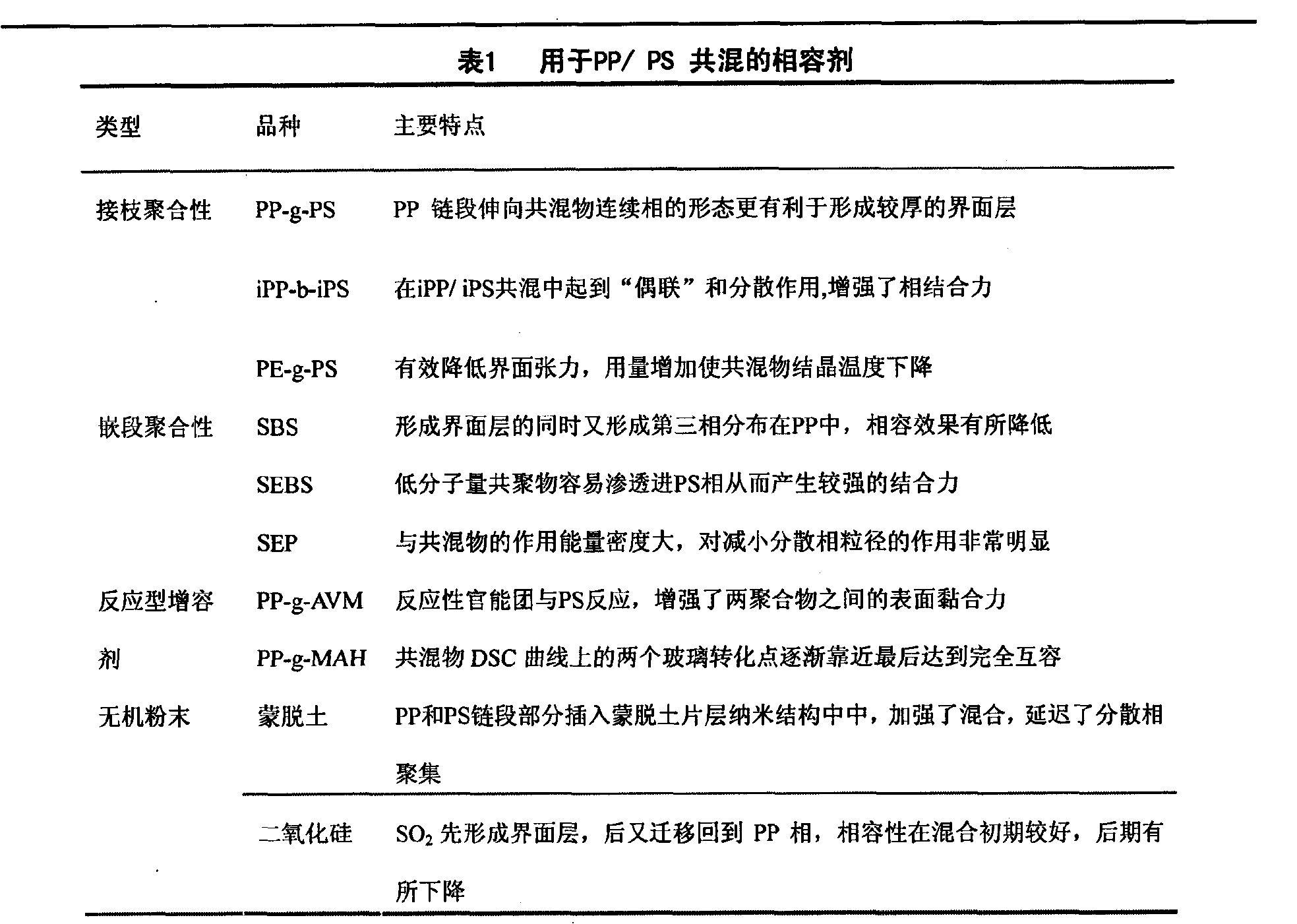

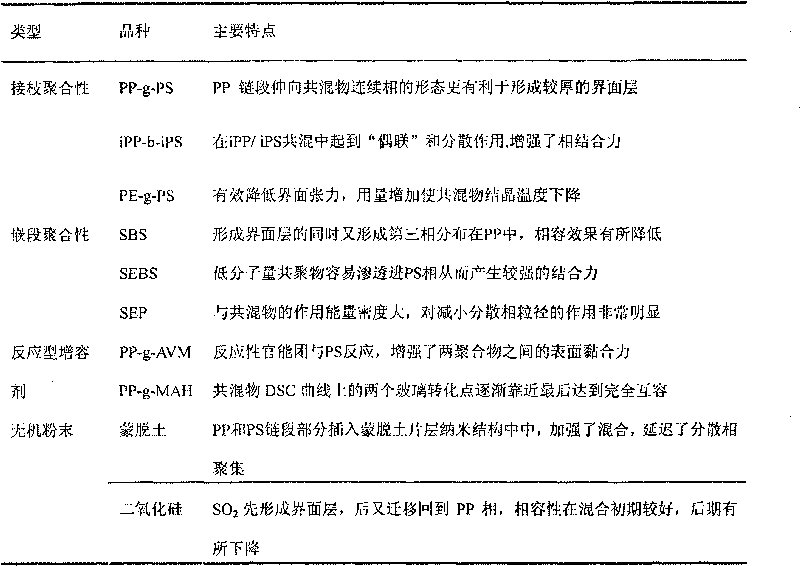

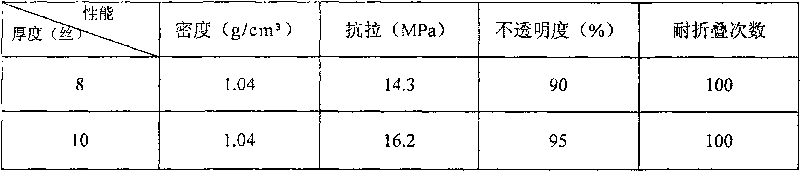

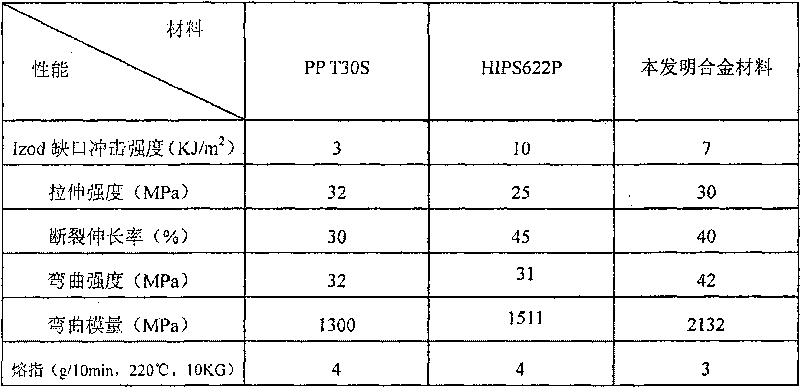

High-performance PS and PP alloy novel synthetic paper material

The invention provides a composition of a novel synthetic paper material and a preparation method. The invention comprises the following components in weight percent: 50-85% of polyolefin blend, 10% of inorganic mineral powder and 5-12% of auxiliary agent; then 0.1-1% of antioxidant calculated according to the total weight the above materials is added for pre-mixing; then a double-screw extruder is utilized for extrusion and pelletizing to manufacture into base resin with high steel and high toughness; and the comprehensive performances are all better than ordinary PP synthetic paper material,thus expanding the application range, and simultaneously by adding auxiliary agent (anti-static agent, antibacterial agent, aromatizing agent and the like), and by the processes of fusion, blending and even dispersion in the resin base body, different functional requirements can be satisfied. The paper manufactured from the high-performance PS and PP alloy novel synthetic paper material can be widely used in packaging, high-quality printed matters, tags, paper money, developing paper, tracing paper, express envelopes, paper fans, umbrellas and the like, can save a large amount of forest resource and water resource, and reduces sewage treatment pressure and energy consumption.

Owner:SICHUAN KINGFA TECH DEV

Manufacturing method of salix mongolica dyed hard wood

ActiveCN101623893AWide range of usesSolve the shortageDrying solid materials with heatWood treatment detailsVolumetric Mass DensityPulp and paper industry

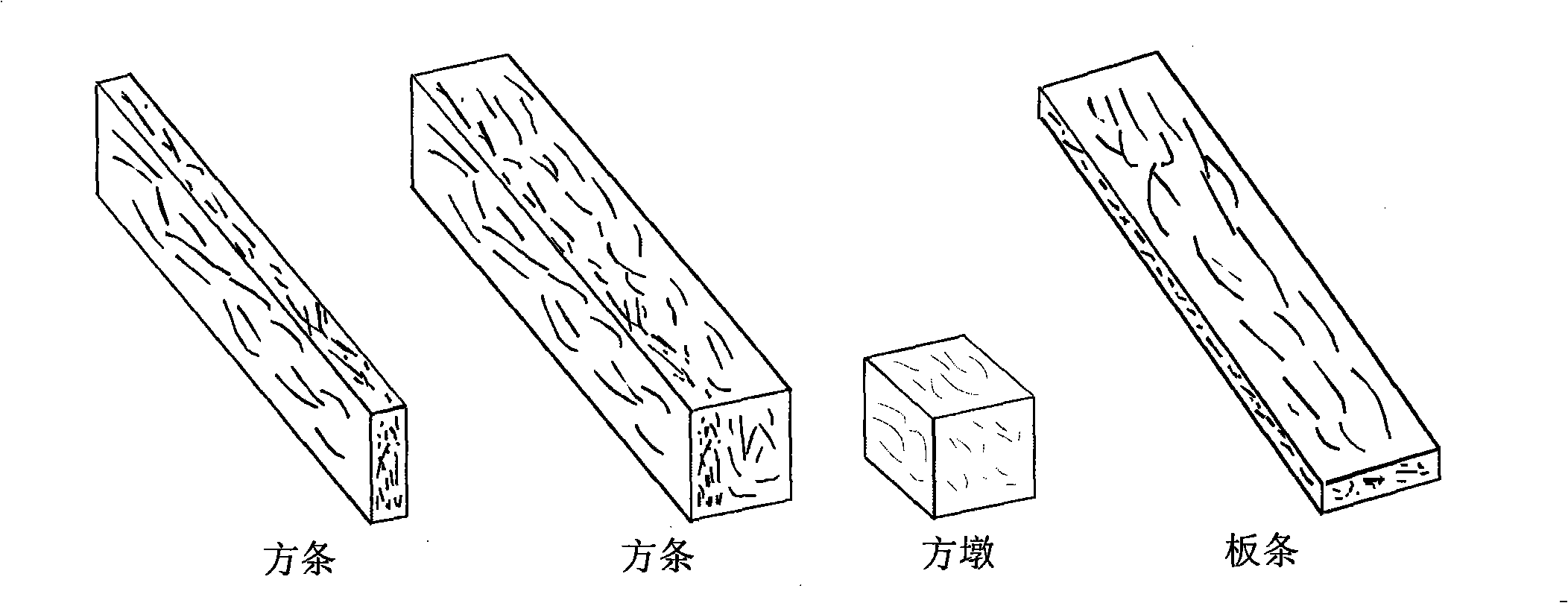

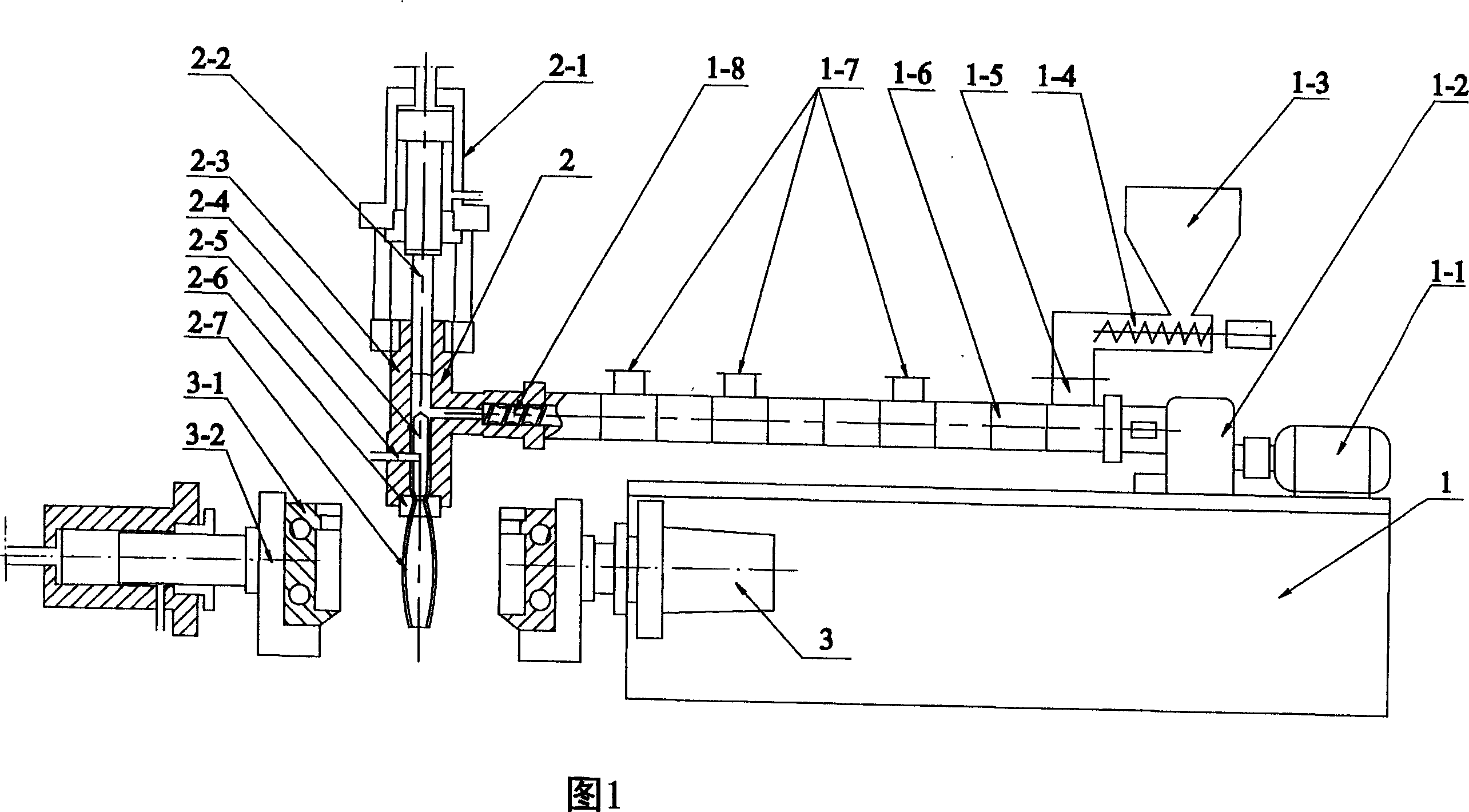

The invention relates to a manufacturing method of salix mongolica dyed hard wood, using salix mongolica as raw material to manufacture dimensional lumber with density being 0.8-1.1 and expanding the application range thereof; the implementation process comprises the followings steps: (1) manufacturing salix mongolica strips into flat and peeled salix mongolica strands by a laminating method; (2) washing the strands with circulating water and bleaching; (3) drying the strands to water content of 20%-25%; (4) dying the strands; (5) using modified phenol gum for gumming the strands; (6) drying the strands to water content of 12%-15% after gumming; (7) using a cold pressing method to compact the compositive blank in a die with using unit pressure being 550-650kg / cm<2>; (8) causing the blank to be glued and solidified into integral salix mongolica dyed hard wood at the temperature of 140 DEG C to 145 DEG C; (9) processing and reforming the salix mongolica dyed hard wood into acceptable products with uniform specification. The invention provides a new hard wood for woodwork industry.

Owner:ERDOS CITY HUALIN SALIX TECH CO LTD

Dendrobium candidum standing timber tree trunk tree pasting intensive cultivation method

ActiveCN105104149AEliminate the use of diseased and rotten seedlingsHigh transpirationCultivating equipmentsSoilless cultivationPesticideDisease

The invention discloses a dendrobium candidum standing timber tree trunk tree pasting intensive cultivation method and belongs to the technical field of dendrobium candidum cultivation. The method includes the steps of dendrobium candidum forest land selection, seedling selection, cultivation management, management and protection, disease and pest damage prevention and the like. A natural forest stand mainly comprising an evergreen broad-leaved forest along a large water river bank is selected, one-year-old seedlings of dendrobium candidum pure in quality are selected, the one-year-old seedlings of dendrobium candidum pure in quality are bundled to standing timber tree trunks to be subjected to tree pasting cultivation after degerming and disinfection treatment, 6000 seedlings can be cultivated in per mu of land, water supply and cooling can be achieved in extremely-high temperature arid climate, disease and pest damage prevention is achieved mainly through botanical pesticides, and pollution-free dendrobium candidum planting is achieved through cooperation of microorganism bacterium agents. As is proved by practice, economic benefits are remarkable. Effective components of dendrobium candidum fresh twigs are higher than effective components generated through other cultivation modes. Compared with greenhouse seedbed planting, investment is small, quality is good, economic benefits are good, and the method can serve as a leading mode for current dendrobium candidum cultivation.

Owner:安龙县西城秀树农林有限责任公司

PS (polystyrene) alloy synthetic paper and preparation thereof

The invention relates to novel PS (polystyrene) alloy synthetic paper which improves the stiffness, the surface polarity and the surface hardness and resists the chemical corrosion. The paper molded by using an extrusion tape casting method has white appearance and opacity, excellent physical property and superior price, can replace current commonly-used calendered paper, and replaces products of common paper PE (polyethylene) and common paper composite BOPP (biaxially-oriented polypropylene) membranes. The novel PS alloy synthetic paper is applied to common printing materials and processing materials by the characteristics of water prevention and tear resistance, applied to data needing permanent preservation by the characteristic of excellent weather resistance, and adapts to various labels of packages of drink bottles and cans. The invention does not produce the environment pollution during the manufacture and use, can save a great quantity of forest resources and water resources for country, lightens the sewage treatment pressure, and reduces the energy consumption.

Owner:SICHUAN KINGFA TECH DEV

Low-carbon, environment-friendly and energy-saving high-level ecotype door and manufacture method thereof

InactiveCN103144179ASave resourcesProtect environmentPaper/cardboardWood veneer joiningSpray coatingSingle plate

The invention provides a low-carbon, environment-friendly and energy-saving high-level ecotype door and a manufacture method of the ecotype door. According to the ecotype door on the market currently, a base material is generally made from the China fir and the African soft and impure pine batten, a low-level agglutinate plywood is taken as an edge frame, and the corner crushed aggregates and the honeycomb paper are taken as filler. The manufacture method of the low-carbon, environment-friendly and energy-saving high-level ecotype door comprises the following five steps of 1, symmetrically arranging single boards by a transverse-lengthways-transverse structure to form a multi-layer board; 2, overlapping two door boards with the thickness of 15-25cm into a standard door board; 3, pressing melamine impregnating resin-impregnated surface-layer decorative paper and shortened density board; 4, thermally pressing the milled door surface board and the door board into the ecotype door; and 5, printing wood grain on the side edge of the door in a transferring way, and carrying put spray coating. The method is used for manufacturing the low-carbon, environment-friendly and energy-saving high-level ecotype door.

Owner:张福贵

Method for planting polyporus umbellatus and humic acid for planting polyporus umbellatus

The invention provides a method for planting polyporus umbellatus and humic acid for planting the polyporus umbellatus and belongs to the technical field of polyporus umbellatus planting methods, wherein the method is simple, is in favor of management and is low in cost. The technical scheme adopted by the invention is as follows: selecting round polyporus umbellatus with full water and multiple bacterium holes outdoors, and simultaneously, removing Yuanpei soil at the periphery of selected seeds; storing for 5-10 days at the temperature of 28 DEG C-35 DEG C at the pH value of 5-7 at the humidity of above 75%; selecting a sloping field which is shady and has sunlight and a sloping degree of 15 degrees-35 degrees as a plant field; excavating a kiln along terrain on the sloping field, wherein the length of the kiln is 1.3-1.6 meters, the width of the kiln is 1-1.3 meters, and the height of the kiln is 1-1.3 meters; and mixing 3-4 parts of Yuanpei soil with 5-7 parts of humic acid and then filling the mixture in the kiln, wherein the planting is carried out on the last ten-day of May or the first ten-day of October each year, the growth period is 13-15 months, and the humidity is maintained to be above 70% in the planting process. And the method is applied to the technical field of polyporus umbellatus planting on a large scale.

Owner:SHANXI SHENGJI AGRI ANIMAL HUSBANDRY DEV

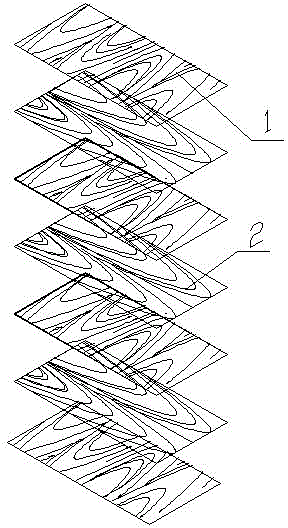

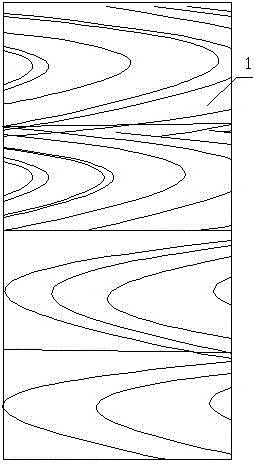

Regeneration artificial board

InactiveCN101337360ASave forest resourcesProtect environmentWood veneer joiningWood layered productsScrapWaste treatment

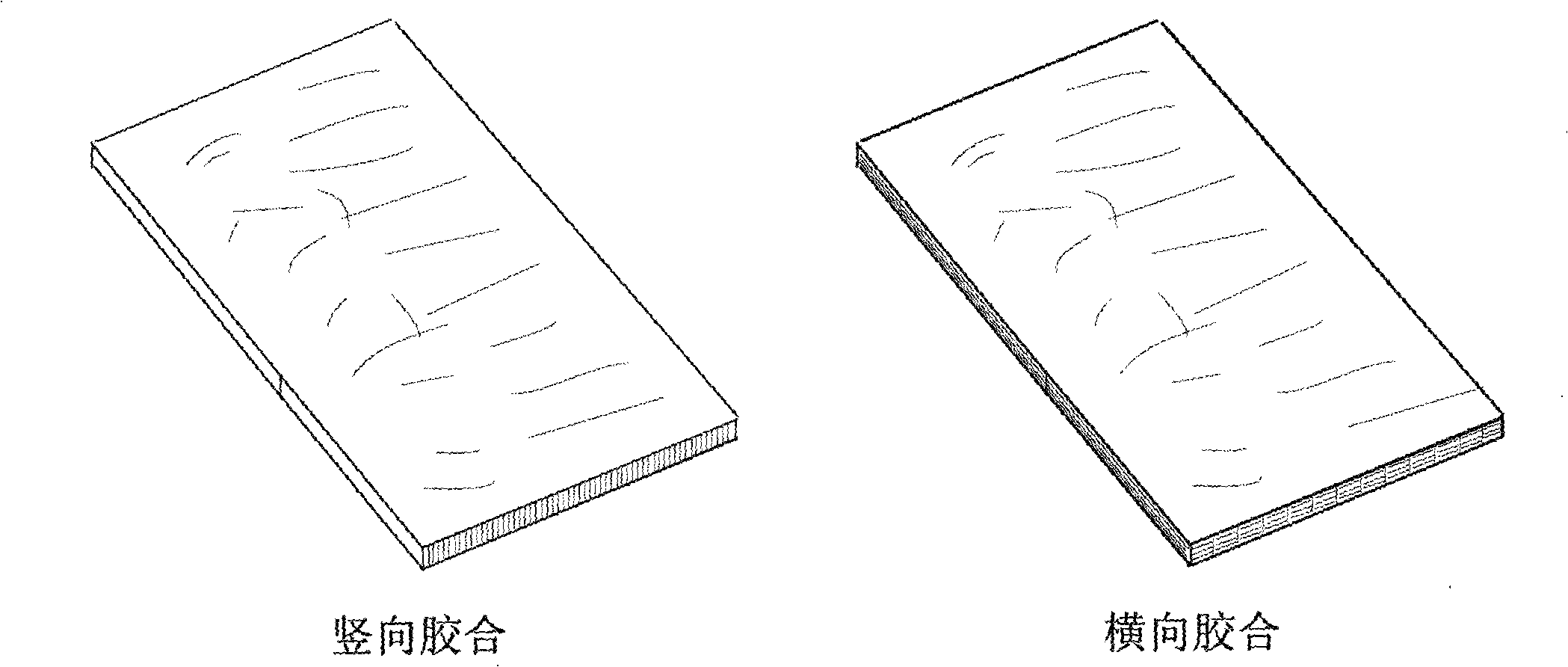

The invention provides a regenerated artificial slab which is mainly made of timber waste (wood shavings, saw dust and wooden chips), four-side plywood waste of plywood manufacture factories and logistic packaging waste (plywood). The logistic packaging waste is artificially processed into strip-shaped slabs with unified specification, then resin cement is applied to the slabs, and the slabs are formed into artificial slabs under the conditions of high temperature and high stress. The slabs can be made into regenerated artificial slabs with two types of different structures: composite flake boards and edge-strip plywood. The thickness of the regenerated artificial slab is larger than 30mm; the regenerated artificial slab, to which a nail can be driven, can be sawed and can replace a raw wood; the regenerated artificial slab improves the comprehensive utilization rate of timber by 1.8 times, reduces forest resource consumption and waste treatment expense, and can be applied to logistic trays, logistic packages, furniture, decorations, etc. The logistic packaging waste is reutilized as far as possible after resource recovery. The regenerated artificial slab attaches profound significance to the building of a resource-conserving and environment-friendly society.

Owner:杨橙双

Floor production process

InactiveCN101623890AFlame retardantMoisture-proofPolishing machinesLayered productsBiochemical engineeringRabbet

The invention provides a floor production process with low cost and simple working procedure, which comprises the following steps: by using a rabbet model, extruding a floor with rabbets at two sides by using an extruder; making rabbets at other two opposite sides of the extruded floor by using a double-head notching machine; printing patterns containing textures on the surface of the floor; and finally adhering an abrasion-resistant layer to the surface of the floor.

Owner:余弟昌

Composite wood made of rice straw polymer and its producing process

InactiveCN101015929AReduce pollutionSave forest resourcesFibrous raw materialsDomestic articlesFiberPolymer science

A straw polymer composite wood is characterized in following materials (mass) that straw fiber is 45-85%, thermal plastic polymer is 15-40%, inorganic stuff is 5-15%, elastic element is 2-8%, graft polymer is 2-5%, strengthen filament is 6-10%, and agent is 2-4%. The invention can utilize waste straw to prepare composite wood to save resource and reduce pollution with wide application.

Owner:徐凌秀

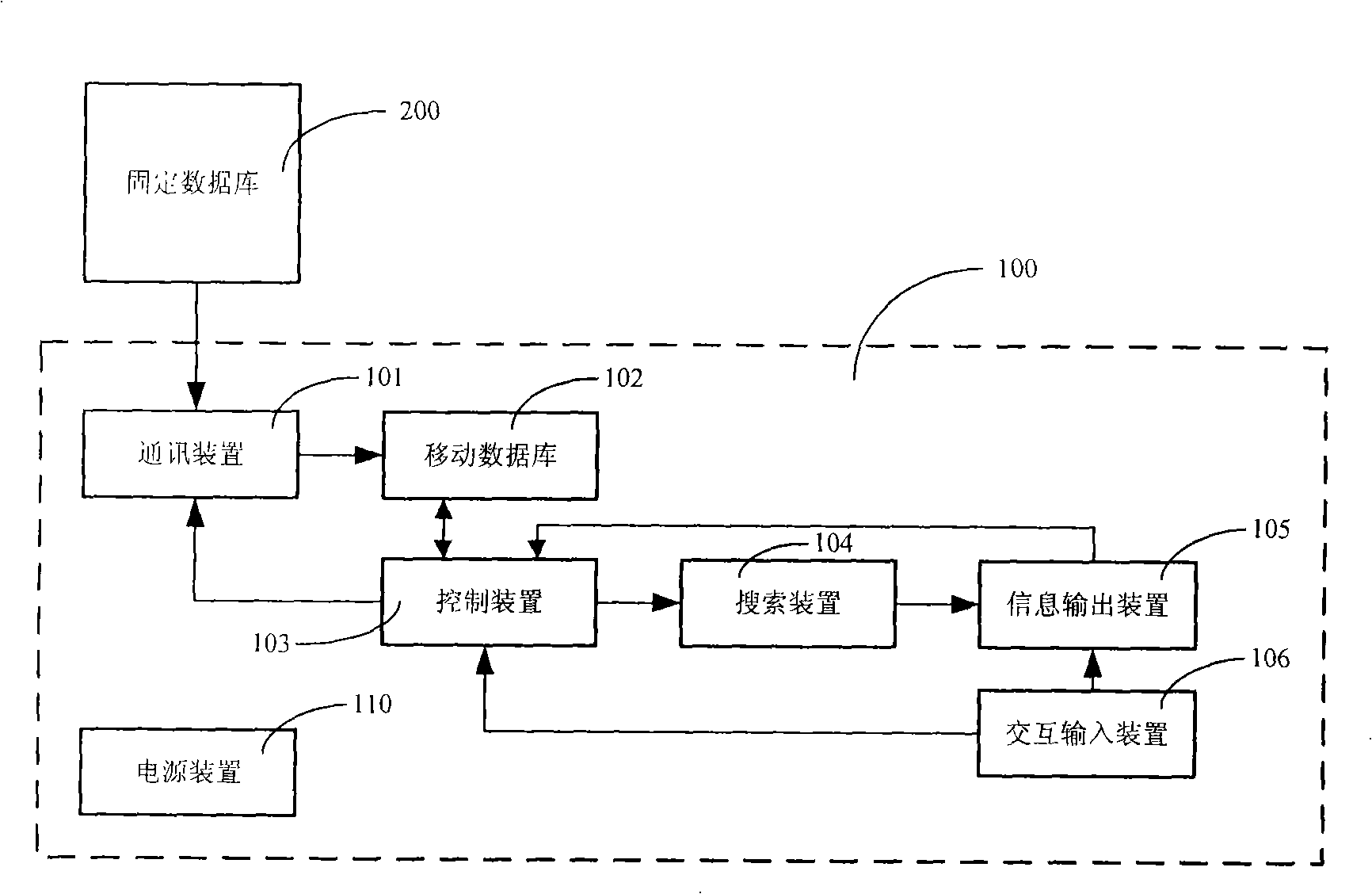

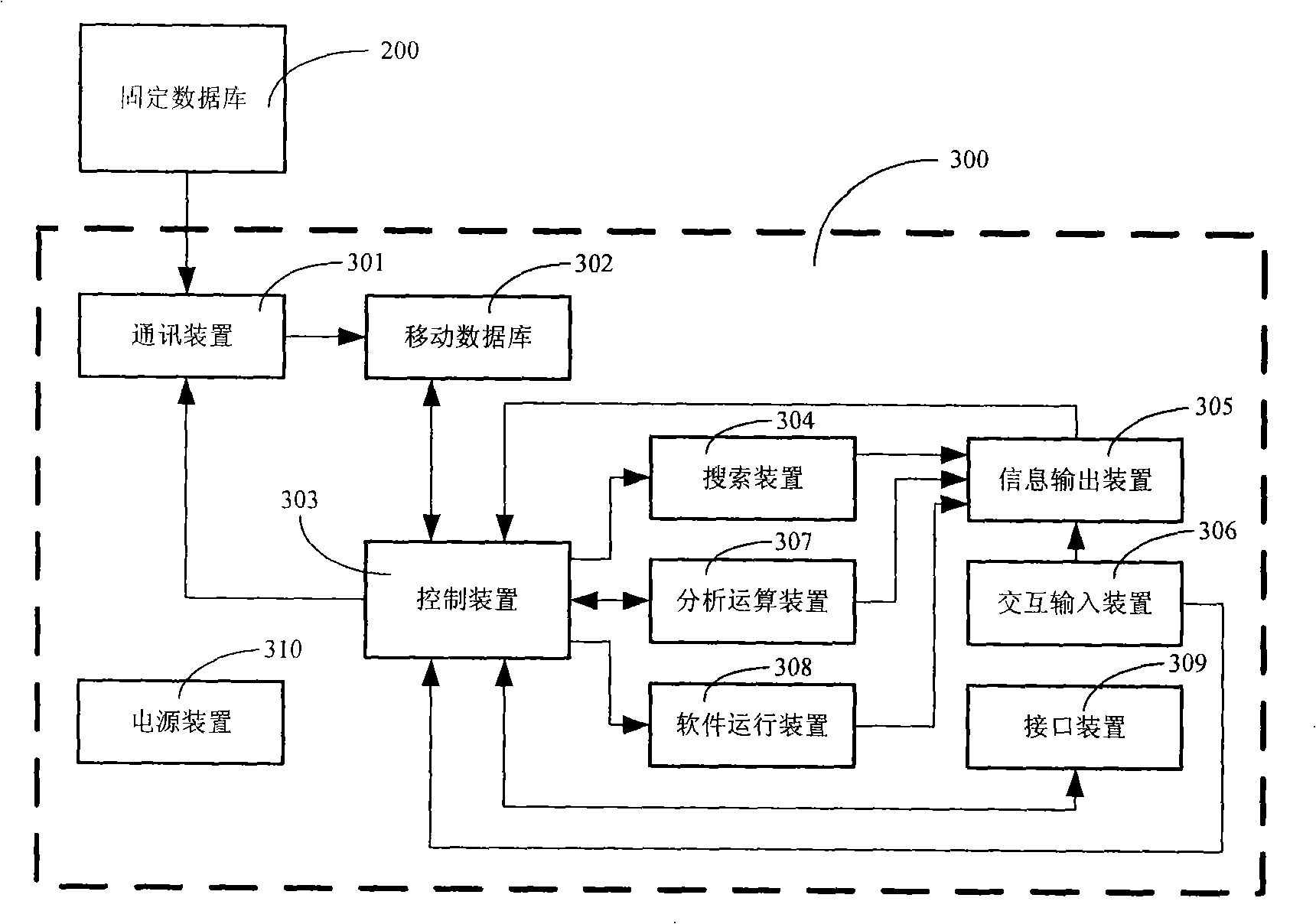

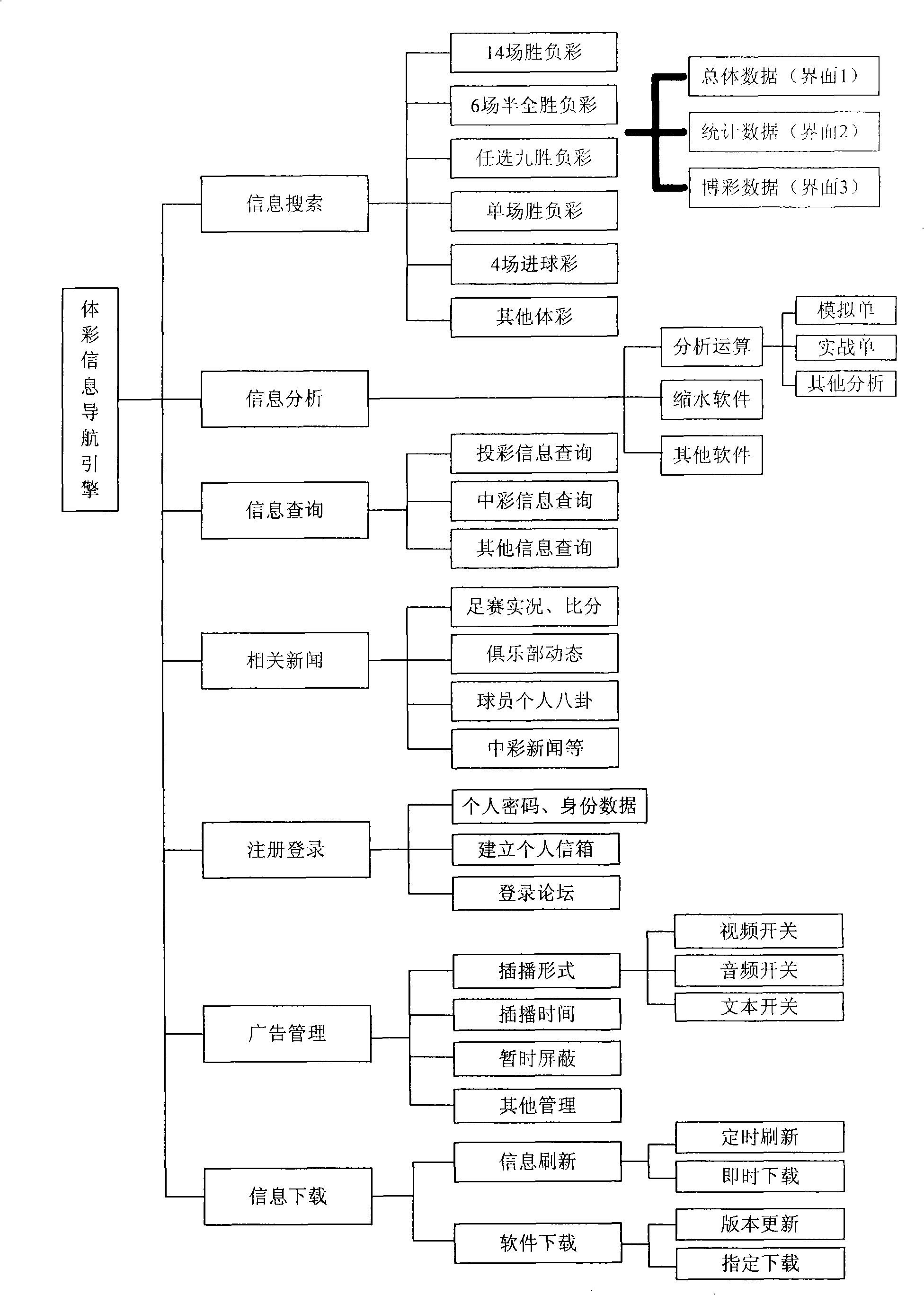

Electronic information browsing device

InactiveCN101290618AKeep it portableSave forest resourcesSpecial data processing applicationsMobile databaseElectronic information

The invention relates to an electronic information browse device, which comprises a communication device, a mobile database, a control device, a search device, a display browse device, an interactive input device, an analysis and operation device, a software operation device, an interface device and a supply unit, wherein, the communication device receives commands of the control device, is communicated with a fixed database, and downloads information data or analysis software in the fixed database into the mobile database; the control device receives input signals of the interactive input device, searches information data in the mobile database through the search device and displays information data which accords with input conditions on the display browse device, or analyzes and operates the information data in the mobile database through the analysis and operation device and displays the result on the display browse device, or operates analysis software in the mobile database through the software operation device, or is connected with an external memory device through the interface device.

Owner:梁荣荣 +2

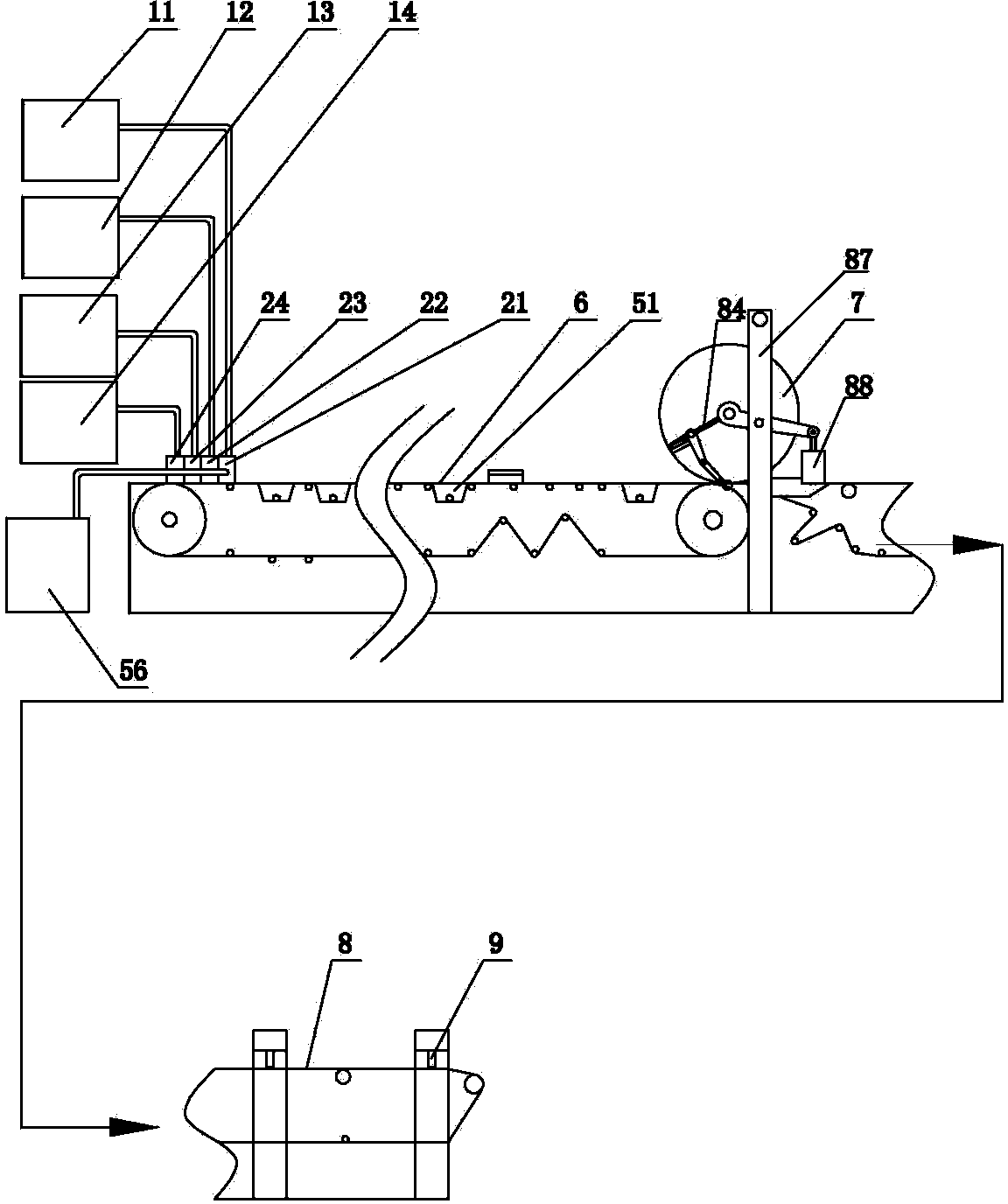

Completely artificial cultivation technology for Polyporus umbellatus Fr.

InactiveCN106718027ABig spacePromote sustainable developmentCultivating equipmentsMushroom cultivationHigh humidityLitter

The invention discloses a completely cultivation technology for Polyporus umbellatus Fr.. The technology comprises the steps of preparation of strains and a completely artificial cultivation method for Polyporus umbellatus Fr.. The cultivation method is not limited by forest region conditions, and Polyporus umbellatus Fr. cannot be cultivated in the forest. Alternatively, high humidity, large space, low temperature and clean environment are mainly adopted in cultivation in the forest. Various waste materials serve as bacteria stick accessories for Polyporus umbellatus Fr. cultivation, oak resources in use are greatly reduced, a lot of forest resources can be saved, and long-term human sustainable development is benefited. Various waste materials of agriculture and forestry are adopted, the waste of precious resources is reduced, a lot of waste materials of agriculture and forestry are also utilized, so that garbage wastes are reduced, and the environmental protection significance on the modern society is great. The growth cycle of Polyporus umbellatus Fr. is shortened, the quality of Polyporus umbellatus Fr. sclerotia is excellent, Polyporus umbellatus Fr. products can be supplied to the Polyporus umbellatus Fr. market, and it is expected that a great help is provided for solving the market contradiction that demand seriously exceeds supply in the current Polyporus umbellatus Fr. market.

Owner:TIANSHUI NORMAL UNIV

Processing technology of labeling-free blister product, and mold used for the same

ActiveCN102431156AHigh cooling costsAvoid deformationPolymer sciencePolyethylene terephthalate glycol

The invention discloses a processing technology of a labeling-free blister product, and a mold used for the same, wherein the technology comprises processes of pattern printing and located blister forming. In the blister forming process, a part with printed patterns is cooled while being processed with the blister forming treatment; correspondingly, the mold of the invention is provided with a cooling structure at a part corresponding to the patterned part of the product. In the processing technology, the patterns are directly printed on plastic sheets, then, the plastic sheets are integrallymolded by blister forming process, and the mold protects the corresponding part of the product from heating while executing the blister forming process, thereby avoiding the consequence of pattern deformation; the plastic sheets are directly used as carriers for the patterns, use of papers is avoided, and forest resource is saved, so that the labeling-free blister product is suitable for pipelineprocessing and mass production, field, flows and workers are all saved, cost is reduced, and the product is easy to store. The processing technology provided by the invention is suitable for the plastic products with patterns, and the mold provided by the invention is suitable for molding the plastic products with patterns, and is suitable for plastics, such as PVC (Polyvinyl Chloride), PET (Polyethylene Terephthalate), PP (Polypropylene), PS (Polystyrene), PE (Polythene), PC (Polycarbonate), PMMA (Polymethyl Methacrylate) and the like.

Owner:石家庄市富强印业有限公司

Preparation method of coating paper

InactiveCN110042699AWith wear resistanceImprove wear resistanceSpecial paperPaper/cardboardWear resistantSuspending Agents

The invention relates to the field of coating paper preparation, in particular to a preparation method of coating paper. The method comprises following steps: (1), base paper is soaked in an impregnating adhesive containing modified urea-formaldehyde resin, a penetrating agent, a curing agent and water, rolled by a roller and dried in a drying oven; (2), a spraying adhesive containing modified melamino-formaldehyde resin, the modified urea-formaldehyde resin, the penetrating agent, a suspending agent, a defoaming agent, the curing agent, aluminium oxide and water is sprayed to the upper surface of the paper obtained in step (1) by spraying equipment, and then the paper is leveled by a leveling roller and dried in the drying oven; (3), the front and back surfaces of the paper obtained in step (2) are coated with a mesh coating adhesive containing the modified melamino-formaldehyde resin, a mold release agent, a dedusting agent, the curing agent and water by a round roller with a grid structure, and then the paper is dried in the drying oven. According to the method, the coating paper with both wear-resistant effect and decorative effect can be prepared, and forest resources are saved.

Owner:HUBEI HONGLIAN IND

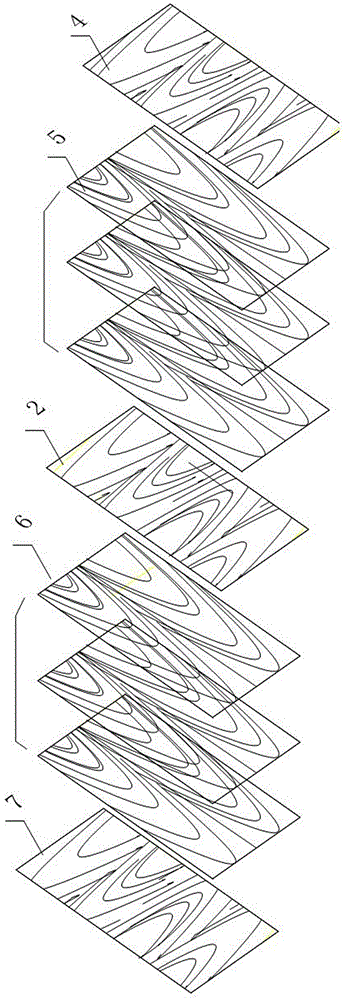

Method for manufacturing environmental-protection anti-deformation board at low carbon

InactiveCN104552496AResolves variable crackingSolve environmental problemsWood veneer joiningBattenMechanical engineering

The invention discloses a method for manufacturing an environmental-protection anti-deformation board at low carbon; timber resources are not inexhaustible resources, so the timber resources have the problems of high demand and high cost. The method comprises the following steps: S1, performing rotary cutting on logs into veneers by a rotary cutter; grading the veneers; drying the veneers until moisture content is lower than 12 percent; coating surface layers and a middle layer with glue, pressing to manufacture a composite board, and cutting into battens which are equal in specification; selecting three layers of cross grain arranged battens; putting one of the three layers of cross grain arranged battens in the middle, and putting the remaining two layers of cross grain arranged battens on the surface layers or inner layers of the surface layers; pressing the three layers of cross grain arranged battens into an anti-deformation board by a hot press; standing for more than 15 days for curing; cutting into broad battens according to fixed length, coating with the glue, and manufacturing an anti-deformation board by an automatic board jointing machine; cutting off the redundant four sides, and sanding with a sanding belt. According to the manufacturing method disclosed by the invention, valuable timber resources are replaced by fully utilizing common timber resources, and therefore the resources are saved; waste is turned into treasure, forest resources are protected strongly, and the cost is reduced.

Owner:HEILONGJIANG HUAXIN FURNITURE

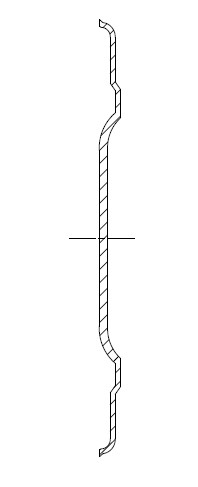

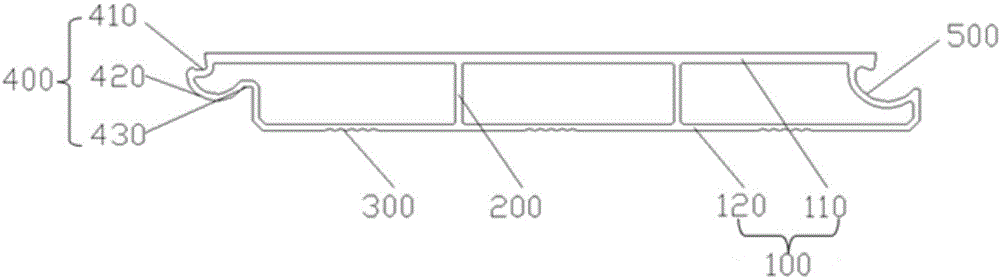

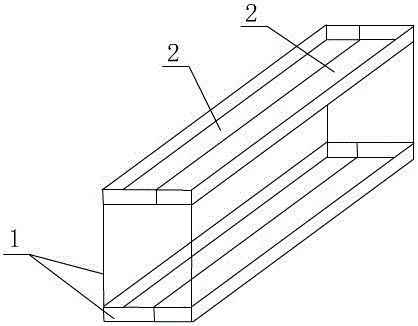

Aluminum alloy floorslab and manufacturing method thereof

The invention provides an aluminum alloy floorslab and a manufacturing method thereof, and relates to the technical field of construction equipment. The floorslab comprises a floorslab main body, a convex part and a concave part, wherein the convex part and the concave part are located on the two sides of the floorslab main body correspondingly. During the floorslab assembling process, the convex parts and the concave parts of adjacent floorslabs are connected sequentially in an inserted mode. The floorslab main body comprises an upper cover plate and a lower cover plate located on the lower portion of the upper cover plate. The upper cover plate, the lower cover plate, the convex part and the concave part define a hollow floorslab inner cavity which is provided with reinforcing pieces used for connecting the upper cover plate and the lower cover plate. Protrusions are arranged in the lower cover plate in the length direction of the lower cover plate and protrude towards the upper cover plate. The lower portions of the protrusions are hollow. The upper cover plate, the lower cover plate, the convex part and the concave part are all made from an aluminum alloy material. By adoption of the aluminum alloy floorslab and the manufacturing method thereof, the technical problems that in the prior art, an adopted wooden floorslab is poor in environment friendliness and low in paving efficiency, or an adopted aluminum alloy floorslab is unreasonable in structural design and short in service life are solved. The aluminum alloy floorslab is good in environment friendliness, high in paving efficiency, and long in service life.

Owner:杨自海

Low-carbon method for manufacturing environmental friendly deformation-prevention fireproof sheet material

InactiveCN103522373AImprove fire performanceSolve environmental problemsWood veneer joiningSingle plateFire retardant

The invention discloses a low-carbon method for manufacturing an environmental friendly deformation-prevention fireproof sheet material. Timber resources are not inexhaustible, so that the problems of large demand and high cost of the timber resources occur. The method includes the following steps that a raw wood is cut into veneers in a rotary mode through a rotary cutter, and the veneers are divided into grades and dried until the moisture content is lower than 12%; surface layers and a middle layer are coated by glue and then pressed to form a composite board, and the composite board is cut into laths of the same specification; three layers of laths with arrayed transverse textures are selected, one layer is placed in the middle layer, and the other two layers of the laths with the arrayed transverse textures are placed into the surface layers or inner layers of the surface layers, and a deformation-prevention sheet material is formed through a hot press in a pressing mode; the deformation-prevention sheet material is stored more than 15 days in a standing mode for conditioning, cut into wide laths according to a fixed length, coated by glue and then manufactured to be a deformation-prevention board through an automatic board jointing machine; the redundant four sides of the deformation-prevention board are cut off, and sanding is performed through a sanding belt; the deformation-prevention sheet material is soaked in a fire retardant and coated by dry oil. Common timber resources are fully used for replacing valuable timber resources, so that the resources are saved, waste is made to be profitable, forest resources are effectively protected, and cost is reduced.

Owner:HEILONGJIANG HUAXIN FURNITURE

Novel beam, column and tiebeam structure of ancient building and manufacturing method thereof

InactiveCN108442515AIncreased durabilityStay beautifulLoad-supporting pillarsMortise and tenonArchitectural engineering

The invention provides a novel beam, column and tiebeam structure of an ancient building. The novel beam, column and tiebeam structure of the ancient building includes beam, column and tiebeam structures which are connected with each another by mortise and tenon joints, and the beam, column and tiebeam structure are all composed of hollow aluminum parts formed by punch forming and welding of aluminum alloy sheets. A mortise is arranged at the upper end of the beam structure, and an electric welding joint is arranged at one end of the mortise; a rabbit is arranged in the column structure; a mortise is arranged at one end of the tiebeam structure, and bolt holes are formed in the mortise; and bolt holes are further formed in the column structure. According to the novel beam, column and tiebeam structure of the ancient building, by adopting beam, column and tiebeam dies and beam, column and tiebeam structure base bodies which are machined by bolts and the aluminum alloy sheets, the cost of manufacturing the beam, column and tiebeam structures of the ancient building is reduced, and a lot of forest resources are saved; and in addition, the building dead load is lightened, the service life of beams, columns and tiebeams used as building units is prolonged greatly, and ancient buildings are kept attractive durably.

Owner:SUZHOU GARDEN DEV

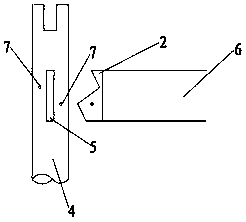

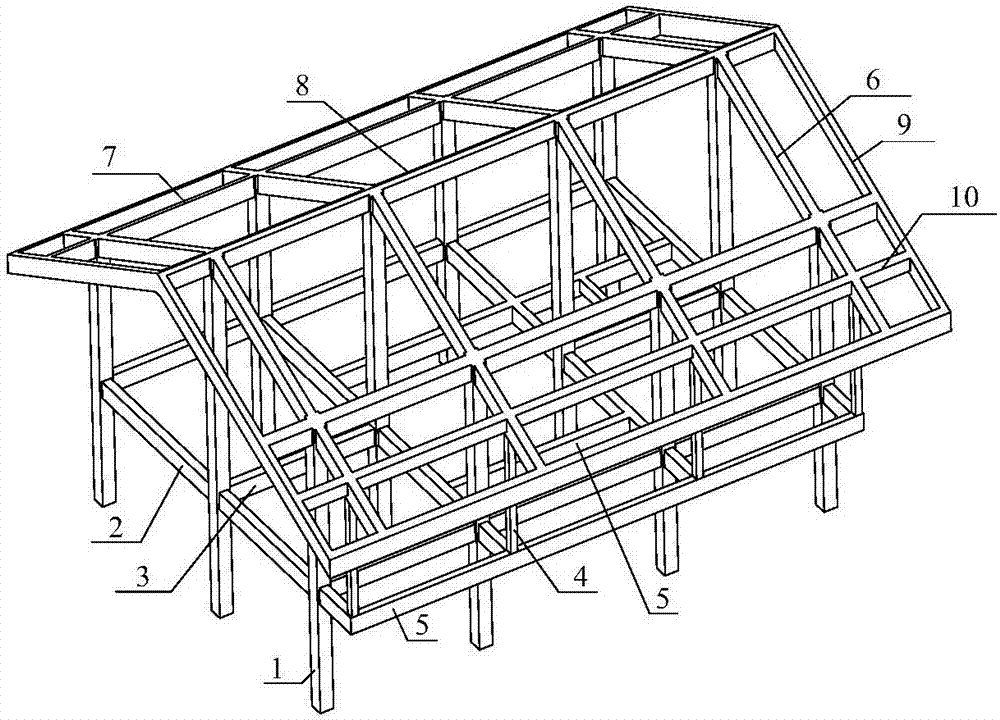

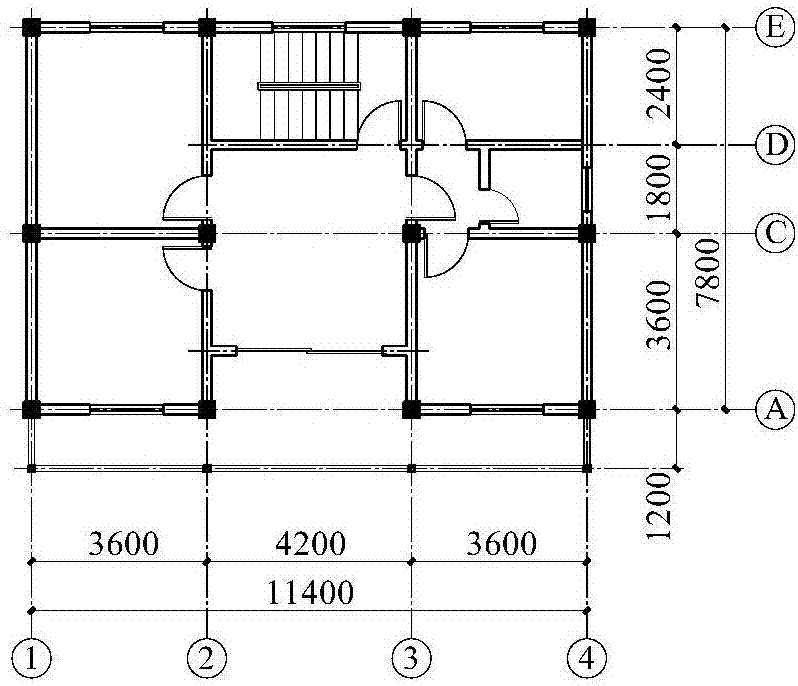

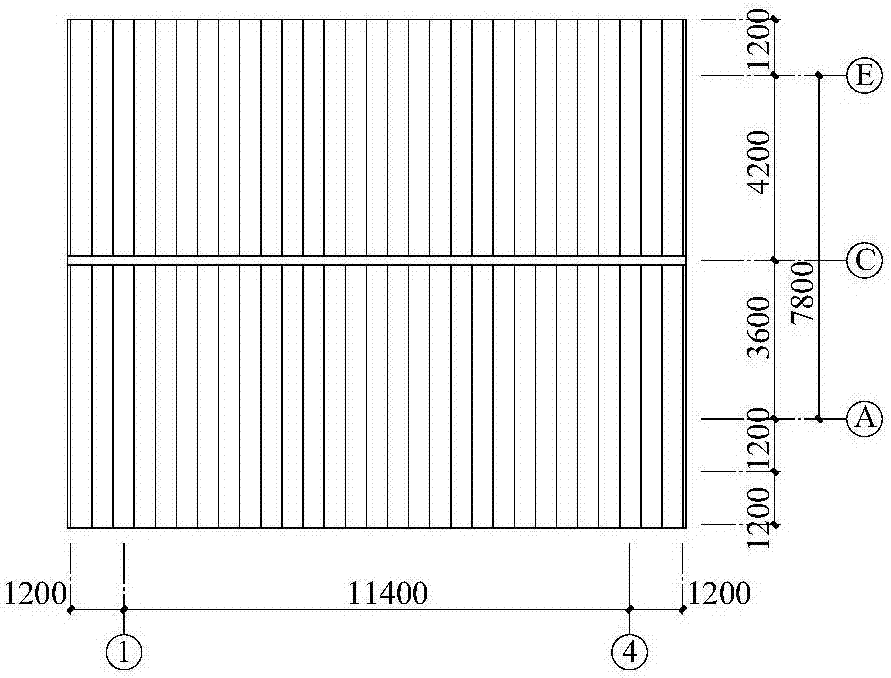

Wood-like building frame structure and manufacturing method thereof

InactiveCN107447865AImprove adaptabilityImprove anti-corrosion performanceWood working apparatusBuilding constructionsPlant fibreArchitectural engineering

The invention belongs to the technical field of building wood structures and discloses a wood-like building frame structure and a manufacturing method of the wood-like building frame structure. The wood-like building frame structure and the manufacturing method are suitable for low-rise residential buildings and public buildings. A structure body of the wood-like building frame structure is composed of frame columns, girders and secondary beams, and the structure components are manufactured in a factory with plant fiber or wood chips as main raw materials; after the structure components are conveyed to a site, the frame columns are fixedly connected with a foundation through shoe sheaths mounted on the foundation; after beam ends are inserted into H-shaped connecting heads of connecting pieces special for joints at frame joints and girder and secondary beam joints, bolt connection is adopted, and the rigid connection of the joints is achieved; and the column tops and the column bottoms are correspondingly connected with upper bearing beams and lower bearing beams through the special connecting pieces by means of on-beam lifting column joints. The wood-like building frame structure and the manufacturing method can be used for flattop buildings or sloping roof buildings and have the beneficial effects that the source of the raw materials is wide, the corrosion-proof performance and fireproof performance are good, the construction speed is high, and the cost is low.

Owner:贵州理工环保新材料研究有限公司

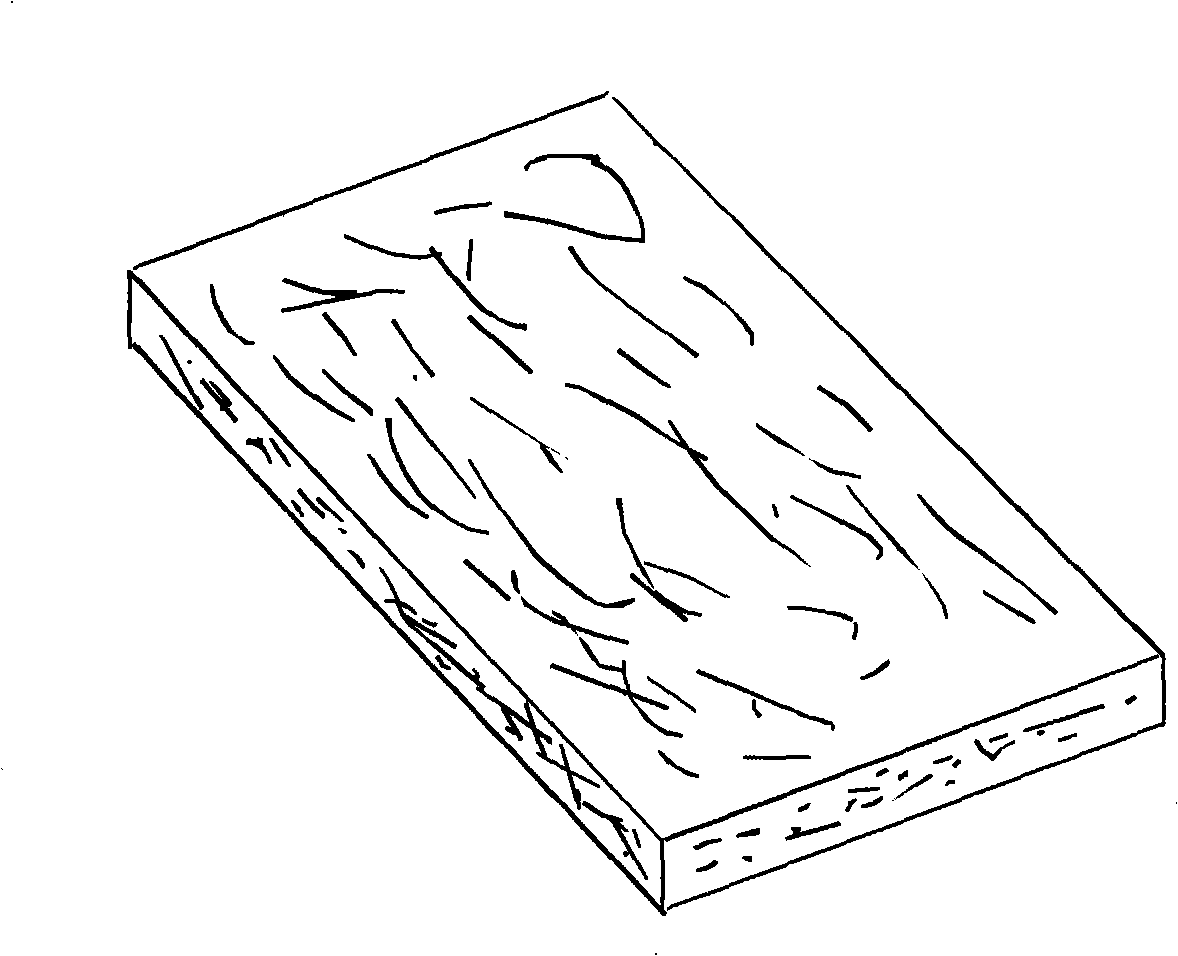

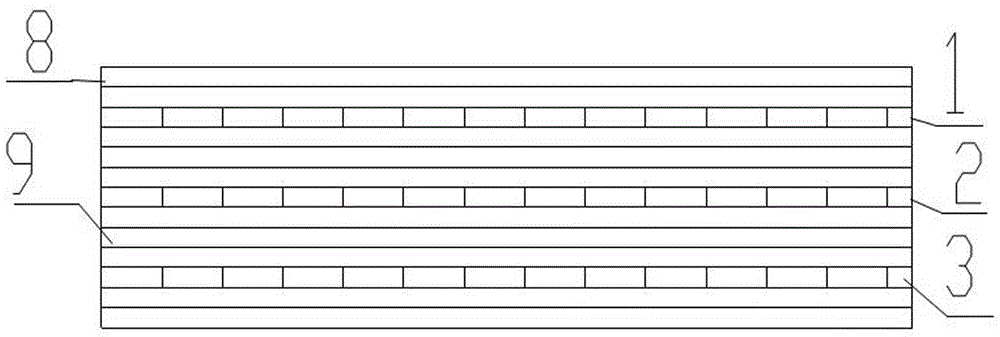

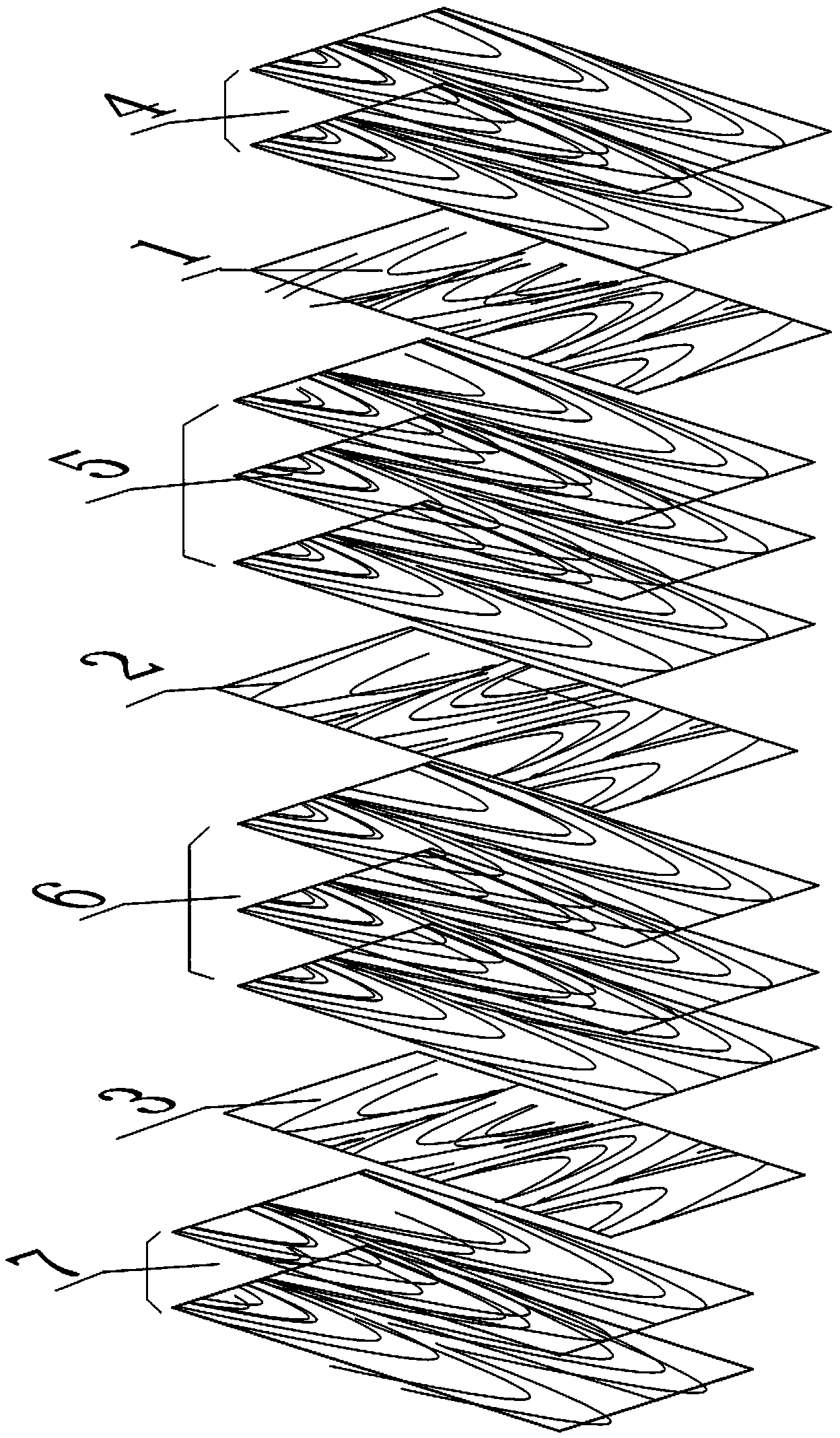

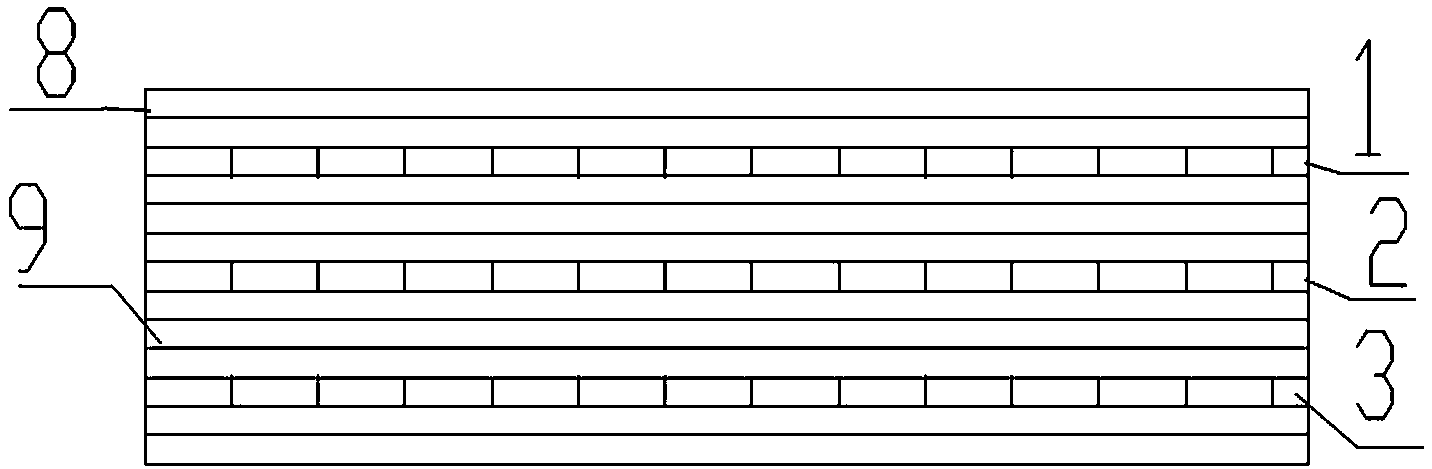

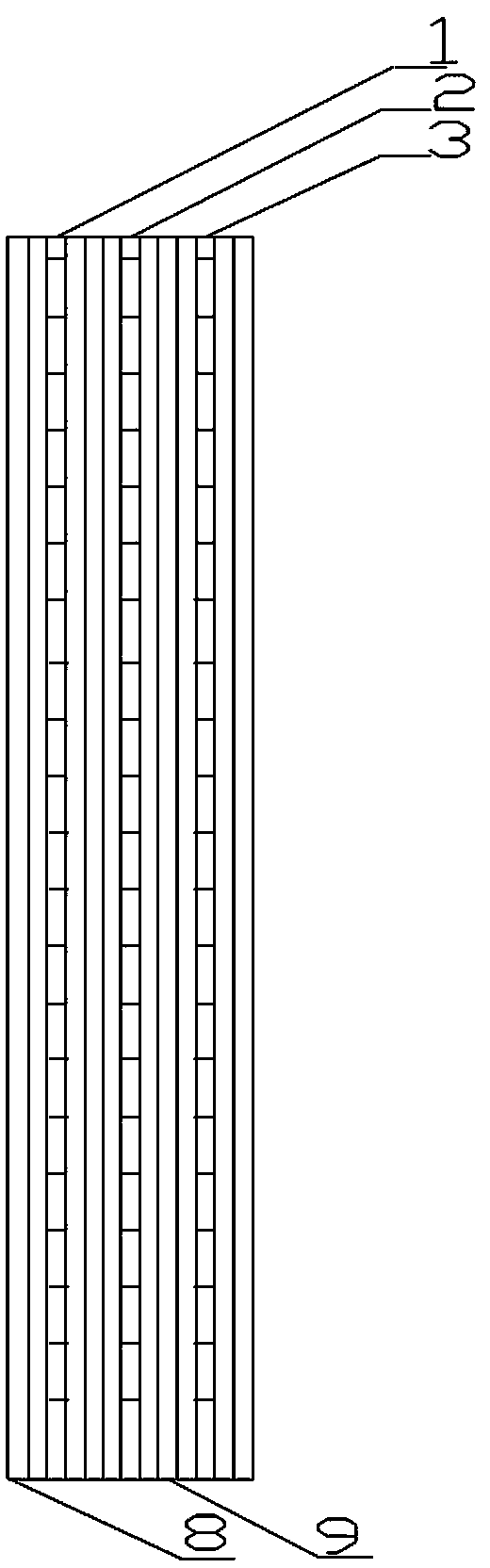

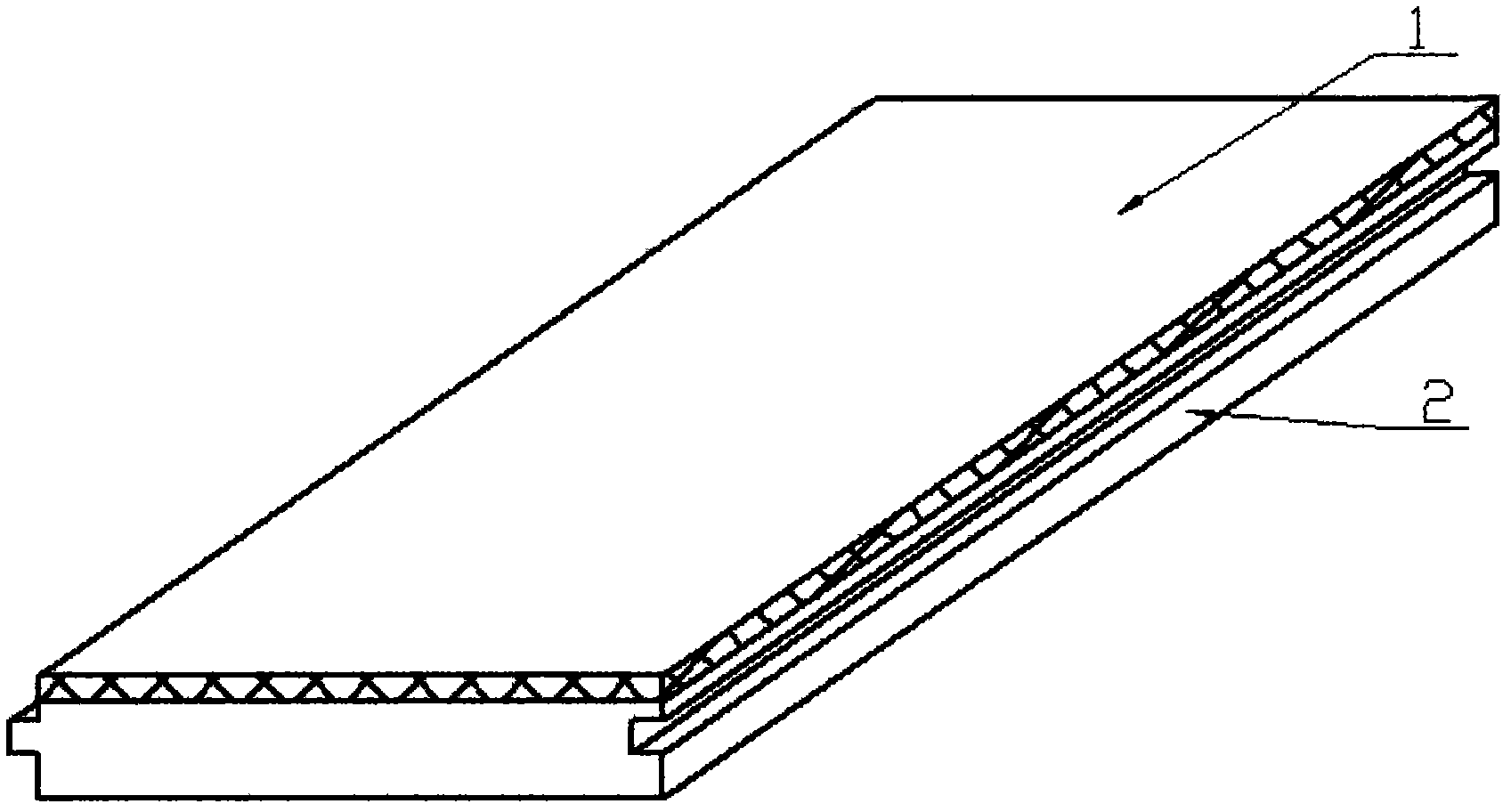

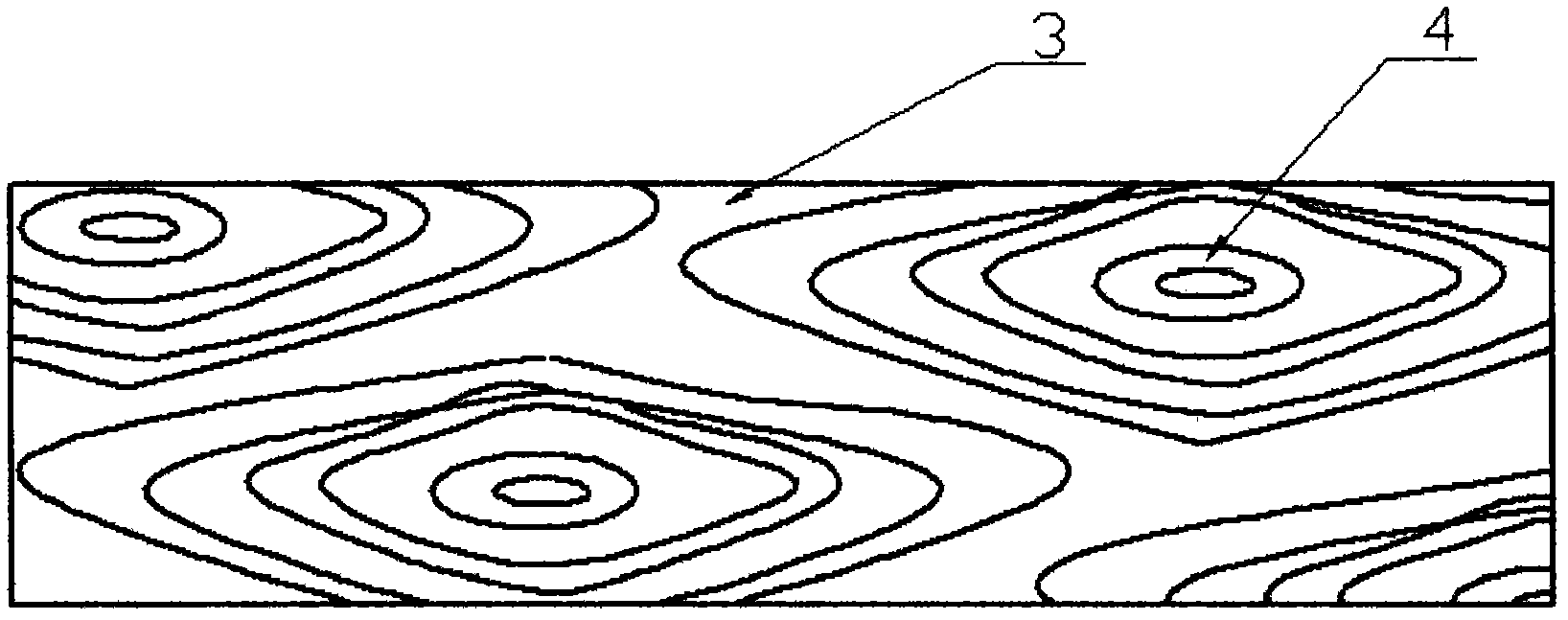

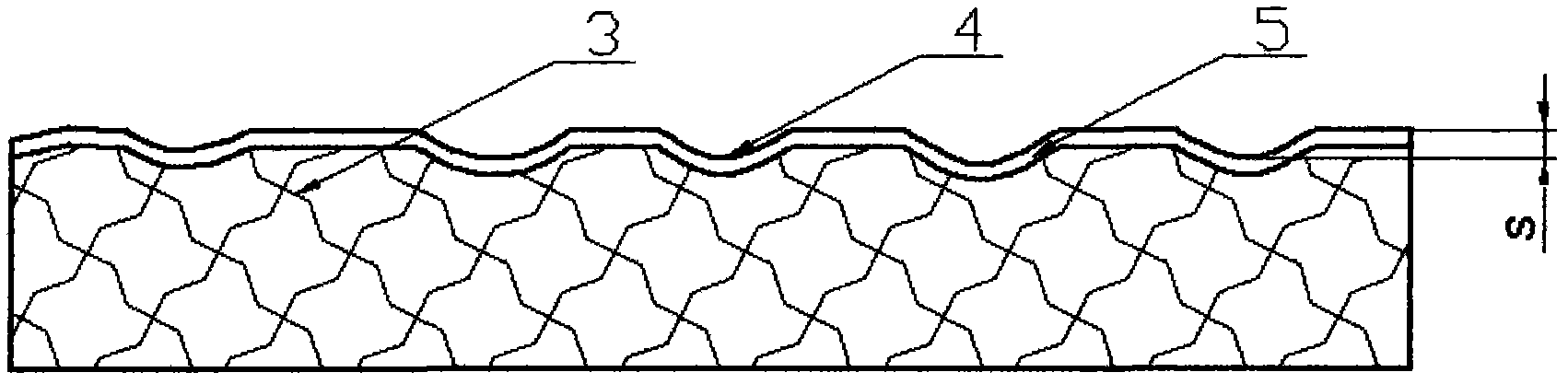

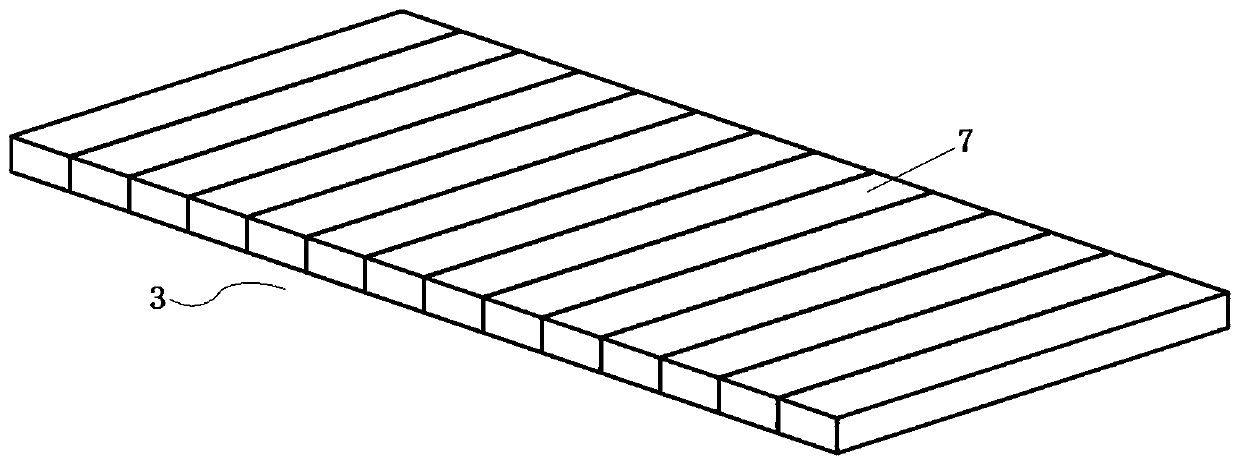

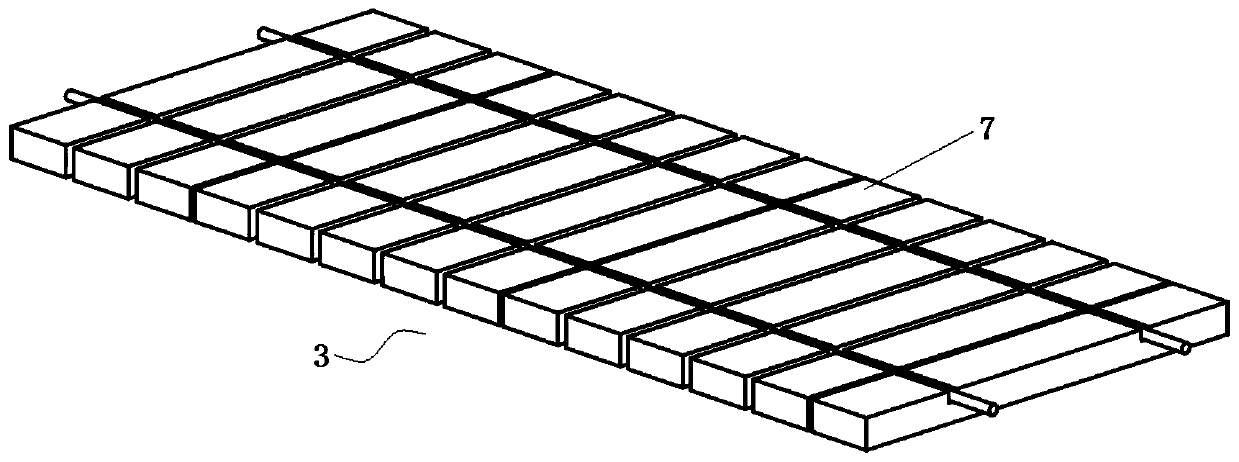

Multi-layer paper-sticking embossing solid-wood antique floor

InactiveCN102852312AImprove toughnessNot easy to crushWood working apparatusFlooringSolid woodEngineering

The invention discloses a multi-layer paper-sticking embossing solid-wood antique floor and relates to the field of floor structure modification. Gumming decorative paper (5) is stuck to the surface of a multi-layer solid-wood composite floor (3) which is made of fast growing wood, the compression is conducted to the decorative paper (5) of the surface of the floor, then the surface of the multi-layer solid-wood composite floor (3) is provided with compressed embossing veins (4), the embossing veins (4) are compressed and formed by a steel roller on which decorative designs are carved through a rolling mode, or the embossing veins (4) are compressed and formed by a steel sheet on which decorative designs are carved through a downward pressure mode. The depths (S) of the compressed decorative designs are in a range from 0.1mm to 1mm. By the aid of the floor, the problem of high cost of an existing multi-layer solid-wood floor is solved.

Owner:梅传龙

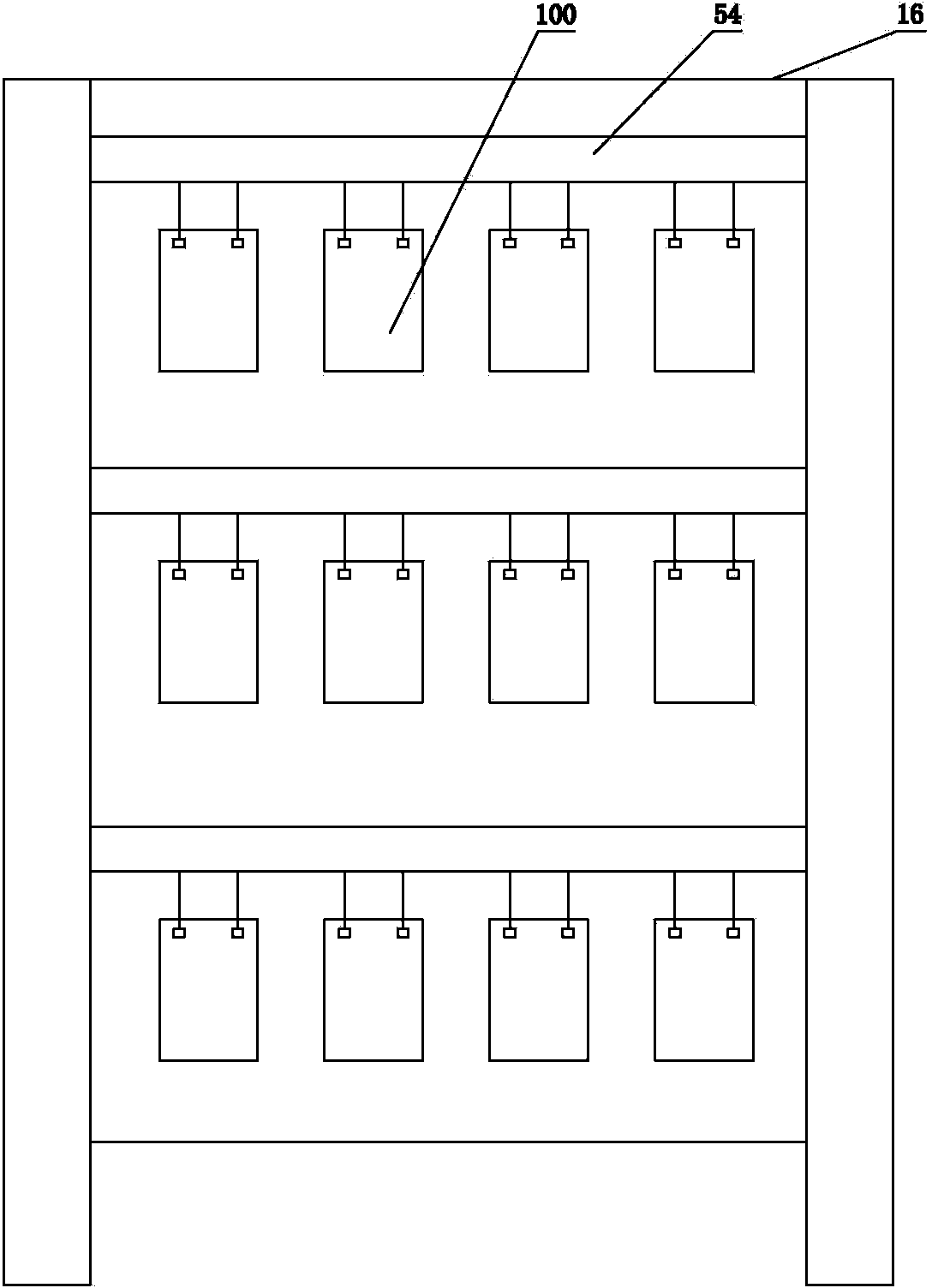

Greenhouse nutritional soil ginseng cultivation method

InactiveCN106258461AQuality improvementIncrease productionCultivating equipmentsPlant cultivationContinuous croppingInsect pest

The invention discloses a greenhouse nutritional soil ginseng cultivation method. The method comprises the following steps of land selection, greenhouse construction and ancillary facility preparation, nutritional soil preparation, seeding or transplanting, moisture management, pest prevention and control and greenhouse temperature and humidity management. Nutritional soil which is prepared from, by volume, 55-65 parts of grass charcoal soil, 25-35 parts of perlite and 10-20 parts of vermiculite serves as a matrix, and ginseng is greenly and rapidly cultivated on a ginseng bed with a specific specification. According to the greenhouse nutritional soilginseng cultivation method, a large number of forestland resources and manpower resources are saved; meanwhile, the time for making ginseng goods is shortened, the yield of ginseng is greatly increased, and the quality of the ginseng is greatly improved. The greenhouse nutritional soil ginseng cultivation method can be popularized on a large scale on non-forestry land, the bottle neck problem that continuous cropping cannot be conducted on forestland and farmland is effectively solved, large-scale and standard cultivation of the ginseng is promoted, temperature, humidity and light environments suitable for ginseng cultivation are artificially created, factors causing ginseng disease and insect pests are reduced, negative influence of frost-melting freezing damage and wide-range temperature fluctuation are eliminated, and the greenhouse nutritional soil ginseng cultivation method is a technical improvement in ginseng cultivation.

Owner:李雄 +1

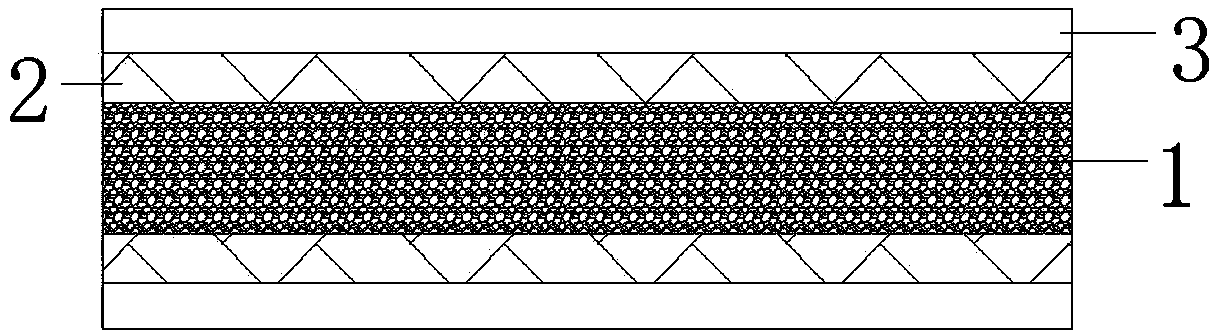

Diatom-needle environment-friendly floor

The invention relates to a diatom-needle environment-friendly floor which is characterized by being prepared from the following raw materials in parts by weight: 10-20 parts of diatomite, 22-28 parts of waste plastics, 45-50 parts of boric sludge waste, 8-12 parts of pine needles and shells in a ratio of 1:1, 0.01-0.2 part of silane coupling agent, 0.06-1.2 parts of dispersing agent, 2.5-5 parts of heat stabilizer and 0.5-1 part of lubricant. The diatom-needle environment-friendly floor is a green and environment-friendly material; low-cost diatomite waste, forestry waste and plastics are adopted instead of wood, and thus the shortage of wood supply in the country due to shortage of forest resources is powerfully relieved; and the diatom-needles environment-friendly floor has the advantages of heat preservation, heat insulation, dehumidification, deodorization, air purification and low cost, and the aims of saving wood and promoting environmental protection can be achieved.

Owner:JILIN FOREST IND GRP JINQIAO FLOORING GRP

High-density environment-friendly regenerated fibre board and production method thereof

Owner:仙桃市宏远纤维科技股份有限公司

Method for planting polyporus by using trimmed walnut forest branche and under-forest space in Yunnan

ActiveCN108967040AIncrease profitReduce decreaseCultivating equipmentsMushroom cultivationEcological environmentPolyporus

The invention discloses a method for planting polyporus by using trimmed walnut forest branch and under-forest space in Yunnan. The method comprises: step one, configuring a halimasch walnut branch cultivation strain matrix; step two, making and cultivating a halimasch walnut branch cultivation strain; step three, selecting a site and establishing a polyporus pool; step four, preparing materials;step five, placing the prepared materials and carrying out field planting of polyporus seeds; and step six, carrying out planting management and harvesting of the polyporus under a walnut forest. Themethod is convenient to operate; the land utilization rate is improved; the new fungus resources are made; the ecological environment is protected; and the healthy development of the polyporus industry is promoted.

Owner:云南省农业科学院生物技术与种质资源研究所 +1

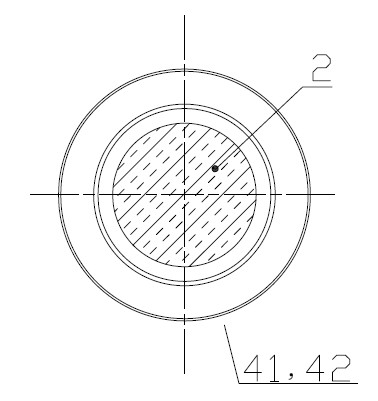

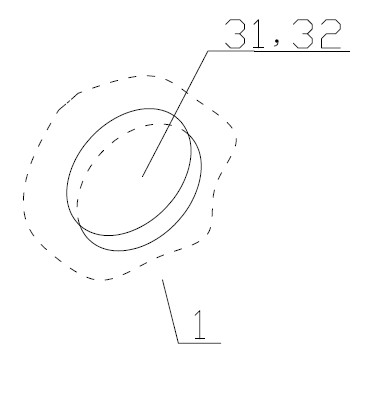

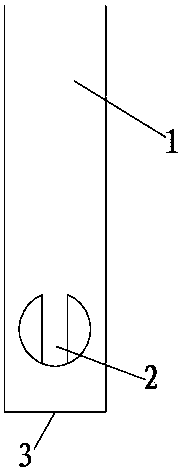

Measuring device for detecting internal defects of wood and processing method thereof

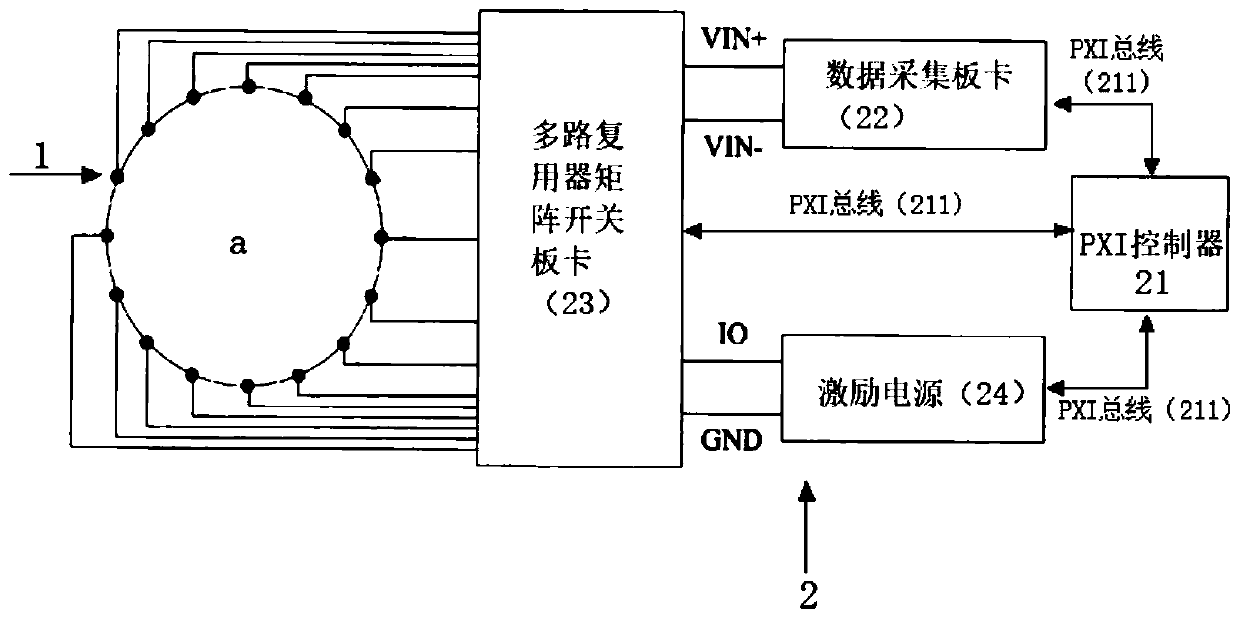

InactiveCN110887870ASimple structureLow costMaterial analysis by electric/magnetic meansMultiplexingMeasurement device

The invention discloses a measuring device for detecting internal defects of wood and a processing method thereof. The measuring device comprises 16 electrode sensors and a data acquisition and processing platform. The 16 electrode sensors are arranged around to-be-detected wood at equal intervals. The data acquisition and processing platform includes a PXI controller, a data acquisition board card, a multiplexer matrix switch board card and an excitation power supply. The 16 electrode sensors are respectively connected with terminals r0 to r15 of the multiplexer matrix switch board card; themultiplexer matrix switch board card is respectively connected with the data acquisition board card and the excitation power supply; and the multiplexer matrix switch board card, the data acquisitionboard card and the excitation power supply are respectively connected to the PXI controller through a PXI bus. According to the measuring device and the processing method thereof, the measuring devicehas a simple structure and the processing method is performed conveniently and rapidly; the measuring result is accurate; the utilization rate of the wood is effectively increased; the forest resources are saved; and the application prospect is broad.

Owner:新沂市超华木业有限公司

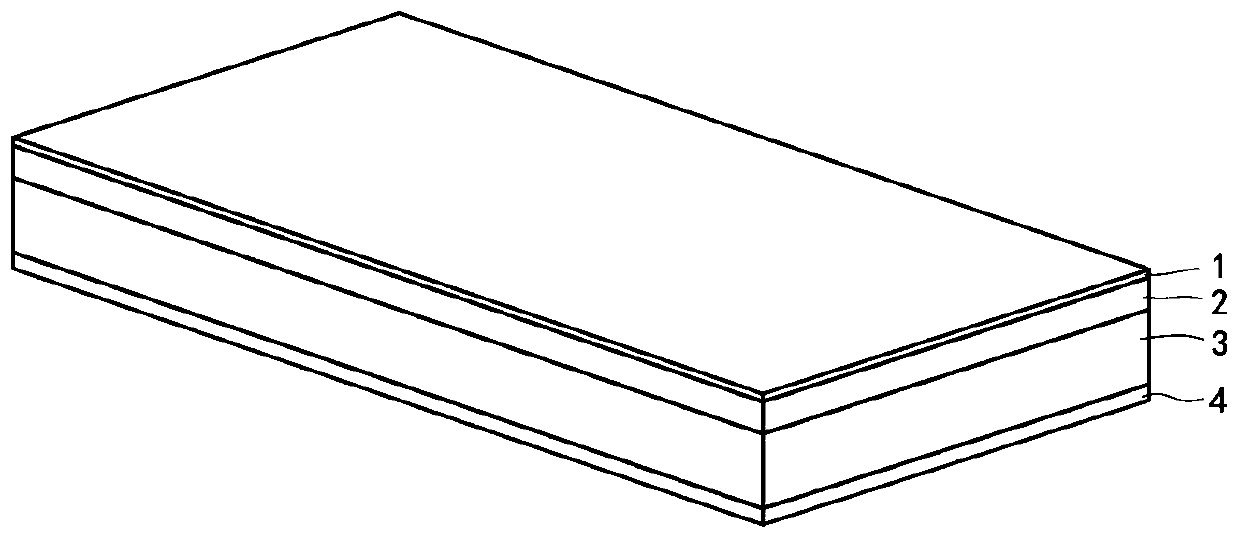

Solid wood composite floor with impregnated paper veneer and production process of solid wood composite floor

InactiveCN111098380AImprove crack resistanceAvoid crackingPaper/cardboard layered productsWood veneer joiningWood veneerSolid wood

The invention discloses a solid wood composite floor with impregnated paper veneer and a production process of the solid wood composite floor. The solid wood composite floor comprises a decorative thin board, a buffer board, a thick core board and a bottom board, wherein the thick core board serves as a core layer and is covered with the buffer board; the buffer board is covered with the decorative thin board; and the bottom board is arranged under the thick core board in a composite manner. Through the addition of a density board, the board surface cracking resistance of the solid wood composite floor can be remarkably improved through the impregnated paper veneer, the solid wood composite floor can be applied to a geothermal environment, and cracks are not easy to appear on the board surface; through the special watering and positioning processes, the problem that after the density board is assembled and hot-pressed with impregnated paper, spots are easy to appear on the board surface and the difficulty in processing a product with synchronous wood grain is high can be solved; and meanwhile, narrow wood slats serve as main raw materials of a substrate and are processed into the thick core substrate in a variety of ways such as splicing or series connection, so that the use of fast growing wood veneer can be reduced, the wood utilization rate can be improved, and forest resources can be saved.

Owner:来安县扬子地板有限公司

Manufacturing method of environment-friendly high-strength anti-deformation aluminum core composite door

InactiveCN104552486AMake up for heavy and easily deformedMake up for crackingLayered product treatmentLaminationInter layerSingle plate

The invention discloses a manufacturing method of an environment-friendly high-strength anti-deformation aluminum core composite door, aiming at the problem that existing plates are uneven in thickness, abnormal in color, overmuch in scab, not environment-friendly and easy to deform. The manufacturing method comprises the steps of rotationally cutting scrap edge environment-friendly wood materials into 2mm-5mm veneers and drying the veneers; gluing an upper-layer panel, a lower-layer panel and a middle-layer panel, pressing the upper-layer panel, the lower-layer panel and the middle-layer panel into a composite plate, sawing the composite plate into plate strips in the same specification, and repeating a gluing process; putting core materials among three layers of transverse-grain balance tension plates, pressing to form multi-layer plates and manufacturing into wide wood strips after conditioning; putting the wide wood strips into an automatic plate splicing machine to form multi-layer plates and sanding into fixed thickness; pressing thin aluminum plates and the multi-layer plates to form an aluminum core composite plate, cutting the aluminum core composite plate into plates with specified shapes, covering wood skin, spraying priming paint, drying, sanding, correcting the color, and spraying finish paint.

Owner:HEILONGJIANG HUAXIN FURNITURE

Method for breeding cerambycidae larvas by utilizing saw dust

The invention discloses a method for breeding cerambycidae larvas by utilizing saw dust, which comprises the following steps of: firstly, adding a soluble nutrient solution into the saw dust to prepare a breeding base stock, and then filling the breeding base stock into a nutrition bag; then perforating on the breeding base stock, and inoculating low-age cerambycidae larvas; secondly, controllingmoisture content of the breeding base stock and a temperature and humidity of air in a breeding environment, and optimizing breeding; and sixteen weeks after inoculating, breaking the breeding base stock open, sorting and gaining the cerambycidae larvas. The soluble nutrient solution comprises raw materials in percentage by mass as follows: 0.1 to 10% of yeast extract, 0.01 to 1% of glucose, 0.01to 1% of decavitamin, 1 to 10% of an adhesive, 0.01 to 0.1% of a preservative and the balance of water. The moisture content of the breeding base stock is 30 to 60%, the relative humidity of the air is 40 to 90%, and the temperature is 20 to 30 DEG C. A problem of environment pollution caused by incinerating and abandoning the saw dust, and cerambycidae breeding is promoted.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

Preparation of high specific surface area and narrow pore distribution porous carbon material

The invention belongs to the preparing field of porous carbon materials, which relates to a porous carbon material with high specific surface area and narrow pore distribution and which is prepared by adopting pin needles with biomass materials. The specific surface area of the porous carbon materials is capable of surpassing 3000m / 2g by adjusting activating agent dosage, activating temperature and activating time. The method of the invention has low requirement for production facilities, and has simple preparing process and low time-consumption. The main byproduct of the reaction is tar which is a product with high value in use. The washing solution of the porous carbon materials is aqueous solution which is rich in potassium ions, and is perfect potash fertilizer for agricultural industry via simple dealing. The porous carbon materials have high application prospect in the fields like the storage and separation of gas, electrode materials, catalysts or catalyst carriers in a plurality of chemical reactions, sewage disposal, recovery of noble metals and the like. The method has the advantages of cheap, plentiful and easily gained raw materials, simple preparing process, preparingcondition without region limitation, thereby being adapted for large-scale industrial production.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com