Aluminum alloy floorslab and manufacturing method thereof

A production method and technology of aluminum alloy, applied in the direction of floor, building, building structure, etc., can solve the problems of unreasonable aluminum alloy floor structure design, low paving efficiency, low floor life, etc., to achieve convenient installation and disassembly, The effect of reducing quality, quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

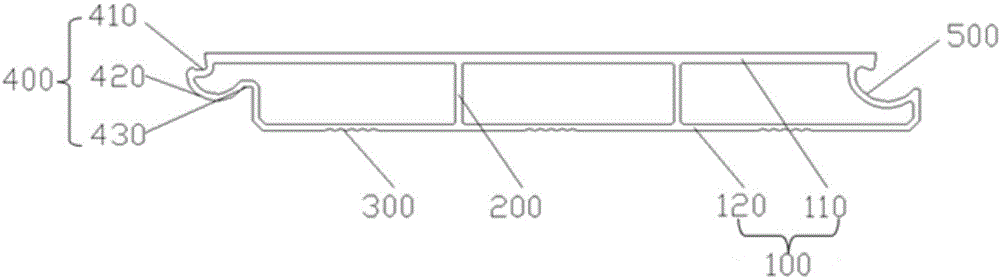

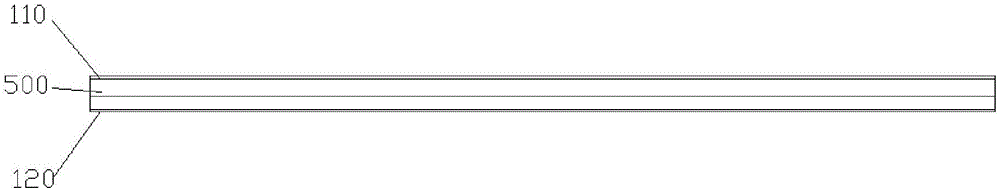

[0045] Please also refer to Figure 1-3 and Figure 5-7 , this embodiment provides an aluminum alloy floor, including a floor main body 100, and protrusions and recesses respectively located on both sides of the floor main body 100. During the process of assembling the floor, the protrusions and recesses of adjacent floors are inserted in sequence, specifically Word:

[0046] The floor main body 100 comprises an upper cover 110 and a lower cover 120 positioned at the lower part of the upper cover 110. The upper cover 110, the lower cover 120, the convex part and the concave part surround a hollow floor cavity, and the floor cavity is provided with connecting The reinforcement 200 of the upper cover 110 and the lower cover 120, the lower cover 120 is provided with a protrusion 300 along the length direction of the lower cover 120 toward the direction close to the upper cover 110, and the lower part of the protrusion 300 is hollow, and the upper cover The plate 110, the lower ...

Embodiment 2

[0057] This embodiment provides a method for manufacturing the aluminum alloy floor in Embodiment 1, comprising the following steps:

[0058] (1) Heat the aluminum alloy rod to 450-550°C to soften the aluminum alloy rod;

[0059] (2) Place the softened aluminum alloy rod into the floor mold of the extruder, and use the extruder to form the aluminum alloy floor at one time;

[0060] (3) Leave the formed aluminum alloy floor at a temperature of 150-250° C. to harden the aluminum alloy floor;

[0061] (4) cooling the hardened aluminum alloy floor to room temperature;

[0062] (5) Heating the resin to 150-250°C, spraying the aluminum alloy floor, so that the resin melts on the surface of the aluminum alloy floor;

[0063] (6) the aluminum alloy floor after spraying is cooled to room temperature;

[0064] (7) Transferring the wood pattern to the surface of the aluminum alloy floor in an environment of 150-250°C.

[0065] In a specific embodiment, in step (1), the aluminum alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com