Wood-like building frame structure and manufacturing method thereof

A frame structure, wood-like technology, applied in building structure, construction, flat products, etc., can solve the problems of weak joint connection, no mention of column lengthening measures, beam simply supported force, etc., and achieve construction speed. Fast, improve anti-corrosion performance, improve the effect of fire resistance limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

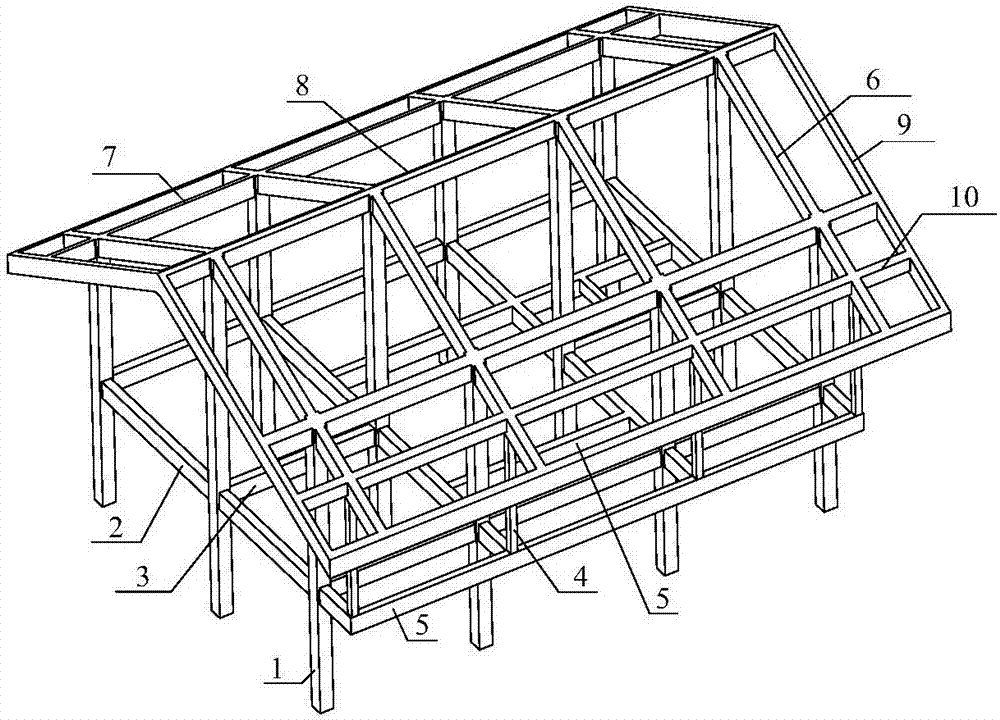

[0040] Specific examples: such as figure 1 The manufacture of a kind of wooden building frame structure shown is carried out according to the following steps:

[0041] (1) Using plant fiber or sawdust as the main raw material, all structural components are produced in the factory according to the design drawings.

[0042] (2) see Figure 8 , first set up the foundation embedded part 13 on the foundation, and leave the foundation anchor bolt 14; after installing the column foot shoe cover 11 of the frame column 1 in place, tighten the nut of the anchor bolt 14; then install the column of the frame column 1 The pin is inserted in the boot cover 11, and the connecting bolts 12 are horizontally tightened from the side, so that the installation of all the frame columns at the bottom of the structure is completed.

[0043] (3) see Figure 9 ~ Figure 10 , the node cylindrical connector 15 is inserted into the top of the frame column at the bottom layer, and the bolt 12 is horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com