High-performance PS and PP alloy novel synthetic paper material

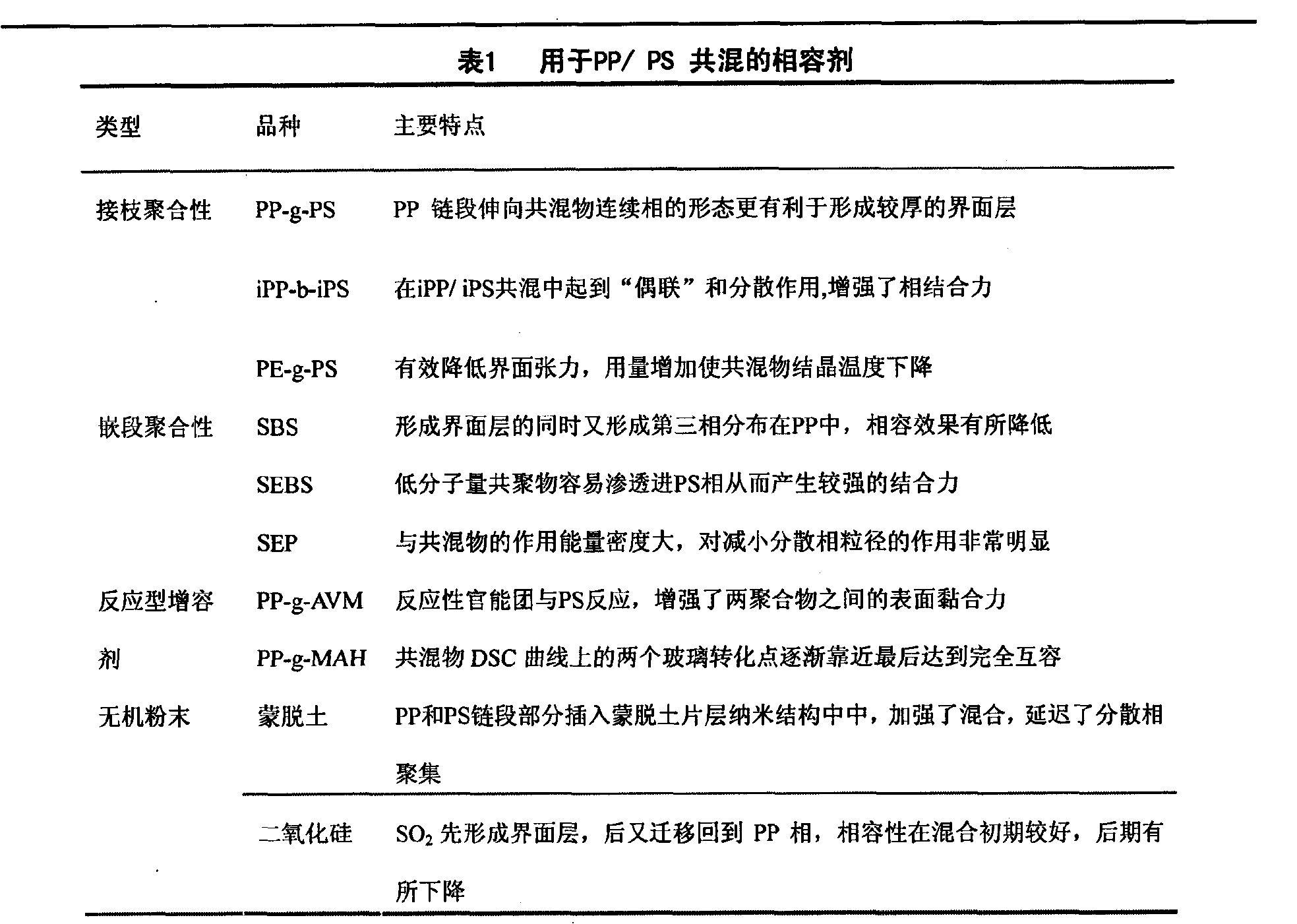

A technology of alloy materials and synthetic paper, which is applied in the field of new PS/PP synthetic paper materials, can solve the problems of low stiffness, water absorption, poor permeability, poor heat resistance and durability, etc., to reduce surface energy, improve compatibility, Effect of increasing surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

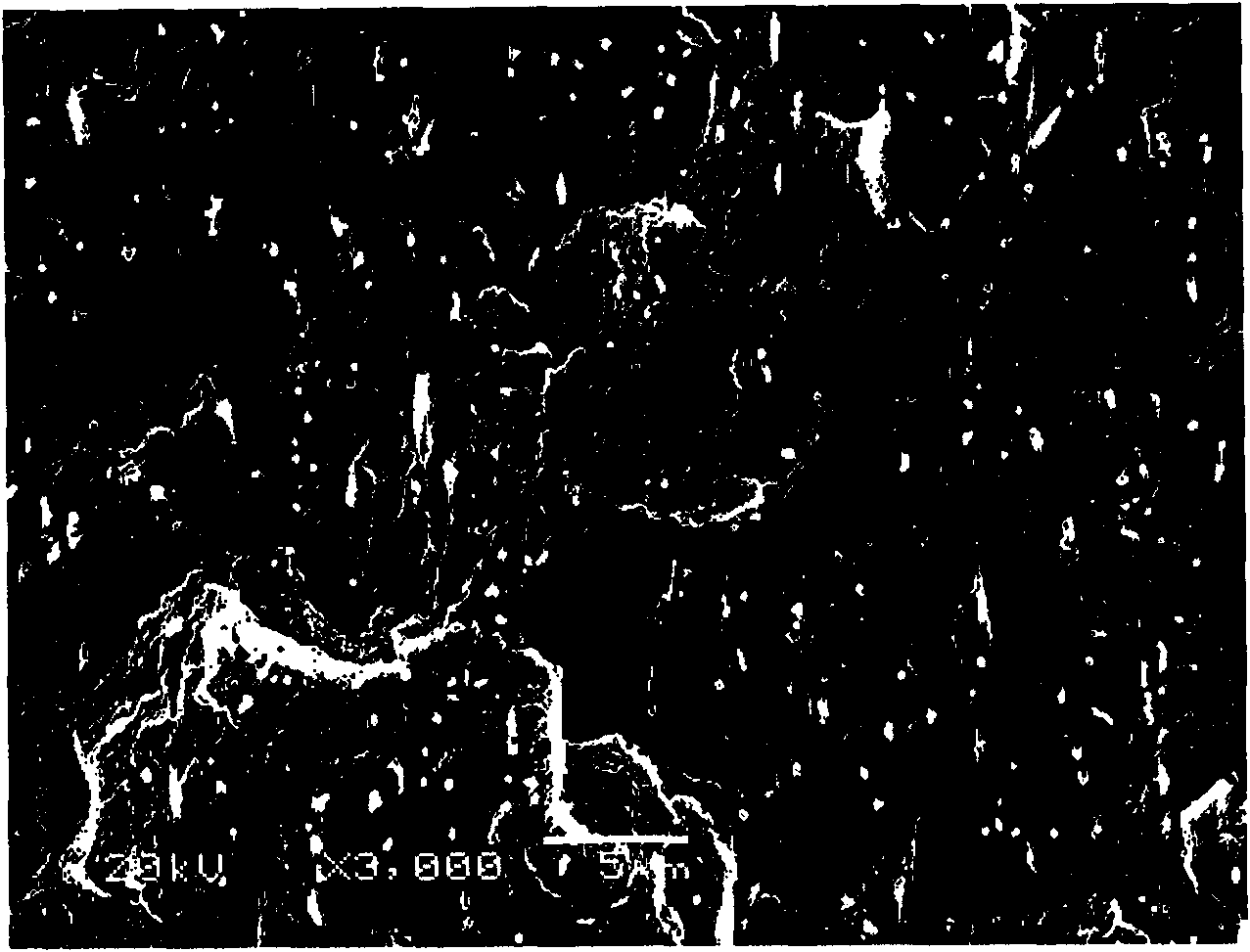

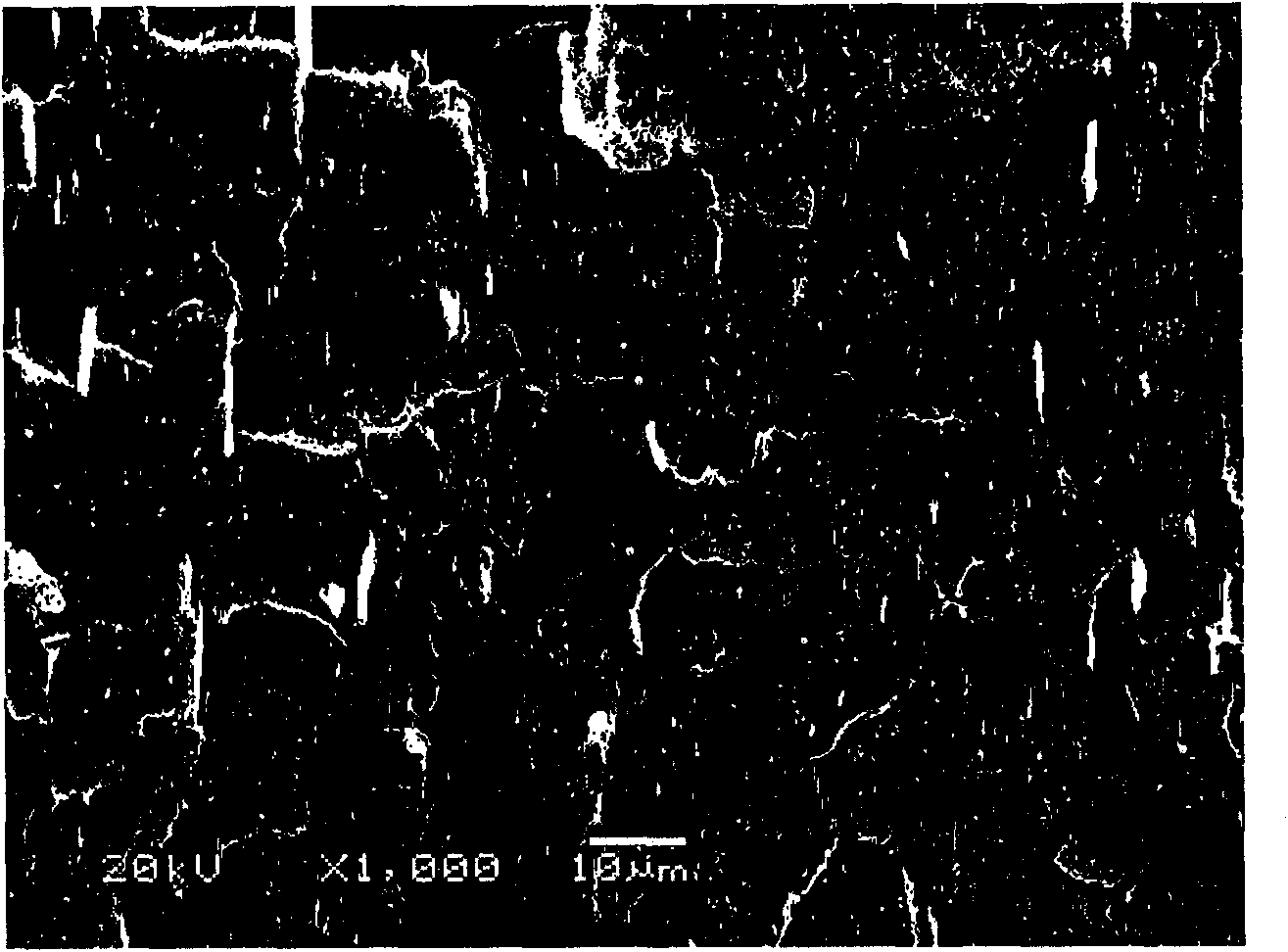

Method used

Image

Examples

Embodiment 1

[0027] 15% HIPS, 48% GPPS, 15% PP, 12% compatibilizer, 10% inorganic powder (treated with coupling agent in advance) by weight percentage, and by their total weight Put 0.5% antioxidant into a high-speed mixer with a rotation speed of about 1000rpm and mix for 3 minutes, and then put it into a twin-screw extruder. The temperature is controlled at: 200°C-215°C, and the screw speed is 450 rpm. Get it by extruding and granulating.

Embodiment 2

[0029] 20% HIPS, 43% GPPS, 22% PP, 5% compatibilizer, 10% inorganic powder (treated with coupling agent in advance) by weight percentage, and 0.5% by weight % of the antioxidant is put into a high-speed mixer with a rotation speed of about 1000rpm and mixed for 3 minutes, and then put into a twin-screw extruder, and extruded at a processing temperature of 200-215°C and a screw speed of 450 rpm. Grains are ready.

Embodiment 3

[0031]28% HIPS, 30% GPPS, 27% PP, 5% compatibilizer, 10% inorganic powder (treated with coupling agent in advance) by weight percentage, and 0.5% by weight % of the antioxidant is put into a high-speed mixer with a rotation speed of about 1000rpm and mixed for 3 minutes, and then put into a twin-screw extruder, and extruded at a processing temperature of 200-215°C and a screw speed of 450 rpm. Grains are ready.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com