Processing technology of labeling-free blister product, and mold used for the same

A processing technology and product technology, applied in the processing technology of label-free blister products and the field of molds used, can solve the problems of high product cost, consumption of forest resources, and large production site area, so as to reduce processing costs and save forests resources, to avoid the effect of pattern deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The processing process of the bowl 41 is based on the following steps:

[0030] ① feed

[0031] Plastic sheet;

[0032] ② pattern printing

[0033] The pattern is attached to the surface of the plastic sheet through the UV printing method;

[0034] ③ tailoring process

[0035] Using traditional tailoring equipment, cutting the entire piece of patterned sheet into the size of the round sheet required by the finished product;

[0036] ④ Breeding molding

[0037] Using mold 1, under the planting temperature, it will be processed with a plastic round sheet with a pattern, that is, the bowl lid 41.

[0038] During the processing of plastics, the surface area will increase due to heating, and the thickness will become smaller. In order to prevent the forming patterns from being heated and deformed, the work of the work of the printed pattern is used to suck the water cooling while the printed pattern is used.

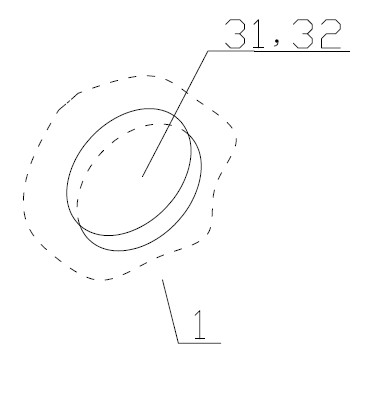

[0039] The mold used in this process 1 is like image 3 It shows that ...

Embodiment 2

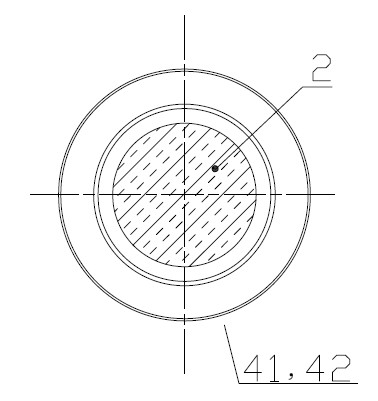

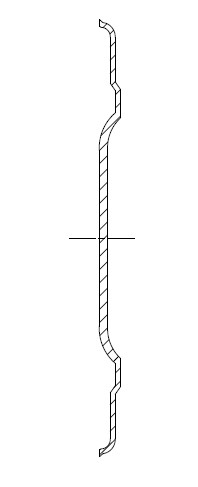

[0043] The structural reference of the cup lid 42 figure 1 and figure 2 , Its processing process is based on the following steps:

[0044] ① feed

[0045] Plastic sheet;

[0046] ② pattern printing

[0047] Through water printing methods, the pattern is attached to the surface of the plastic sheet;

[0048] ③ tailoring process

[0049] Use traditional tailoring equipment to cut the entire piece of pattern printed with patterns into the actual circular chip required by the finished product;

[0050] ④ Breeding molding

[0051] Using mold 1, under the absorbing temperature, a round piece of the pattern will be made into a cup lid 42 with a pattern.

[0052] During the processing of plastics, the surface area will increase due to heating, and the thickness will become smaller. In order to prevent the forming patterns from being heated and deformed, the work of the work of the printed pattern is used to suck the plastic.

[0053] On the mold 1 used in this process, there is a wind -co...

Embodiment 3

[0057] The processing process of its processing is the same as the embodiment 1. The difference is that the mold used to turn the water -cooled and cooling cavity or the air -cooled cavity, and it includes multiple cold cavity settings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com