Synthetic method of α-amino acid derivatives substituted by α-alkyl branched chain

A synthesis method and amino acid technology are applied in the field of synthesis of α-amino acid derivatives, which can solve the problems of few optional species, high difficulty in preparing reagents, harsh storage conditions, etc., and achieve simple and feasible operation process, non-toxic raw materials, and method. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

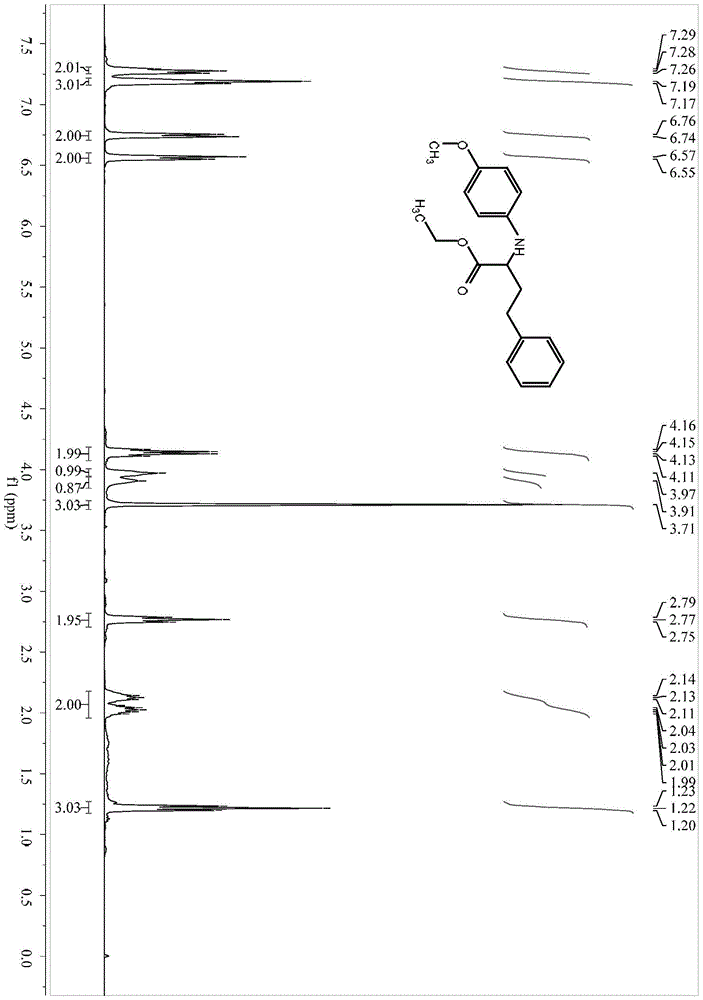

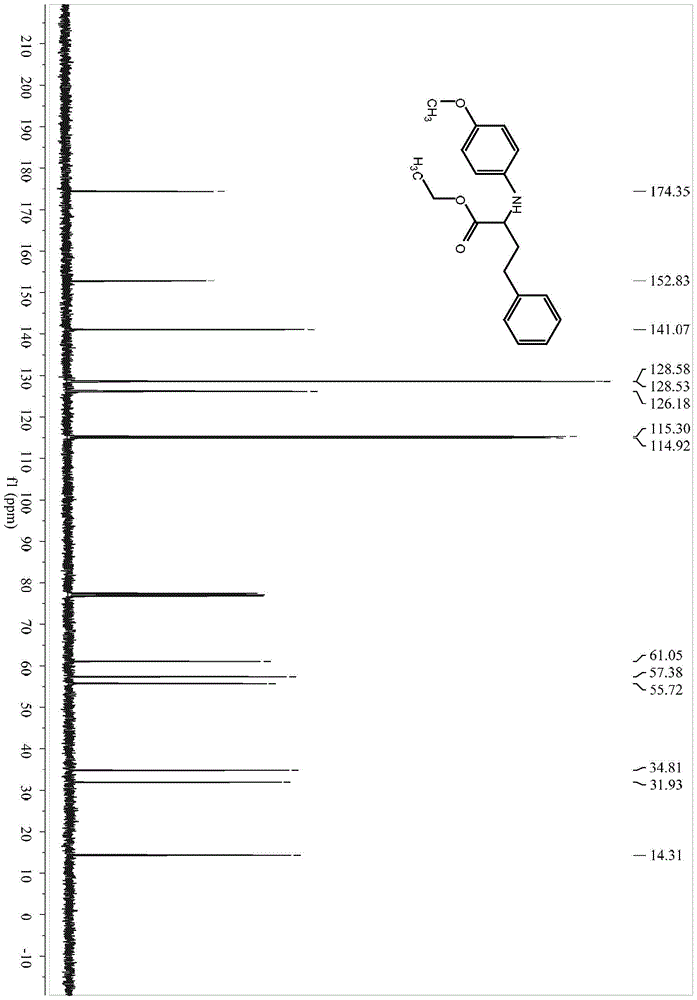

[0038] A synthetic method for α-amino acid derivatives, comprising the following steps:

[0039] (1) In a sealed tube, add p-methoxyaniline (12.3mg, 0.1mmol), ethyl glyoxylate (10.2mg, 0.1mmol), anhydrous sodium sulfate (71mg, 0.5mmol), dichloromethane ( 2 mL), the mixture was stirred at room temperature for 0.5 h. Then the sodium sulfate was removed by filtration, the filter residue was washed with dichloromethane, and the solvent was spin-dried with dichloromethane to obtain 0.1 mmol of imine.

[0040]

[0041] (2) Add styrene (15.1mg, 0.15mmol), 9-bbn (0.3mL, 0.15mmol, 9-bbn is 0.5mol / L THF solution) and anhydrous toluene in a sealed tube that has been evacuated and filled with nitrogen. 1 mL, the mixture was stirred and reacted at 60°C for 1 h, then stopped heating and cooled to room temperature. Then cesium carbonate (5mg, 0.015mmol), cuprous cyanide (0.9mg, 0.01mmol) and the imine of step (1) were added successively, sealed and reacted at 70°C for 24h. After the re...

Embodiment 2

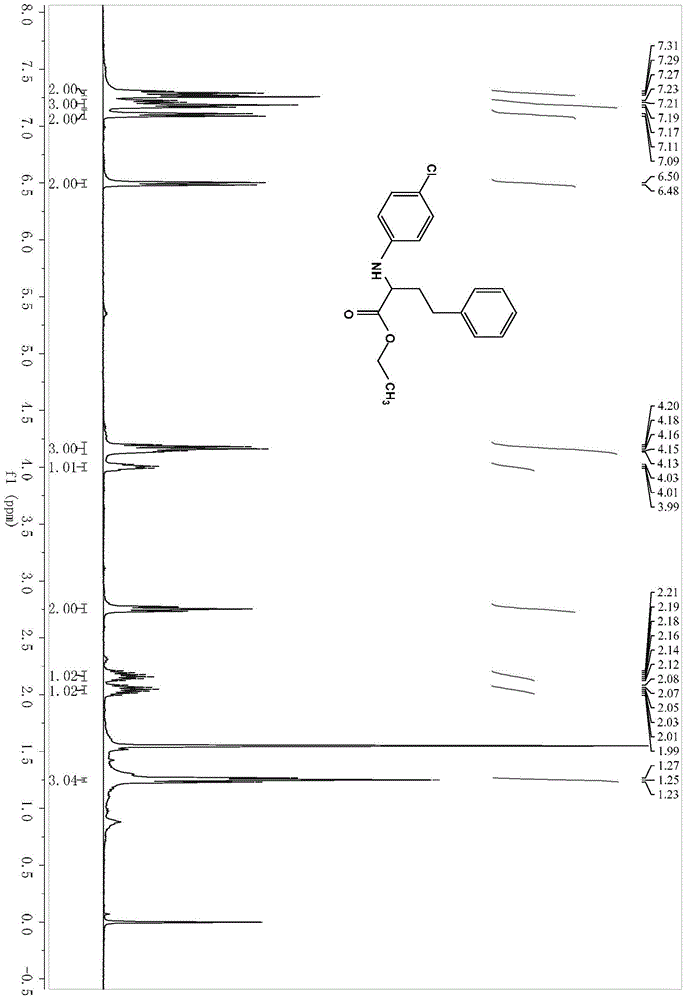

[0049] A synthetic method for α-amino acid derivatives, comprising the following steps:

[0050] (1) In a sealed tube, add p-chloroaniline (12.7mg, 0.1mmol), ethyl glyoxylate (10.2mg, 0.1mmol), anhydrous sodium sulfate (71mg, 0.5mmol), dichloromethane (2mL) , The mixture was stirred and reacted at room temperature for 0.5h. Then the sodium sulfate was removed by filtration, the filter residue was washed with dichloromethane, and the solvent was spin-dried with dichloromethane to obtain 0.1 mmol of imine.

[0051]

[0052] (2) Add styrene (15.1mg, 0.15mmol), 9-bbn (0.3mL, 0.15mmol, 9-bbn is 0.5mol / L THF solution) and anhydrous toluene in a sealed tube that has been evacuated and filled with nitrogen. 1 mL, the mixture was stirred at 0°C for 1 h, then stopped heating and cooled to room temperature. Then sodium carbonate (1.6mg, 0.015mmol), cuprous iodide (1.9mg, 0.01mmol) and the imine of step (1) were added sequentially, sealed and reacted at 90°C for 24h. After the react...

Embodiment 3

[0060] A synthetic method for α-amino acid derivatives, comprising the following steps:

[0061] (1) In a sealed tube, add p-methoxyaniline (12.3mg, 0.1mmol), ethyl glyoxylate (10.2mg, 0.1mmol), anhydrous sodium sulfate (71mg, 0.5mmol), dichloromethane ( 2 mL), the mixture was stirred at room temperature for 0.5 h. Then the sodium sulfate was removed by filtration, the filter residue was washed with dichloromethane, and the solvent was spin-dried with dichloromethane to obtain 0.1 mmol of imine.

[0062]

[0063] (2) Add p-bromostyrene (27mg, 0.15mmol), 9-bbn (0.3mL, 0.15mmol, 0.5mol / L THF solution of 9-bbn) in a sealed tube that has been evacuated and filled with nitrogen, anhydrous Toluene 1mL, the mixture was stirred and reacted at 80°C for 1h, then the heating was stopped and cooled to room temperature. Then sequentially add NaO t Bu (1.5mg, 0.015mmol), palladium acetate (2.4mg, 0.01mmol), the imine of step (1), sealed and reacted at 0°C for 24h. After the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com