Solid wood composite floor with impregnated paper veneer and production process of solid wood composite floor

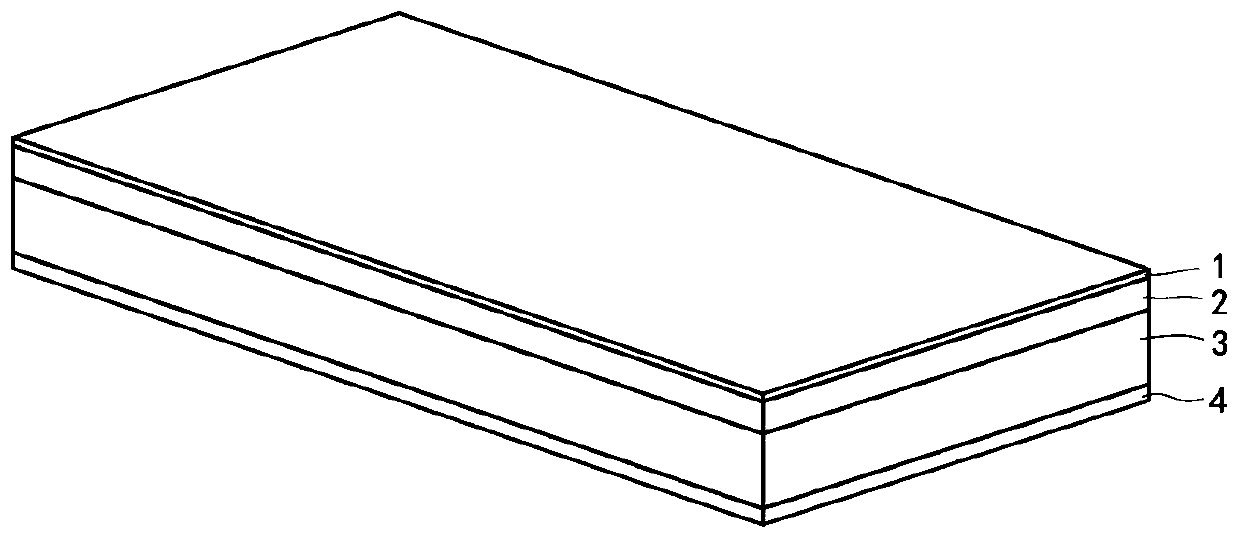

A technology of solid wood composite flooring and production technology, which is applied in the direction of paper/cardboard layered products, wood processing equipment, and wooden veneer joints, which can solve the problem of poor crack resistance of the board surface, reduced wood utilization, The number of layers is too many to achieve the effect of improving crack resistance, improving wood utilization, and saving forest resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare the buffer board 2 as a single-layer veneer, choose eucalyptus and poplar species, the thickness is 4.0mm, the moisture content is 8%, and the direction of wood fiber is consistent with the length direction of the product.

[0038] Real-time example two

[0039] Prepare the buffer board 2 as plywood, choose eucalyptus and poplar species for the upper and lower veneers, the thickness is 2.0mm, the moisture content is 10%, the direction of wood fiber is consistent with the length direction of the product, and the middle veneer is selected for beech and birch species, and the thickness is 2.0mm. 1.0mm, moisture content 7%, wood fiber direction consistent with the product width direction, making plywood: Put the upper and lower veneers into the glue coating machine in turn, apply hot pressing glue on one side, the glue amount is 190g / m2, and coat After gluing the upper and lower veneers and the middle veneer into blanks, put them into a press, and hot press them at ...

Embodiment 3

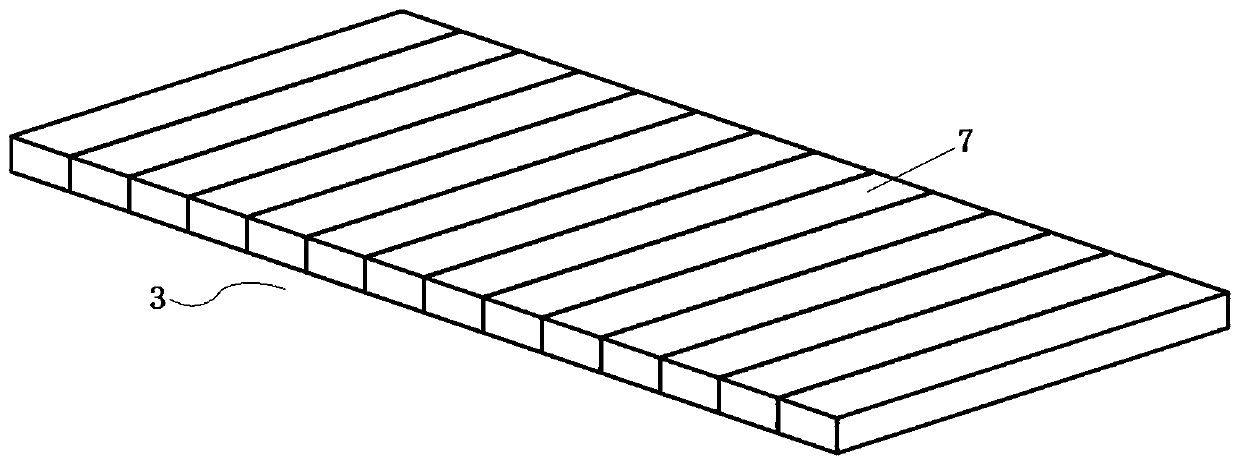

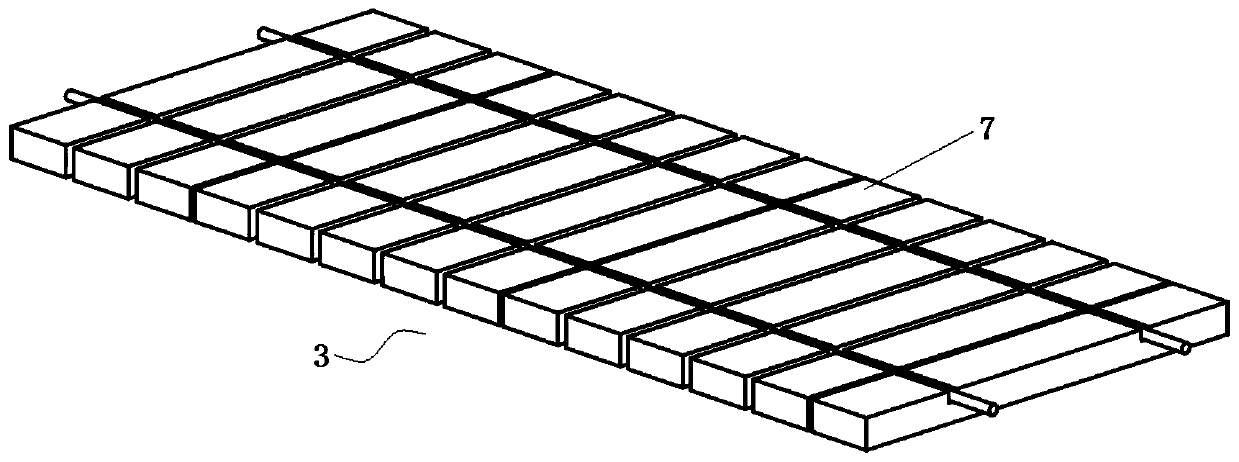

[0041] The veneer sheet 1 is made as a plane type, and the impregnated paper 5 and the density board 6 blanks are put into a press, pressed and solidified under the conditions of a pressure of 1.0MPa, a hot pressing time of 70s, and a hot pressing temperature of 160°C to obtain Flat veneer sheet 1, then take the sheet out of the press and quickly apply pressure with a heavy object to reduce curl.

Embodiment 4

[0043] The decorative veneer 1 is made of synchronous wood grain. Align the impregnated paper 5 with the specific side of the density board 6 to form a blank. When putting it into the press, ensure that the specific side of the density board 6 is aligned with the mark on the steel plate of the press. The mark ensures that the impregnated The wood grain of paper 5 is aligned with the texture of the steel plate on the press, and before being combined with the impregnated paper 5, sprinkle water evenly on the surface of the density board 6. When forming the blanks, put them into the press at a pressure of 3.0MPa and a hot-pressing temperature of 200°C Under certain conditions, it is pressed and solidified in two times, and the hot pressing time is 100s each time to obtain a synchronous wood-grain veneer veneer. Then the veneer is taken out of the press and quickly pressed with a heavy object to reduce curling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com