Composite wood made of rice straw polymer and its producing process

A technology of high polymer and straw, which is applied in the direction of wood processing equipment, hollow objects, flat products, etc., can solve problems such as environmental pollution, traffic accidents, air flights grounded, and comprehensive utilization rate less than 10%, so as to reduce environmental pollution, The effect of saving forest resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Make the first kind of straw high polymer composite wood,

[0024] 1. Prepare the following materials in proportions by weight:

[0026] Thermoplastic Polymer 30

[0027] Inorganic filler 10

[0028] Elastomer 5

[0029] Graft Copolymer 3

[0030] Reinforced Long Fiber 8

[0031] Auxiliary 3

[0032] 2. Its preparation method comprises the following steps:

[0033] 1) Prepare materials, prepare all the components required for the formula; initially mix the prepared components;

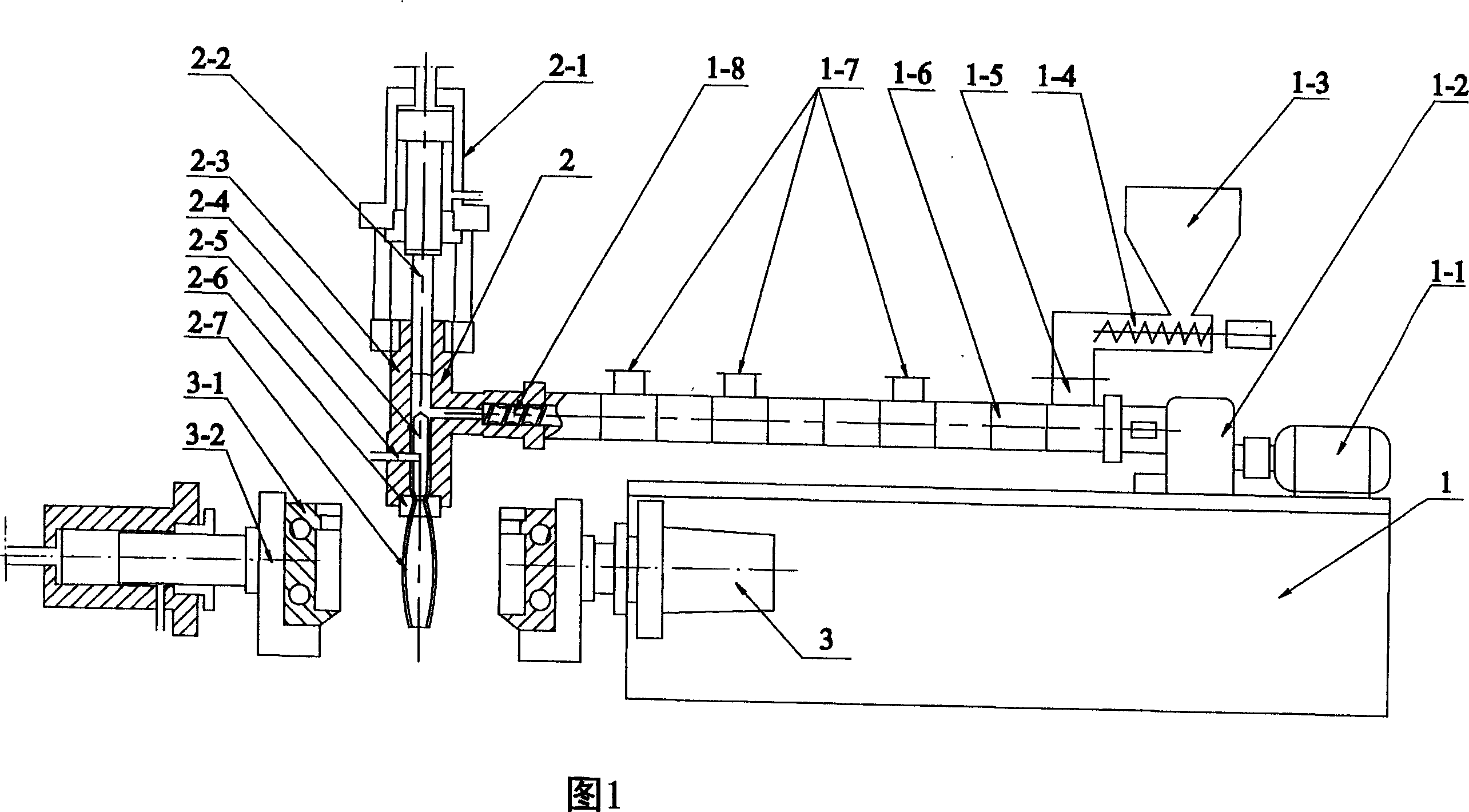

[0034] 2) kneading and molding, each component that is initially mixed is kneaded, exhausted and plasticized in a twin-screw high-speed mixing extruder 1, and is granulated or pressurized and extruded through a hole die; as shown in Figure 1, The material is fed from the hopper 1-3, and sent to the barrel 1-6 through the feeding device 1-4 and the barrel mouth 1-5; the barrel 1-6 has a twin screw 1-8, and the twin screw 1-8 is composed of The driving...

Embodiment 2

[0039] Embodiment 2 Make the 2nd kind of straw high polymer composite wood,

[0040] 1. Prepare the following materials in proportions by weight:

[0042] Thermoplastic Polymer 40

[0043] Inorganic filler 15

[0044] Elastomer 8

[0045] graft copolymer 5

[0046] Reinforced Long Fiber 10

[0047] Auxiliary 2

[0048] 2, its preparation method is identical with embodiment 1.

Embodiment 3

[0049] Embodiment 3 Make the 3rd kind of straw high polymer composite wood,

[0050] 1. Prepare the following materials in proportions by weight:

[0051] Straw Fiber 45

[0052] thermoplastic polymer 15

[0053] Inorganic filler 5

[0054] Elastomer 2

[0055] Graft Copolymer 2

[0056] Reinforced long fiber 6

[0057] Auxiliary 2

[0058] 2, its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com