High-density environment-friendly regenerated fibre board and production method thereof

A regenerated fiber and high-density technology, which is applied in the direction of fiberboard, chemical instruments and methods, paper/cardboard layered products, etc., can solve the problems of low utilization rate, damage to the environment, and high price, and achieve good water resistance, large market capacity, and bright color effect

Active Publication Date: 2014-12-17

仙桃市宏远纤维科技股份有限公司

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The invention provides a low-cost, pollution-free, high-density environmentally friendly regenerated fiberboard and a manufacturing metho

Method used

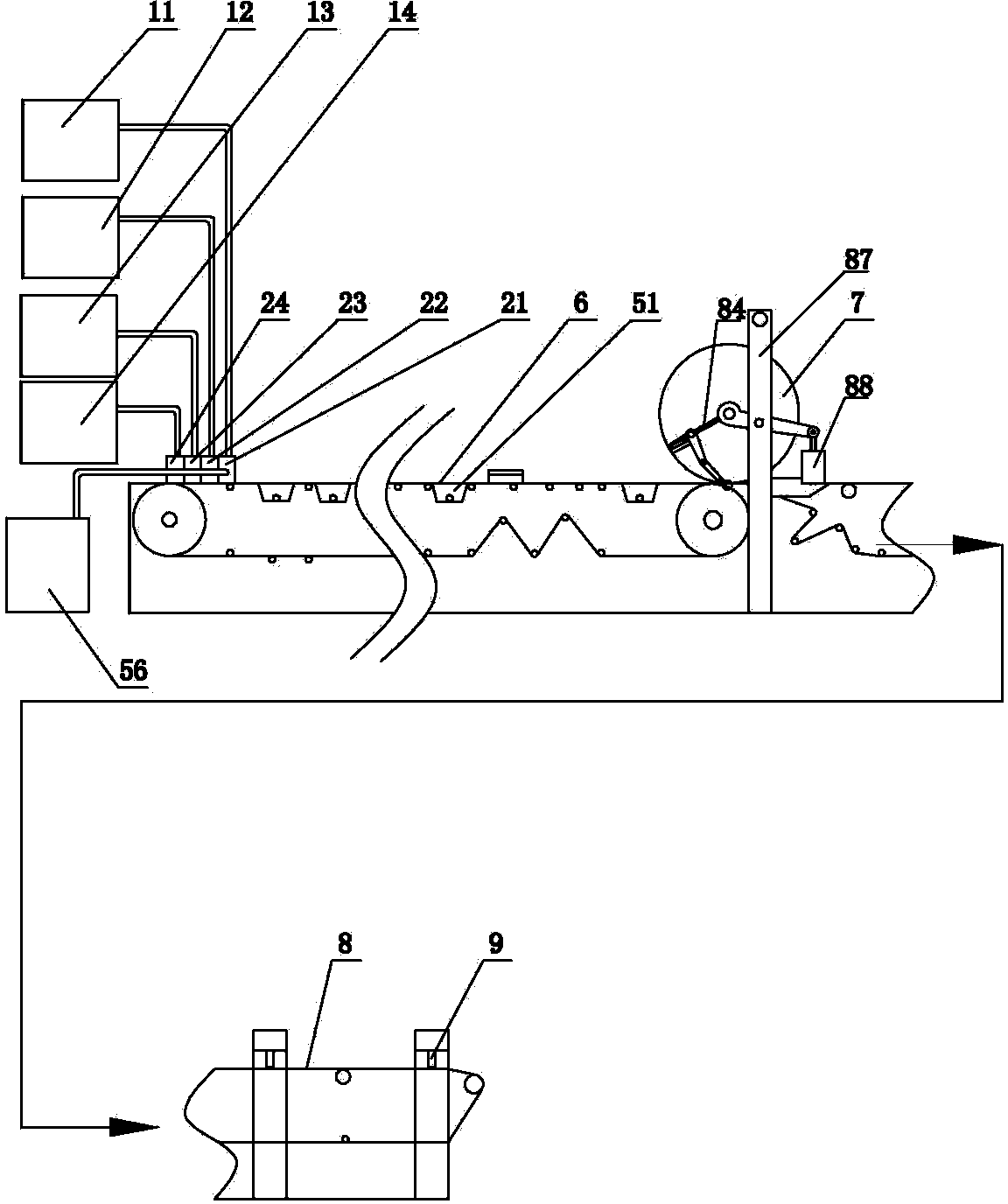

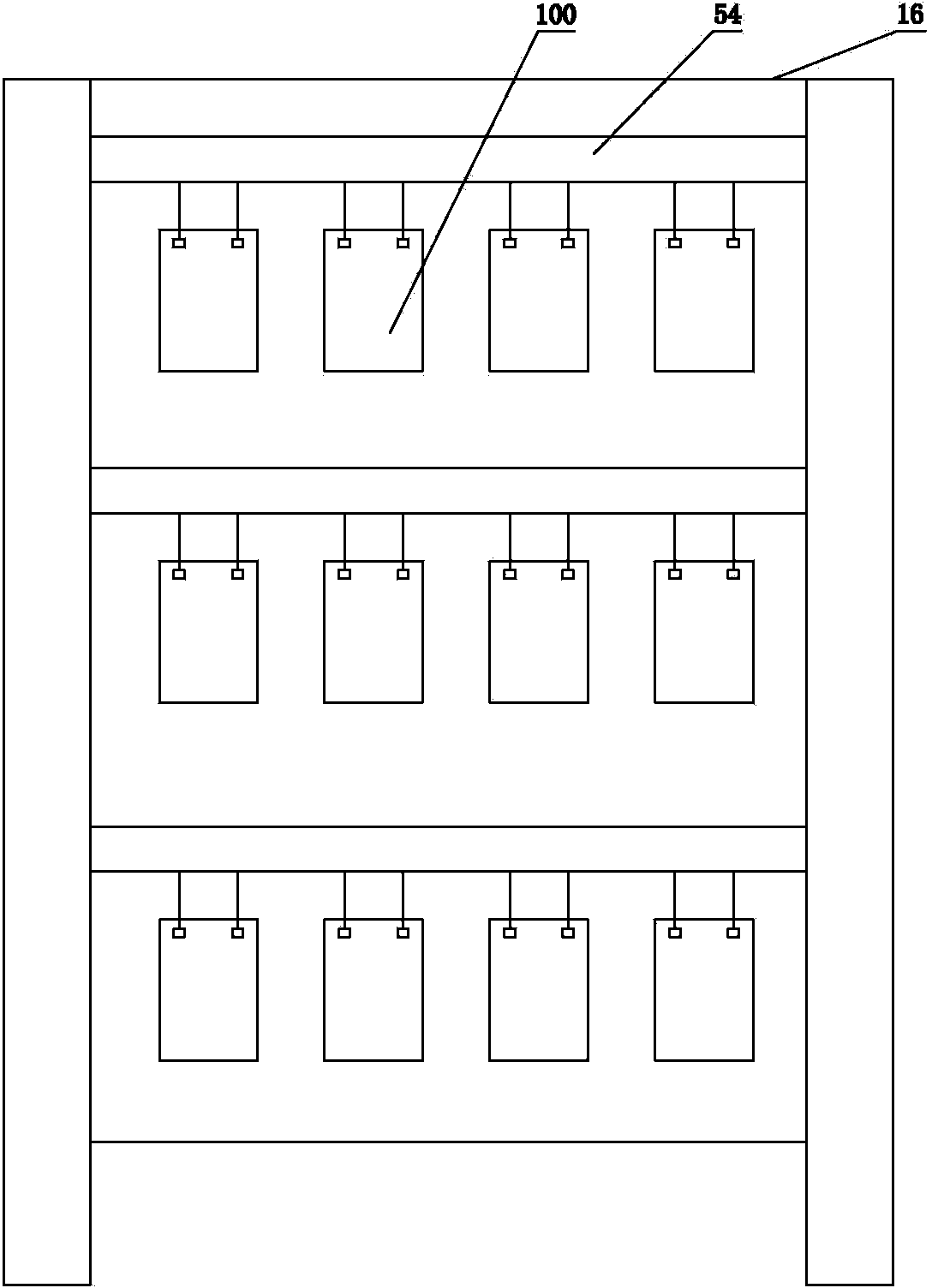

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

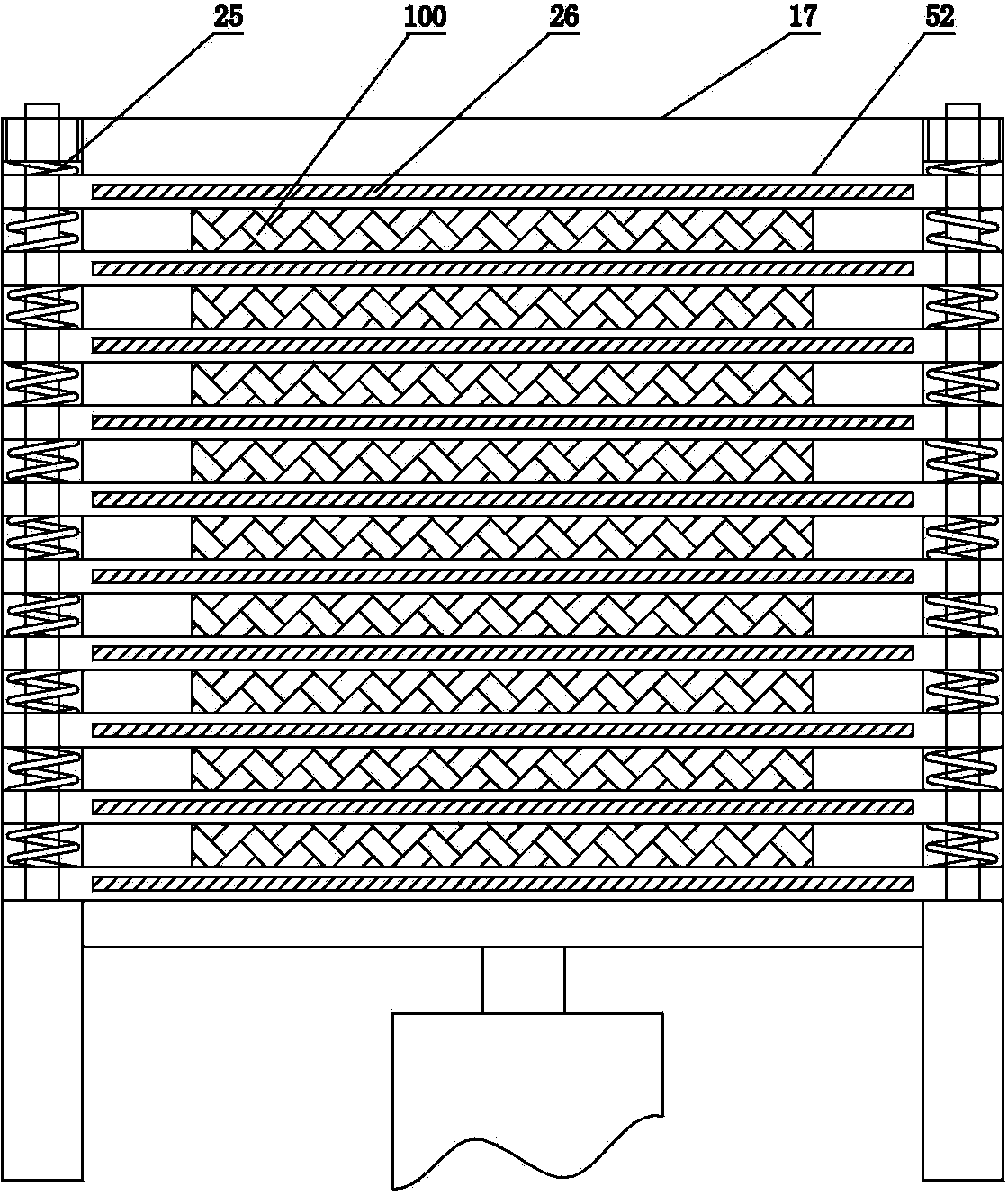

The invention discloses a high-density environment-friendly regenerated fiber board. The high-density environment-friendly regenerated fiber board is characterized by comprising an upper wood pulp layer, a lower wood pulp layer, an upper bonding layer, a lower bonding layer and a waste wood pulp main layer which are compounded together, wherein the waste wood pulp main layer is arranged between the upper bonding layer and the lower bonding layer; the upper wood pulp layer is compounded on the exterior of the upper bonding layer, and the lower wood pulp layer is compounded on the exterior of the lower bonding layer. The high-density environment-friendly regenerated fibre board is a substitute product for resources and is produced by the utilization of large amount of waste plant fiber such as waste paper or straw paper pulp; the price is low, and a large amount of forest resource can be saved; the upper and lower wood pulp layers are made of pure wood pulp; according to the fiber board, an efficient, energy-saving, environment-friendly and recyclable novel manufacturing process is adopted, so that the fiber board product has good waterproof property, is bent resistant, bright and clean in surface, bright in color, good in toughness and can be completely comparable with a pure wood pulp fiber board. The high-density environment-friendly regenerated fibre board can be widely applicable to industries of automotive interior, shoe making, artistic packaging, electrical appliance and furniture, can replace wood boards, wood pulp fiber boards and plastic boards, and has large market capacity and broad prospect.

Description

technical field [0001] The invention relates to a resource substitution product, in particular to a high-density environment-friendly regenerated fiberboard and a production method thereof. Background technique [0002] Fiberboard is also known as density board. The existing fiberboard is a wood-based panel made of wood fiber or other vegetable fiber and applied with urea-formaldehyde resin or other suitable adhesives. Fiberboard is an ideal raw material for high-end gift packaging, automotive interior lining, electrical circuit trays, shoemaking, furniture and other high-end products. It has high density, good water resistance, folding resistance, smooth surface, bright color and good toughness; but currently Some fiberboards are mainly made of raw wood, which are extremely expensive and have low utilization rates. It takes about 2.5-3 cubic meters of wood to manufacture 1 cubic meter of fiberboard, which seriously damages the ecological balance and has a great impact on t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21J1/16B32B29/00B32B37/02

Inventor 张代成

Owner 仙桃市宏远纤维科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com