High specific surface area and narrow pore distribution porous carbon material

A technology of high specific surface area, porous carbon materials, applied in the field of porous carbon materials, can solve the problems of limitation, low specific surface area of porous carbon materials, uneven distribution of activated carbon pore size, etc., achieving low equipment requirements, less time-consuming, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

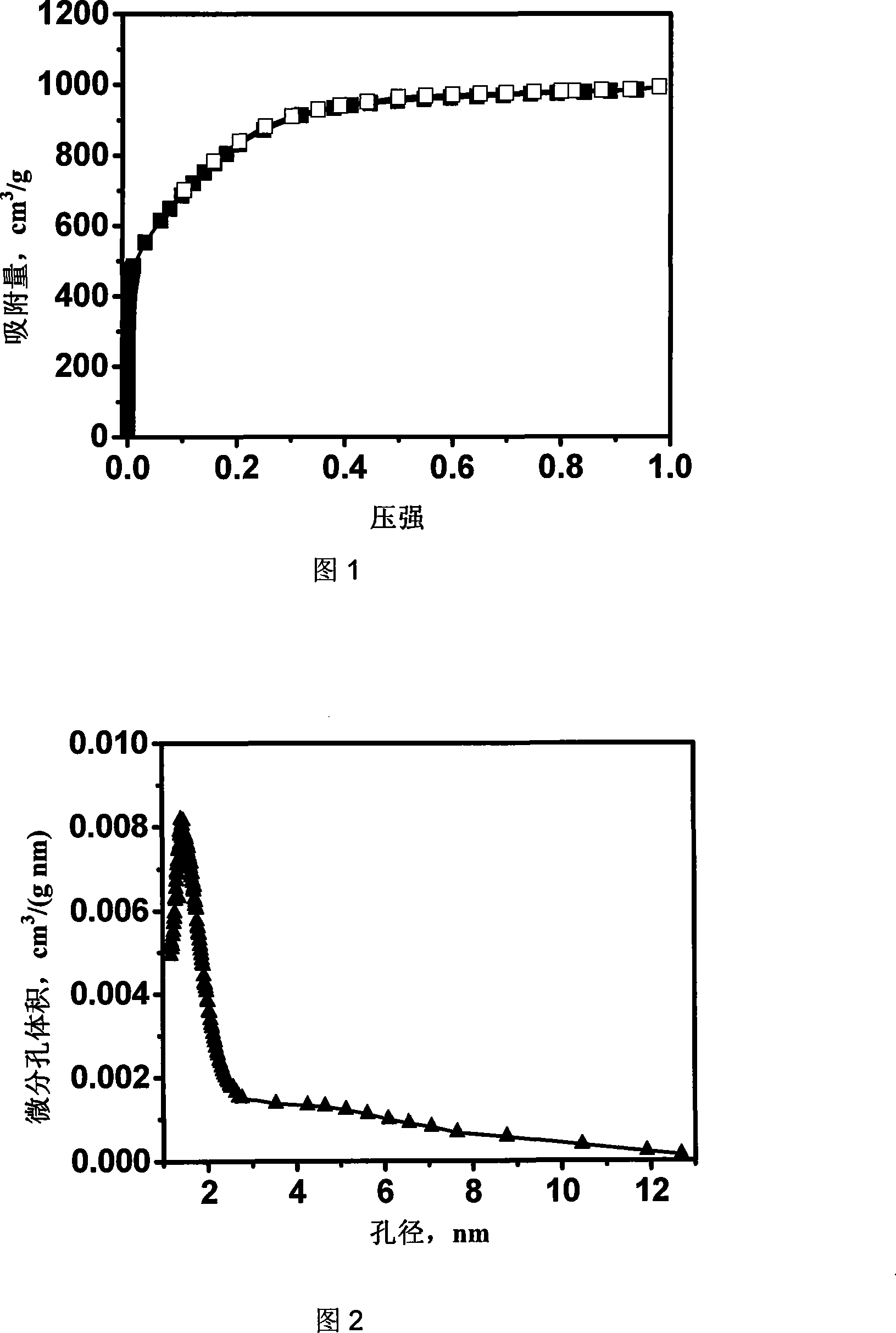

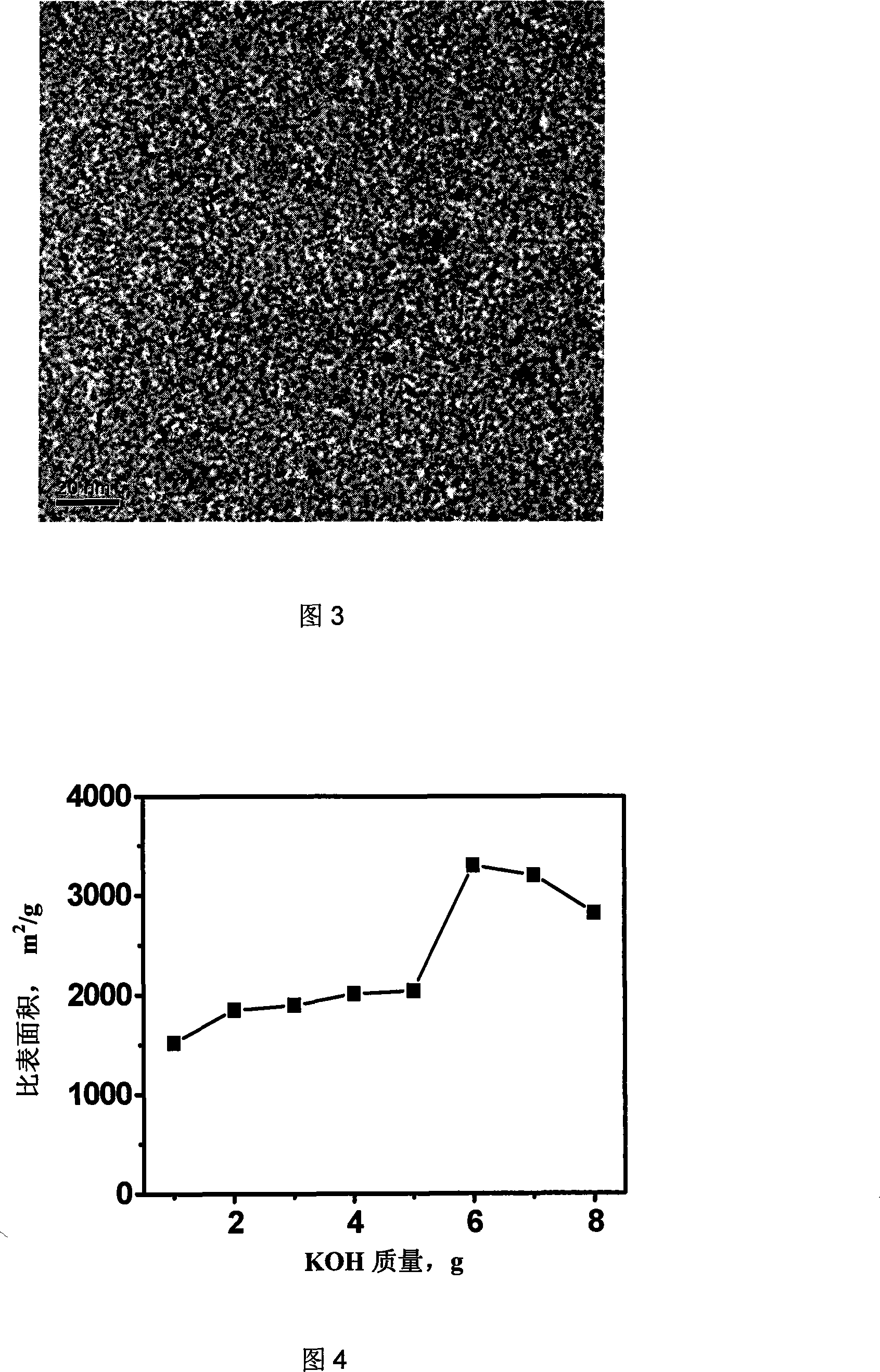

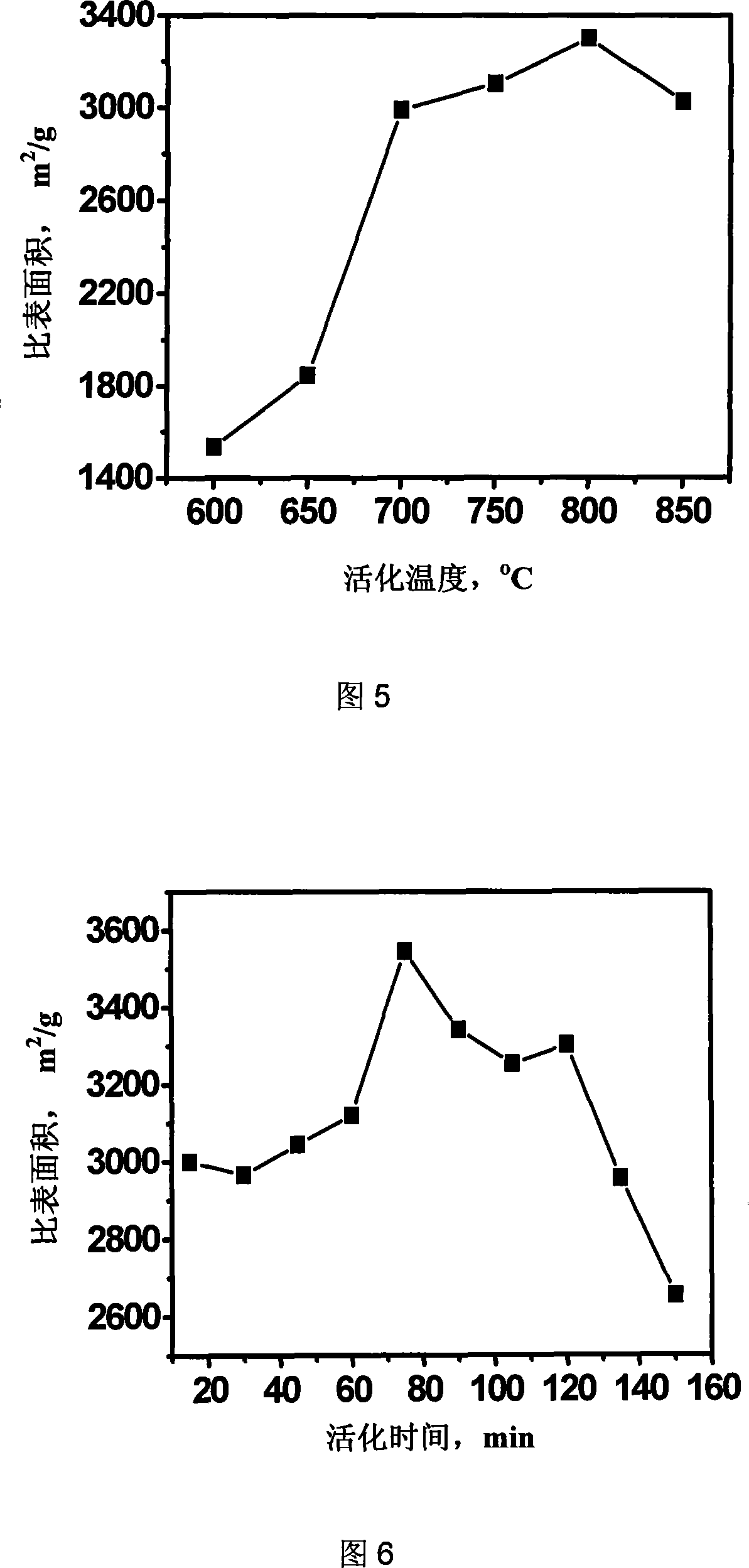

Embodiment 1

[0031]Wash the pine needles and dry them. Under the protection of 99.9% nitrogen, carbonize at 450° C. for 3 hours to obtain carbonized products and tar, then pulverize the carbonized products and screen them with a 35-mesh sieve. Dissolve 2 grams of KOH in a mixed solution of 35 mL of water / ethanol (volume ratio 2.5:1), then add 1 gram of carbonized product to the above system, ultrasonically disperse for 5 minutes, soak for 24 hours, and finally dissolve the solvent at 70°C Evaporate to dryness, then activate the remaining mixture under the protection of inert gas (nitrogen or argon 99.9%) at 800°C for 120 minutes, cool to room temperature naturally, then wash the product with water until the pH value of the washing liquid is close to 8, using 0.1mol / Soak in L dilute hydrochloric acid for 3 hours, then wash with water until the pH value of the washing solution is close to 7, then dry in the air at 100°C for 7 hours, and finally obtain a porous carbon material with a specifi...

Embodiment 2

[0033] The experimental method is the same as in Example 1, except that the amount of the activator KOH is changed to 3 grams, and a porous carbon material is also obtained, and the specific surface area of the material is 1900m 2 / g, the pore size is mainly 1.5 nm.

Embodiment 3

[0035] The experimental method is the same as in Example 1, except that the amount of the activator KOH is changed to 4 grams, and the porous carbon material is obtained equally, and the specific surface area of the material is 2014m 2 / g, the pore size is mainly 1.5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com