Wood Adhesives Containing Reinforced Additives for Structural Engineering Products

a technology of reinforced additives and wood adhesives, which is applied in the direction of fiberboard, other domestic articles, transportation and packaging, etc., can solve the problems of not being suitable for osb and osl production, and being about 10-40% heavier than similarly-sized plywood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0055]Commercially available cellulose microfibers were added to phenol-formaldehyde resin (GP 205C) to ascertain whether the structural performance of the bulk resin could be increased. These data are presented in Table 1 obtained by three-point bending method according to ASTM D 790 standard. Both modulus of rupture (MOR) and modulus of elasticity (MOE) were shown to be enhanced by the addition of cellulose microfibers. Even relatively low amounts of cellulose gave significant improvement. For example, 3% added cellulose microfiber (based on oven-dried weight of resin) resulted in a 24.1% increase in MOR (from 79 to 98 MPa) and a 31.6% increase in MOE (from 3388 to 4460 MPa).

[0056]Preparation of reinforcing PF resin composites for these examples was performed in the following manner:

[0057]a) Commercially available cellulose microfibers (TC40) were added to PF resin (GP 205C) and mixed by a mechanical mixer to obtain a uniform resin additives mixture.

[0058]b) To make PF composite f...

example 2

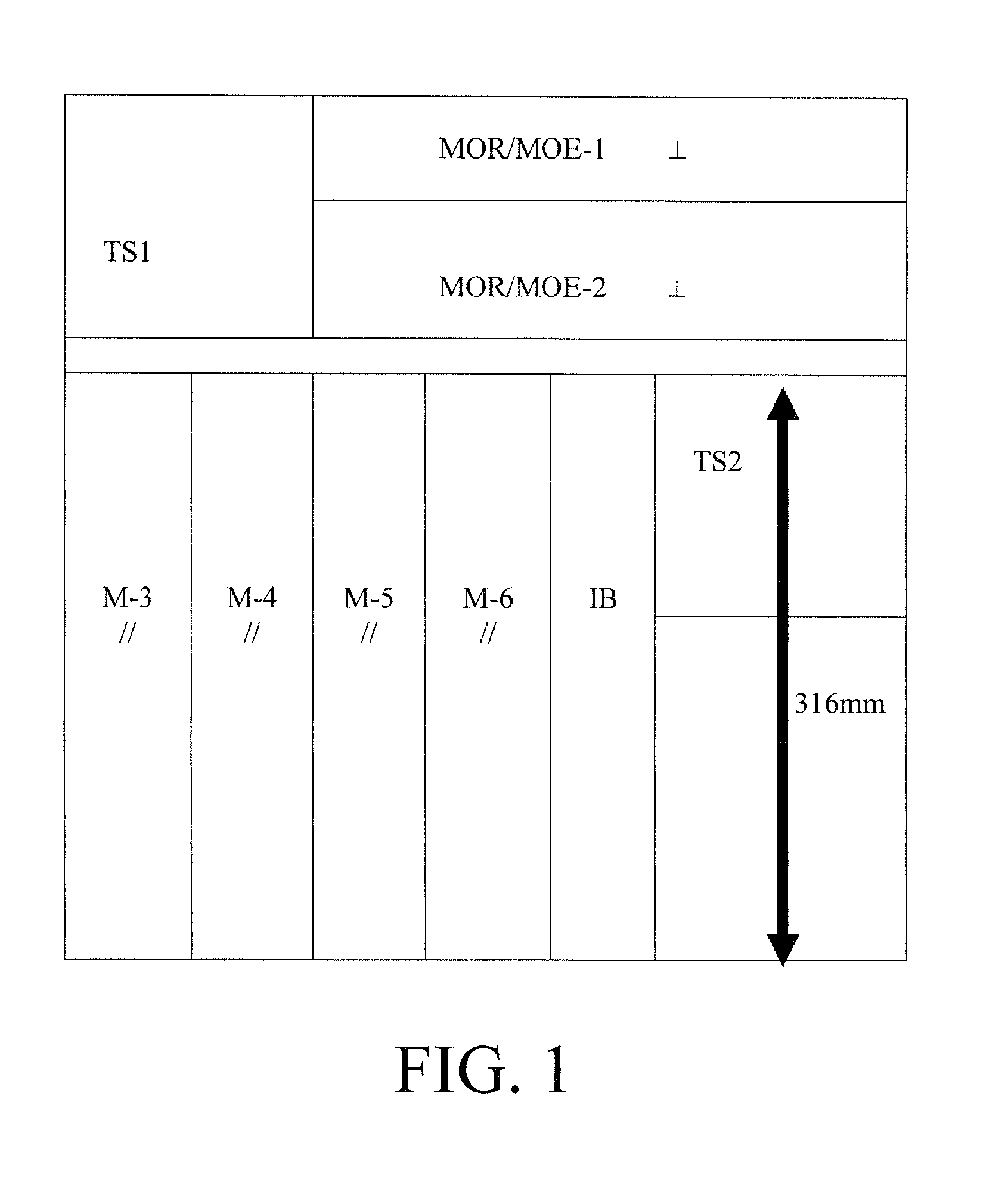

[0059]The uniform reinforced PF resin mixture (the same as in Example 1) was then used to produce OSB for testing. These data were obtained by the test method of ASTM D1037 standard and are presented in Table 2. At all levels of added cellulose, both internal bonding (IB) strength and MOR were increased. IB increased by as much as 9.3% (from 0.54 to 0.59 MPa when using a 4% cellulose formulation), and MOR (bending strength) increased by as much as 14.5% (from 26.9 to 30.8 when using a 4% cellulose formulation). MOE of OSB panels increased 12.1% to 3605 MPa by adding 4% of cellulose microfiber into resin (based on oven-dried weight of resin). Thickness swell (TS), an undesirable property, was reduced at all levels of added cellulose. Other properties of the oriented strand board generally tended to be improved by the use of reinforced resin, but the results were not entirely uniform. MOE was improved with resin formulations containing 4% and 8% cellulose (increases of 12.1% and 5.2% ...

example 3

[0068]In another embodiment, a reinforced resin formula was produced by adding nano materials including commercially available nano materials. Results obtained by the test method of the ASTM D1037 standard are summarized in Table 3. Very narrow variations in panel thickness and density were achieved; differences in structural properties between panels are thus solely due to differences in resin formulations. As shown in Example 1, the 3% added cellulose microfiber (TC40) resulted in significant increases in MOR and MOE of PF resin (Table 1). This formulation “TC0” improved OSB properties with a 7.63% increase in MOE, a 3.59% increase in MOR and a 39.0% increase in internal bonding strength (Table 3).

[0069]The same raw materials as used in the formulation of TC40 were converted into cellulose fibril aggregates by 15 or 30 second ultrasonic treatment. The use of this ultrasonically treated adhesive formulation resulted in OSB having improved properties as compared to OSB manufactured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com