Anti-skid natural rubber material for sneaker soles and preparation method thereof

A technology for natural rubber and sports shoes, applied in the field of sports shoe materials, can solve the problems such as the need for further improvement of the anti-skid effect, poor compatibility between alloys and rubber, unsatisfactory anti-skid performance, etc. Performance improvement, obvious effect of anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

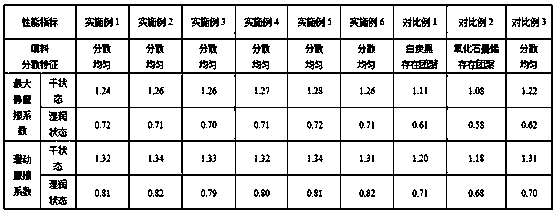

Examples

Embodiment 1

[0030] (1) Add precipitated silica and phenyl isocyanate to anhydrous acetone, pass N 2 , first magnetically stirred evenly, then heated to react, washed and vacuum-dried to obtain modified silica grafted with isocyanate; the reaction temperature was 66°C, and the time was 4h; the parts by weight of each raw material were, precipitated white 5 parts by weight of carbon black, 5 parts by weight of phenylisocyanate, 90 parts by weight of anhydrous acetone;

[0031] (2) Disperse graphene oxide in water, add carboxylated nitrile rubber latex, stir magnetically for 1.5 hours, then add a mixed aqueous solution of sodium chloride and sulfuric acid, stir well, let stand for 20 minutes, filter with suction, and then disperse the solid again In water, magnetically stirred for 4h, and suction filtered to obtain carboxylated nitrile rubber / graphene oxide composite latex; the parts by weight of each raw material are 7 parts by weight of graphene oxide, 11 parts by weight of carboxylated ni...

Embodiment 2

[0034] (1) Add precipitated silica and phenyl isocyanate to anhydrous acetone, pass N 2 , first magnetically stirred evenly, then heated to react, washed and vacuum-dried to obtain modified silica grafted with isocyanate; the reaction temperature was 62°C, and the time was 4.5h; the parts by weight of each raw material were, 4 parts by weight of white carbon black, 4 parts by weight of phenylisocyanate, 92 parts by weight of anhydrous acetone;

[0035] (2) Disperse graphene oxide in water, add carboxylated nitrile rubber latex, stir magnetically for 1 hour, then add a mixed aqueous solution of sodium chloride and sulfuric acid, stir evenly, let stand for 20 minutes, filter with suction, and then disperse the solid in In water, magnetically stirred for 3.5h, and suction filtered to obtain carboxylated nitrile rubber / graphene oxide composite latex; the parts by weight of each raw material were 6 parts by weight of graphene oxide, 10 parts by weight of carboxylated nitrile rubber...

Embodiment 3

[0038] (1) Add precipitated silica and phenyl isocyanate to anhydrous acetone, pass N 2 , first magnetically stirred evenly, then heated to react, washed and vacuum-dried to obtain modified silica grafted with isocyanate; the reaction temperature was 68°C, and the time was 3.5h; the parts by weight of each raw material were, 5 parts by weight of white carbon black, 5 parts by weight of phenylisocyanate, 90 parts by weight of anhydrous acetone;

[0039] (2) Disperse graphene oxide in water, add carboxylated nitrile rubber latex, stir magnetically for 2 hours, then add a mixed aqueous solution of sodium chloride and sulfuric acid, stir evenly, let stand for 20 minutes, filter with suction, and then disperse the solid in In water, magnetically stirred for 4.5h, and suction filtered to obtain carboxylated nitrile rubber / graphene oxide composite latex; the parts by weight of each raw material were 9 parts by weight of graphene oxide, 13 parts by weight of carboxylated nitrile rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com