Nanoporous silicon/carbon composite material and preparation method thereof

A silicon-carbon composite material, nanoporous technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that hinder the practical process of silicon negative electrode materials, are not suitable for large-scale production, and are highly toxic Solve problems such as HF corrosion, achieve high performance, stability and conductivity, improve low activity, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Place a Si / Al alloy sheet with a thickness of 100 microns, a width of 1 cm, and a length of 2 cm, with a composition of 10 atomic percent Si and 90 atomic percent Al in 1 mol / L sodium hydroxide in solution.

[0025] (2) Freely corrode for 24 hours at a room temperature of 25°C.

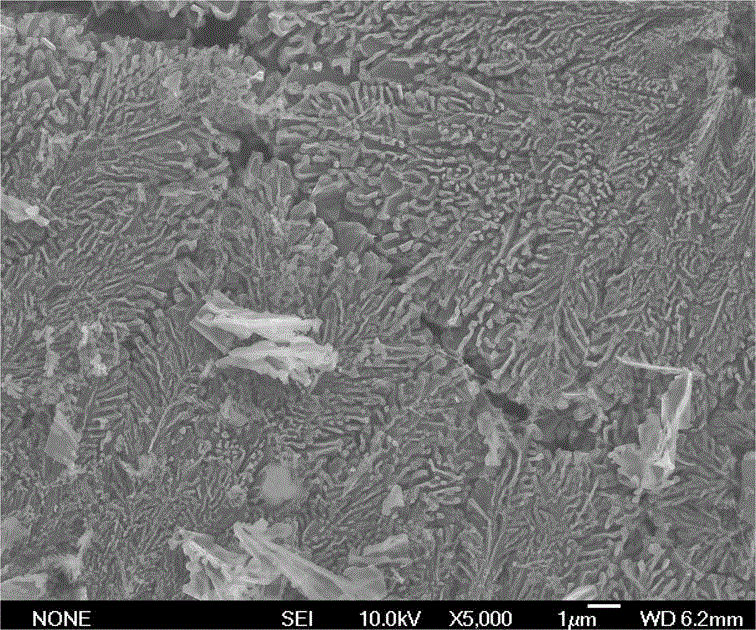

[0026] (3) Collect the corroded alloy pieces and wash them repeatedly with ultrapure water until the sodium hydroxide solution is completely washed away. Then dry at 25°C to obtain nanoporous silicon material. Its SEM photo see figure 1 , with a pore size of around 200 nm.

Embodiment 2

[0028] (1) Place a Si / C / Al alloy sheet with a thickness of 100 microns, a width of 1 cm, and a length of 2 cm, with a composition of 5 atomic percent Si, 5 atomic percent C, and 90 atomic percent Al. In 0.5 mol / L hydrochloric acid solution.

[0029] (2) Free corrosion for 48 hours at room temperature of 25°C.

[0030] (3) Collect the corroded alloy sheets and wash them repeatedly with ultrapure water until the hydrochloric acid solution is completely washed away. Then dry at 25 °C to obtain nanoporous Si / C composites.

Embodiment 3

[0032] (1) Place a Si / C / Al alloy sheet with a thickness of 100 microns, a width of 1 cm, and a length of 2 cm, with a composition of 10 atomic percent Si, 5 atomic percent C, and 85 atomic percent Al. in 1 mol / L sulfuric acid solution.

[0033] (2) Freely corrode for 24 hours at a room temperature of 25°C.

[0034] (3) Collect the corroded alloy pieces and wash them repeatedly with ultrapure water until the sulfuric acid solution is completely washed away. Then dry at 25 °C to obtain nanoporous Si / C composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com